Caterpillar NPV20N3D to NSF16N3SS Service Manual SM23GB1DHSC3

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM23GB1DHSC3

- Number of Pages: 286

- Size: 14.0MB

- Format: PDF

-

Model List:

- NPV20N3D, NPF20N3DR, NPF20N3DS, NSV12N3, NSF12N3R, NSF12N3S, NSV12N3I, NSF12N3IR, NSF12N3IS, NSV16N3, NSF16N3R, NSF16N3S, NSV16N3I, NSF16N3IR, NSF16N3IS, NSV16N3S, NSF16N3SR, NSF16N3SS

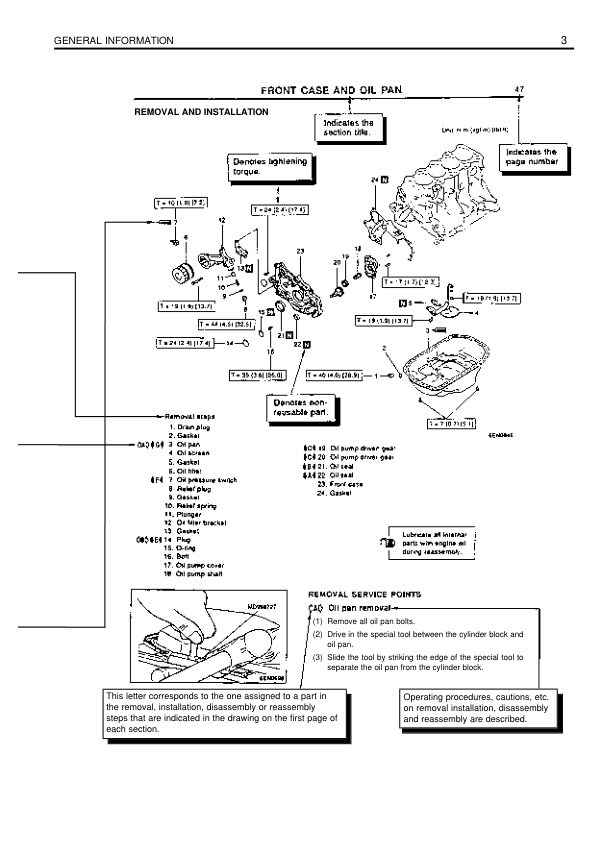

- 1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1. Introduction

- 1.1.1. General

- 1.1.2. The trucks

- 1.1.3. Authorised service personnel

- 1.1.4. Symbol key

- 1.2. Safety

- 1.2.1. General

- 1.2.2. Safety instructions

- 1.2.3. Truck modification

- 1.2.4. Lifting the truck

- 1.2.5. Welding on truck

- 1.2.6. Gas spring

- 1.3. Environmental considerations

- 1.3.1. We respect the environment

- 1.4. Preparations

- 1.4.1. Service

- 1.4.2. Troubleshooting

- 1.5. Truck data

- 1.5.1. Machine plates

- 1.5.2. Safety and warning signs

- 1.5.3. Type designation

- 1.5.4. Truck types

- 1.5.5. Weights, double stacker

- 1.5.6. Weights, high lift stacker

- 1.5.7. Dimensions double stacker – Duplex (T)

- 1.5.8. Dimensions high lift stacker, load capacity 1250 kg – Duplex (TV/TFV)

- 1.5.9. Dimensions high lift stacker, load capacity 1600 kg – Duplex (TFV)

- 1.5.10. Dimensions high lift stacker, load capacity 1600 kg – Triplex (DTFV)

- 1.5.11. Miscellaneous

- 1.6. Component placement

- 1.7. Component specification

- 1.8. Recommended consumable materials

- 1.8.1. Oil and grease types

- 1.9. Code explanations

- 1.9.1. Colour codes for wiring diagrams

- 1.9.2. Designations for electrical components in electrical diagram

- 1.9.3. Standard abbreviations and units

- 1.9.4. Acronyms and abbreviations

- 2. SPECIAL TOOLS

- 2.1. List of tools

- 3. SERVICE

- 3.1. Service schedule / inspection

- 3.1.1. Introduction

- 3.1.2. Safety

- 3.1.3. Service schedule explanation

- 3.1.4. Inspection daily / monthly / PDI and commissioning

- 3.1.5. First service (200 hours)

- 3.1.6. Main service

- 3.1.7. Extra service inspections

- 3.1.8. Service inspection

- 3.1.9. Dye penetration inspection instruction

- 3.2. Service Schedule

- 3.3. Lubrication

- 3.3.1. Recommended lubricants

- 3.3.2. Symbol key, lubrication chart

- 3.3.3. Lubrication chart

- 3.4. Specific instructions

- 3.4.1. Traction motor

- 3.4.2. Gearbox

- 3.5. Maintaining the battery (not for Li-ION)

- 3.6. Battery servicing

- 4. CHASSIS

- 4.1. Design and function

- 4.1.1. Machine housing

- 4.1.2. Covers and panels

- 4.1.3. Wheel system

- 4.1.4. Wheels

- 4.1.5. Friction force system, double stacker

- 4.1.6. Adjustable damped floor (option for fixed platform truck variants)

- 4.2. Repair and maintenance instructions

- 4.2.1. Before work is performed

- 4.2.2. Remove and install panels and covers

- 4.2.3. Remove and install the side protection gates

- 4.2.4. Remove and install the platform damper (option)

- 4.2.5. Wheels

- 4.2.6. Friction force system, double stacker

- 5. DRIVE UNIT

- 5.1. Design and function

- 5.1.1. Description

- 5.1.2. Traction Motor

- 5.1.3. Gearbox

- 5.1.4. Drive wheel

- 5.2. Repair and maintenance instructions

- 5.2.1. Before work is performed

- 5.2.2. Servicing and maintenance

- 5.2.3. Traction motor

- 5.2.4. Gearbox

- 5.2.5. Drive wheel

- 5.3. Diagnostics and troubleshooting

- 5.3.1. Troubleshooting chart

- 6. MAST SYSTEM

- 6.1. Design and function

- 6.1.1. Mast systems

- 6.1.2. Initial lift (option for high lift stacker)

- 6.1.3. Fork carriage

- 6.1.4. Link system

- 6.2. Repair and maintenance instructions

- 6.2.1. Before work is performed

- 6.2.2. Leaning angle of truck, adjustment

- 6.2.3. Initial lift

- 6.2.4. Fork carriage

- 6.2.5. Inspection of welded fork carriages

- 6.2.6. Inspection of forged forks

- 6.2.7. Lift chains

- 6.2.8. Link system

- 6.2.9. Wheels

- 6.2.10. Closed pallet entry and exit (option for double stacker)

- 6.3. Diagnostics and troubleshooting

- 6.3.1. Troubleshooting chart

- 7. STEERING

- 7.1. Design and function

- 7.1.1. General

- 7.1.2. Mechanical steering

- 7.1.3. Electrical power steering

- 7.1.4. Feedback sensors

- 7.1.5. Communication between the servo components

- 7.2. Repair and maintenance instructions

- 7.2.1. Before work is performed

- 7.2.2. Cleaning

- 7.2.3. Tiller arm

- 7.2.4. Mechanical steering

- 7.2.5. Power steering

- 8. HYDRAULIC SYSTEM

- 8.1. Design and function

- 8.1.1. Overview

- 8.1.2. Description

- 8.1.3. Lifting and lowering

- 8.1.4. Hydraulic diagram

- 8.1.5. Hydraulic unit

- 8.1.6. Hydraulic unit valves

- 8.1.7. Hydraulic oil

- 8.2. Repair and maintenance instructions

- 8.2.1. Before work is performed

- 8.2.2. General instructions

- 8.2.3. Installation

- 8.2.4. Connections

- 8.2.5. Hydraulic hoses

- 8.2.6. Start-up

- 8.2.7. Remove and install the hydraulic unit

- 8.2.8. Raise the hydraulic unit, double stacker

- 8.2.9. Hydraulic oil, changing/draining

- 8.2.10. Replace the air filter

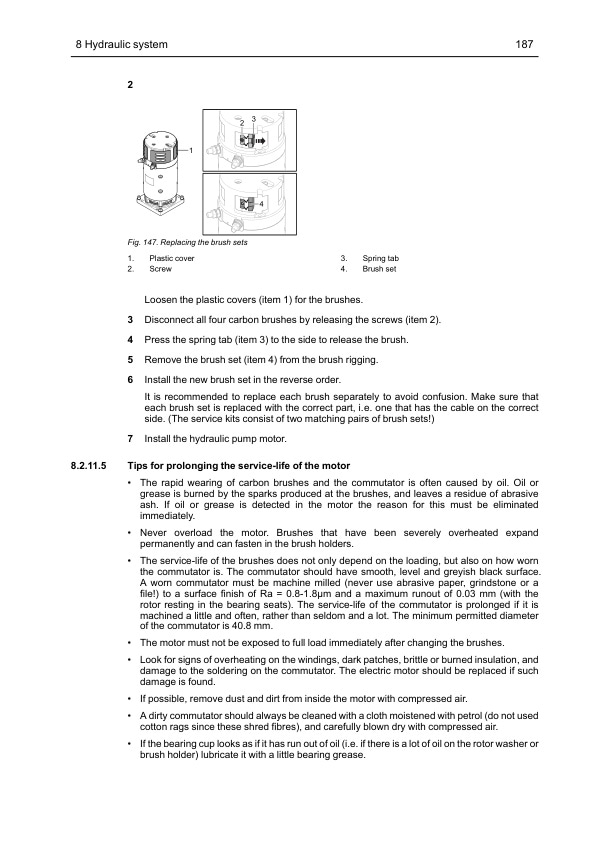

- 8.2.11. Hydraulic motor

- 8.2.12. Hydraulic control valves

- 8.2.13. Installation instruction for pipe couplings

- 8.3. Diagnostics and troubleshooting

- 8.3.1. Symptoms and Actions

- 9. CYLINDERS

- 9.1. Design and function

- 9.1.1. Description

- 9.1.2. Hose break valve

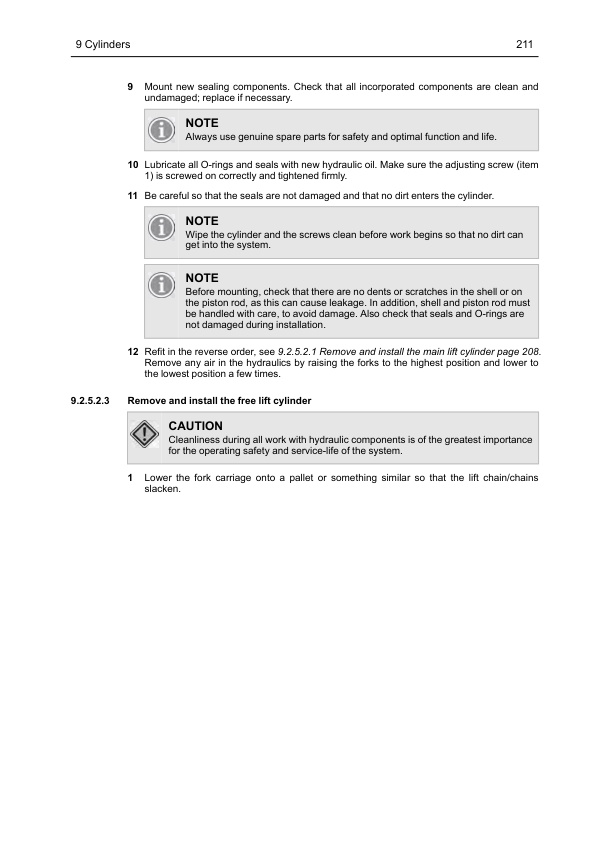

- 9.2. Repair and maintenance instructions

- 9.2.1. Before work is performed

- 9.2.2. Bleeding of the hydraulic cylinders with an air bleed screw

- 9.2.3. Bleeding of the hydraulic cylinders without a bleed air screw

- 9.2.4. Double stacker

- 9.2.5. High lift stacker

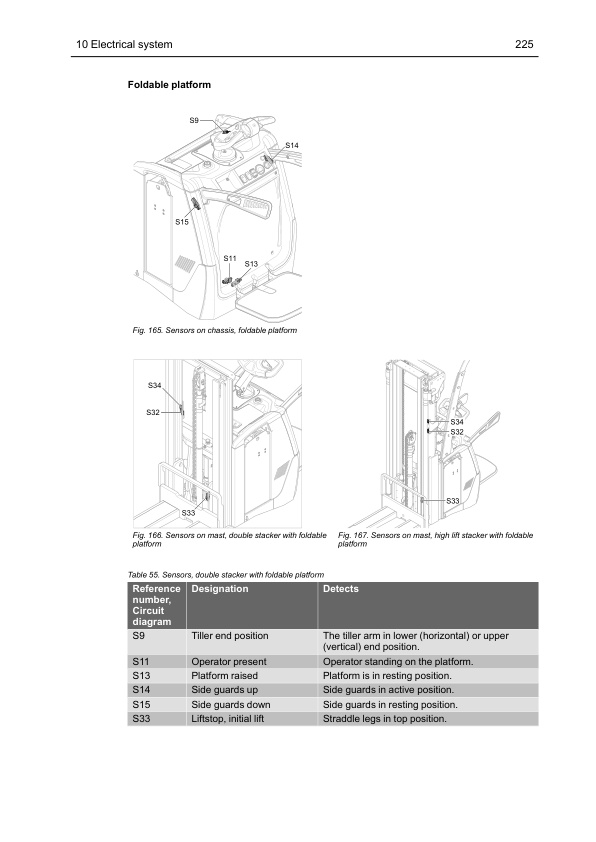

- 10. ELECTRICAL SYSTEM

- 10.1. Introduction

- 10.1.1. Overview of components

- 10.1.2. CAN bus communication

- 10.2. Safety

- 10.2.1. Safety instructions

- 10.2.2. Electronic controllers

- 10.2.3. Safety checks

- 10.2.4. Servo steering system

- 10.2.5. Hydraulic system

- 10.2.6. Hydraulic pressure sensors for initial lift and main lift (S26, S30)

- 10.2.7. Brake system

- 10.2.8. Traction system

- 10.2.9. Sensors

- 10.2.10. Maximum drive speed and drive stop

- 10.3. Design and function

- 10.3.1. Battery capacity

- 10.3.2. VCM (Vehicle Control Module) (truck computer)

- 10.3.3. Display

- 10.3.4. CMC (Combi Motor Controller)

- 10.3.5. EPS (Electrical Power Steering) controller

- 10.3.6. Connector specifications

- 10.4. Repair and maintenance instructions

- 10.4.1. Before work is performed

- 10.4.2. Wiring diagram

- 10.4.3. Insulation resistance test

- 10.4.4. Remove and install the battery lock

- 10.4.5. Battery replacement (with rollers)

- 10.4.6. Battery replacement (without rollers)

- 10.4.7. Battery replacement (Lithium-ion)

- 10.4.8. Replacing the Electric panel components

- 10.4.9. Remove and install the VCM

- 10.4.10. Remove and install the emergency stop

- 10.4.11. Remove and install the standard display (HMI-10)

- 10.4.12. Remove and install the multi function display (HMI-20)

- 10.4.13. Replace the Foot protection sensor (S1) Reflector, Fixed rear platform

- 10.4.14. Remove and install the safety sensors

- 10.4.15. TruckTool

- 10.5. Diagnostics and troubleshooting

- 11. SPEED CONTROL AND BRAKE SYSTEMS

- 11.1. Design and function

- 11.1.1. Speed and brake control

- 11.1.2. Electric brake

- 11.2. Repair and maintenance instructions

- 11.2.1. Before work is performed

- 11.2.2. Electric brake

- 11.3. Diagnostics and troubleshooting

- 11.3.1. Troubleshoot the speed controller

- 11.3.2. Troubleshoot the brake

- 12. MISCELLANEOUS

- 12.1. Options

- 12.1.1. Additional equipment

- 12.1.2. Additional equipment overview

- 12.1.3. Battery lock, quick lock (option)

- 12.1.4. Adjustable damped floor (option)

- 12.1.5. Load backrest (option)

- 12.1.6. power supply socket (option)

- 12.1.7. USB-power supply socket (option)

- 12.1.8. Equipment bar installation (option)

- 12.1.9. Work light (only with overhead guard)

- 12.1.10. Floor spot (option)

- 12.1.11. Writing surface installation

- 12.1.12. Foot protection (option)

- 12.1.13. Closed Pallet Entry and Exit (option)

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Gasoline Engine Service Manual 99729-84120

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1.4 Liter (4G33) to 3.0 Liter (6G72) LP Gas Supplement Service Manual SENB8531

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-64102

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8609

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Fuel System Supplement Service Manual 99729-85110

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99719-84130

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110