Caterpillar S4S-E35AFL(F) Diesel Engine Service Manual SCEEG-CT14J-230

$50.00

- Type Of Manual: Service Manual

- Manual ID: SCEEG-CT14J-230

- Number of Pages: 222

- Size: 9.3MB

- Format: PDF

-

Model List:

- S4S-E35AFL(F) Diesel Engine

- 1. BINDING

- 2. INTRODUCTION

- 2.1. How to use this manual

- 2.1.1. Methods of presentation

- 2.1.2. Terms used in this manual

- 2.1.3. Abbreviations

- 2.1.4. Units of measurement

- 2.2. Safety Cautions

- 2.2.1. Fire and explosion

- 2.2.2. Stay clear of all rotating and moving parts

- 2.2.3. Be careful of burns

- 2.2.4. Be careful of exhaust fume poisoning

- 2.2.5. Protect ears from noises

- 2.2.6. Be careful of falling down

- 2.2.7. Be careful of handling fuel, engine oil and LLC

- 2.2.8. Service battery

- 2.2.9. When abnormality occurs

- 2.2.10. Other cautions

- 2.2.11. About warning labels

- 3. GENERAL CONTENTS

- 4. GENERAL

- 4.1. External view (in-line fuel injection pump and distributor-type fuel injection pump)

- 4.1.1. S4S in-line fuel injection pump specification

- 4.1.2. S4S-DT in-line fuel injection pump specification

- 4.1.3. S4S distributor-type fuel injection pump specification

- 4.1.4. S4S-DT distributor-type fuel injection pump specification

- 4.2. System flow diagrams

- 4.2.1. Fuel system – flow diagram

- 4.2.2. Lubrication system – flow diagram

- 4.2.3. Cooling system – flow diagram

- 4.2.4. Inlet and exhaust system – flow diagram

- 4.3. Engine serial number location

- 4.4. Main specifications

- 4.4.1. S4S in-line fuel injection pump specification (varies depending on the specification)

- 4.4.2. S4S distributor-type fuel injection pump specification (varies depending on the specification)

- 4.5. Tips on disassembling and reassembling

- 4.5.1. Disassembling

- 4.5.2. Reassembling

- 5. SERVICE DATA

- 5.1. Maintenance service data

- 5.1.1. General

- 5.1.2. Basic engine

- 5.1.3. Fuel system

- 5.1.4. Lubrication system

- 5.1.5. Cooling system

- 5.1.6. Inlet and exhaust system

- 5.1.7. Electrical system

- 5.2. Tightening torque table

- 5.2.1. Major bolt tightening torque

- 5.2.2. Standard bolt and nut tightening torque

- 5.2.3. Standard stud tightening torque

- 6. SERVICE TOOLS

- 6.1. Special tool

- 7. DETERMINATION OF OVERHAUL

- 7.1. Determining overhaul timing

- 7.2. Testing compression pressure

- 8. DISASSEMBLY OF BASIC ENGINE

- 8.1. Disassembling and inspecting cylinder head and valve mechanism

- 8.1.1. Removing rocker shaft assembly

- 8.1.2. Disassembling rocker shaft assembly

- 8.1.3. Removing cylinder head bolt

- 8.1.4. Removing cylinder head assembly

- 8.1.5. Removing valve and valve spring

- 8.1.6. Removing valve stem seal

- 8.2. Disassembling and inspecting flywheel

- 8.2.1. Removing flywheel

- 8.2.2. Removing flywheel housing

- 8.3. Disassembling and inspecting gear case, timing gear and camshaft

- 8.3.1. Removing crankshaft pulley

- 8.3.2. Removing cover

- 8.3.3. Removing timing gear case

- 8.3.4. Measuring timing gear backlash

- 8.3.5. Measuring idler gear and camshaft gear end play

- 8.3.6. Removing fuel injection pump

- 8.3.7. Removing oil pan

- 8.3.8. Removing oil strainer

- 8.3.9. Removing oil pump gear

- 8.3.10. Removing idler gear

- 8.3.11. Removing camshaft

- 8.3.12. Separating camshaft gear

- 8.3.13. Installing camshaft gear and thrust plate

- 8.3.14. Removing front plate

- 8.3.15. Removing oil pump

- 8.4. Disassembling and inspecting piston, connecting rod, crankshaft and crankcase

- 8.4.1. Removing connecting rod cap

- 8.4.2. Removing carbon deposits from the upper part of cylinder

- 8.4.3. Pulling out piston

- 8.4.4. Removing piston ring

- 8.4.5. Removing piston pin and piston

- 8.4.6. Removing main bearing cap

- 8.4.7. Removing crankshaft

- 8.4.8. Removing tappet

- 9. INSPECTION AND REPAIR OF BASIC ENGINE

- 9.1. Inspecting and repairing cylinder head and valve mechanism

- 9.1.1. Measuring clearance between rocker bushing and rocker shaft

- 9.1.2. Measuring valve stem outside diameter and valve guide inside diameter

- 9.1.3. Replacing valve guide

- 9.1.4. Inspecting valve face

- 9.1.5. Refacing valve face

- 9.1.6. Refacing valve seat

- 9.1.7. Replacing valve seat

- 9.1.8. Lapping valve and valve seat

- 9.1.9. Measuring perpendicularity and free length of valve spring

- 9.1.10. Measuring distortion of the bottom surface of the cylinder head

- 9.1.11. Measuring pushrod runout

- 9.1.12. Removing combustion jet

- 9.2. Inspecting and repairing flywheel

- 9.2.1. Measuring flatness of flywheel

- 9.2.2. Measuring flywheel face and radial runouts

- 9.2.3. Inspecting ring gear

- 9.2.4. Replacing ring gear

- 9.3. Inspecting and repairing timing gear and camshaft

- 9.3.1. Measuring timing gear backlash

- 9.3.2. Measuring idler gear and camshaft gear end play

- 9.3.3. Measuring cam lift

- 9.3.4. Measuring camshaft runout

- 9.3.5. Measuring camshaft journal outside diameter

- 9.3.6. Measuring camshaft hole (bushing) inside diameter

- 9.3.7. Replacing camshaft bushing

- 9.3.8. Measuring idler bushing inside diameter and idler shaft outside diameter

- 9.3.9. Replacing idler shaft

- 9.3.10. Measuring clearance between tappet and tappet guide hole

- 9.3.11. Inspecting tappet

- 9.3.12. Inspecting V-belt groove wear

- 9.4. Inspecting and repairing piston, connecting rod, crankshaft and crankcase

- 9.4.1. Measuring crankcase top surface distortion

- 9.4.2. Measuring cylinder inside diameter

- 9.4.3. Measuring piston outside diameter

- 9.4.4. Measuring piston ring end gap

- 9.4.5. Measuring clearance between piston ring groove and piston ring

- 9.4.6. Measuring piston pin bore diameter and piston pin outside diameter

- 9.4.7. Measuring piston protrusion

- 9.4.8. Measuring clearance between connecting rod bearing and crankpin

- 9.4.9. Measuring clearance between connecting rod bushing and piston pin

- 9.4.10. Replacing connecting rod bushing

- 9.4.11. Inspecting connecting rod bend and twist

- 9.4.12. Inspecting connecting rod bearing

- 9.4.13. Measuring connecting rod end play

- 9.4.14. Weight difference of connecting rod assembly in one engine

- 9.4.15. Measuring crankshaft journal outside diameter

- 9.4.16. Measuring crankshaft crankpin outside diameter

- 9.4.17. Grinding crankshaft

- 9.4.18. Measuring crankshaft end play

- 9.4.19. Measuring crankshaft runout

- 9.4.20. Replacing crankshaft gear

- 9.4.21. Inspecting oil seal contact surface

- 9.4.22. Installing oil seal sleeve

- 9.4.23. Removing oil seal sleeve

- 9.4.24. Inspecting main bearing surface

- 9.4.25. Measuring clearance between main bearing and crankshaft journal

- 10. REASSEMBLY OF BASIC ENGINE

- 10.1. Reassembling piston, connecting rod, crankshaft and crankcase

- 10.1.1. Installing main bearing

- 10.1.2. Installing thrust plate

- 10.1.3. Installing tappet

- 10.1.4. Installing crankshaft

- 10.1.5. Installing main bearing caps

- 10.1.6. Inserting side seal

- 10.1.7. Installing main bearing cap bolt

- 10.1.8. Measuring crankshaft end play

- 10.1.9. Reassembling piston and connecting rod

- 10.1.10. Installing piston ring

- 10.1.11. Preparation for installing pistons

- 10.1.12. Installing connecting rod bolt and connecting rod bearing

- 10.1.13. Installing pistons

- 10.1.14. Installing connecting rod cap

- 10.2. Reassembling timing gear and camshaft

- 10.2.1. Installing oil pump

- 10.2.2. Installing front plate

- 10.2.3. Installing camshaft gear and thrust plate

- 10.2.4. Installing camshaft

- 10.2.5. Installing idler gear

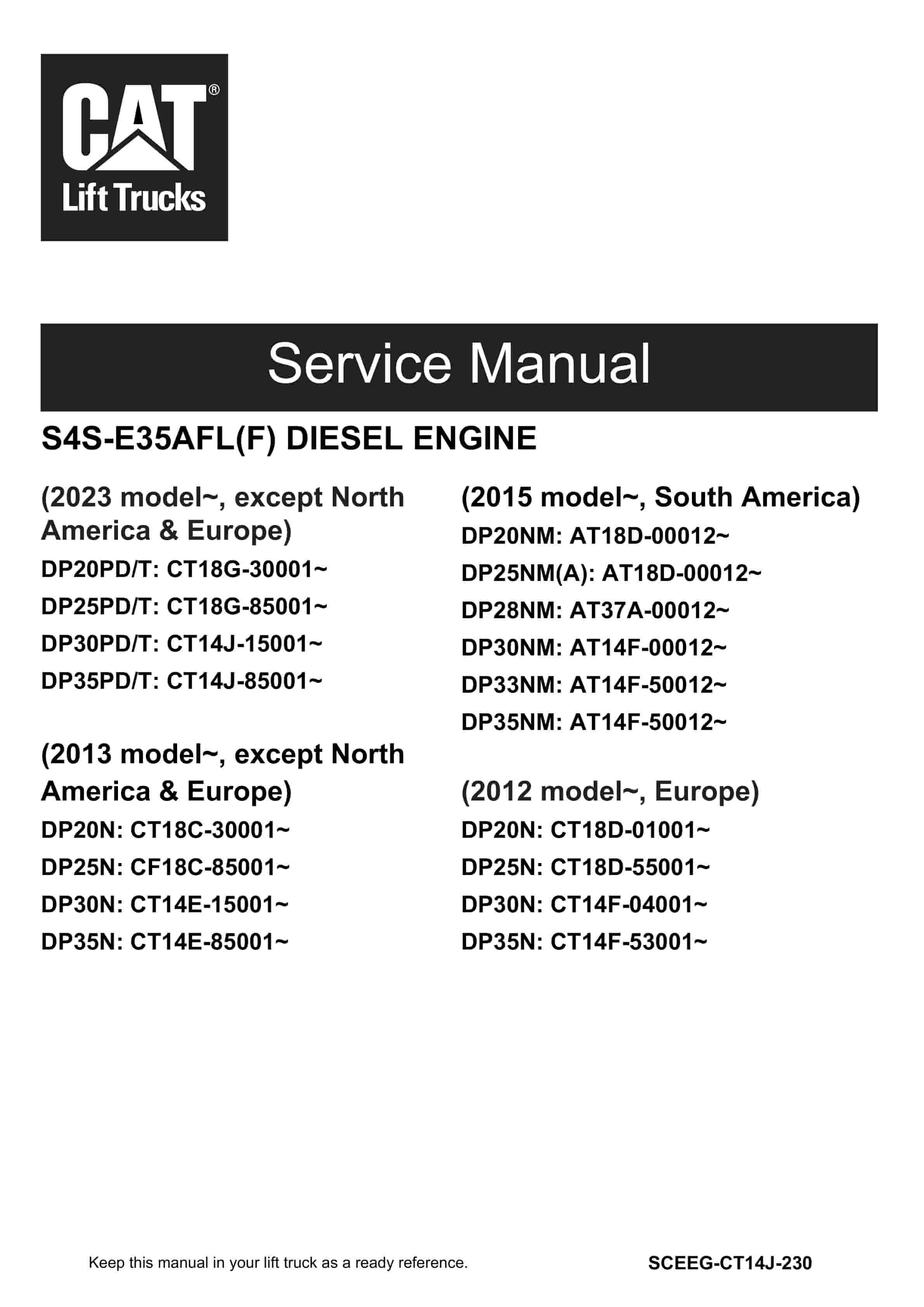

- 10.2.6. Installing oil pump gear

- 10.2.7. Installing fuel injection pump

- 10.2.8. Inspecting and adjusting timing gear after installation

- 10.2.9. Installing front oil seal

- 10.2.10. Installing timing gear case

- 10.2.11. Installing oil strainer

- 10.2.12. Installing oil pan

- 10.2.13. Installing cover

- 10.2.14. Installing crankshaft pulley

- 10.3. Reassembling flywheel

- 10.3.1. Installing oil seal

- 10.3.2. Installing flywheel housing

- 10.3.3. Installing flywheel

- 10.4. Reassembling cylinder head and valve mechanism

- 10.4.1. Cleaning cylinder head bottom surface

- 10.4.2. Installing valve stem seal

- 10.4.3. Installing valve and valve spring

- 10.4.4. Installing cylinder head gasket

- 10.4.5. Installing cylinder head assembly

- 10.4.6. Tightening cylinder head bolts

- 10.4.7. Inserting pushrod

- 10.4.8. Reassembling rocker shaft assembly

- 10.4.9. Installing rocker shaft assembly

- 10.4.10. Determining top dead center of No.1 cylinder compression stroke

- 10.4.11. Adjusting valve clearance

- 10.4.12. Installing rocker cover

- 11. FUEL SYSTEM

- 11.1. Removing fuel system

- 11.1.1. Removing fuel filter and fuel pipe

- 11.1.2. Removing fuel injection pipe, fuel leak-off pipe and fuel injection nozzle

- 11.1.3. Removing fuel injection pump

- 11.2. Disassembling, inspecting and reassembling fuel system

- 11.2.1. Disassembling and inspecting fuel filter (in-line type fuel injection pump)

- 11.2.2. Disassembling and inspecting fuel filter

- 11.2.3. Changing fuel filter

- 11.2.4. Disassembling and inspecting fuel injection nozzle (swirl chamber type)

- 11.2.5. Disassembling and inspecting fuel injection nozzle (direct injection type)

- 11.2.6. Inspecting and adjusting fuel injection valve opening pressure

- 11.2.7. Inspecting fuel spray pattern of fuel injection nozzle

- 11.2.8. Cleaning and inspecting nozzle tip

- 11.2.9. Reassembling fuel injection nozzle (swirl chamber type)

- 11.2.10. Reassembling fuel injection nozzle (direct injection type)

- 11.2.11. Inspecting and cleaning gauze filter of distribute type fuel injection pump (Bosch)

- 11.3. Installing fuel system

- 11.3.1. Installing fuel injection pump

- 11.3.2. Checking fuel injection timing (in-line fuel injection pump type)

- 11.3.3. Inspecting fuel injection timing (distributor-type fuel injection pump)

- 11.3.4. Installing fuel injection pipe, fuel leak-off pipe and fuel injection nozzle

- 11.3.5. Installing fuel filter and fuel pipe

- 12. LUBRICATION SYSTEM

- 12.1. Removing lubrication system

- 12.1.1. Removing oil filter and relief valve

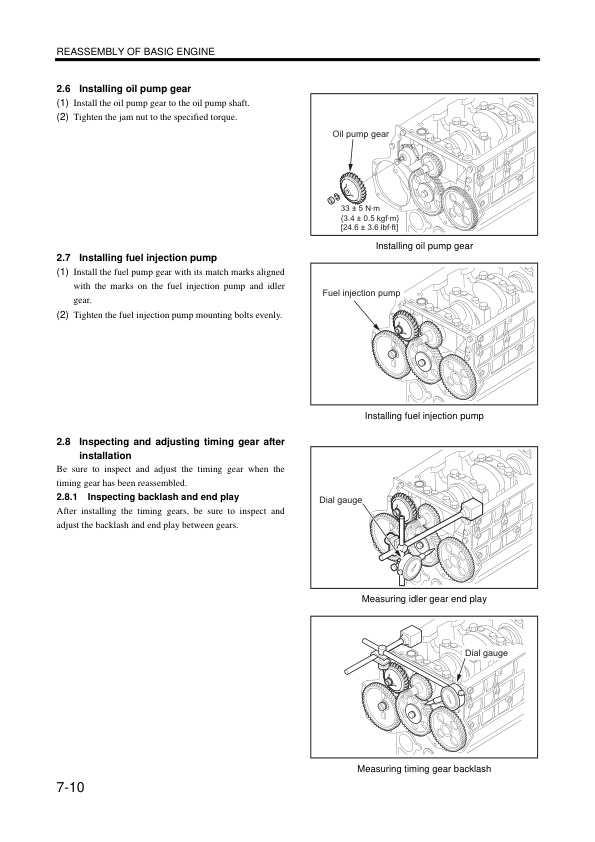

- 12.1.2. Removing oil cooler

- 12.1.3. Removing oil pump, oil pan and oil strainer

- 12.2. Disassembling, inspecting and reassembling lubrication system

- 12.2.1. Disassembling and inspecting oil pump

- 12.2.2. Inspecting oil pump

- 12.2.3. Reassembling oil pump

- 12.2.4. Disassembling and inspecting oil cooler

- 12.2.5. Inspecting oil filter

- 12.2.6. Inspecting relief valve

- 12.2.7. Inspecting safety valve (for the engine with oil cooler)

- 12.3. Installing lubrication system

- 12.3.1. Installing oil pump, oil pan and oil strainer

- 12.3.2. Installing oil cooler

- 12.3.3. Installing oil filter and relief valve

- 13. COOLING SYSTEM

- 13.1. Removing cooling system

- 13.1.1. Removing cooling fan, fan pulley and V-belt

- 13.1.2. Removing thermostat

- 13.1.3. Removing water pump

- 13.2. Disassembling, inspecting and reassembling cooling system

- 13.2.1. Disassembling and inspecting thermostat

- 13.2.2. Inspecting thermostat

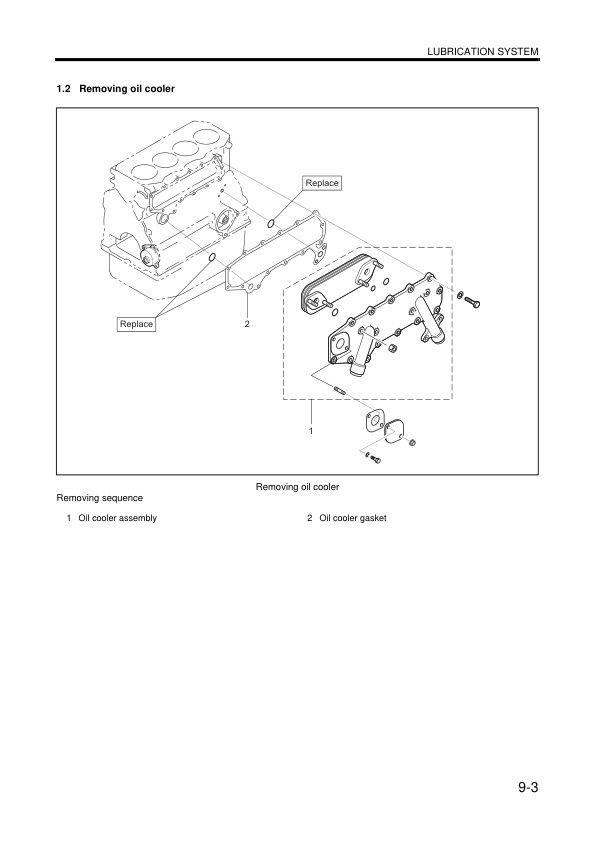

- 13.2.3. Disassembling water pump

- 13.2.4. Inspecting water pump

- 13.3. Installing cooling system

- 13.3.1. Installing water pump

- 13.3.2. Installing thermostat

- 13.3.3. Installing cooling fan, fan pulley and V-belt

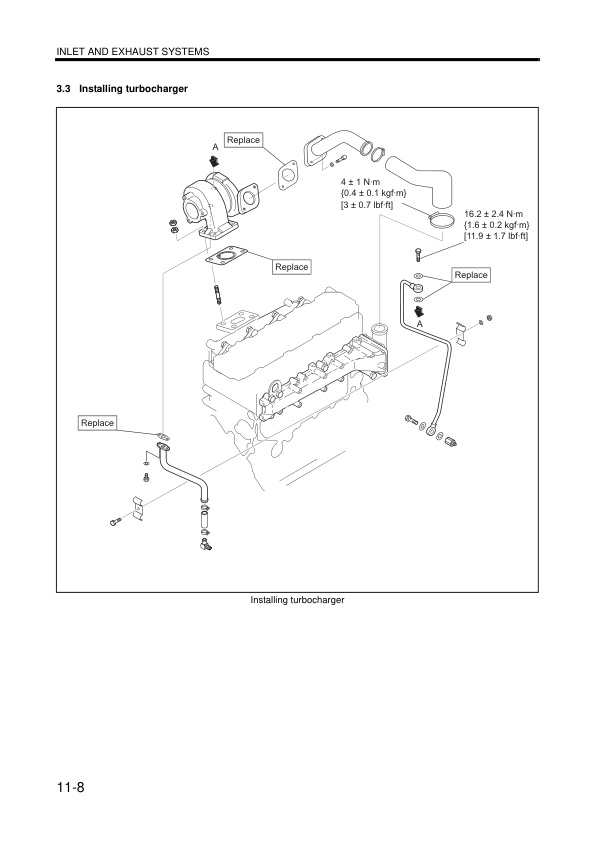

- 14. INLET AND EXHAUST SYSTEMS

- 14.1. Removing turbocharger, inlet and exhaust systems

- 14.1.1. Removing turbocharger

- 14.1.2. Removing inlet manifold

- 14.1.3. Removing exhaust manifold

- 14.2. Disassembling, inspecting and reassembling inlet and exhaust systems

- 14.2.1. Measuring exhaust manifold distortion

- 14.3. Installing turbocharger, inlet and exhaust systems

- 14.3.1. Installing exhaust manifold

- 14.3.2. Installing inlet manifold

- 14.3.3. Installing turbocharger

- 15. ELECTRICAL SYSTEM

- 15.1. Removing electrical system

- 15.1.1. Removing starter

- 15.1.2. Inspection before removing alternator

- 15.1.3. Removing alternator (12V-50A)

- 15.1.4. Removing alternator (12V-75A, option)

- 15.1.5. Removing glow plug

- 15.2. Disassembling, inspecting and reassembling electrical system

- 15.2.1. Inspection before disassembling starter

- 15.2.2. Disassembling and inspecting starter

- 15.2.3. Inspecting and repairing starter

- 15.2.4. Reassembling starter

- 15.2.5. Disassembling and inspecting alternator

- 15.2.6. Inspecting and repairing alternator

- 15.2.7. Reassembling alternator

- 15.2.8. Heating test of glow plug

- 15.2.9. Inspecting air heater

- 15.2.10. Inspecting magnetic valve (stop solenoid, distributor-type)

- 15.2.11. Installing magnetic valve (stop solenoid)

- 15.2.12. Installing stop solenoid (RUN-ON type, for in-line pump type)

- 15.3. Installing electrical system

- 15.3.1. Installing glow plug

- 15.3.2. Installing alternator (12V-50A)

- 15.3.3. Installing alternator (12V-75A, option)

- 15.3.4. Installing starter

- 16. ADJUSTMENT AND OPERATION

- 16.1. Adjusting engine

- 16.1.1. Inspecting and adjusting valve clearance

- 16.1.2. Draining fuel system

- 16.1.3. Bleeding fuel system

- 16.1.4. Inspecting V-belt and adjusting V-belt tension

- 16.1.5. Inspecting V-belt

- 16.1.6. Adjusting V-belt tension

- 16.2. Break-in operation

- 16.2.1. Starting up

- 16.2.2. Inspecting engine condition after starting up

- 16.2.3. Break-in operation time

- 16.2.4. Inspection and adjustment after break-in operation

- 16.3. Performance test (JIS standard)

Caterpillar Service Manual PDF

Caterpillar 2EC15-30 Chassis and Mast Service Manual 99759-80100

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Service Manual SCEEA-AT15E-200

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 1.4 Liter (4G33) to 3.0 Liter (6G72) LP Gas Supplement Service Manual SENB8531

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Troubleshooting Service Manual 99799-67104

Caterpillar Service Manual PDF

Caterpillar 4G15, 4G63, 4G64, 6G72 Engine Service Manual 99719-34130

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Fuel System Supplement Service Manual 99729-85110

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-64105

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-64103