Mitsubishi FD70N1 Forklift Trucks Operation and Maintenance Manual 99700-70100

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 99700-70100

- Number of Pages: 232

- Size: 6.7MB

- Format: PDF

-

Model List:

- FD70N1 Forklift Trucks

- 1. CHAPTER 1 SAFETY RULES FOR FORKLIFT TRUCK OPERATORS

- 1.1. General

- 1.2. Location of Decals and Plates

- 1.3. Description of Danger, Warning, and Caution Decals

- 1.3.1. Fasten Seat Belt Decal

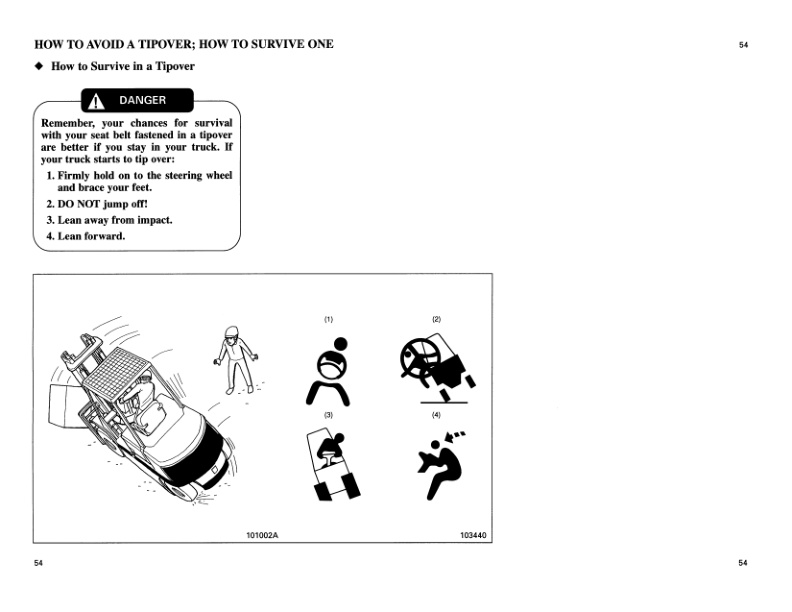

- 1.3.2. In Case of a Tipover Decal

- 1.3.3. Backup Alarm Decal

- 1.3.4. No Riders Warning Decal

- 1.3.5. Operation Warning Decal

- 1.3.6. Overhead Guard Decal

- 1.3.7. Pinch Point Decal

- 1.3.8. Radiator Cap Warning Decal

- 1.3.9. No Access With Engine Running Decal

- 1.3.10. Parking Brake Decal

- 1.3.11. Brake Buzzer Warning Decal

- 1.3.12. No One Under / On Forks and No One Between Mast and Chassis Decal

- 1.3.13. Load Backrest Extension Decal

- 1.3.14. Capacity Plate

- 1.3.15. Precautions for Handling E.C.U Decal

- 1.3.16. Operator Restraint System Decal

- 1.3.17. Precautions for Refilling Decal

- 1.3.18. No Contamination Permissible Decal

- 1.4. Safety Rules

- 1.5. Operating Precautions

- 1.6. Working Precautions

- 2. CHAPTER 2 KNOW YOUR FORKLIFT TRUCK

- 2.1. Serial Number and Capacity Plate

- 2.2. Electrical Components

- 2.3. Model View

- 2.3.1. Model View

- 2.3.2. MC Model

- 2.3.3. FC Model

- 2.4. Driving Switches and Controls

- 2.4.1. Driving Switches and Controls

- 2.4.2. Key Switch

- 2.4.3. Direction Lever (Powershift)

- 2.4.4. Inching Pedal

- 2.4.5. Turn Signal / Light Switch

- 2.4.6. Steering Column Tilt Lever

- 2.5. Meter Panel

- 2.5.1. Meter Panel

- 2.5.2. Warning Icons Glow Check

- 2.5.3. LCD Screen

- 2.5.4. Warning Icons and Indicators

- 2.5.5. Basic Screen Display

- 2.5.6. Basic Operation

- 2.5.7. When Diagnostic Code Is Shown on Display

- 2.5.8. When Several Warnings Occur Simultaneously

- 2.5.9. Warning Symbols

- 2.5.10. Warning Icons

- 2.5.11. Optional Functions

- 2.6. SCR Warning Icon

- 2.7. Side Panel

- 2.8. Integrated Presence System

- 2.8.1. Integrated Presence System

- 2.8.2. Mast Interlock System

- 2.8.3. Mast Interlock System Functions

- 2.8.4. Driving Interlock System

- 2.8.5. Driving Interlock System Functions

- 2.8.6. Neutral System

- 2.8.7. Neutral System Functions

- 2.8.8. Seat Belt Warning Icon

- 2.8.9. Seat Belt Warning Functions

- 2.8.10. Parking Brake Warning Icon and Warning Alarm

- 2.8.11. Parking Brake Warning Functions

- 2.9. Operating Control Levers (MC Model)

- 2.9.1. Operating Control Levers (MC Model)

- 2.9.2. Lift Lever

- 2.9.3. Tilt Lever

- 2.9.4. Attachment Lever

- 2.10. FC Control Box (FC Model)

- 2.10.1. FC Control Box (Type-A)

- 2.10.2. FC Control Box (Type-B)

- 2.10.3. Lift Switch

- 2.10.4. Tilt Switch

- 2.10.5. Attachment Switch A/B (Option)

- 2.10.6. Selector Switch Between Fourth and Fifth Attachment

- 2.10.7. Other Controls (Type-A)

- 2.10.8. Emergency Mast Stop Button

- 2.10.9. Forward and Backward Adjustment Stopper Knob (Type-A)

- 2.10.10. Up and Down Adjustment Stopper Knob (Type-A)

- 2.10.11. Forward and Backward Adjustment (Type-B)

- 2.10.12. Up and Down Adjustment (Type-B)

- 2.10.13. Other Controls (Option, Type-A)

- 2.10.14. Lowering Speed Selector Switch (Option, Type-A)

- 2.10.15. Mast Vertical Switch (Option, Type-A)

- 2.10.16. Direction Switch (Option, Type-A)

- 2.11. Operator Seat

- 2.11.1. Seat Adjustment

- 2.11.2. Forward and Back Adjustment

- 2.11.3. Adjustment of Suspension (FC Model)

- 2.11.4. Lumbar Support Adjustment (FC Model)

- 2.11.5. Pocket for the Manual

- 2.11.6. Operator Presence Switch and Buzzer

- 2.11.7. How to Tip the Seat Forward

- 2.12. Seat Belt

- 2.13. Fork Locking Pins

- 2.14. Replacing Forks

- 2.14.1. Replacing Forks (Hook Type Lift Bracket)

- 2.14.2. Replacing Forks (Bar Type Lift Bracket)

- 2.15. Drawbar Pin (Option)

- 2.16. Assist Grips and Foot Step

- 2.17. Engine Hood

- 2.17.1. Engine Hood

- 2.17.2. Hood Latch

- 2.18. Hydraulic Tank Oil Filler Hole

- 2.19. Fuel Filler Cap

- 2.20. Fire Extinguisher (Option)

- 2.21. Integrated Side Sifter (Option)

- 2.22. Fork Positioner (Option)

- 3. CHAPTER 3 HOW TO AVOID A TIPOVER / HOW TO SURVIVE ONE

- 3.1. Know What Forklift Truck Stability Is

- 3.2. Center of Gravity (CG)

- 3.3. Stability and Center of Gravity (Top View)

- 3.4. Stability and Center of Gravity (Side View)

- 3.5. Forklift Truck Stability Base

- 3.6. Capacity (Weight and Load Center)

- 3.7. Capacity Plate

- 3.7.1. Capacity Plate

- 3.7.2. Sample

- 3.8. Dos and Donts to Avoid Tipover

- 3.9. How to Survive in a Tipover

- 4. CHAPTER 4 REFUELING

- 4.1. Fuel

- 4.2. DEF (Diesel Exhaust Fluid)

- 5. CHAPTER 5 OPERATION

- 5.1. New Forklift Truck Break-in

- 5.2. Before Starting Engine

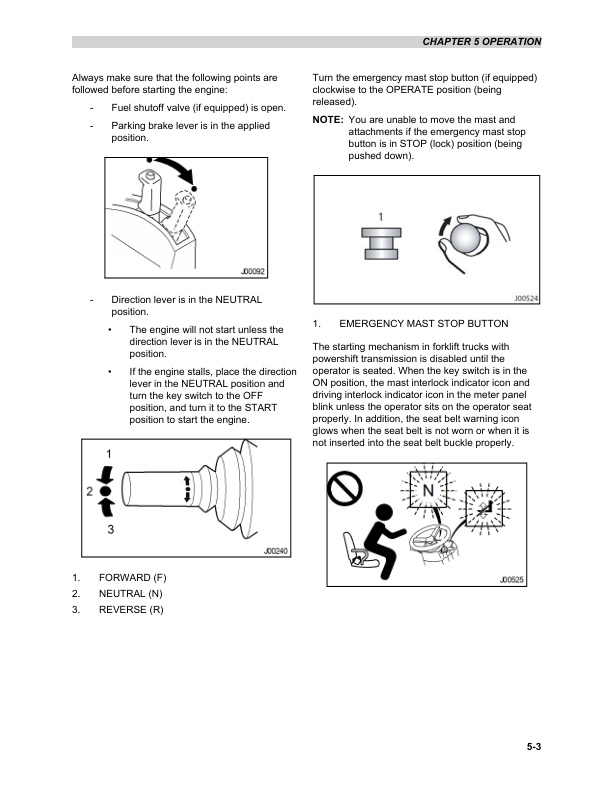

- 5.3. Starting Engine

- 5.4. Engine Wont Start

- 5.5. After Starting Engine

- 5.6. Before Moving Forklift Truck

- 5.7. Forklift Truck Operation

- 5.8. Stopping Forklift Truck

- 5.9. Parking Forklift Truck (After Stopping)

- 6. CHAPTER 6 OPERATING TECHNIQUES

- 6.1. Stacking Methods

- 6.1.1. Stacking Different Size Loads

- 6.1.2. Stacking Small Identical Loads

- 6.1.3. Stacking Large Identical Loads

- 6.2. Handling Loads Safely

- 6.2.1. Handling Loads Safely

- 6.2.2. Adjusting Fork Spread

- 6.3. Before Operating the Forklift Truck

- 6.4. Blinking of the Mast Interlock Indicator Icon

- 6.5. Lifting the Load

- 6.6. Traveling With the Load

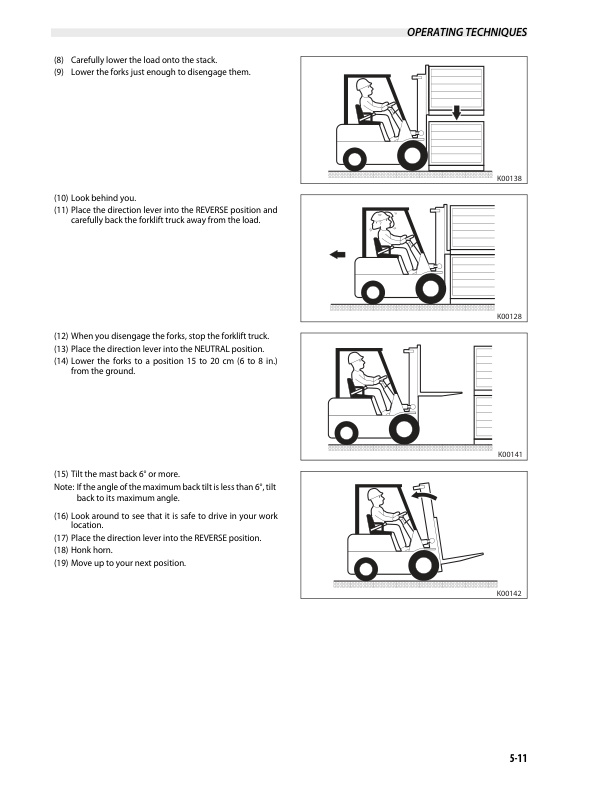

- 6.7. Unloading

- 6.8. Working on Grades

- 6.8.1. Normal Travel Position

- 6.8.2. Traveling on a Grade

- 6.8.3. Stopping on a Grade

- 6.9. Starting on a Grade (Engine Stalls on a Grade)

- 7. CHAPTER 7 STORING THE FORKLIFT TRUCK

- 7.1. End of Each Shift Storage

- 7.2. Long Term Storage

- 7.3. DEF System Storage

- 8. CHAPTER 8 TRANSPORTATION HINTS

- 8.1. Forklift Truck Loading and Shipping

- 8.2. Forklift Truck Lifting and Tie Down Information

- 9. CHAPTER 9 SPECIAL SITUATIONS

- 9.1. Care in Cold Weather

- 9.1.1. Fuel Oils and Lubrication Oils

- 9.1.2. Battery

- 9.1.3. DEF System

- 9.1.4. Engine Coolant

- 9.2. Care in Hot Weather

- 9.2.1. Fuel Oils and Lubrication Oils

- 9.2.2. Battery

- 9.2.3. Engine Coolant

- 9.2.4. DEF

- 9.3. Severe Dust or Lint Conditions

- 10. CHAPTER 10 TROUBLESHOOTING

- 10.1. Stalled Engine

- 10.2. Starting With Jumper Cables

- 10.3. If Lights Wont Glow

- 10.3.1. If Lights Wont Glow

- 10.3.2. How to Check Fuses and Lights

- 10.4. If the Engine Coolant Temperature Gauge Shows RED Zone

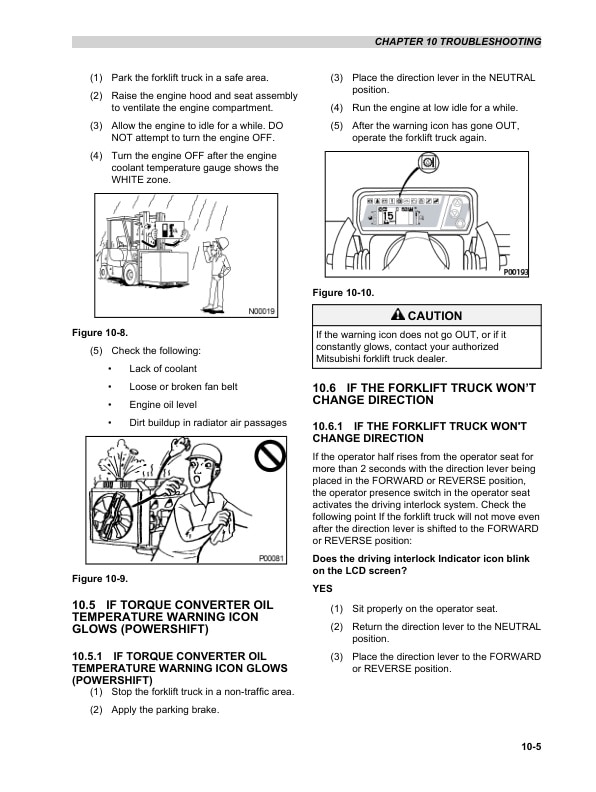

- 10.5. If Torque Converter Oil Temperature Warning Icon Glows (Powershift)

- 10.6. If the Forklift Truck Wont Change Direction

- 10.7. If the Mast and Attachments Stop Moving

- 10.8. If the Mast and Attachments Malfunction (FC Model)

- 10.9. If the Forklift Truck Begins to Lose Power

- 10.10. If a Tire Blew Out

- 10.11. Diagnostic Codes and Explanations

- 11. CHAPTER 11 MAINTENANCE

- 11.1. General

- 11.2. Inspection Precautions

- 11.3. LOCKOUT/TAGOUT

- 11.4. Maintenance Schedule

- 11.4.1. Maintenance Schedule

- 11.4.2. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 11.4.3. Every 50 Service Hours or Weekly, Whichever Comes First

- 11.4.4. One Month (30 days) or 200 Service Hours After Delivery of a New Forklift Truck, Whichever ComesFirst

- 11.4.5. Every 500 Service Hours or 3 Months, Whichever Comes First

- 11.4.6. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 11.4.7. Every 2000 Service Hours or 1 Year, Whichever Comes First

- 11.4.8. Every 3000 Service Hours or 18 Months, Whichever Comes First

- 11.4.9. Every 10000 Service Hours or 60 Months, Whichever Comes First

- 11.5. Every 10 Service Hours or Daily (Prestart), Whichever Comes First

- 11.5.1. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 11.5.2. Faulty Operation Found the Day Before

- 11.5.3. Oil, Fuel, or Coolant Leaks

- 11.5.4. Brake Pedal

- 11.5.5. Brake Hoses, Pipes, and Joints

- 11.5.6. Parking Brake Lever

- 11.5.7. Service Brake Fluid

- 11.5.8. Cooling Fan

- 11.5.9. Engine Coolant

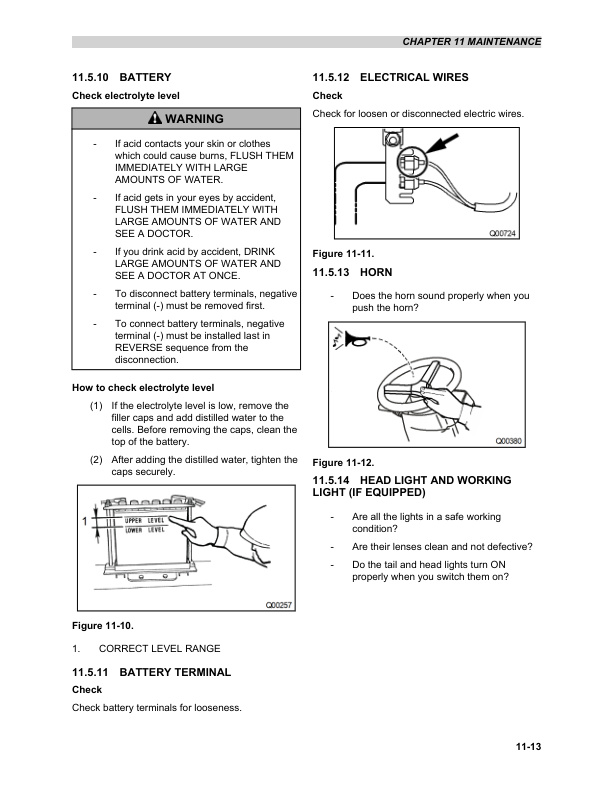

- 11.5.10. Battery

- 11.5.11. Battery Terminal

- 11.5.12. Electrical Wires

- 11.5.13. Horn

- 11.5.14. Head Light and Working Light (If Equipped)

- 11.5.15. Stop Lights

- 11.5.16. Backup Lights

- 11.5.17. Backup Alarm

- 11.5.18. Icons of Meter Panel

- 11.5.19. Mast Interlock System

- 11.5.20. Driving Interlock System

- 11.5.21. Parking Brake Warning Alarm and Warning Icon

- 11.5.22. Seat Belt Warning Icon and Alarm

- 11.5.23. Engine (Exhaust, Noise, and Vibration)

- 11.5.24. Engine Oil

- 11.5.25. Assist Grips

- 11.5.26. Overhead Guard

- 11.5.27. Seat Belt

- 11.5.28. Operator Seat

- 11.5.29. Rear View Mirrors (Option)

- 11.5.30. Fuel

- 11.5.31. Fuel System

- 11.5.32. DEF

- 11.5.33. DEF Tank

- 11.5.34. Hydraulic Oil

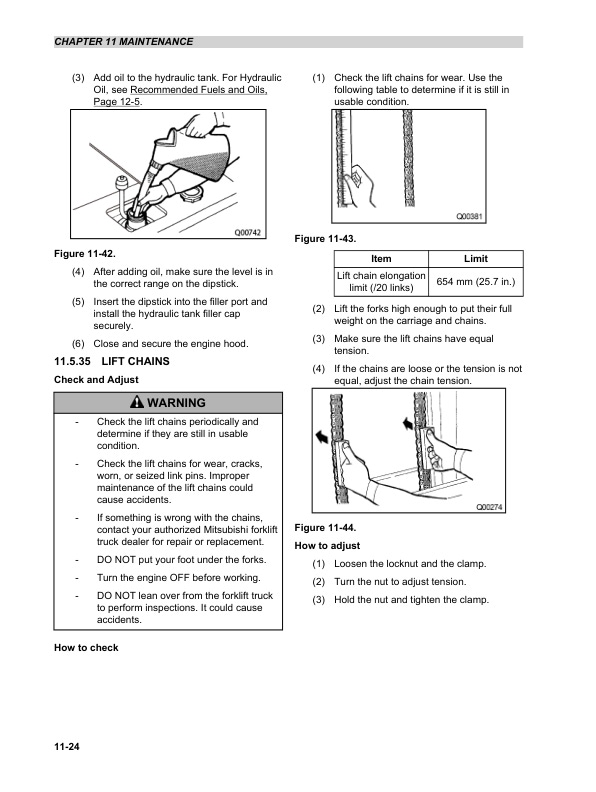

- 11.5.35. Lift Chains

- 11.5.36. Mast and Forks (Bar Type Lift Bracket)

- 11.5.37. Mast and Forks (Hook Type Lift Bracket)

- 11.5.38. Load Backrest Extension and Lift Bracket

- 11.5.39. Lift Cylinder Mounting Bolts

- 11.5.40. Lift and Tilt Cylinders

- 11.5.41. Mast Strip Sliding Surfaces

- 11.5.42. Lift Bracket Main Rollers and Side Rollers

- 11.5.43. Tilt Cylinder Socket Bolts

- 11.5.44. Steering Wheel and Column

- 11.5.45. Transmission Oil

- 11.5.46. Accelerator Pedal

- 11.5.47. Inching Pedal

- 11.5.48. Wheel Nuts

- 11.5.49. Tires and Rims

- 11.6. Every 50 Service Hours or Weekly, Whichever Comes First

- 11.6.1. Every 50 Service Hours or Weekly, Whichever Comes First

- 11.6.2. Fuel Hoses, Pipes, and Joints

- 11.6.3. DEF Filler Screen

- 11.6.4. Hydraulic Hoses, Pipes, and Joints

- 11.6.5. Lift Chains

- 11.6.6. Air Cleaner Element

- 11.7. One Month (30 Days) or 200 Service Hours After Delivery of a New Forklift Truck, Whichever Comes First

- 11.7.1. One Month (30 Days) or 200 Service Hours After Delivery of a New Forklift Truck, Whichever Comes First

- 11.7.2. Alternator Belt

- 11.7.3. Engine Oil and Oil Filter

- 11.7.4. Primary Fuel Filter

- 11.7.5. Secondary Fuel Filter

- 11.7.6. Hydraulic Tank Return Oil Filter and Wash Strainer

- 11.8. Every 500 Service Hours or 3 Months, Whichever Comes First

- 11.8.1. Every 500 Service Hours or 3 Months, Whichever Comes First

- 11.8.2. Engine Oil

- 11.8.3. Primary Fuel Filter

- 11.8.4. Secondary Fuel Filter

- 11.8.5. Fork Guide Bar

- 11.8.6. Mast Supports

- 11.8.7. Mast Strips and Roller Surfaces

- 11.8.8. Lift Bracket Side Rollers

- 11.8.9. Tilt Sockets

- 11.8.10. Rear Axle Center Pins

- 11.8.11. Tie Rod Pins

- 11.8.12. King Pins

- 11.8.13. Universal Joints

- 11.8.14. Differential Oil

- 11.9. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 11.9.1. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 11.9.2. Hydraulic System

- 11.9.3. Air Cleaner

- 11.9.4. Differential Oil

- 11.9.5. Powershift Transmission

- 11.10. Every 2000 Service Hours or 1 Year, Whichever Comes First

- 11.10.1. Every 2000 Service Hours or 1 year, Whichever Comes First

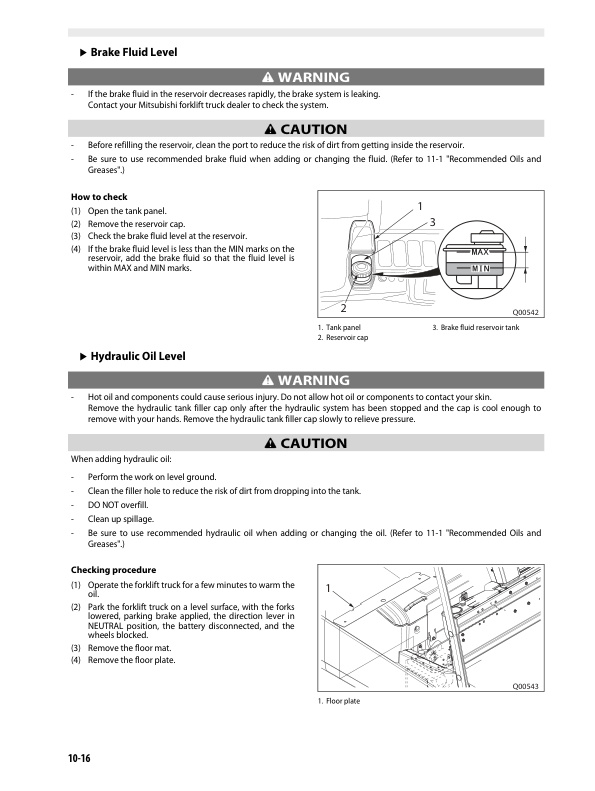

- 11.10.2. Service Brake Fluid

- 11.10.3. Vacuum Pump

- 11.10.4. Engine Coolant

- 11.10.5. Hydraulic Oil

- 11.11. Every 3000 Service Hours or 18 Months, Whichever Comes First

- 11.11.1. Every 3000 Service Hours or 18 Months, Whichever Comes First

- 11.11.2. DEF Filter Element

- 11.12. Lubrication Chart

- 11.13. Periodic Replacement Parts

- 12. CHAPTER 12 SERVICE DATA

- 12.1. Fuel Information

- 12.2. Coolant Information

- 12.2.1. Coolant Information

- 12.2.2. Coolant Water

- 12.2.3. Antifreeze Solution

- 12.3. DEF Information

- 12.4. Recommended Fuels and Oils

- 12.5. Specifications (Standard Models)

- 12.6. Refill Capacities

- 12.7. Capacities and Forklift Truck Weight (Standard Models)

- 13. CHAPTER 13 TO THE MITSUBISHI FORKLIFT TRUCK OWNER

- 13.1. The Importance of Genuine Parts

- 13.2. Proper Disposal of Your Forklift Truck

- 13.3. Instructions for Ordering Parts

- 13.4. Service Registration

- 13.5. Transfer of Ownership Report for Mitsubishi Forklift Trucks Customers

Mitsubishi Operation Manual PDF

Mitsubishi FB16PNT, FB18PNT, FB20PNT Operation and Maintenance Manual 99750-7M100

Mitsubishi Operation Manual PDF

Mitsubishi FB16N, FB18N, FB20CN Forklift Trucks Operation and Maintenance Manual 99750-56100

Mitsubishi Operation Manual PDF

Mitsubishi EP10CB-35CB, EP20-25LCB Lift Trucks Operation and Maintenance Manual OCFEM-M22C0-200

Mitsubishi Operation Manual PDF

Mitsubishi OPB10P, OPBM10P, OPBH12PH Operation and Maintenance Manual OM19GBOR1AA7

Mitsubishi Operation Manual PDF

Mitsubishi FB10 to FB25 Operation and Maintenance Manual 99750-12101

Mitsubishi Operation Manual PDF

Mitsubishi FB25-35(C)N Operation and Maintenance Manual 623321 EN

Mitsubishi Operation Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Operation and Maintenance Manual 99750-7B100

Mitsubishi Operation Manual PDF

Mitsubishi EOP15N3 Operating and Maintenance Instructions 51481376

Mitsubishi Operation Manual PDF

Mitsubishi FB16K to FB35K PAC Operation and Maintenance Manual 99750-52140

Mitsubishi Operation Manual PDF

Mitsubishi ESR, EDR, ESS Operation and Maintenance Manual WEBU6685-01