Mitsubishi K15, K21, K25 Gasoline Engine Service Manual 99789-77100

$50.00

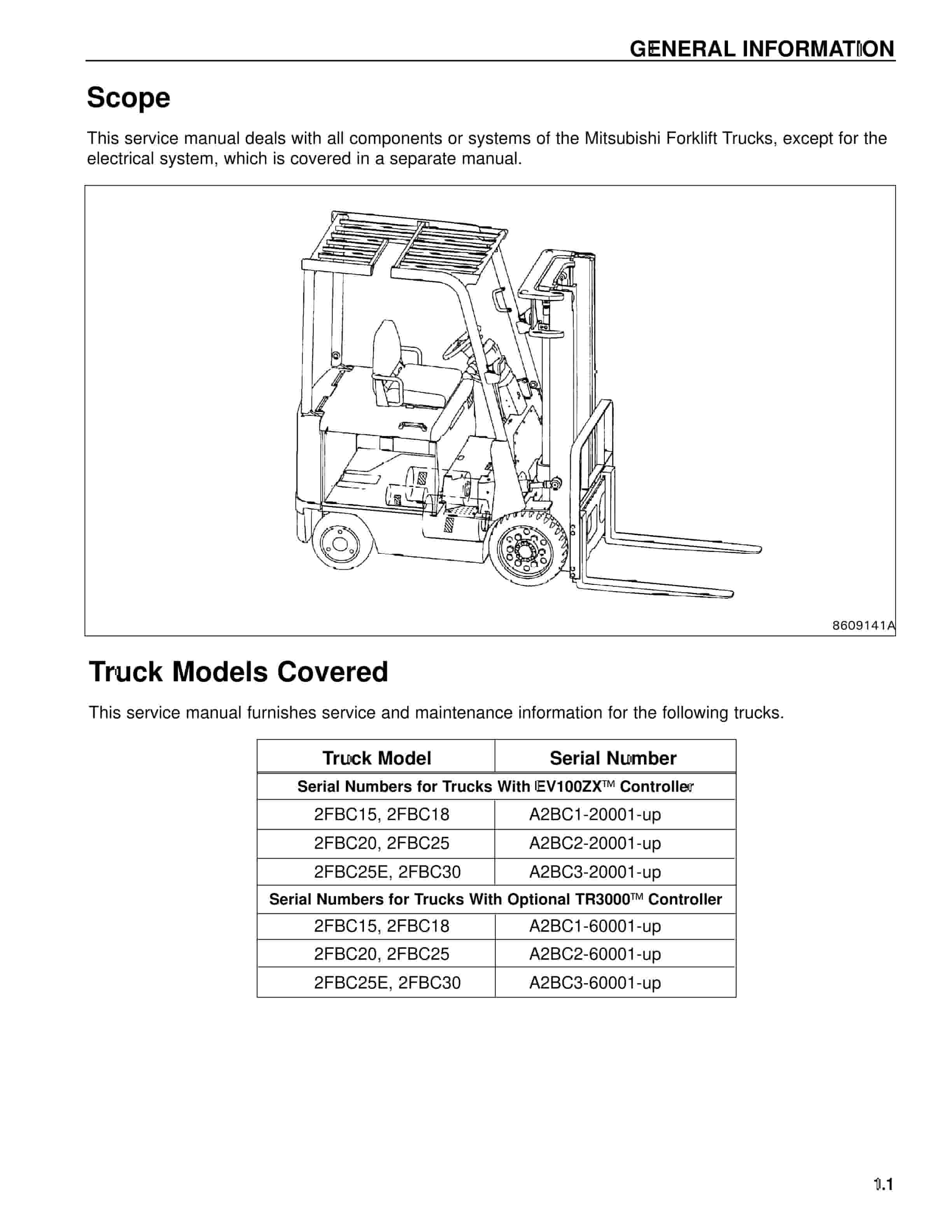

- Type Of Manual: Service Manual

- Manual ID: 99789-77100

- Number of Pages: 236

- Size: 4.4MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- K15 Gasoline Engine, K21 Gasoline Engine, K25 Gasoline Engine

- 1. How to use this manual

- 1.1. Description

- 1.2. Definition of Terms

- 1.3. Definition of Units

- 1.4. Description

- 2. Precautions for safety and quality

- 2.1. Safe Operation

- 2.2. Correct Operation

- 2.3. Precautions for Radio Equipment Installation

- 3. Precautions

- 3.1. Precautions in Draining Engine Coolant

- 3.2. Precautions for Disconnecting Fuel Piping

- 3.3. Precautions for Removing and Disassembling

- 3.4. Precautions for Inspection, Correction, and Replacement

- 3.5. Precautions for Assembly and Installation

- 3.6. Parts Requiring Angle Tightening

- 3.7. Caution With Use of Power Tools

- 3.8. Precautions for Liquid Gasket Application

- 4. Tightening torque

- 4.1. Standard Bolt Tightening Torque

- 4.2. Standard Bolt Tightening Torque (Contd)

- 4.3. Engine Part Tightening Torque

- 5. Special Service Tools

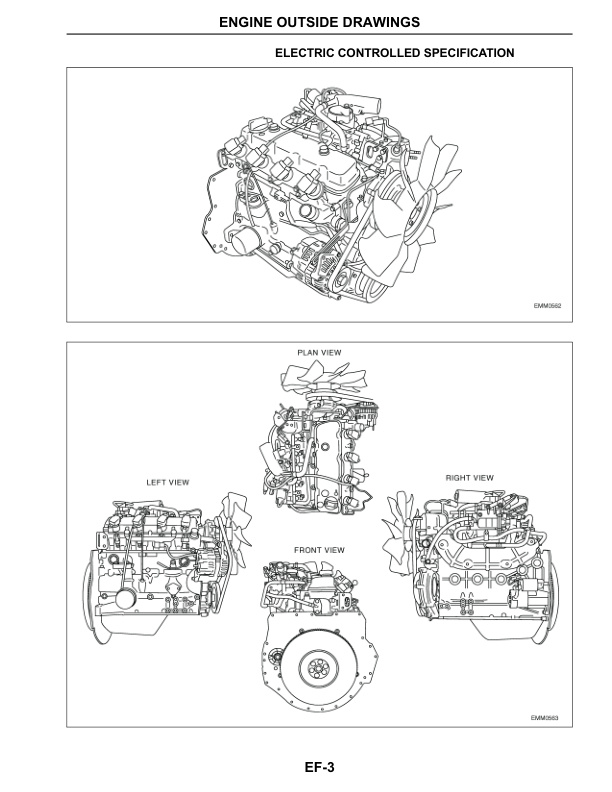

- 6. Engine outside drawings

- 7. MAIN SPECIFICATIONS

- 8. MAIN SPECIFICATIONS

- 9. Standard and repair limit

- 10. ocation of engine No.

- 11. Trouble diagnosis

- 11.1. Engine Adjustment

- 11.2. Engine LPG Fuel System

- 12. Engine maintenance

- 12.1. Specifications

- 12.2. Tightening Torque

- 12.3. Maintenance Schedule

- 12.4. Maintenance Schedule (Contd)

- 12.5. Oil and Grease, and Capacity

- 12.6. On Board Inspection and Service

- 13. Specifications

- 14. Tightening torque

- 15. Trouble diagnosis

- 16. ENGINE INSPECTION AND ADJUSTMENT

- 16.1. Engine Body Related

- 16.2. Ignition and Fuel Systems

- 17. Special Service Tools For carburetor model

- 18. Precautions

- 18.1. Precautions for Draining Engine Coolant

- 18.2. Precautions for Disconnecting Fuel Piping

- 18.3. Precautions for Removing and Disassembling

- 18.4. Precautions for Inspection, Correction, and Replacement

- 18.5. Precautions for Assembly and Installation

- 18.6. Parts Requiring Angle Tightening

- 18.7. Caution With Use of Power Tools

- 18.8. Precautions for Liquid Gasket Application

- 19. Main specifications

- 20. Adjustment value

- 21. Tightening torque

- 21.1. Standard Bolt Tightening Torque

- 21.2. Engine Part Tightening Torque

- 22. Trouble diagnosis

- 23. Special Service Tools

- 24. Removal and installation of engine

- 24.1. Removal

- 24.2. Installation

- 24.3. Inspection

- 25. Engine service

- 25.1. Engine Disassembly

- 25.2. Engine Disassembly (Contd)

- 25.3. Inspection and Correction

- 25.4. Inspection and Correction (Contd)

- 25.5. Engine Assembly

- 26. Precautions

- 26.1. On Board Diagnostic (OBD) System of Engine

- 26.2. Precaution

- 26.3. Special Service Tools

- 27. Description

- 27.1. Description

- 28. trouble diagnosis

- 28.1. Component Parts Location

- 28.2. ECM Component

- 28.3. Circuit Diagram

- 28.4. Circuit Diagram (Contd)

- 28.5. ECM Terminal

- 29. Trouble Diagnosis

- 29.1. How to Proceed with Trouble Diagnosis

- 29.2. Diagnosis Chart by Symptom

- 29.3. Description

- 29.4. Fail-Safe Function

- 29.5. Table of DTC

- 29.6. Service Tool

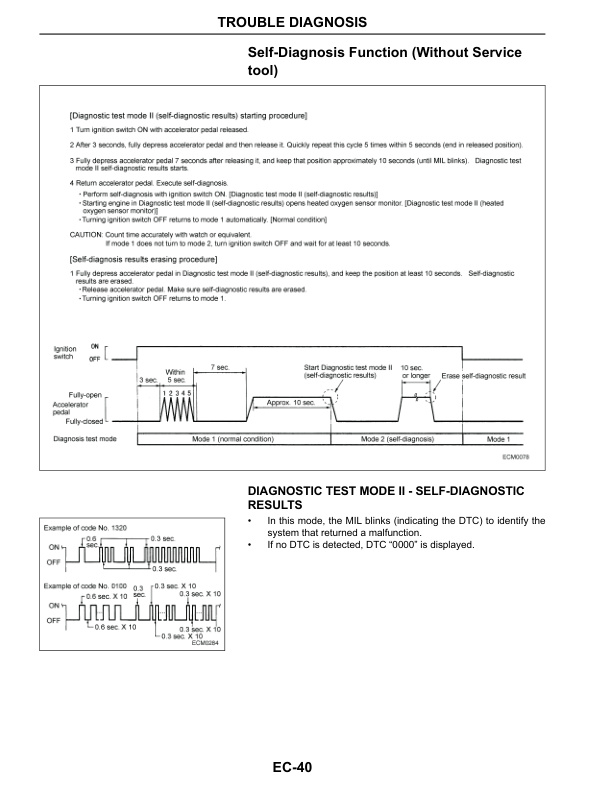

- 29.7. Self-Diagnosis Function (Without Service tool)

- 29.8. ECM Active Test

- 30. Basic inspection

- 30.1. Inspection of Idle Speed and Ignition Timing

- 30.2. Throttle Valve Closed Position Learning and Idle Air Volume Learning

- 30.3. Accelerator Pedal Fully Released Position Learning

- 30.4. Fuel Pressure Inspection

- 30.5. Accelerator Pedal Fully Released Position Learning

- 31. COMPONENT PARTS INSPECTION

- 31.1. Crankshaft Position Sensor (POS)

- 31.2. Camshaft Position Sensor (PHASE)

- 31.3. Mass Air Flow Sensor

- 31.4. Engine Coolant Temperature Sensor

- 31.5. Throttle Position Sensor 1, 2 (Electric throttle control actuator assembly)

- 32. Component Parts Inspection

- 32.1. Accelerator Pedal Position Sensors 1, 2 (Accelerator work unit)

- 32.2. Intake Air Temperature Sensor (Joined with mass air flow sensor)

- 32.3. Stop Lamp Switch

- 32.4. Spark Plug

- 32.5. Ignition Coil

- 32.6. Injector

- 32.7. Fuel Pump

- 32.8. Electric Throttle Control Motor (Electric throttle control actuator assembly)

- 32.9. Heated Oxygen Sensor

- 32.10. LPG Injector

- 32.11. LPG Assistance Injector

- 32.12. LPG Fuel Pressure Sensor

- 32.13. PTC Heater

- 32.14. LPG Interception Valve

- 32.15. System Diagram

- 32.16. Component Parts Inspection

- 33. ECM components

- 33.1. Removal and Installation

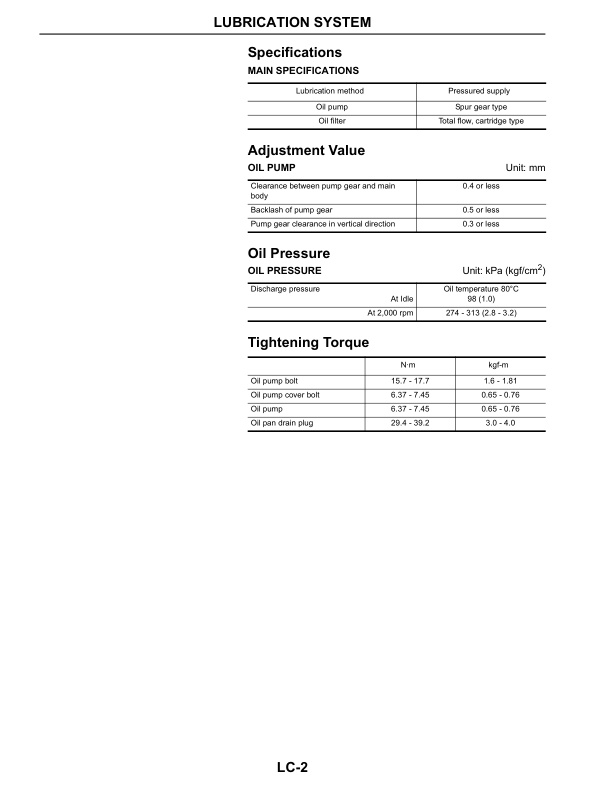

- 34. Lubrication system

- 34.1. Specifications

- 34.2. Adjustment Value

- 34.3. Oil Pressure

- 34.4. Tightening Torque

- 34.5. Trouble Diagnosis

- 34.6. Lubrication Schematic Diagram

- 34.7. Oil Pump

- 35. Engine coolant system

- 35.1. Specifications

- 35.2. Adjustment Value

- 35.3. Tightening Torque

- 35.4. Trouble Diagnosis

- 35.5. Cooling System Configuration

- 35.6. Water Pump

- 35.7. Thermostat

- 36. Emission control system

- 37. ENGINE OUTSIDE DRAWINGS

- 38. SYSTEM DIAGRAM

- 38.1. K-Engine System Diagram (Gasoline)

- 38.2. K-Engine System Diagram (Combined Use)

- 39. UNIT LAYOUT

- 40. S (SDS)

- 40.1. Electric Control System Specifications

- 40.2. Carburetor Specifications

- 41. LPG FUEL SYSTEM TROUBLE DIAGNOSIS

- 42. DISASSEMBLY AND ASSEMBLY OF FUEL SYSTEM

- 42.1. Electric Control Throttle Assembly

- 42.2. Gasoline Fuel Injector (Electric Controlled Gasoline and Combined Use)

- 42.3. LPG Device (Specifications for LPG and Combined Use)

- 43. disassembly and assembly of fuel system

- 43.1. Vaporizer Mechanism and Operation

- 43.2. LPG Fuel Injector

- 43.3. LPG Assist Fuel Injector

- 43.4. Relief Valve (2 Relief Valves)

- 44. DISASSEMBLY AND ASSEMBLY OF VAPORIZER

- 44.1. Components Around Carburetor and Pneumatic Governor (Carburetor Specifications)

- 44.2. Tar drain, Removal, Installation, Disassembly and Inspection of Vaporizer

- 44.3. Secondary Valve Room

- 45. Adjustment value

- 46. Trouble diagnosis

- 46.1. Structure

- 46.2. Disassembly

- 46.3. Inspection

- 46.4. Assembly

- 46.5. Inspection After Assembly

- 47. STARTER MOTOR (DRY TYPE)

- 47.1. Specifications

- 47.2. Components

- 47.3. Component Parts Location

- 47.4. Overhaul

- 47.5. Assembly Inspection

- 48. STARTER MOTOR (WET TYPE)

- 48.1. Specifications

- 48.2. Components

- 48.3. Exploded View

- 48.4. Inspection

- 49. ALTERNATOR

- 49.1. Exploded View

- 49.2. Disassembly

- 49.3. Inspection

Rate this product

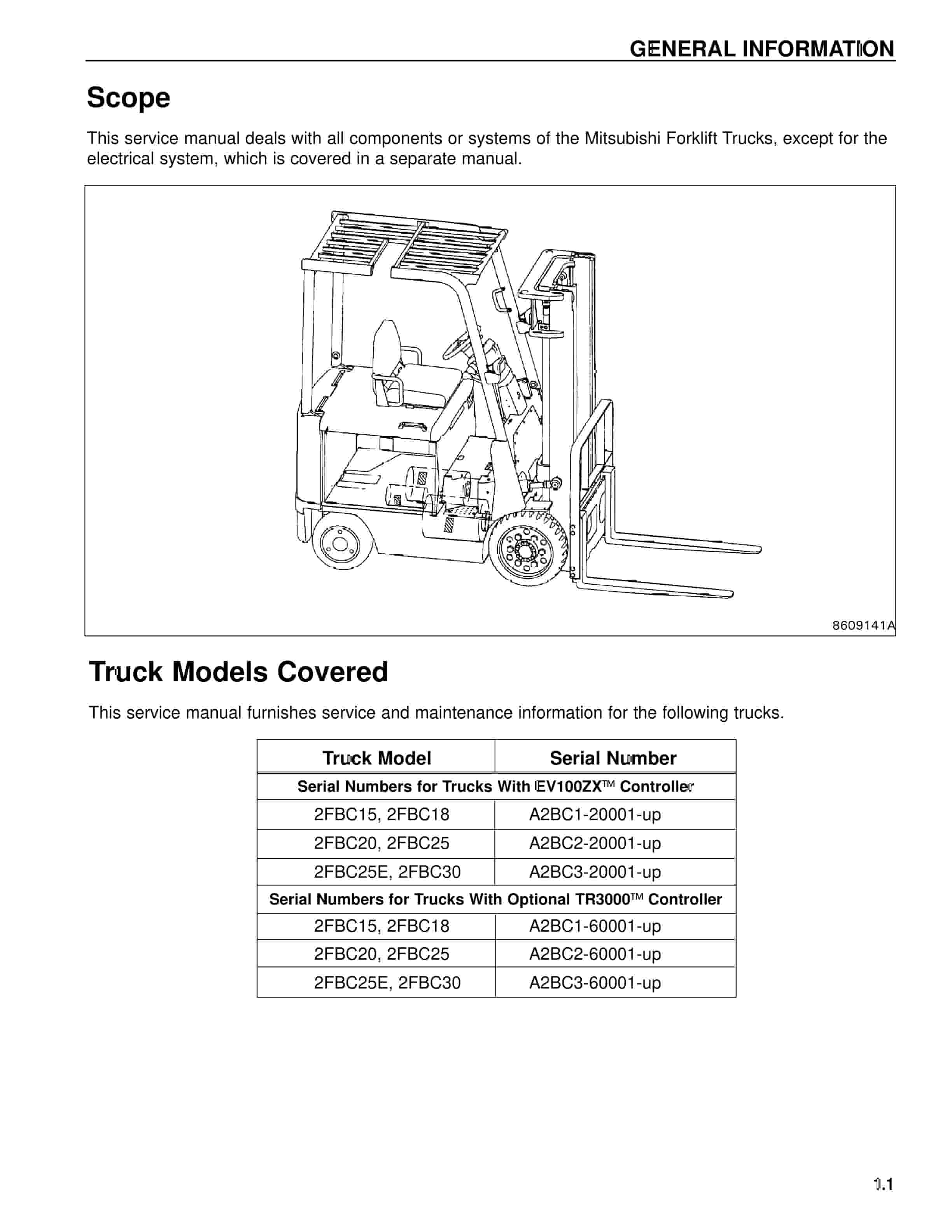

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-74120

$50.00