Caterpillar NR14N2L to NR25N2X Service Manual 622076 EN-D

$50.00

- Type Of Manual: Service Manual

- Manual ID: 622076

- Language: EN-D

- Number of Pages: 436

- Size: 44.9MB

- Format: PDF

-

Model List:

- NR14N2L, NR16N2L, NR14N2S, NR14N2HS, NR16N2S, NR16N2HS, NR16N2, NR16N2H, NR16N2C, NR16NHC, NR20N2H, NR20N2X, NR25N2X

- 1. EN-D-01_Foreword

- 2. EN-D-02_How to read this manual

- 3. EN-D-03_Safety instructions

- 4. EN-D-04_General information

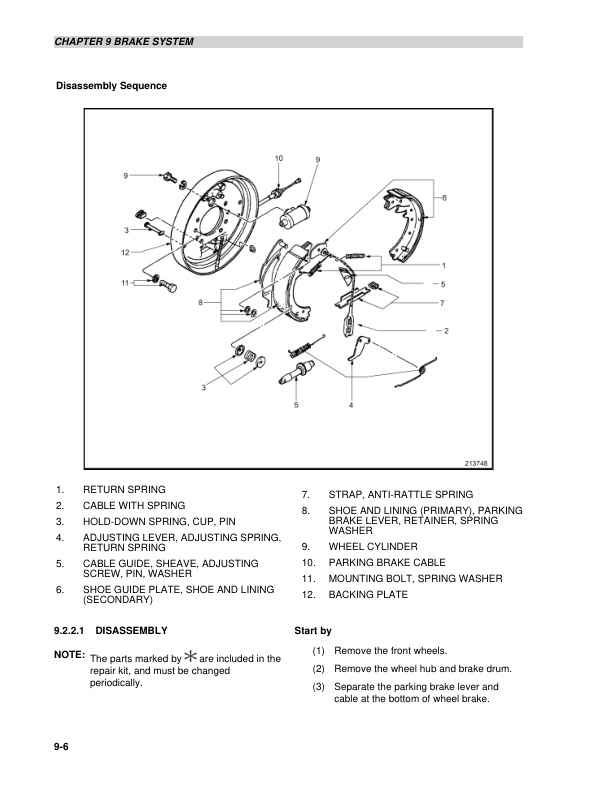

- 5. EN-D-05_Mechanical maintenance

- 6. EN-D-06_Electrical operation

- 7. EN-D-07_Battery maintenance

- 8. EN-D-08_Electric system maintenance

- 9. EN-D-09_Electric system adjustments and measurements

- 10. EN-D-10_Hydraulic operation

- 11. EN-D-11_TruckTool Diagnostics

- 12. EN-D-12_Parameter descriptions

- 13. EN-D-13_Alarm Codes

- 14. EN-D-14_Service Data

- 15. EN-D-15_Options

- 16. EN-D-16_Technical Specifications

- 17. EN-D-17_Index

- 18. EN-D-18_Appendix A Stickers

- 18.1. Contents

- 18.2. Foreword

- 18.3. How to read this manual

- 18.3.1. Safety-related signs

- 18.3.2. Symbols and abbreviations

- 18.3.2.1. Safety symbols

- 18.3.2.2. Other symbols and abbreviations

- 18.3.3. Units

- 18.4. Safety instructions

- 18.4.1. Safety requirements for industrial trucks

- 18.4.2. Repairs and structural modifications

- 18.4.3. Service area safety

- 18.4.4. Personal safety

- 18.4.5. Work safety

- 18.4.6. Operating temperature

- 18.5. General information

- 18.5.1. Truck models covered by this manual

- 18.5.2. Identification plates on the truck

- 18.5.3. Overview of the truck

- 18.5.3.1. Overhead guard

- 18.5.3.2. Cabin

- 18.5.3.3. Emergency exits (cabin truck only)

- 18.5.3.4. Operating devices

- 18.5.3.5. Control panel

- 18.5.3.6. Steering wheel

- 18.5.3.7. Arm rest

- 18.5.3.8. Display panel

- 18.5.3.9. Truck operation modes

- 18.5.3.10. Truck display

- 18.5.3.11. Pedals

- 18.5.3.12. Operators seat

- 18.5.3.13. Drive unit, hydraulic system and instrument panel

- 18.5.3.14. Sensors

- 18.5.3.15. Reach carriage

- 18.5.3.16. Mast

- 18.5.3.17. Load backrest

- 18.6. Mechanical maintenance

- 18.6.1. Lifting points

- 18.6.1.1. Jack points

- 18.6.1.2. Hoist points

- 18.6.2. How to tow the truck

- 18.6.2.1. Release the magnetic brake manually

- 18.6.3. Transportation

- 18.6.4. Assembly and commissioning

- 18.6.4.1. Install the mast

- 18.6.5. Order spare parts

- 18.6.6. How to clean the truck

- 18.6.7. Truck covers

- 18.6.7.1. Remove the machinery cover

- 18.6.7.2. Remove the front bumper

- 18.6.7.3. Remove the floor plate

- 18.6.7.4. Open the machinery top cover

- 18.6.7.5. Open the instrument panel

- 18.6.7.6. Remove the gas spring of the instrument panel

- 18.6.7.7. Remove the instrument panel cover

- 18.6.7.8. Remove the control panel

- 18.6.7.9. Remove the cup holder

- 18.6.7.10. Remove the reach carriage cover

- 18.6.8. Steering wheel

- 18.6.8.1. Remove the steering wheel

- 18.6.9. Transmission gear

- 18.6.9.1. Remove the transmission gear

- 18.6.10. Slewing bearing

- 18.6.10.1. Lubricate the slewing bearing

- 18.6.11. Traction wheel

- 18.6.11.1. Disassemble the traction wheel

- 18.6.11.2. Assemble the traction wheel

- 18.6.12. Corner supports

- 18.6.12.1. Replace the corner supports

- 18.6.13. Load wheels

- 18.6.13.1. Remove the load wheels

- 18.6.13.2. Electric load wheel brakes (High performance model, optional for Standard model)

- 18.6.13.3. Adjust the load wheel brakes (High performance model, optional for Standard model)

- 18.6.14. Battery roller frame

- 18.6.14.1. Remove the battery roller frame

- 18.6.15. Reach carriage

- 18.6.15.1. Lubricate the rollers of the reach carriage

- 18.6.15.2. Adjust the guidance rollers of the reach carriage

- 18.6.15.3. Sensors of the reach carriage

- 18.6.15.4. Remove the reach carriage

- 18.6.15.5. Remove the reach cylinder

- 18.6.15.6. Replace the reach carriage hoses

- 18.6.16. Integral mast

- 18.6.16.1. Detailed construction

- 18.6.16.2. Maintenance of the mast

- 18.6.16.3. Lubricant recommendations

- 18.6.16.4. Remove the lifting carriage

- 18.6.16.5. Remove the mast

- 18.6.16.6. Disassemble the mast

- 18.6.16.7. Fork inspection

- 18.6.16.8. Mast chains

- 18.6.16.9. Guidance rollers

- 18.6.16.10. Main rollers

- 18.6.16.11. Free lift cylinder

- 18.6.16.12. Side cylinders

- 18.6.16.13. Tilt cylinders

- 18.6.16.14. Sideshift cylinder

- 18.6.17. LX-mast

- 18.6.17.1. Detailed construction

- 18.6.17.2. Maintenance of the mast

- 18.6.17.3. Lubricant recommendations

- 18.6.17.4. Lifting carriage

- 18.6.17.5. Remove the mast

- 18.6.17.6. Disassemble the mast

- 18.6.17.7. Fork inspection

- 18.6.17.8. Mast chains

- 18.6.17.9. Main rollers

- 18.6.17.10. Free lift cylinder

- 18.6.17.11. Side cylinders

- 18.6.18. Load backrest

- 18.6.18.1. Replace the load backrest

- 18.6.19. Operators seat

- 18.6.19.1. Replace the seat switch

- 18.6.20. Arm rest

- 18.6.20.1. Remove the arm rest

- 18.6.20.2. Open the arm rest

- 18.6.20.3. Remove the arm rest levers

- 18.6.20.4. Remove the arm rest buttons

- 18.6.21. Cabin

- 18.6.21.1. Cabin covers

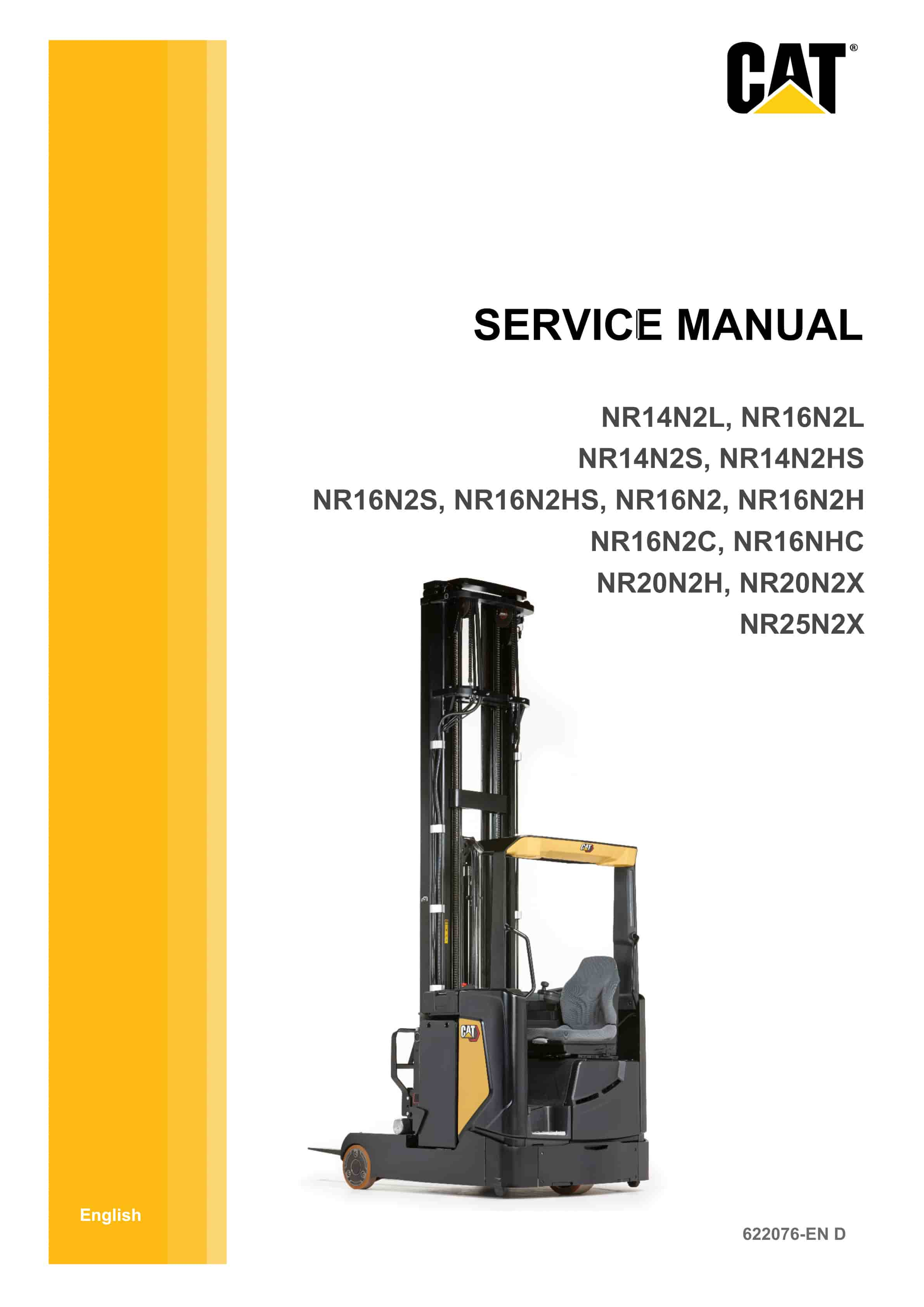

- 18.6.21.2. Operator door

- 18.6.21.3. Roof window

- 18.6.21.4. Cabin seals

- 18.6.21.5. Heater

- 18.6.21.6. Loudspeakers

- 18.6.21.7. Cabin windows

- 18.7. Electrical operation

- 18.7.1. How to use the schematic diagram

- 18.7.2. Power supply

- 18.7.3. Safety circuit (emergency stop button)

- 18.7.4. Key switch

- 18.7.5. Traction

- 18.8. Battery maintenance

- 18.8.1. General information

- 18.8.2. Safety signs for lead-acid batteries

- 18.8.3. Requirements for the battery charging areas

- 18.8.4. Charge the battery

- 18.8.5. Measure the specific gravity of the battery water

- 18.8.6. Battery maintenance

- 18.8.6.1. How to clean batteries with a damp cleaning cloth

- 18.8.6.2. How to clean batteries with high-pressure cleaning equipment

- 18.8.6.3. Daily maintenance

- 18.8.6.4. Weekly maintenance

- 18.8.6.5. Monthly maintenance

- 18.8.6.6. Annual maintenance

- 18.8.7. Malfunctions

- 18.8.8. Acquire a new battery

- 18.8.9. Replace the battery

- 18.8.9.1. Guide the battery connector cables

- 18.8.10. Quick battery replacement

- 18.8.11. Storage

- 18.8.12. Lithium-ion batteries

- 18.8.12.1. General information

- 18.8.12.2. Safety signs

- 18.8.12.3. Requirements for the battery charging areas

- 18.8.12.4. Charge the battery

- 18.8.12.5. Battery maintenance

- 18.8.12.6. Service and repair

- 18.8.12.7. Replace the battery

- 18.8.12.8. Acquire a new battery

- 18.8.12.9. Storage

- 18.9. Electric system maintenance

- 18.9.1. Display panel

- 18.9.1.1. Emergency stop button

- 18.9.1.2. Key switch

- 18.9.2. Pedals

- 18.9.2.1. Operator presence pedal

- 18.9.2.2. Accelerator pedal

- 18.9.2.3. Brake pedal

- 18.9.3. Instrument panel

- 18.9.3.1. Discharge the controllers

- 18.9.3.2. Vehicle controller

- 18.9.3.3. Vehicle controller connectors

- 18.9.3.4. Traction controller

- 18.9.3.5. Traction controller connectors

- 18.9.3.6. Pump controller

- 18.9.3.7. Pump controller connectors

- 18.9.3.8. Steering controller

- 18.9.3.9. Steering controller connectors

- 18.9.3.10. Fuses

- 18.9.3.11. Additional fuses with the cabin

- 18.9.4. Motor compartment

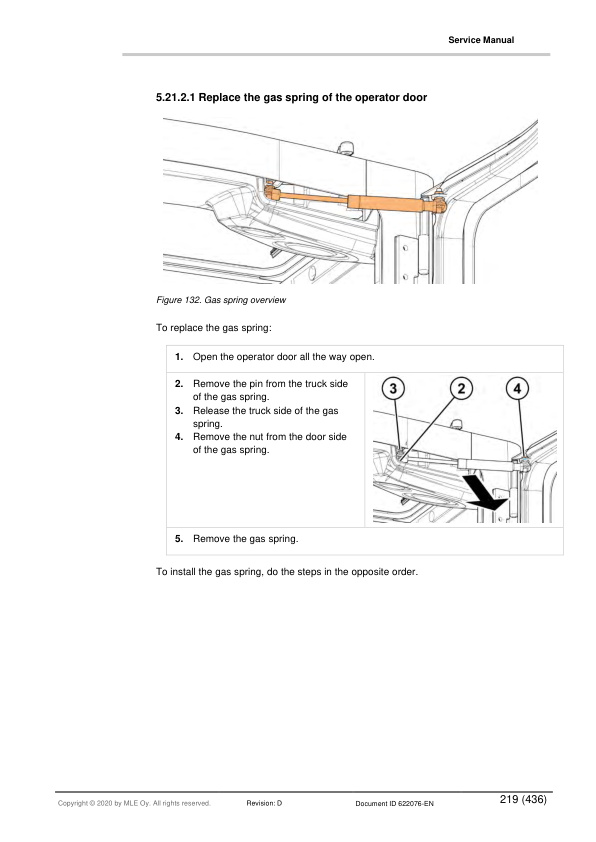

- 18.9.4.1. Traction motor

- 18.9.4.2. Steering motor

- 18.9.4.3. Magnetic brake

- 18.9.4.4. Release the magnetic brake manually

- 18.9.5. Pump motor

- 18.9.5.1. Pump motor (Standard model)

- 18.9.5.2. Pump motor (High performance model)

- 18.9.5.3. Replace the pump motor

- 18.9.5.4. Lubricate the pump axle splines

- 18.9.5.5. Replace the HALL sensor

- 18.9.6. Sensors

- 18.9.6.1. Steering wheel sensor

- 18.9.6.2. Steering reference sensor

- 18.9.6.3. Reach end stop, retract limit, retract end stop and reach limit switch

- 18.9.6.4. Battery lock sensor

- 18.9.6.5. Pressure sensor

- 18.9.6.6. Height reference sensor

- 18.10. Electric system adjustments and measurements

- 18.10.1. Calibrate the arm rest levers

- 18.10.2. Insulation resistance test

- 18.10.2.1. Test voltage

- 18.10.2.2. Insulation tester check

- 18.10.2.3. Measure the insulation resistance

- 18.11. Hydraulic operation

- 18.11.1. Hydraulic symbols

- 18.11.2. Hydraulic oil recommendations

- 18.11.3. Maintenance points of the hydraulic system

- 18.11.3.1. Replace the hydraulic oil return filter (sieve)

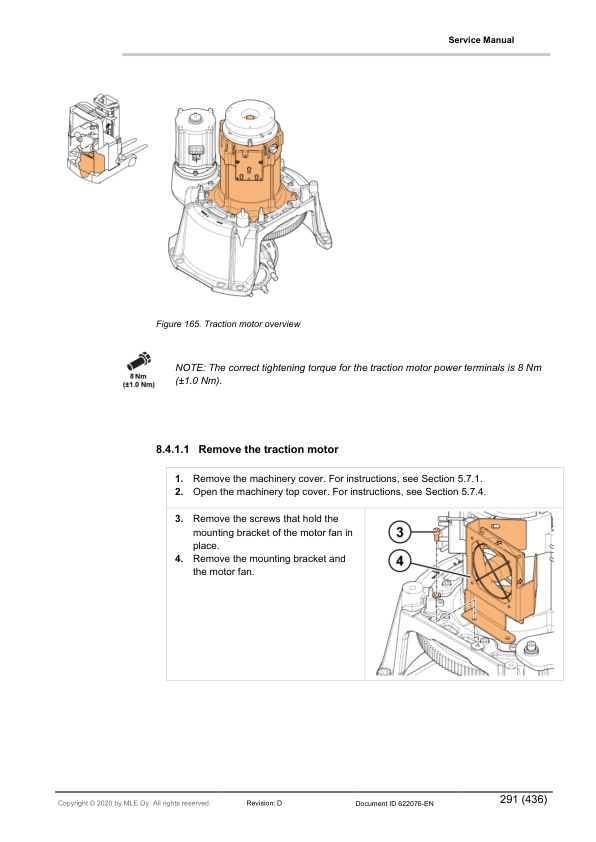

- 18.11.3.2. Clean the hydraulic oil suction filter

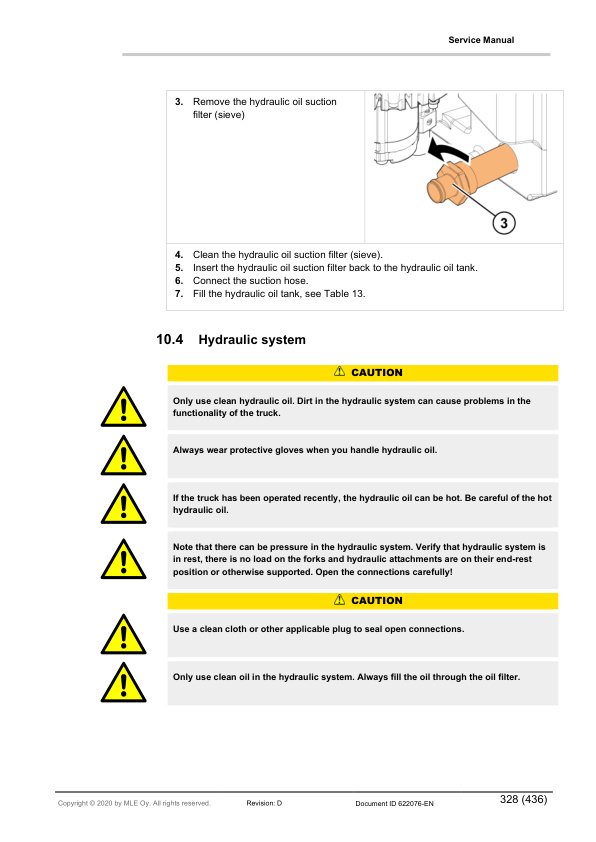

- 18.11.4. Hydraulic system

- 18.11.4.1. Disassemble the hydraulic system

- 18.11.5. Hydraulic valve unit

- 18.11.5.1. Valve M1

- 18.11.5.2. Valve M3, M4, M7 and M8

- 18.11.5.3. Valve M2, M5, M6, M9 and M10

- 18.11.5.4. Emergency lowering valve

- 18.11.5.5. Set the lifting pressure

- 18.11.5.6. Disassemble the valves

- 18.12. TruckTool Diagnostics

- 18.12.1. Location of the service socket

- 18.12.1.1. Connect TruckTool to the service socket

- 18.13. Parameter descriptions

- 18.14. Alarm codes

- 18.15. Service data

- 18.15.1. Special tightening torques

- 18.15.2. Tightening torque for standard bolts and nuts

- 18.15.3. Maintenance check list

- 18.15.4. Lubrication

- 18.15.4.1. Hydraulic oil

- 18.15.4.2. Transmission oil

- 18.15.4.3. Heavy duty grease for slewing bearing

- 18.15.4.4. Pump axle splines

- 18.15.4.5. Traction motor axle splines

- 18.15.4.6. Lubrication points

- 18.15.4.7. Mast chains

- 18.15.4.8. Mast channels

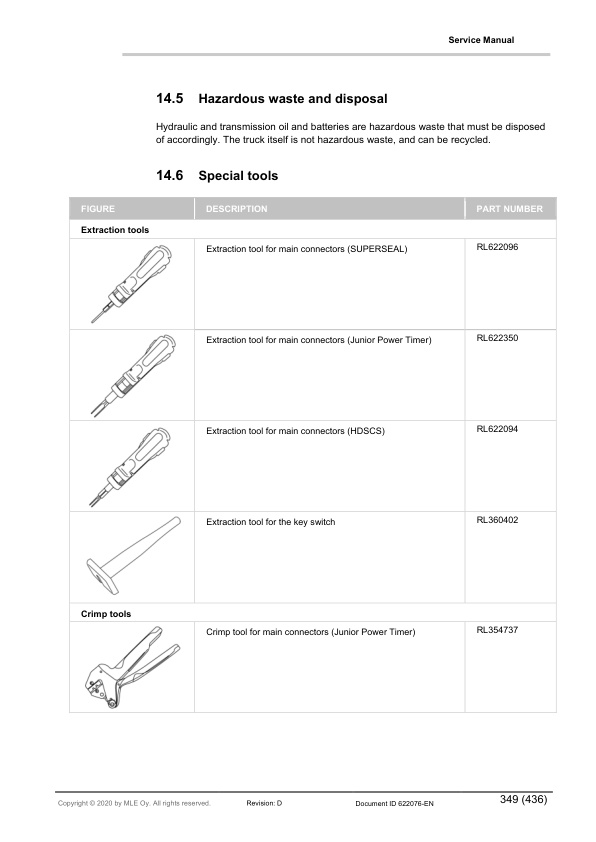

- 18.15.5. Hazardous waste and disposal

- 18.15.6. Special tools

- 18.15.7. Storage

- 18.15.7.1. Return the truck to operation

- 18.15.8. Decommissioning

- 18.16. Options

- 18.16.1. Special color labels

- 18.16.2. Customer design labels

- 18.16.3. Truck display languages

- 18.16.4. Accessory rack

- 18.16.4.1. Install the accessory rack

- 18.16.4.2. Install the list bracket

- 18.16.4.3. Install the computer rack

- 18.16.4.4. Install the rear view mirror

- 18.16.5. Accessory rack under the truck floor

- 18.16.5.1. Install the accessory rack under the floor

- 18.16.6. Reading lamp

- 18.16.6.1. Install the reading lamp

- 18.16.7. Audio system

- 18.16.7.1. Install the audio system

- 18.16.8. Warning light

- 18.16.8.1. Install the warning light

- 18.16.9. Warning light with an extension arm

- 18.16.9.1. Install the warning light with an extension arm

- 18.16.10. Working lights

- 18.16.10.1. Install the working lights

- 18.16.11. Floor point rear light

- 18.16.11.1. Install the floor point rear light

- 18.16.12. Operator compartment fan

- 18.16.12.1. Install the operator compartment fan

- 18.16.13. Drive alarm (programmable)

- 18.16.13.1. Install the drive alarm

- 18.16.14. Steel safety net for overhead guard

- 18.16.14.1. Install the steel safety net to the overhead guard

- 18.16.15. Plexiglass safety cover for the overhead guard

- 18.16.15.1. Install the plexiglass safety cover to the overhead guard

- 18.16.16. Left shoulder protection plate

- 18.16.16.1. Install the left shoulder protection plate

- 18.16.17. Fire extinguisher

- 18.16.17.1. Install the fire extinguisher

- 18.16.18. Cold storage modification

- 18.16.19. Hot storage modification

- 18.16.20. DC-DC converter

- 18.16.20.1. Install the DC-DC converter

- 18.16.21. Battery changing device for 2 batteries

- 18.16.21.1. Remove an empty battery with the battery changing device for 2 batteries

- 18.16.21.2. Install a charged battery with the battery changing device for 2 batteries

- 18.16.22. Battery connector cables

- 18.16.22.1. Replace the battery connector

- 18.16.23. Charger connector

- 18.16.23.1. Replace the charger connector

- 18.16.24. Extra valve with hosing to fork carriage

- 18.16.25. Fork positioner with sideshift

- 18.16.26. Fork carriage strengthening part

- 18.16.27. Fork camera with 7 LCD color display

- 18.16.28. Telescopic forks

- 18.16.29. Sideshift and tilt centering

- 18.16.29.1. Sideshift centering direction, sideshift centering midpoint and tilt centering sensor

- 18.16.30. Load weight indicator

- 18.16.31. Active Sway Control (ASC)

- 18.16.31.1. Troubleshooting

- 18.16.32. Lowering cut-off

- 18.16.33. Operators seat options and accessories

- 18.16.33.1. Arm rest

- 18.16.33.2. Backrest extension for MSG65/MSG75

- 18.16.33.3. Seat belt for MSG20 seat

- 18.16.34. PIN code access to the Start switch

- 18.16.35. Abbot 2

- 18.16.35.1. Install the Abbot 2

- 18.16.36. Lifting height pre-selection

- 18.16.36.1. Define the lifting height target levels

- 18.16.36.2. How to unstack with the lifting height pre-selection

- 18.16.36.3. How to stack with the lifting height pre-selection

- 18.17. Technical specification

- 18.17.1. Dimensions

- 18.17.2. Technical data

- 18.17.3. Mast heights

- 18.18. Index

- 18.19. APPENDIX A Stickers

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99719-84130

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Disassembly and Assembly Service Manual 99799-67102

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Specifications Service Manual 99799-67101

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 5M15D to 5M35D Mast Supplement Service Manual 99739-351T0

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Fuel System Supplement Service Manual 99729-85110

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02