Mitsubishi FB16PNT, FB18PNT, FB20PNT Controller Service Manual 99759-7P100

$50.00

- Type Of Manual: Service Manual

- Manual ID: 99759-7P100

- Number of Pages: 272

- Size: 13.6MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- FB16PNT, FB18PNT, FB20PNT

- 1. FOREWORD

- 1.1.

- 1.2. Safety

- 1.3. How to Use This Manual

- 1.4. Units

- 1.4.1. Chapter 1 CONTROLLER

- 1.4.2. Chapter 2 TROUBLESHOOTING FOR CONTROL CIRCUITS

- 1.4.3. Chapter 3 MOTOR

- 1.4.4. Chapter 4 HOW TO READ CIRCUIT DIAGRAMS

- 1.4.5. Chapter 5 CIRCUIT DIAGRAM

- 2. Chapter 1 CONTROLLER

- 2.1. Controller System

- 2.1.1. System Layout

- 2.1.2. Controller Area Network (CAN)

- 2.1.3. Outline of Logic Unit

- 2.1.4. Outline of Inverter

- 2.1.5. Outline of EPS Controller

- 2.2. Traction Controller Feature

- 2.2.1. Modification of Traction Characteristics

- 2.2.2. Anti-rollback

- 2.2.3. Boost

- 2.2.4. Limitation of Maximum Travel Speed

- 2.2.5. Controlled Cornering Speed

- 2.2.6. Miscellaneous Features for Traction

- 2.3. Lifting Controller Feature

- 2.3.1. Setting and Limitation of Lift work Speed

- 2.3.2. Lift Stop

- 2.4. Other Feature

- 2.4.1. IPS (Integrated Presence System) Feature

- 2.4.2. Display Function

- 2.4.3. Parking Brake Interlock

- 2.4.4. BDI (Battery Discharge Indicator) Display Features

- 2.4.5. Miscellaneous Features

- 2.4.6. Hour Meter

- 2.5. Setup Option

- 2.5.1. Outline

- 2.5.2. Details of Setup Options (Group-1)

- 2.5.3. Details of Setup Options (Group-2)

- 2.5.4. Details of Setup Options (Group-3)

- 2.5.5. Setup Options (Group 1)

- 2.5.6. Setup Options (Group 2)

- 2.5.7. Setup Options (Group 3)

- 2.6. Diagnostics

- 2.6.1. Outline

- 2.6.2. Operation Procedure

- 2.6.3. Self-Diagnostics

- 2.6.4. Power Steering Diagnostics

- 2.6.5. Run Time Diagnostics

- 2.6.6. Fail-Safe Restriction List

- 2.7. Removal and Installation

- 2.7.1. Inverter Discharging Procedure

- 2.7.2. Replacing Inverter

- 2.7.3. Replacing DSP (Digital Signal Processor) Card

- 2.7.4. Replacing Logic Unit

- 2.7.5. Replacing EPS Controller

- 2.7.6. Replacing Logic Card

- 2.7.7. Replacing Power Supply Card

- 2.8. Basic Check

- 2.8.1. Testing Tools

- 2.8.2. Measurement of Card Voltage

- 2.8.3. Checking Contactor Coil

- 2.8.4. Checking Contactor Tips

- 2.8.5. Checking Inverter

- 2.8.6. Regeneration Check

- 2.9. AC Motor System Basics

- 2.9.1. Feature of AC motor

- 2.9.2. Speed control of Induction Motors

- 2.9.3. Inverter

- 3. Chapter 2 TROUBLESHOOTING FOR CONTROL CIRCUITS

- 3.1. General Information

- 3.1.1. Before Replacing Devices

- 3.1.2. Connection of the service tool

- 3.1.3. How to Clean Harness Connectors and System Components

- 3.2. List of Error Codes

- 3.3. Troubleshooting

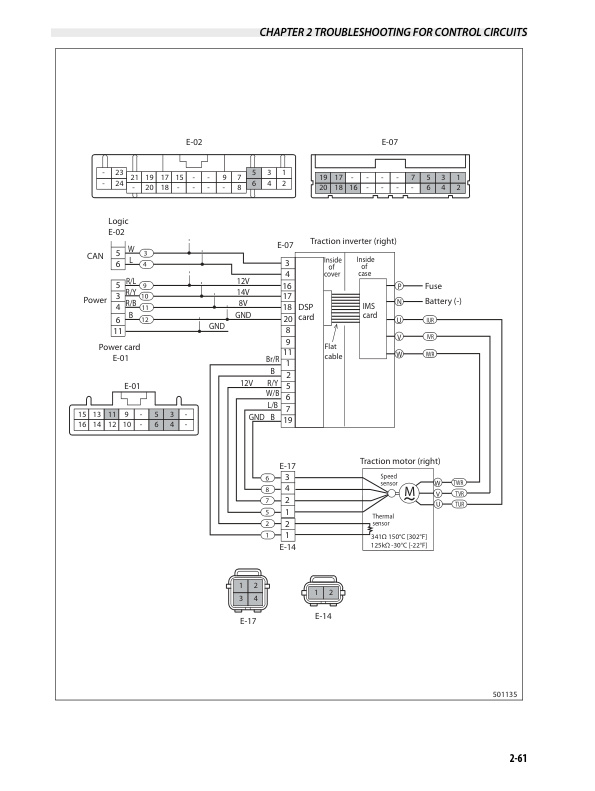

- 3.3.1. Traction Motor R.H.,Overheating (E0)

- 3.3.2. Traction Motor L.H.,Overheating (E1)

- 3.3.3. Pump Motor,Overheating(E2)

- 3.3.4. Traction Inverter R.H., Overheating (E5)

- 3.3.5. Traction Inverter L.H., Overheating (E6)

- 3.3.6. Pump Inverter, Overheating (E7)

- 3.3.7. PS Controller,Overheating (E9)

- 3.3.8. Traction Motor Current Sensor R.H., Fault (14)

- 3.3.9. Traction Motor R.H., Over-current (15)

- 3.3.10. Traction Motor R.H., Stall Timer (16)

- 3.3.11. Traction Motor Current Sensor L.H., Fault (24)

- 3.3.12. Traction Motor L.H., Over-current (25)

- 3.3.13. Traction Motor L.H., Stall Timer (26)

- 3.3.14. Pump Motor Current Sensor Fault (34)

- 3.3.15. Pump Motor Over-current (35)

- 3.3.16. Line Contactor Fault (40)

- 3.3.17. Steering Contactor Fault (41)

- 3.3.18. Traction Motor R.H., Open (45)

- 3.3.19. Traction Motor L.H., Open (46)

- 3.3.20. Pump Motor Open (47)

- 3.3.21. PS Motor Open (49)

- 3.3.22. Tire Angle Sensor Fault (50)

- 3.3.23. Accelerator Sensor Fault (51)

- 3.3.24. Traction Motor R.H., Pulse Input Fault (52)

- 3.3.25. Traction Motor L.H., Pulse Input Fault (53)

- 3.3.26. FNR Lever or Accelerator, Faulty Setting (E)

- 3.3.27. Seat Switch, Faulty Setting for Traction ((E))

- 3.3.28. Lift Lever, Faulty Setting (H1)

- 3.3.29. Tilt Lever, Faulty Setting (H2)

- 3.3.30. Attachment 1 Lever, Faulty Setting (H3)

- 3.3.31. Attachment 2 Lever, Faulty Setting (H4)

- 3.3.32. Seat Switch, Faulty Setting for Hydraulic (L)

- 3.3.33. FNR Lever Fault (EE)

- 3.3.34. Display Communication Fault (60)

- 3.3.35. Logic Card Initialize Failure (61)

- 3.3.36. Logics Fault (62)

- 3.3.37. Traction Inverter R.H., Fault (63)

- 3.3.38. Traction Inverter L.H., Fault (64)

- 3.3.39. Pump Inverter Fault(65)

- 3.3.40. Input Unit Fault (67)

- 3.3.41. Output Unit Fault (68)

- 3.3.42. EPS Controller Fault (71)

- 3.3.43. Contactor Coil Fault (72)

- 3.3.44. Hydraulic Lock Solenoid Fault (74)

- 3.3.45. Parking Brake Fault (75)

- 3.3.46. IPS Buzzer Fault (76)

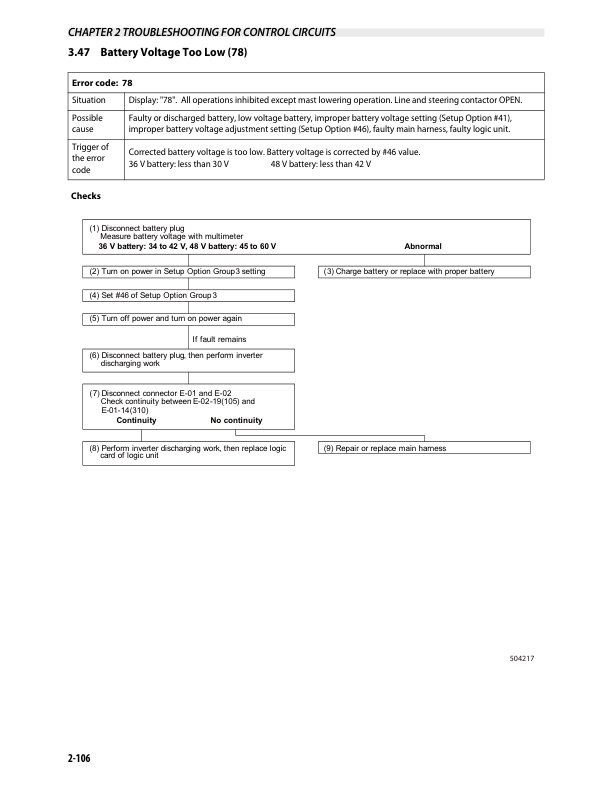

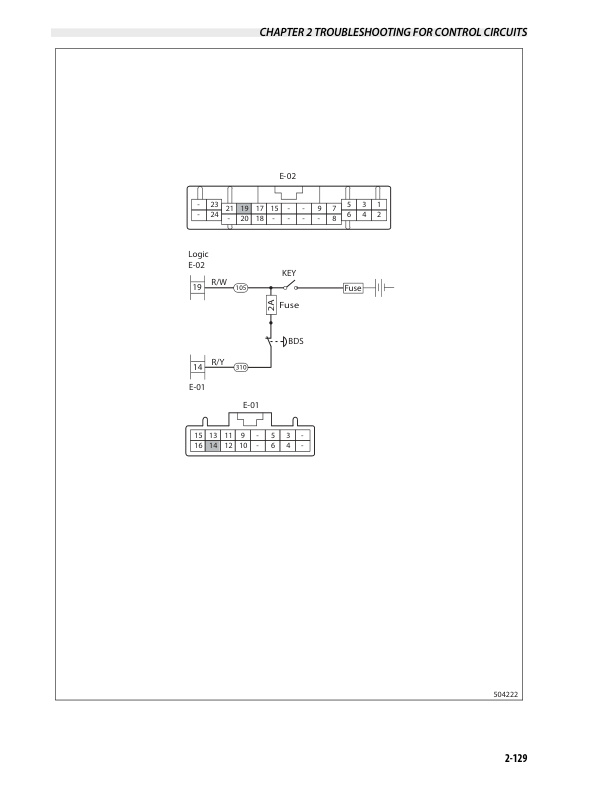

- 3.3.47. Battery Voltage Too Low (78)

- 3.3.48. Battery Voltage Too High (79)

- 3.3.49. Battery Consumption Too Much (Lo)

- 3.3.50. Tilt Angle Sensor Fault (80)

- 3.3.51. Load Sensor Fault (81)

- 3.3.52. Handle Sensor Fault (82)

- 3.3.53. PS Motor Current Sensor Fault (A4)

- 3.3.54. PS Motor Over-current (A5)

- 3.3.55. PS Handle Brake Fault (A7)

- 3.3.56. Battery Side Way Exchange Interlock (A8)

- 3.3.57. Parking brake warning (A9)

- 3.3.58. Battery Consumption Much

- 3.3.59. Brake Oil, Low Level

- 3.3.60. RTC Battery Low

- 4. Chapter 3 MOTOR

- 4.1. Motor Installation Positions

- 4.2. Specifications

- 4.3. Structures

- 4.3.1. Traction motor

- 4.3.2. Pump motor

- 4.3.3. EPS motor

- 4.4. Removing Transfer Assemblies, Traction Motors

- 4.5. Disassembling Traction motor

- 4.5.1. Disassembly Sequence

- 4.6. Inspecting Traction Motor

- 4.6.1. Inspecting Rotor

- 4.6.2. Inspecting Motor

- 4.6.3. Inspection of insulation

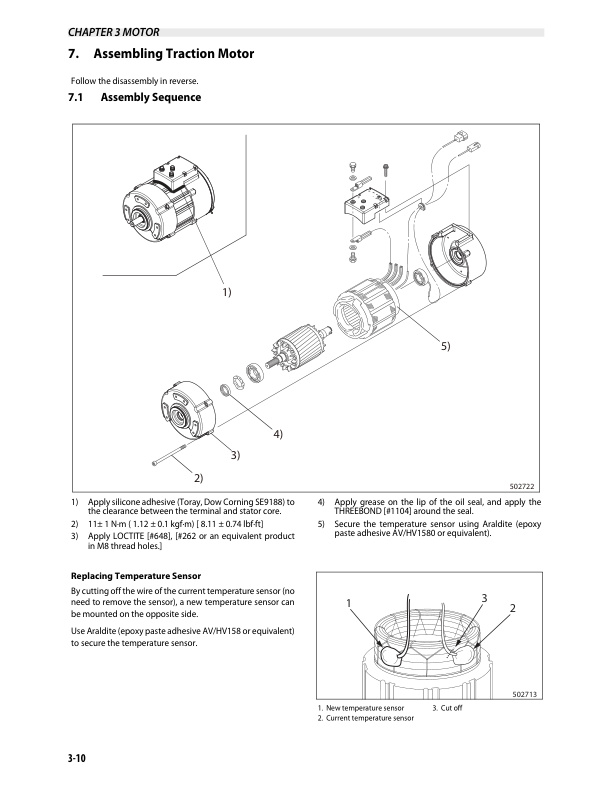

- 4.7. Assembling Traction Motor

- 4.7.1. Assembly Sequence

- 4.8. Removing Pump Motor

- 4.8.1. Suggestions for Removal

- 4.9. Disassembing Pump Motor

- 4.9.1. Disassembly Sequence

- 4.10. Inspecting Pump Motor

- 4.10.1. Inspecting Rotor

- 4.10.2. Inspecting Motor

- 4.10.3. Inspection of insulation

- 4.11. Assembling Pump motor

- 4.11.1. Assembly Sequence

- 4.12. Tightening of High-power Cable Terminals

- 4.13. Removing EPS Motor

- 4.13.1. Suggestions for Removal

- 4.14. Disassembling EPS Motor

- 4.15. Inspecting EPS Motor

- 4.15.1. Inspecting Armature

- 4.15.2. Inspecting Motor

- 4.15.3. Inspecting Oil Seal and Permanent Magnet

- 4.16. Inspecting EPS Motor

- 4.16.1. Brush

- 4.17. Troubleshooting

- 5. Chapter 4 HOW TO READ CIRCUIT DIAGRAMS

- 5.1. Description of Circuit Diagrams

- 5.1.1. Schematic Diagram

- 5.1.2. Connector Diagrams

- 5.2. How to Read Circuit Diagrams

- 5.2.1. Symbols

- 5.2.2. Sheet Symbol

- 5.2.3. Connecting Lines

- 5.2.4. Equipment

- 5.2.5. Relay Contactor and Coil

- 5.2.6. Connectors

- 5.2.7. Indication of Connecting Line

- 5.2.8. Indication of GND (Earth)

- 5.2.9. Indication of Another Specification

- 5.3. How to Read Connector Diagrams

- 6. Chapter 5 CIRCUIT DIAGRAM

Rate this productYou may also likeMitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00Mitsubishi Service Manual PDF

$50.00Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

$50.00Mitsubishi Service Manual PDF

$50.00Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

$50.00Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

$50.00Mitsubishi Service Manual PDF

$50.00