Mitsubishi FG15N-35NM, FD20N-35N Operation and Maintenance Manual 99710-7M110 Vol 1

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 99710-7M110 Vol 1

- Number of Pages: 133

- Size: 22.3MB

- Format: PDF

-

Model List:

- FG15N, FG15NM, FG18N, FG18NM, FG20CN, FG20CNM, FG20N, FG20NM, FG25N, FG25NM, FG30N, FG30NM, FG33N, FG35N, FG35NM, FD20N, FD25N, FD30N, FD33N, FD35N

- 1. FOREWORD

- 2. HOW TO USE THIS MANUAL

- 2.1. Truck Models Covered in This Manual

- 3. CHAPTER INDEX

- 4. TABLE OF CONTENTS

- 5. SAFETY RULES FOR LIFT TRUCK OPERATORS

- 5.1. General

- 5.2. Warning Decals, Location

- 5.3. Decals for Dual Fuel Only

- 5.4. Warning Decals, Description

- 5.4.1. Parking Brake

- 5.4.2. No Rider

- 5.4.3. Backup Alarm

- 5.4.4. For Safety Observe the Following Warnings

- 5.4.5. Radiator Cap

- 5.4.6. Cooling Fan

- 5.4.7. Overhead Guard

- 5.4.8. No One under / on Forks

- 5.4.9. Load Backrest Extension

- 5.4.10. Crush Points

- 5.4.11. Capacity Plate

- 5.4.12. Inspection / Lubrication Chart

- 5.4.13. Tipover Warnings

- 5.4.14. Maintenance Procedure

- 5.4.15. LPG Fuel Cylinder Replacement

- 5.4.16. Gasoline / LPG Changeover

- 5.5. Safety Rules

- 5.5.1. Authorized and trained operators only

- 5.5.2. Dress properly for the job

- 5.5.3. Always be alert

- 5.5.4. No smoking while refueling

- 5.5.5. Know all signals and traffic rules

- 5.5.6. Unauthorized addition or modification is prohibited

- 5.5.7. Know the lift truck and attachments

- 5.5.8. Avoid being splashed by scalding hot coolant

- 5.5.9. Turn OFF the key switch before servicing

- 5.5.10. Lift truck exhaust fumes contain carbon monoxide and could kill you

- 5.5.11. Inspect the lift truck prior to operation

- 5.5.12. DO NOT operate an unsafe lift truck

- 5.5.13. DO NOT remove the overhead guard

- 5.5.14. DO NOT operate the lift truck under the influence of drugs or alcohol

- 5.5.15. Keep the operators compartment clean

- 5.5.16. LP-Gases are flammable.

- 5.5.17. The back-up alarm must activate when traveling in reverse

- 5.5.18. Operate only in approved areas

- 5.5.19. Sit in the operators seat when starting the engine

- 5.5.20. DO NOT operate a damaged or defective lift truck

- 5.5.21. Face the lift truck when mounting and dismounting

- 5.5.22. Adjust the operators seat before operating the lift truck

- 5.5.23. Always check overhead clearance

- 5.5.24. Use lights in dark, dim areas

- 5.5.25. When operating the lift truck, BE SURE to fasten the seat belt

- 5.5.26. Stay within the confines of the lift truck

- 5.5.27. Always be aware of floor capacity

- 5.5.28. Avoid off-center loading

- 5.5.29. Stay under the overhead guard

- 5.5.30. Check fork locking pins for engagement

- 5.5.31. Be careful of forks that extend beyond the load

- 5.5.32. Check work places for high risk

- 5.5.33. Slow down for wet and slippery surfaces

- 5.5.34. When handling ECM, VCM, DCM and OCM

- 5.6. Operating Precautions

- 5.6.1. DO NOT allow any riders

- 5.6.2. Position levers correctly for starting

- 5.6.3. DO NOT pass another lift truck

- 5.6.4. DO NOT indulge in stunt driving or horseplay

- 5.6.5. Take care when turning with a load

- 5.6.6. Obey all traffic regulations and warning signs, including authorized plant speed limits

- 5.6.7. Always look in the direction of travel

- 5.6.8. Travel in REVERSE if forward visibility is blocked

- 5.6.9. Travel safely on grades with a loaded lift truck

- 5.6.10. Travel safely on grades with an empty lift truck

- 5.6.11. Be particularly careful when driving up or down a steep slope

- 5.6.12. Starting the lift truck on an upgrade carefully

- 5.6.13. Be careful of drive end swing when turning while operating with load end leading

- 5.6.14. DO NOT operate the lift truck under windy conditions

- 5.7. Working Precautions

- 5.7.1. Keep out

- 5.7.2. A helper must NOT be near the lift truck

- 5.7.3. Be careful of changes in capacity

- 5.7.4. Watch out for pedestrians at all times

- 5.7.5. Use the proper attachment

- 5.7.6. DO NOT speed when approaching loads

- 5.7.7. Ensure the load isnt too high

- 5.7.8. DO NOT move when someones next to the lift truck

- 5.7.9. Handle only stable and safely arranged loads

- 5.7.10. Stay clear of pinch points

- 5.7.11. DO NOT allow unloading from raised loads

- 5.7.12. Inspect a trailer before entering

- 5.7.13. DO NOT use damaged pallets

- 5.7.14. DO NOT abuse forks

- 5.7.15. DO NOT use lift truck improperly

- 5.7.16. Operate the direction lever smoothly

- 5.7.17. Always stay within the capacity

- 5.7.18. Park in authorized areas only

- 5.7.19. Watch out for personnel

- 5.7.20. DO NOT lift personnel except on a securely attached, specially designed work platform

- 5.7.21. Park disabled lift truck safely

- 5.8. LP-Gas

- 6. KNOW YOUR LIFT TRUCK

- 6.1. Serial Number and Capacity Plate

- 6.2. Electrical Components

- 6.3. Model View

- 6.3.1. MC Model

- 6.3.2. FC Model

- 6.4. Driving Switches and Controls

- 6.4.1. Key Switch

- 6.4.2. Direction Lever (Powershift)

- 6.4.3. Inching Pedal (Powershift)

- 6.4.4. Turn Signal / Light Switch

- 6.4.5. Steering Tilt Lever

- 6.5. Instrument Panel

- 6.5.1. LCD Screen

- 6.5.2. Warning Lamps and Indicators

- 6.5.3. Basic Screen Display

- 6.5.4. Basic Operation

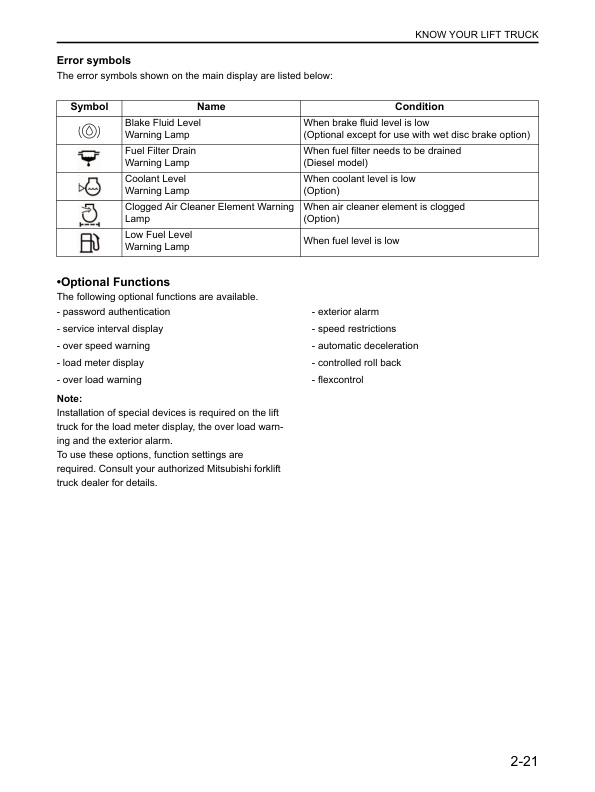

- 6.5.5. When an Error Occurs

- 6.5.6. Optional Functions

- 6.5.7. Optional Functions for Use With Wet Disc Brake

- 6.6. Integrated Presence System

- 6.6.1. Mast Interlock System (MC Model)

- 6.6.2. Mast Interlock System (FC Model)

- 6.6.3. Mast Interlock System Functions

- 6.6.4. Driving Interlock System

- 6.6.5. Driving Interlock System Functions

- 6.6.6. Neutral System

- 6.6.7. Neutral System Functions

- 6.6.8. Seat Belt Warning Lamp

- 6.6.9. Seat Belt Warning Functions

- 6.6.10. Parking Brake Warning Buzzer and Lamp

- 6.6.11. Parking Brake Warning Functions

- 6.7. Parking Brake Dragging Warning

- 6.8. Operating Switches and Controls (MC Model)

- 6.8.1. Lift Lever

- 6.8.2. Tilt Lever

- 6.8.3. Attachment Lever

- 6.9. Operating Switches and Controls (FC Model)

- 6.9.1. Lift Lever

- 6.9.2. Tilt Lever

- 6.9.3. Attachment Lever A/B (Optional)

- 6.9.4. Selector Switch Between Forth and Fifth Attachment

- 6.9.5. Other Controls (Standard)

- 6.9.6. Emergency Stop Button

- 6.9.7. Forward and Back Adjustment Stopper Knob

- 6.9.8. Up and Down Adjustment Stopper Knob

- 6.9.9. Other Controls (Optional)

- 6.9.10. Lowering Speed Selector Switch (Optional)

- 6.9.11. Mast Vertical Switch (Optional)

- 6.9.12. Direction Switch (Optional)

- 6.10. Operators Seat

- 6.10.1. Seat Adjustment

- 6.10.2. Forward and Back Adjustment

- 6.10.3. Adjustment of Suspension (FC Model)

- 6.10.4. Lumbar Support Adjustment (FC Model)

- 6.10.5. Pocket for the Manual

- 6.10.6. Operator Presence Switch and Buzzer

- 6.10.7. How to Tip the Seat Forward

- 6.11. Seat Belt

- 6.12. Fork Locking Pins

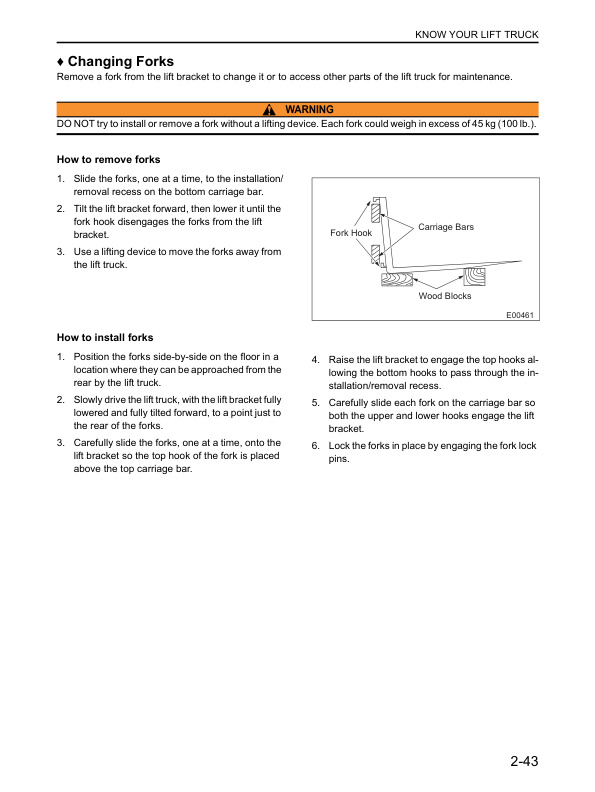

- 6.13. Changing Forks

- 6.14. Drawbar Pin

- 6.15. Assist Grip

- 6.16. Engine Hood

- 6.16.1. Hood Latch

- 6.17. Hydraulic Tank Oil Level / Filler Hole

- 6.18. Fuel Filler

- 6.19. Brake Tank Oil Level / Air Breather

- 7. HOW TO AVOID A TIPOVER HOW TO SURVIVE ONE

- 7.1. Know What Lift Truck Stability Is

- 7.2. Center of Gravity (CG)

- 7.3. Stability and Center of Gravity (Top View)

- 7.4. Stability and Center of Gravity (Side View)

- 7.5. Lift Truck Stability Base

- 7.6. Capacity (Weight and Load Center)

- 7.7. Capacity Plate

- 7.7.1. For Example

- 7.8. Dos and Donts to Avoid Tipover

- 7.8.1. Fasten the seat belt

- 7.8.2. DO NOT jump off your lift truck if it starts to tip over

- 7.8.3. DO watch Tail swing

- 7.8.4. DO check surface strengths

- 7.8.5. DO avoid fast starts, turns and sudden stops

- 7.8.6. DO NOT elevate forward tilted loads

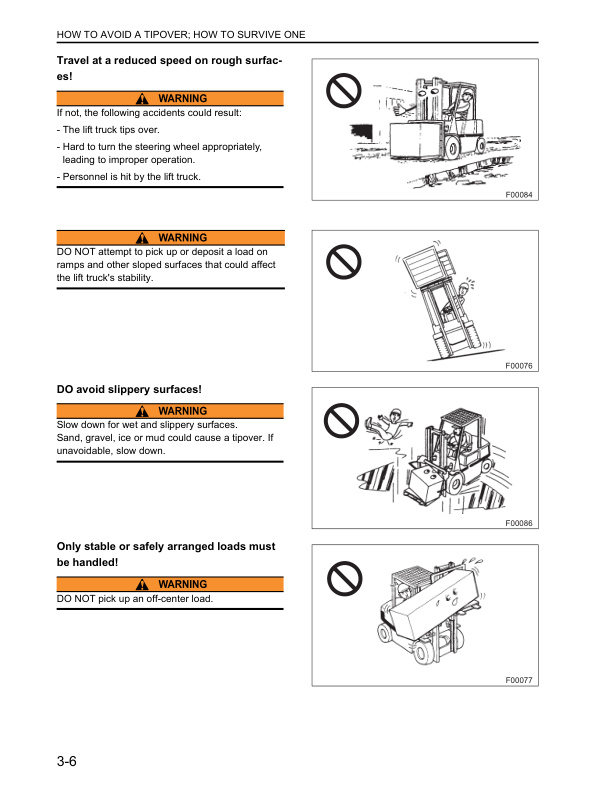

- 7.8.7. Travel at a reduced speed on rough surfaces

- 7.8.8. DO avoid slippery surfaces

- 7.8.9. Only stable or safely arranged loads must be handled

- 7.8.10. DO NOT travel with forks higher than 15 to 20 cm (6 to 8 in.) above the ground

- 7.8.11. DO NOT make fast or sharp turns with a loaded or unloaded lift truck

- 7.8.12. DO NOT turn sharply, even with an empty raised mast, to avoid a tipover

- 7.8.13. DO wear a hard hat

- 7.8.14. Be aware of the stability of an empty lift truck

- 7.9. How to Survive in a Tipover

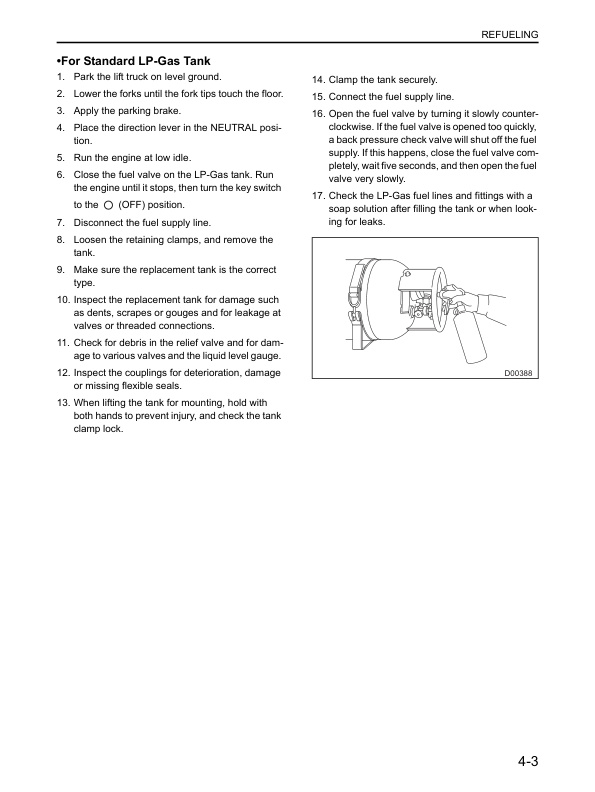

- 8. REFUELING

- 8.1. Gasoline and Diesel Engine Equipped

- 8.2. LP-Gas Engine Equipped

- 8.2.1. For Standard LP-Gas Tank

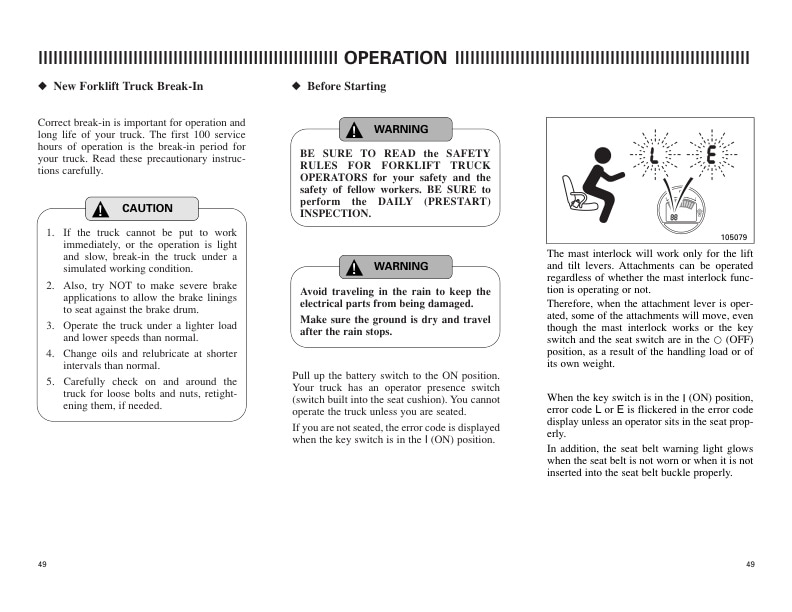

- 9. OPERATION

- 9.1. New Lift Truck Break-in

- 9.2. Before Starting Engine

- 9.2.1. FC model

- 9.2.2. MC model

- 9.2.3. Gasoline / LP-Gas Dual Fuel Type

- 9.2.4. FC Model

- 9.2.5. Seat Adjustment

- 9.3. Starting Gasoline Engine

- 9.3.1. If the engine wont start

- 9.4. Starting LP-Gas Engine

- 9.5. Starting Diesel Engine

- 9.5.1. If the engine wont start

- 9.6. Engine Wont Start

- 9.6.1. When Engine Is Flooded

- 9.6.2. When Engine Is Started After Long Recess

- 9.7. After Starting Engine

- 9.8. Before Moving Lift Truck

- 9.9. Lift Truck Operation

- 9.9.1. Changing Speed

- 9.9.2. Changing Direction

- 9.9.3. Operating Techniques

- 9.9.4. Steering (Turning)

- 9.9.5. Inching

- 9.10. Stopping Lift Truck

- 9.11. Parking Lift Truck (After Stopping)

- 9.12. Leaving Lift Truck (FC Model)

- 9.12.1. For Use With Wet Disc Brake Option

- 10. OPERATING TECHNIQUES

- 10.1. Stacking Methods

- 10.1.1. Stacking Different Loads in Size

- 10.1.2. Stacking Small Identical Loads

- 10.1.3. Stacking Large Identical Loads

- 10.2. Handling Loads Safely

- 10.2.1. Handle ONLY stable loads to prevent the load from falling

- 10.3. Correct Operating Steps

- 10.4. Incorrect Operating Steps

- 10.4.1. Example 1

- 10.5. Inching Into and Lifting the Load

- 10.6. Traveling With the Load

- 10.7. Unloading

- 10.8. Working on Grades

- 10.8.1. Normal Travel position

- 10.8.2. Traveling on a Grade

- 10.8.3. Stopping on a Grade

- 10.8.4. Starting on a Grade (Engine Stalls on a Grade)

- 11. STORING THE LIFT TRUCK

- 11.1. End of Each Shift Storage

- 11.2. Long Term Storage

- 11.2.1. Fuel System

- 11.2.2. Hydraulic System

- 11.2.3. Engine Cooling System

- 11.2.4. Engine Cylinders

- 11.2.5. Battery

- 11.2.6. Controller

- 11.2.7. Other

- 12. TRANSPORTATION HINTS

- 12.1. Lift Truck Loading and Shipping

- 12.2. Lift Truck Lifting and Tiedown Information

- 13. SPECIAL SITUATIONS

- 13.1. Care in Cold Weather

- 13.1.1. Fuel Oils and Lubrication Oils

- 13.1.2. Battery

- 13.1.3. Engine Coolant

- 13.2. Care in Hot Weather

- 13.2.1. Fuel Oils and Lubrication Oils

- 13.2.2. Battery

- 13.2.3. Engine Coolant

- 13.3. Severe Dust or Lint Conditions

- 14. TROUBLESHOOTING

- 14.1. Stalled Engine

- 14.2. Starting With Jumper Cables

- 14.3. If Lamps Wont Glow

- 14.3.1. How to Check Fuses and Lamps

- 14.4. If the Water Temperature Gauge Shows Red Zone

- 14.5. If Torque Converter Oil Temperature Warning Lamp Glows (Powershift)

- 14.6. Trouble With the LP-Gas Equipment

- 14.7. If the Lift Truck Wont Change Direction

- 14.8. If the Lift Truck Wont Move

- 14.9. If the Mast and Attachments Stop Moving

- 14.10. If the Mast and Attachments Malfunction (FC Model)

- 14.11. If a Tire Blew Out

- 14.11.1. If a Tire Blew Out During Traveling or Operation

- 14.12. Changing Tires

- 14.12.1. Before Changing a Tire

- 14.12.2. To Remove Wheel

- 14.12.3. To Raise Front Wheel

- 14.12.4. To Raise Rear Wheel

- 14.12.5. To Install Wheel

- 14.12.6. To Add Air to Tires

- 14.12.7. Dual Tire (Optional)

- 14.13. Error Codes and Explanations

- 15. MAINTENANCE

- 15.1. General

- 15.2. Inspection Precautions

- 15.3. Maintenance Schedule

- 15.3.1. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 15.3.2. Every 50 Service Hours or Weekly, Whichever Comes First

- 15.3.3. One Month (30 days) or 200 Service Hours After Delivery of a New Truck, Whichever Comes First

- 15.3.4. Every 200 Service Hours or Monthly, Whichever Comes First

- 15.3.5. Every 500 Service Hours or 3 Months, Whichever Comes First

- 15.3.6. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 15.3.7. Every 2000 Service Hours or 1 year, Whichever Comes First

- 15.4. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 15.4.1. Faulty Operation Found the Day Before

- 15.4.2. Oil, Fuel or Coolant Leaks

- 15.4.3. Head Lamp and Working Lamp (if equipped)

- 15.4.4. Load Backrest Extension

- 15.4.5. Tilt Cylinder Socket Bolts

- 15.4.6. Overhead Guard

- 15.4.7. Assist Grip

- 15.4.8. Accelerator Pedal

- 15.4.9. Brake Pedal

- 15.4.10. Inching Pedal

- 15.4.11. Parking Brake Lever

- 15.4.12. Parking Brake System

- 15.4.13. Seat Belt

- 15.4.14. Operators Seat

- 15.4.15. Steering Wheel and Column

- 15.4.16. Stop Lamps

- 15.4.17. Lamps of Instrument Panel

- 15.4.18. Lift Chains

- 15.4.19. Engine (Exhaust, Noise and Vibration)

- 15.4.20. Mast Strip Sliding Surfaces

- 15.4.21. Back-up Lamps (If Equipped)

- 15.4.22. Engine Oil

- 15.4.23. Engine Coolant

- 15.4.24. Hydraulic Oil

- 15.4.25. Powershift Transmission

- 15.4.26. Service Brakes

- 15.4.27. Brake Oil

- 15.4.28. Wheel Nuts

- 15.4.29. Tires and Rims

- 15.4.30. Mast and Forks

Mitsubishi Operation Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Operation and Maintenance Manual 99750-7B100

Mitsubishi Operation Manual PDF

Mitsubishi FB10-12-15KRT PAC Operation and Maintenance Manual 99750-5G100

Mitsubishi Operation Manual PDF

Mitsubishi EOP15N3 Operating and Maintenance Instructions 51481376

Mitsubishi Operation Manual PDF

Mitsubishi Operation Manual PDF

Mitsubishi Operation Manual PDF

Mitsubishi OPB10P, OPBM10P, OPBH12PH Operation and Maintenance Manual OM19GBOR1AA7

Mitsubishi Operation Manual PDF

Mitsubishi ESR15N2-ESR23N2, EDR18N2 Operating Instructions 51620220

Mitsubishi Operation Manual PDF

Mitsubishi FB10CB-35CB, FB20-25LCB Forklift Trucks Operation and Maintenance Manual OMFEM-M22C0-200

Mitsubishi Operation Manual PDF

Mitsubishi FB10 to FB25 Operation and Maintenance Manual 99750-12101

Mitsubishi Operation Manual PDF

Mitsubishi FB14-20A(C)NT, FB16-20A(C)N Operation and Maintenance Manual 654390 EN A