Mitsubishi FB16PNT, FB18PNT, FB20PNT Operation and Maintenance Manual 99750-7M100

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 99750-7M100

- Number of Pages: 212

- Size: 29.0MB

- Format: PDF

-

Model List:

- FB16PNT, FB18PNT, FB20PNT

- 1. FOREWORD

- 1.1.

- 1.2. How to Use This Manual

- 2. SAFETY RULES FOR FORKLIFT TRUCK OPERATORS

- 2.1. General

- 2.2. Warning Decals, Location

- 2.3. Warning Decals, Description

- 2.4. Safety Rules

- 2.5. Operating Precautions

- 2.6. Working Precautions

- 3. KNOW YOUR FORKLIFT TRUCK

- 3.1. Serial Number and Capacity Plate

- 3.2. Electrical Components

- 3.3. Model View

- 3.4. Driving Switches and Controls

- 3.5. Meter Panel

- 3.6. Integrated Presence System

- 3.7. Parking Brake Warning Buzzer

- 3.8. Operating Switches and Controls (MC Model)

- 3.9. Operator Seat

- 3.10. Seat Belt

- 3.11. Fork Locking Pins

- 3.12. Changing Forks

- 3.13. Drawbar Pin

- 3.14. Assist Grip

- 3.15. Battery Cover

- 3.16. Hydraulic Tank Oil Level / Filler Hole

- 3.17. Brake Reservoir Tank Fluid Level

- 4. HOW TO AVOID A TIPOVER HOW TO SURVIVE ONE

- 4.1. Know What Forklift Truck Stability Is

- 4.2. Center of Gravity (CG)

- 4.3. Stability and Center of Gravity (Top View)

- 4.4. Stability and Center of Gravity

- 4.5. Capacity (Weight and Load Center)

- 4.5.1. Capacity (Weight and Load Center)

- 4.6. Capacity Plate

- 4.7. Dos and Donts to Avoid Tipover

- 4.8. How to Survive in a Tipover

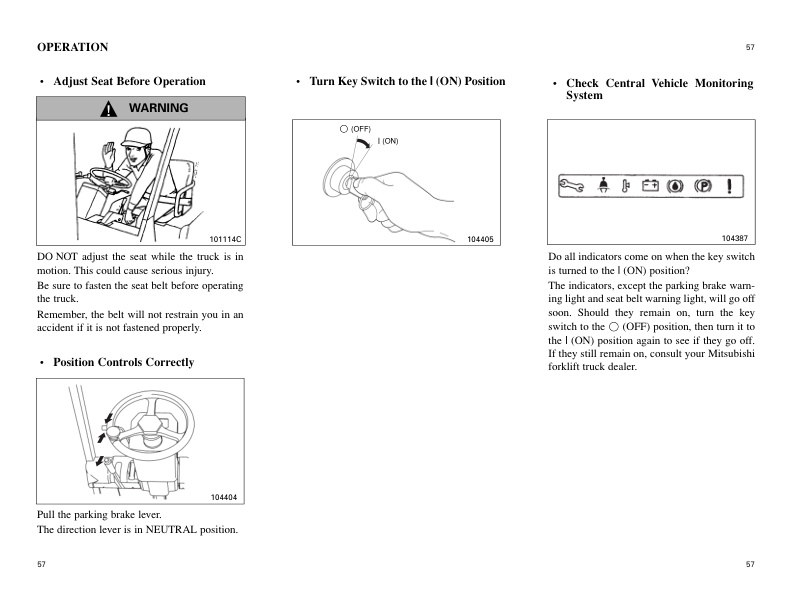

- 5. OPERATION

- 5.1. New Forklift Truck Break-In

- 5.2. Before Starting

- 5.3. Check Central Vehicle Monitoring System

- 5.4. Before Moving Forklift Truck

- 5.5. Forklift Truck Operation

- 5.6. Stopping Forklift Truck

- 5.7. Parking Forklift Truck (After Stopping)

- 5.8. Leaving Forklift Truck

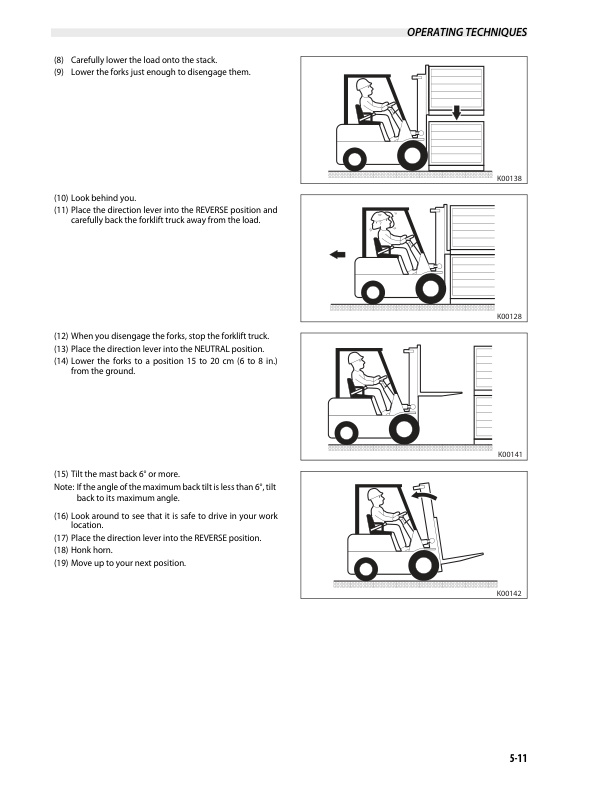

- 6. OPERATING TECHNIQUES

- 6.1. Stacking Methods

- 6.2. Handling Loads Safely

- 6.3. Operating Steps

- 6.4. Flickering of the Interlock Indicator Light

- 6.5. Inching into and Lifting the Load

- 6.6. Traveling with the Load

- 6.7. Unloading

- 6.8. Working on Grades

- 7. STORING THE FORKLIFT TRUCK

- 7.1. End of Each Shift Storage

- 7.2. Long Term Storage

- 8. TRANSPORTATIONS HINTS

- 8.1. Forklift Truck Loading and Shipping

- 8.2. Forklift Truck Lifting and Tiedown Information

- 8.3. Operating the Forklift Truck Without Power Supply

- 9. SPECIAL SITUATIONS

- 9.1. Care in Cold Weather

- 9.2. Care in Hot Weather

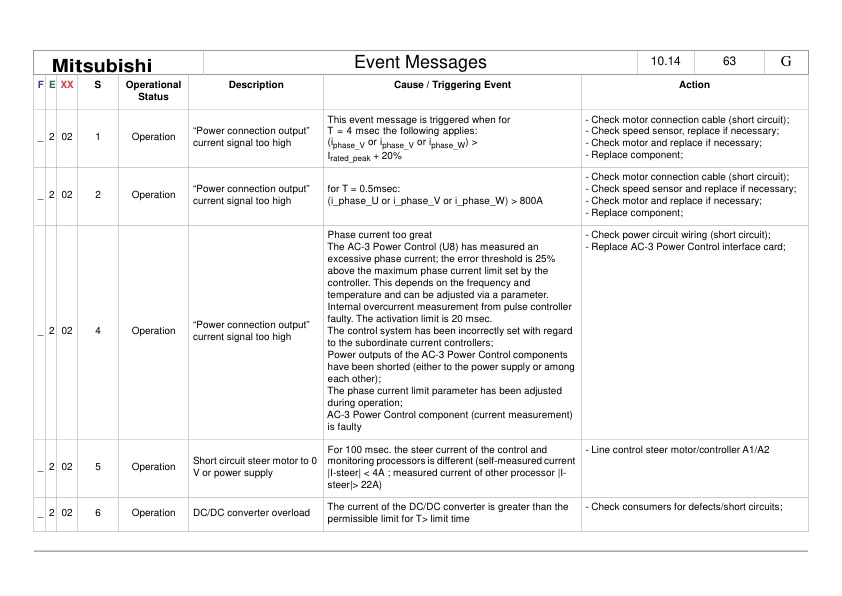

- 10. TROUBLESHOOTING

- 10.1. If the Truck Shuts Down Suddenly

- 10.2. If Central Vehicle Monitoring System Does Not Come On

- 10.3. If Abnormal Noise Sounds From Electro-Magnetic Brakes

- 10.4. If Light Bulbs Burn Out

- 10.5. If Error Code Light Flickers or Flashes and the Forklift Truck Stop Moving

- 10.6. If the Mast and Attachments Malfunction

- 10.7. Changing Tires

- 10.8. Before Changing a Tire

- 10.9. Manually Releasing Electro-Magnetic Brakes

- 10.10. Error Code List

- 11. MAINTENANCE

- 11.1. General

- 11.2. Inspection Precautions

- 11.2.1. DANGER

- 11.2.2. DO NOT OPERATE

- 11.3. Maintenance Schedule

- 11.3.1. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 11.3.2. Every 50 Service Hours or Weekly, Whichever Comes First

- 11.3.3. One Month (30 days) or 200 Service Hours After Delivery of a New Truck, Whichever Comes First

- 11.3.3.1. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 11.3.3.2. Every 2000 Service Hours or 1 year, Whichever Comes First

- 11.4. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 11.4.1. Faulty Operation Found the Day Before

- 11.4.2. Oil or Battery Electrolyte Leaks

- 11.4.3. Tires and Rims

- 11.4.3.1. Unit 5 mm (0.2 in.)

- 11.4.4. Wheel Nuts

- 11.4.4.1. Stand behind the tread of the tire, NOT in front of the rim.

- 11.4.4.2. Tighten the nuts evenly and in a diagonal sequence to the specified torque.

- 11.4.5. Head Light and Rear Light (Option)

- 11.4.6. Hydraulic Hoses, Pipes, and Joints

- 11.4.7. Load Backrest Extension, Lift Bracket

- 11.4.7.1. Load backrest extension

- 11.4.7.2. Lift bracket

- 11.4.8. Lift Cylinder and Tilt Cylinder

- 11.4.8.1. Lift cylinder

- 11.4.8.2. Tilt cylinder

- 11.4.9. Tilt Cylinder Socket Bolts

- 11.4.9.1. Carefully inspect the forks for cracks. Special attention should be given to the heel section, all weld areas and mounting brackets (2).

- 11.4.9.2. Check the difference in height of one fork tip to the other when mounted on the lift bracket. Also check each fork for its deviation by setting a straight fork length pole against the fork to measure a difference in height between the fork tip an…

- 11.4.9.3. Check the fork blade.

- 11.4.10. Overhead Guard

- 11.4.11. Assist Grip

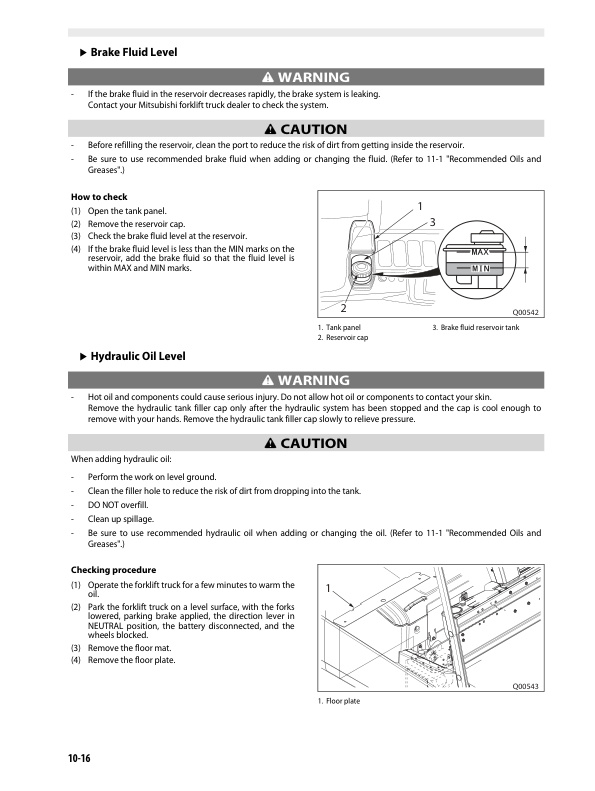

- 11.4.12. Brake Fluid Level

- 11.4.12.1. Open the tank panel.

- 11.4.12.2. Remove the reservoir cap.

- 11.4.12.3. Check the brake fluid level at the reservoir.

- 11.4.12.4. If the brake fluid level is less than the MIN marks on the reservoir, add the brake fluid so that the fluid level is within MAX and MIN marks.

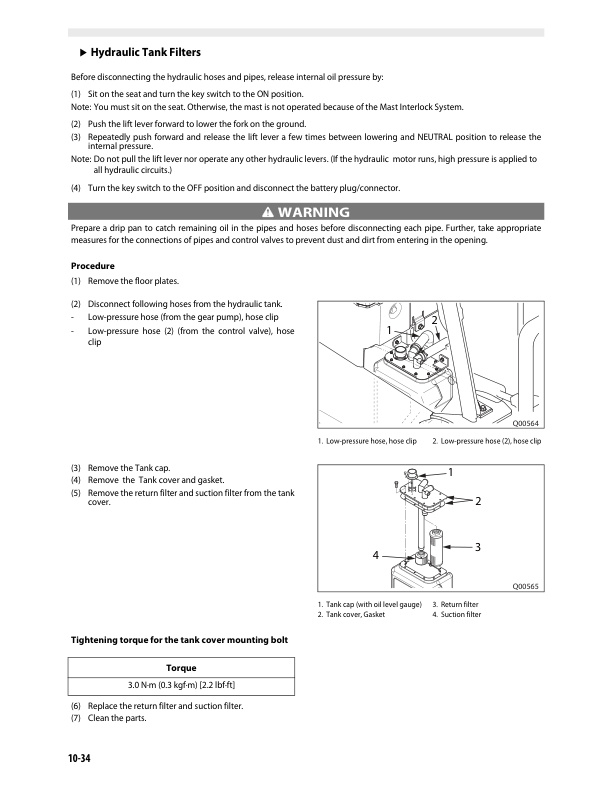

- 11.4.13. Hydraulic Oil Level

- 11.4.13.1. Operate the forklift truck for a few minutes to warm the oil.

- 11.4.13.2. Park the forklift truck on a level surface, with the forks lowered, parking brake applied, the direction lever in NEUTRAL position, the battery disconnected, and the wheels blocked.

- 11.4.13.3. Remove the floor mat.

- 11.4.13.4. Remove the floor plate.

- 11.4.13.5. Check the hydraulic oil level using the gauge of the cap.

- 11.4.13.6. If the oil level is less than the correct level range, add oil so that the oil level is within correct level range.

- 11.4.13.7. Put the cap back on.

- 11.4.13.8. Check for oil leaks.

- 11.4.14. Battery Electrolyte

- 11.4.14.1. Open the battery cover.

- 11.4.14.2. Open the vent cap.

- 11.4.14.3. Check to see if the white line (indicator) on the float (amber) is visible.

- 11.4.14.4. If the indicator is not visible, the electrolyte level is low. Need to add distilled water.

- 11.4.14.5. Clean the top of the battery and open vent caps and add distilled water to all cells.

- 11.4.14.6. Stop adding water just when the white indicator becomes visible.

- 11.4.14.7. Set the vent caps and wipe the top of the battery with a saturated cloth after filling.

- 11.4.15. Operator Seat

- 11.4.15.1. Slide lever

- 11.4.16. Seat Belt

- 11.4.17. Accelerator Pedal

- 11.4.18. Brake Pedal

- 11.4.18.1. Horn switch (MC model)

- 11.4.19. Parking Brake Switch

- 11.4.19.1. Apply

- 11.4.19.2. Release

- 11.4.20. Key Switch and Meter Panel

- 11.4.20.1. Turn the key switch to the ON position.

- 11.4.20.2. All lights of the display panel flash, and after 1 second they go out.

- 11.4.20.3. Then the normal screen is displayed.

- 11.4.21. Battery Charge Level

- 11.4.21.1. Full charged

- 11.4.21.2. Less than 20

- 11.4.21.3. Less than 10

- 11.4.21.4. Empty

- 11.4.21.5. Charge the battery immediately

- 11.4.22. Steering Wheel and Column

- 11.4.23. Lift Chains

- 11.4.23.1. Loosen the lock nut and clamp.

- 11.4.23.2. Turn the nut to adjust tension.

- 11.4.23.3. Hold the nut and tighten the clamp.

- 11.4.23.4. Hold the nut and tighten the lock nut to the specified torque.

- 11.4.24. Mast Interlock System

- 11.4.24.1. Release the accelerator pedal and apply the brake pedal.

- 11.4.24.2. Raise the forks high enough to see them from the operator seat.

- 11.4.24.3. Apply the parking brake.

- 11.4.24.4. Place the direction lever to the NEUTRAL position.

- 11.4.24.5. Half rise from the operator seat.

- 11.4.24.6. Check the following after 2 seconds

- 11.4.25. Driving Interlock System

- 11.4.25.1. Slightly raise the forks from the floor.

- 11.4.25.2. Turn the key switch to ON position.

- 11.4.25.3. Place the direction lever to the FORWARD or REVERSE position.

- 11.4.25.4. Half rise from the operator seat.

- 11.4.25.5. Check the following after 2 seconds.

- 11.4.25.6. Sit properly in the operator seat and press the brake pedal to hold the forklift truck.

- 11.4.25.7. Return the direction lever to the NEUTRAL position, then place the lever to the FORWARD or REVERSE position.

- 11.4.25.8. Push the parking brake switch to apply once and then push the switch to release.

- 11.4.26. Parking Brake Warning Buzzer

- 11.4.26.1. Park the forklift truck on level ground.

- 11.4.26.2. Lower the forks until the fork tips touch the floor.

- 11.4.26.3. Apply the parking brake.

- 11.4.26.4. Place the direction lever in the NEUTRAL position.

- 11.4.26.5. Block the wheels.

- 11.4.26.6. Remove the key.

- 11.4.26.7. Release the parking brake and leave the operator seat.

- 11.4.26.8. After approximately 2 seconds, check that the warning buzzer will activate.

- 11.4.26.9. Apply the parking brake.

- 11.4.27. Driving Control System (Traction Motors, Steering System and Brake System)

- 11.4.28. Rear Axle Steering Gear (3-Wheel Model)

- 11.4.29. Parking Brake (PKB) Check Mode

- 11.4.30. Turn the key switch to the ON position and screen 1 appears.

- 11.4.31. Push Mode button and screen 2 appears.

- 11.4.32. Move the cursor to PKB CHECK MODE by pushing the t or y button.

- 11.4.33. Push (R) button. Then screen 4 appears.

- 11.4.34. No error code indicated on display.

- 11.4.35. PKB switch applied.

- 11.4.36. Accelerator pedal released.

- 11.4.37. Directional lever in NEUTRAL position.

- 11.4.38. Traveling speed must be 0 Km/h.

- 11.4.39. Steer tire angle must be straight by tire indicator on the display.

- 11.4.40. Move the direction lever to the FORWARD or REVERSE position.

- 11.4.41. Slowly press the accelerator pedal to the floor or full position. while pressing the accelerator pedal, <> mark on the display moves to indicate the PKB check mode is operating. If the forklift truck moves, it will automatically shut OFF after…

- 11.4.42. Hold the accelerator pedal to the floor or full position for 5-10 seconds and confirm that the forklift truck does not move.

- 11.4.43. Release the accelerator pedal and move the direction lever to the NEUTRAL position.

- 11.4.44. Turn the key switch to the OFF position to exit the PKB CHECK MODE.

- 11.4.45. Every 50 Service Hours Or Weekly, Whichever Comes First

- 11.4.45.1. Bolts and Nuts

- 11.4.45.2. Battery Electrolyte Specific Gravity

- 11.4.46. One Month (30 days) or 200 Service Hours After Delivery of a New Truck, Whichever Comes First

- 11.4.46.1. Electrical Wires

- 11.4.46.2. Contactors and Fuses

- 11.4.46.3. Microswitches and Steering Sensor

- 11.4.46.4. Chain Wheel

- 11.4.47. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 11.4.47.1. Wheel Bearings

- 11.4.47.2. Drift Lowering Distance of Lift Cylinders

- 11.4.47.3. Drift Forward Tilting Distance of Tilt Cylinders

- 11.4.47.4. Hydraulic Tank Filters

- 11.4.47.5. Transfer Oil

- 11.4.47.6. Mast Supports

- 11.4.47.7. Tilt Sockets

- 11.4.47.8. Lift Chains

- 11.4.47.9. Mast Strips and Roller Surfaces

- 11.4.48. Every 2000 Service Hours or 1 Year, Whichever Comes First

- 11.4.48.1. Hydraulic Oil

- 11.4.48.2. Brake Fluid

- 11.4.49. Parts to Be Changed Periodically

- 12. SERVICE DATA

- 12.1. Recommended Oils and Greases

- 12.2. Specifications (Standard Models)

- 12.3. Capacities and Forklift Truck Weight (Standard Models)

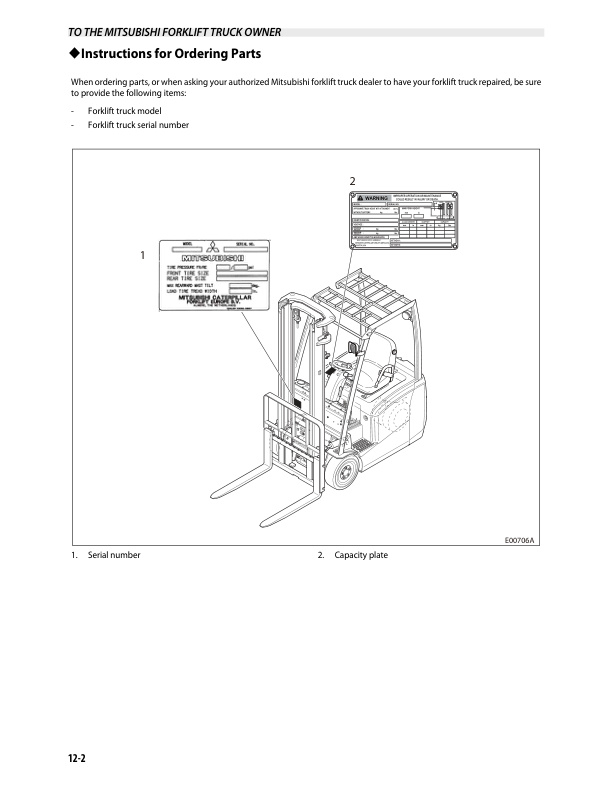

- 13. TO THE MITSUBISHI FORKLIFT TRUCK OWNER

- 13.1. The Importance of Genuine Parts

- 13.2. Proper Disposal of Your Forklift Truck

- 13.3. Instructions for Ordering Parts

- 13.4. Service Registration

- 13.5. Transfer of Ownership Report for Mitsubishi Folklift Trucks Customers Only

- 14. APPENDIX

- 14.1. Description of Circuit Diagrams

- 14.2. How to Read Circuit Diagrams

- 14.3. How to Read Connector Diagrams

- 14.4. Circuit Diagrams

Rate this productYou may also likeMitsubishi Operation Manual PDF

Mitsubishi FB10-25H Operation and Maintenance Manual 99750-11110

$30.00Mitsubishi Operation Manual PDF

Mitsubishi FB10CB-35CB, FB20-25LCB Forklift Trucks Operation and Maintenance Manual OMFEM-M22C0-200

$30.00Mitsubishi Operation Manual PDF

Mitsubishi ESR15N2, ESR 18N2 Operating and Maintenance Instructions 51423155

$30.00Mitsubishi Operation Manual PDF

$30.00Mitsubishi Operation Manual PDF

Mitsubishi FB10-28(H)CA1, FB30CA1 Operation and Maintenance Manual 99710-17110

$30.00Mitsubishi Operation Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Operation and Maintenance Manual 99750-7B111

$30.00Mitsubishi Operation Manual PDF

Mitsubishi OPB10P, OPBM10P, OPBH12PH Operation and Maintenance Manual OM19GBOR1AA7

$30.00Mitsubishi Operation Manual PDF

$30.00Mitsubishi Operation Manual PDF

Mitsubishi FB 40-50 (C) S Operating and Maintenance Instructions

$30.00Mitsubishi Operation Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Forklift Trucks Operation and Maintenance Manual 99750-5B110

$30.00