Caterpillar K15, K21, K25 Gasoline Engine Service Manual 99789-85110

$50.00

- Type Of Manual: Service Manual

- Manual ID: 99789-85110

- Number of Pages: 254

- Size: 5.0MB

- Format: PDF

-

Model List:

- K15 Gasoline Engine, K21 Gasoline Engine, K25 Gasoline Engine

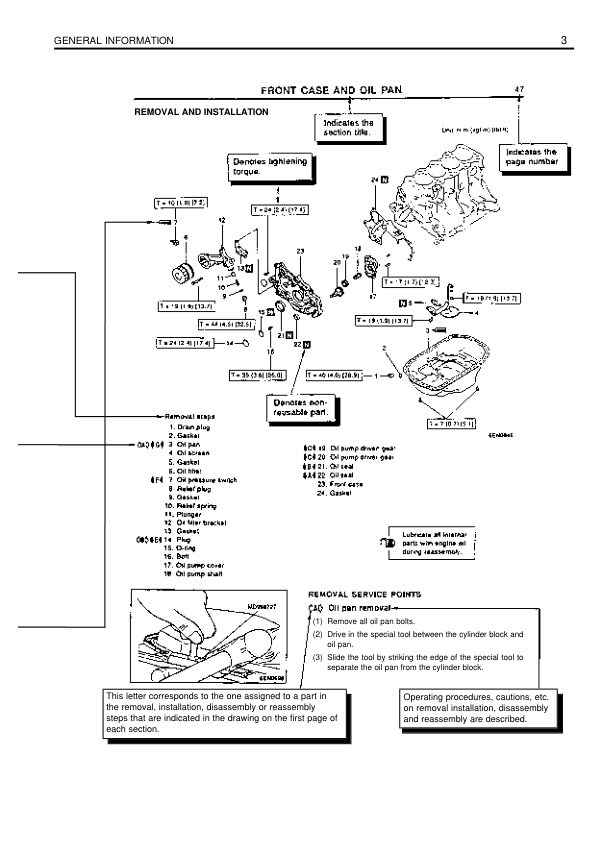

- 1. How to use this manual

- 1.1. Description

- 1.2. Definition of Terms

- 1.3. Definition of Units

- 1.4. Description

- 2. Precautions for safety and quality

- 2.1. Safe Operation

- 2.2. Correct Operation

- 2.3. Precautions for Radio Equipment Installation

- 3. Precautions

- 3.1. Precautions in Draining Engine Coolant

- 3.2. Precautions for Disconnecting Fuel Piping

- 3.3. Precautions for Removing and Disassembling

- 3.4. Precautions for Inspection, Correction, and Replacement

- 3.5. Precautions for Assembly and Installation

- 3.6. Parts Requiring Angle Tightening

- 3.7. Caution for Use of Power Tools

- 3.8. Precautions for Liquid Gasket Application

- 4. Tightening torque

- 4.1. Standard Bolt Tightening Torque

- 4.2. Engine Part Tightening Torque

- 5. Special Service Tools

- 6. Engine outside drawings

- 7. Main specifications

- 8. Standard and repair limit

- 9. ocation of engine No.

- 10. Trouble diagnosis

- 10.1. Engine Adjust.

- 10.2. Engine LPG Fuel System

- 11. Engine maintenance

- 11.1. Specifications

- 11.2. Tightening Torque

- 11.3. Maintenance Schedule

- 11.4. Maintenance Schedule (Contd)

- 11.5. Oil and Grease, and Capacity

- 11.6. On Board Inspection and Service

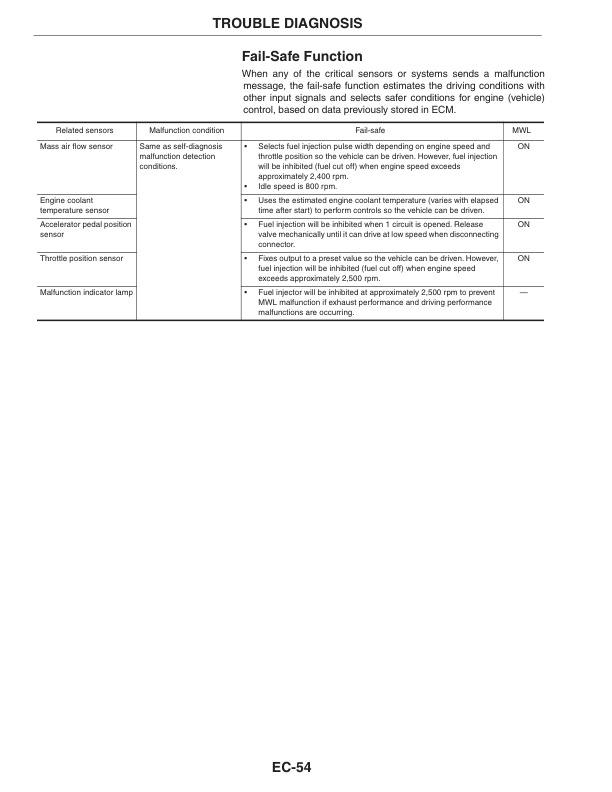

- 11.7. Fail-Safe Function

- 12. Specifications

- 13. Tightening torque

- 14. Trouble diagnosis

- 15. ENGINE INSPECTION AND ADJUSTMENT

- 15.1. Engine Body Related

- 15.2. Ignition and Fuel Systems

- 16. Special Service Tools For carburetor model

- 17. Precautions

- 17.1. Precautions for Draining Engine Coolant

- 17.2. Precautions for Disconnecting Fuel Piping

- 17.3. Precautions for Removing and Disassembling

- 17.4. Precautions for Inspection, Correction, and Replacement

- 17.5. Precautions for Assembly and Installation

- 17.6. Parts Requiring Angle Tightening

- 17.7. Caution for Use of Power Tools

- 17.8. Precautions for Liquid Gasket Application

- 18. Engine outside drawings

- 19. Main specifications

- 20. Adjustment value

- 21. Tightening torque

- 21.1. Standard Bolt Tightening Torque

- 21.2. Engine Part Tightening Torque

- 22. Trouble diagnosis

- 23. Special Service Tools

- 24. Removal and installation of engine

- 24.1. Removal

- 24.2. Installation

- 24.3. Inspection

- 25. Engine service

- 25.1. Engine Disassembly

- 25.2. Inspection and Correction

- 25.3. Engine Assembly

- 26. Precautions

- 26.1. General precautions for service operations

- 27. Preparation

- 27.1. Special Service Tools

- 28. Description

- 29. Basic inspection

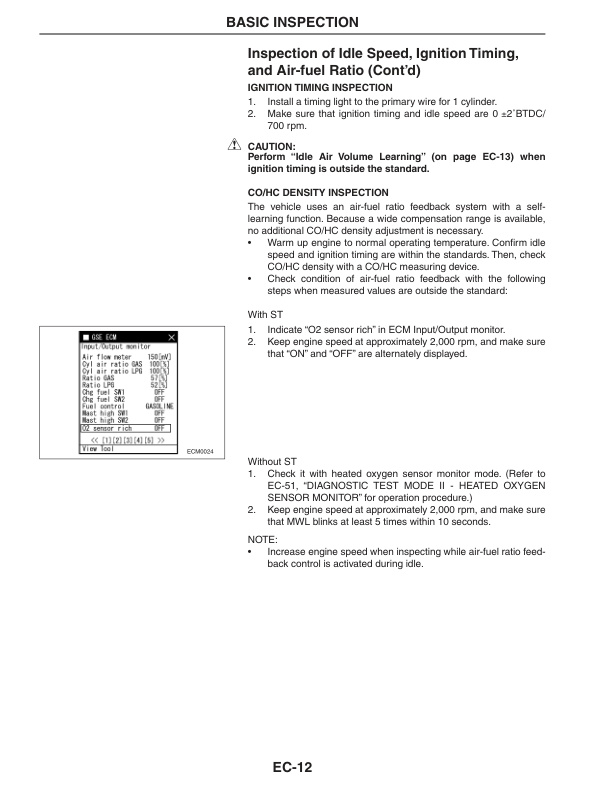

- 29.1. Inspection of Idle Speed, Ignition Timing, and Air-fuel Ratio

- 29.2. Throttle Valve Closed Position Learning and Idle Air Volume Learning

- 29.3. Accelerator Pedal Released Position Learning

- 29.4. Fuel pressure inspection

- 30. Trouble Diagnosis

- 30.1. How to Proceed with Trouble Diagnosis

- 30.2. Diagnosis Chart by Symptom

- 30.3. Component Parts Location

- 30.4. ECM Component

- 30.5. Circuit Diagram

- 30.6. ECM Terminal Layout

- 30.7. ECM Input/Output Signal Specifications

- 30.8. Service Tool (ST)

- 30.9. Self-Diagnosis Function (Without ST)

- 30.10. ST Reference Value in Data Monitor

- 31. Power supply and ground system

- 31.1. ECM Input/Output Signal Specifications

- 31.2. Circuit Diagram

- 32. Crankshaft position sensor (POS) sys tem

- 32.1. ECM Input/Output Signal Specifications

- 32.2. Circuit Diagram

- 32.3. Component Parts Inspection

- 33. Camshaft position sensor (PHASE) sys tem

- 33.1. ECM Input/Output Signal Specifications

- 33.2. Circuit Diagram

- 33.3. Component Parts Inspection

- 34. Mass air flow sensor system

- 34.1. ST Data Monitor Display

- 34.2. ECM Input/Output Signal Specifications

- 34.3. Circuit Diagram

- 34.4. Component Parts Inspection

- 35. Engine coolant tempera ture sensor system

- 35.1. ST Data Monitor Display

- 35.2. ECM Input/Output Signal Specifications

- 35.3. Circuit Diagram

- 35.4. Component Parts Inspection

- 36. Heated oxygen sensor system

- 36.1. ST Data Monitor Display

- 36.2. ECM Input/Output Signal Specifications

- 36.3. Circuit Diagram

- 37. Throttle position sensor system

- 37.1. ST Data Monitor Display

- 37.2. ECM Input/Output Signal Specifications

- 37.3. Circuit Diagram

- 37.4. Component Parts Inspection

- 38. Accelerator pedal position sensor system

- 38.1. ST Data Monitor Display

- 38.2. ECM Input/Output Signal Specifications

- 38.3. Circuit Diagram

- 38.4. Component Parts Inspection

- 39. Intake air temperature sensor

- 39.1. ST Data Monitor Display

- 39.2. ECM Input/Output Signal Specifications

- 39.3. Circuit Diagram

- 39.4. Component Parts Inspection

- 40. PNP switch system

- 40.1. ST Data Monitor Display

- 40.2. ECM Input/Output Signal Specifications

- 40.3. Circuit Diagram

- 41. Stop lamp switch system

- 41.1. ST Data Monitor Display

- 41.2. ECM Input/Output Signal Specifications

- 41.3. Circuit Diagram

- 41.4. Component Parts Inspection

- 42. Electric load switch system

- 42.1. ST Data Monitor Display

- 42.2. ECM Input/Output Signal Specifications

- 42.3. Circuit Diagram

- 43. CAN communication system

- 43.1. ECM Input/Output Signal Specifications

- 43.2. Circuit Diagram

- 44. Ignition system

- 44.1. ST Data Monitor Display

- 44.2. ECM Input/Output Signal Specifications

- 44.3. Circuit Diagram

- 44.4. Component Parts Inspection

- 45. Fuel injector system

- 45.1. ST Data Monitor Display

- 45.2. ECM Input/Output Signal Specifications

- 45.3. Circuit Diagram

- 45.4. Component Parts Inspection

- 46. Fuel pump system

- 46.1. ST Data Monitor Display

- 46.2. ECM Input/Output Signal Specifications

- 46.3. Circuit Diagram

- 46.4. Component Parts Inspection

- 47. Throttle control motor system

- 47.1. ECM Input/Output Signal Specifications

- 47.2. Circuit Diagram

- 47.3. Component Parts Inspection

- 48. Heated oxygen sensor heater system

- 48.1. ST Data Monitor Display

- 48.2. ECM Input/Output Signal Specifications

- 48.3. Circuit Diagram

- 48.4. Component Parts Inspection

- 49. PCV gas recirculation device

- 49.1. System Diagram

- 49.2. Component Parts Inspection

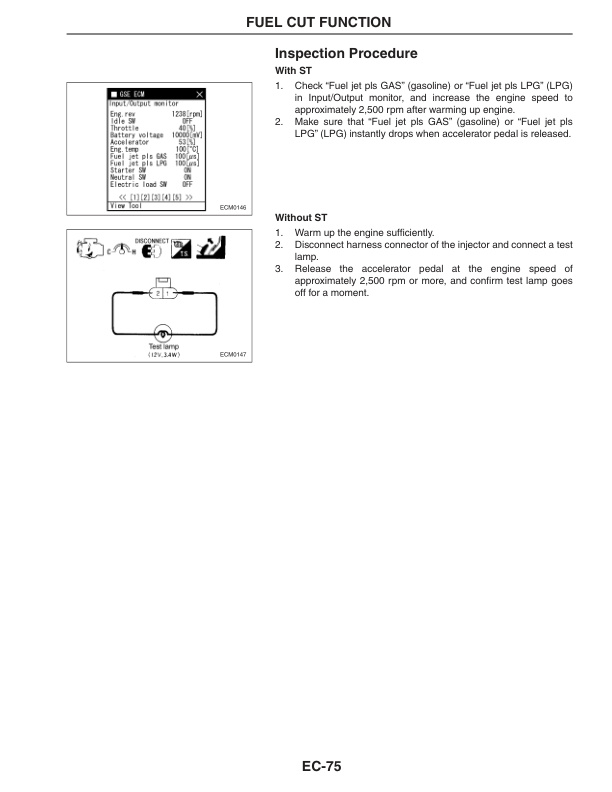

- 50. Fuel cut function

- 50.1. Inspection Procedure

- 51. Removal and installation of ECM components

- 51.1. Removal and Installation of ECM

- 51.2. Removal and Installation of Crankshaft Position Sensor (POS)

- 51.3. Removal and Installation of Camshaft Position Sensor (PHASE)

- 51.4. Removal and Installation of Mass Air Flow Sensor

- 51.5. Removal and Installation of Engine Coolant Temperature Sensor.

- 51.6. Removal and Installation of Heated Oxygen Sensor (with Heated Oxygen Sensor Heater)

- 51.7. Removal and Installation of Throttle Position Sensor (Electric Throttle Control Actuator Assembly)

- 51.8. Removal and Installation of Accelerator Pedal Position Sensor (Accelerator Pedal Assembly)

- 51.9. Removal and Installation of Intake Air Temperature Sensor (with Mass Air Flow Sensor)

- 51.10. Removal and Installation of Neutral Switch (M/T Model)

- 51.11. Removal and Installation of Ignition Coil (with Power Transistor)

- 51.12. Removal and Installation of Fuel Injector

- 51.13. Removal and Installation of Fuel Pump

- 51.14. Removal and Installation of Throttle Control Motor (Electric Throttle Control Actuator Assembly)

- 51.15. Removal and Installation of LPG Injector Holder

- 51.16. Standard, Repair Limit

- 52. Lubrication system

- 52.1. Specifications

- 52.2. Adjustment Value

- 52.3. Oil Pressure

- 52.4. Tightening Torque

- 52.5. Trouble Diagnosis

- 52.6. Lubrication Schematic Diagram

- 52.7. Oil Pump

- 53. Engine coolant system

- 53.1. Specifications

- 53.2. Adjustment Value

- 53.3. Tightening Torque

- 53.4. Trouble Diagnosis

- 53.5. Cooling System Configuration

- 53.6. Water Pump

- 53.7. Thermostat

- 54. Emission control system (only for electronic controlled type)

- 55. Unit layout

- 56. SERVICE DATA AND SPECI FICATIONS (SDS)

- 56.1. Electronic Control System Specifications

- 56.2. Carburetor Specifications

- 57. LPG fuel system trouble diagnosis

- 58. Disassembly and assembly of fuel system

- 58.1. Removal and Installation of LPG Injector Drive Unit Connector

- 58.2. Removal and Installation of Electronic Control Throttle Assembly

- 58.3. Removal and Installation of Gasoline Fuel Injector (Electronically Controlled Gasoline and Combined Use)

- 58.4. Injector Holder

- 58.5. LPG Device Components (Specifications for LPG and Combined Use)

- 58.6. Components Around Carburetor and Pneumatic Governor (Carburetor Specifications)

- 59. Vaporizer mechanism and operation

- 59.1. Primary (Decompression) Room

- 59.2. Description

- 59.3. Secondary Valve Room

- 60. Adjustment value

- 61. Trouble diagnosis

- 62. Distributor (Carburetor type)

- 62.1. Structure

- 62.2. Disassembly

- 62.3. Inspection

- 62.4. Assembly

- 62.5. Inspection After Assembly

- 63. Starter motor

- 63.1. Starter Motor Specifications

- 63.2. Component Parts Location

- 63.3. Overhaul

- 63.4. Assembly Inspection

- 64. Alternator

- 64.1. Components of Alternator

- 64.2. Disassembly

- 64.3. Inspection

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-64105

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Service Manual SCEEA-AT15E-200

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-85100

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02

Caterpillar Service Manual PDF

Caterpillar 2EC15-30 Chassis and Mast Service Manual 99759-80100

Caterpillar Service Manual PDF

Caterpillar 5V15D to 5V35D Mast Supplement Service Manual 99739-351S0

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Gasoline Engine Service Manual 99729-84120

Caterpillar Service Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Disassembly and Assembly Service Manual 99799-67102