Warning: Undefined array key "active_product" in /usr/local/lsws/ownersmanualpdf.net/html/wp-content/plugins/text-to-speech-mh/public/class-text-to-speech-mh-public.php on line 115

Description

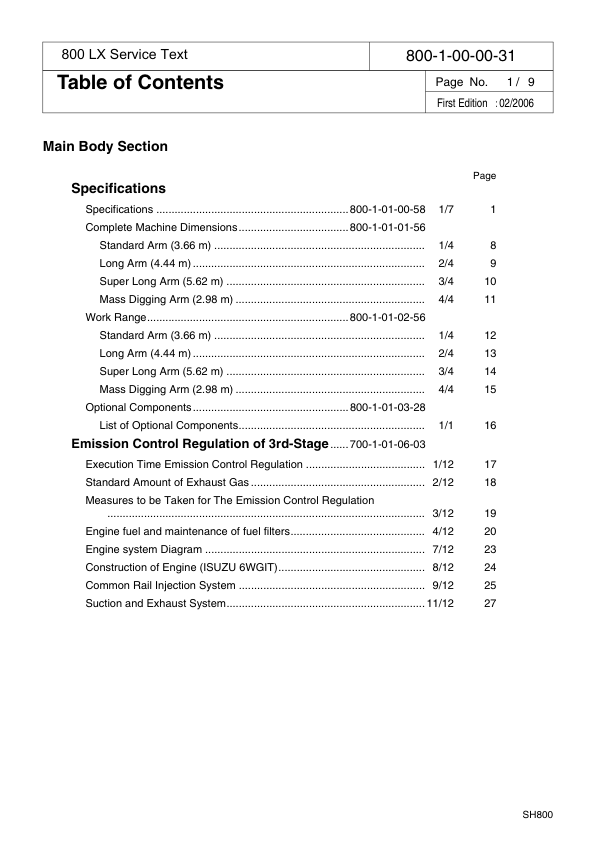

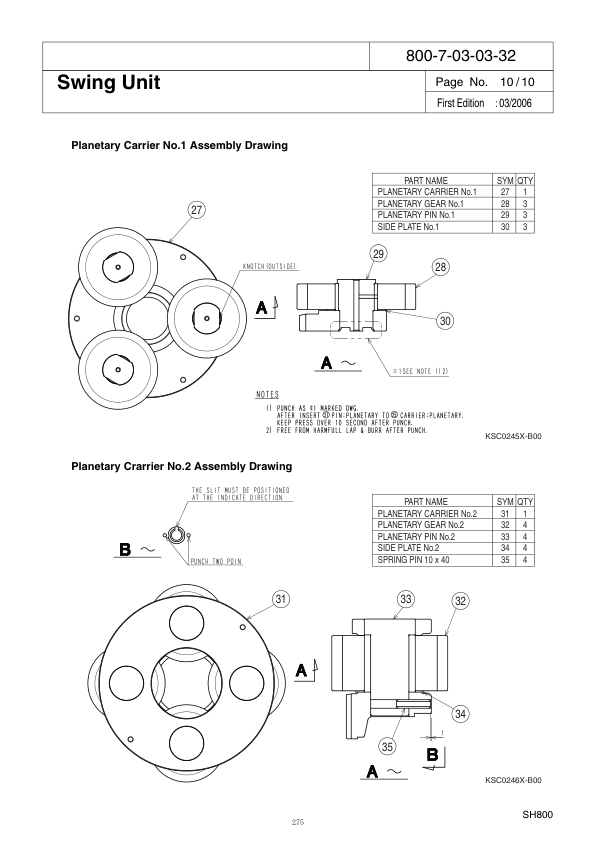

Table of Contents

1. Specifications

- Major Equipment Specifications

- Complete Machine Dimensions

- Standard Arm (3.66 m)

- Long Arm (4.44 m)

- Super Long Arm (5.62 m)

- Mass Digging Arm (2.98 m)

- Work Range

- Standard Arm (3.66 m)

- Long Arm (4.44 m)

- Super Long Arm (5.62 m)

- Mass Digging Arm (2.98 m)

- Optional Components

- List of Optional Components

- Complete Machine Dimensions

- Emission Control Regulation of 3rd-Stage

- Execution Time Emission Control Regulation

- Standard Amount of Exhaust Gas

- Measures to be Taken for the Emission Control Regulation

- Engine Fuel and Maintenance of Fuel Filters

- Engine System Diagram

- Construction of Engine (ISUZU 6WGIT)

- Common Rail Injection System

- Suction and Exhaust System

- Major Equipment

- Equipment

- Overall

- Operator’s Cab

- Lower Mechanism

- Assembly Drawing

- Travel Unit

- Idler Wheel

- Upper Roller

- Lower Roller

- Recoil Spring

- Shoes

- Upper Mechanism

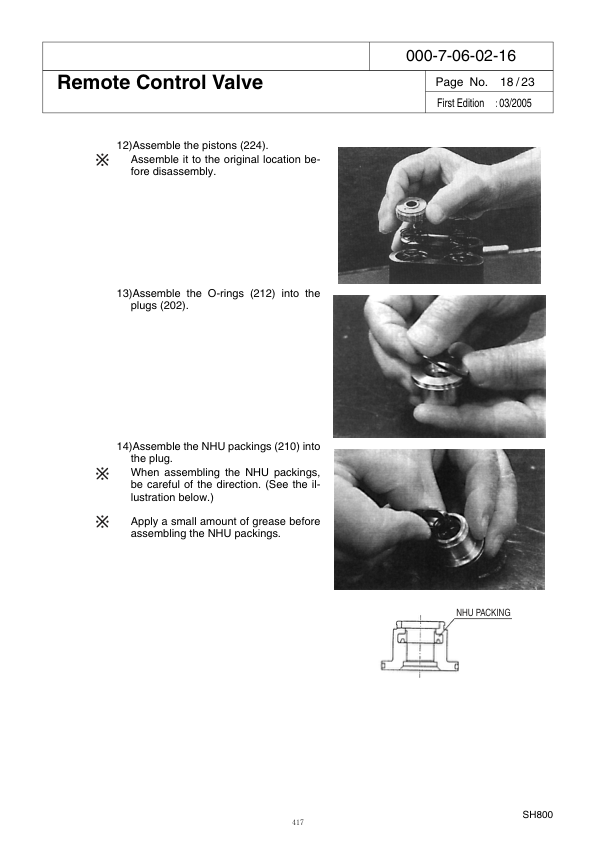

- Swing Unit

- Engine and Related Areas

- Engine

- Muffler

- Air Cleaner (With Pre-Cleaner)

- Radiator

- Fuel Tank

- Hydraulic System

- Hydraulic Pump

- Hydraulic Reservoir

- Rotating Joint

- Solenoid Valve

- Controls

- Control Valve

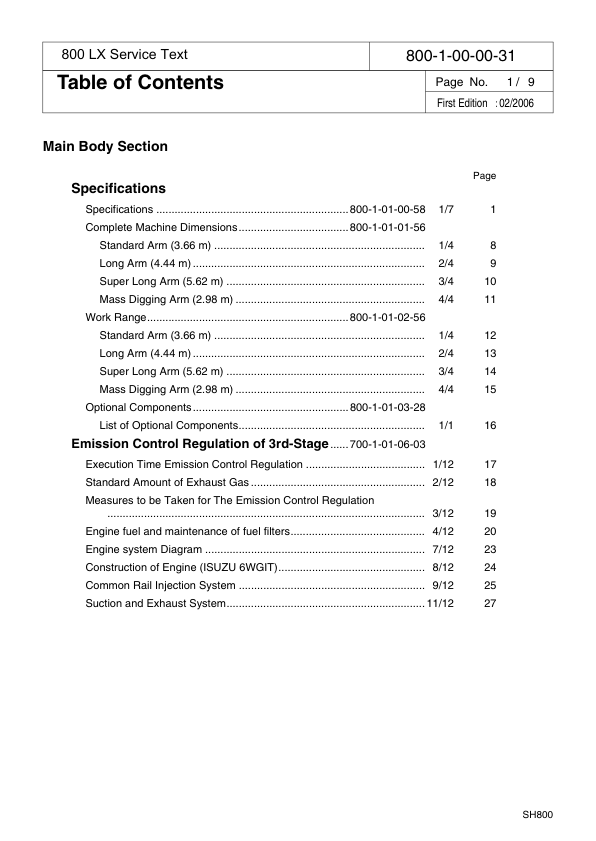

- Remote Control Valve (Left/Right, Travel Operations)

- Backhoe Attachments

- Cylinder

- Attachments

- Equipment

2. Hydraulic Section

- Hydraulic Pump

- Operation Principle

- Internal Structure Drawing

- Control Valve

- Operation Explanation of Each Part

- Main Relief Valve

- Overload Relief Valve

- Foot Relief Valve

- Load Holding Valve

- Arm Regenerative

- Priority Valve

- Boom Regenerative

- Swing Unit

- Operation Principle

- Hydraulic Motor

- Anti-Cavitation Check Valve Section

- Relief Valve

- Reversal Prevention Valve

- Brake Section

- Internal Structure Drawing

- Travel Unit

- Operation Principle

- Hydraulic Motor

- Parking Brake

- 2-Speed Switch Mechanism Operation Principle

- Relief Valve

- Double Counterbalance Valve

- Fan Motor for Hydraulic Drive

- Outside Drawing

- Internal Structure Drawing

- Operation Principle

- Hydraulic Motor

- Suction Safety Valve

- Variable Flow Control Valve

- Operation of Forward/Reverse Changeover Valve

3. Hydraulic Circuits Section

- Port Locations

- Hydraulic Pump

- Control Valve

- Pilot Hose Connection Diagrams

- Pilot P&T Lines

- Pilot Control Lines

- Functional Explanation

- Functional Table

- Travel Circuits

- High Speed Travel Circuit

- Low Speed Travel Circuit

- Straight Travel Circuit

- Swing Circuits

- Swing Parking Circuit (Lever in Neutral/Swing Locked)

- Swing Parking Circuit (Brake Released)

- Swing Push Digging

- Arm Circuits

- Arm-Out Circuit

- Arm-In Load Holding

- Arm-In Circuit

- Boom Circuits

- Boom-Up Circuit (Single)

- Boom-Up Circuit (Combined)

- Boom-Down Load Holding

- Boom-Down Circuit

- Backup Circuits

- Combined Circuit (Breaker Circuit)

- Combined Circuit (High Speed Confluence Circuit)

- Other Circuits

- High Dump

- Hydraulic Circuit Diagram

4. Electric Circuits Section

- Operation Explanation

- System Chart of Functions

- Engine Control

- Work Mode Selection

- H.S.L Modes

- Auto Modes

- Load Prefetch Control

- Throttle Control

- Idling Control (Auto/One-Touch)

- Breaker Mode

- Auto Preheat (Glow Control)

- Auto Warm-Up

- Overheat Protection

- Atmospheric Pressure Compensation

- Control When Starting Engine

- Control When Stopping Engine

- Emergency Stop of the Engine

- Engine Protection Function (EPF)

- Lever Lock

- Auto Boost Control

- Swing Lock

- Swing Brake Control

- Travel Speed Switch-Over

- Travel Alarm

- Power Shut-Off Delay

- Control of Hydraulic Driven Fan

- Fuel Supply Pump Control (Automatic Stop, Optional)

- Power Transistor Protection

- Monitor Display

- Normal Display

- Message Display

- Service Support

- Summary

- Operating Instructions

- Measuring Electrical Device

- Instruments to be Measured

- Equipment for Measuring

- Measuring Methods

- Initial Controller Settings

- Verifying the Settings

- Resetting Procedures

- Setting Procedures

- List of Settings

- Error Display Functions

- Troubleshooting

- Problem Symptoms

- Inspections Prior to Troubleshooting

- Troubleshooting Procedures

- Using the Flow Chart

- Diagnosis

- Refilling Fuel

- Refilling Coolant

- Low Engine Oil Pressure

- Overheat

- Battery Charging

- Faulty Electrical System

- Electric Wiring Diagrams

- Electrical Components and Wiring (Frame)

- Electrical Components and Wiring (Cab)

- Harness Diagrams

- Frame Main Harness

- Cab Main Harness

- Electric Circuits Diagram

5. Maintenance Section

- New Machine Performance

- Performance Evaluation Check Sheet

- Reference Values

- Instructions for Measuring and Adjusting Pressure

- Measuring Pressure

- Basic Conditions

- Set Values

- Pressure Measuring Port

- Preparation for Measuring Pressure

- Measuring Pressure

- Measuring Other Pressures

- Adjusting Pressure

- Pressure Adjusting Points

- Instructions for Adjusting Pressure

- Measuring Pressure

- Maintenance of the Circumference of Engine

- Circumference Filter Arrangement of Engine

- Fuel Element System Diagram

- Main Body Weight

- Major Component Weight

- Individual Part Weight

- Shoe Weight

- Arm Weight

- Attachments Dimensions

- Compatibility

- Plastic Shim

- Procedures for Changing Operation Type

- ISO Type

- Old Sumitomo Type

- Old Mitsubishi Type

- Old Kobelco Type

6. Assembly and Disassembly Section

- Summary of Assembling

- Total Work Process

- Major Machines, Tools, and Equipment Table

- Matters to be Attended

- Prior Preparation

- Prior Preparation Procedure

- Unloading Work

- Connection of Lower Sideframes to Upper Swing Body

- Mounting Travel Motor Lines

- Mounting Counterweight

- Mounting Attachments

- Checking Work

- Confirmation of Movement After Assembling Work

- Summary of Disassembling

- Attached Data

7. Appendix

- Unit Conversion Table

- New Hydraulic Oil

Rate this product

You may also like