Mitsubishi RBM20K, RBM25K Multiway Reach Truck Service Manual 631057

$50.00

- Type Of Manual: Service Manual

- Manual ID: 631057

- Number of Pages: 319

- Size: 7.4MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- RBM20K, RBM25K

- 1.

- 1.1. TS761104

- 1.1.1. AC-RBM 20K/25K

- 1.1.1.1. POWERSUPPLY 48V

- 1.1.1.2. POWERSUPPLY 12/24V

- 1.1.1.3. MAINCIRCUITS

- 1.1.1.4. DRIVECIRCUIT 1

- 1.1.1.5. DRIVECIRCUIT 2

- 1.1.1.6. STEERING CIRCUIT

- 1.1.1.7. STEERING CIRCUIT 2

- 1.1.1.8. STEERING CIRCUIT 3

- 1.1.1.9. HYDRAULIC CONTROL CIRCUIT 1

- 1.1.1.10. HYDRAULIC CONTROL CIRCUIT 2

- 1.1.1.11. CONTROL CIRCUIT 1

- 1.1.1.12. CONTROL CIRCUIT 2

- 1.1.1.13. SIGNAL- /LIGHTCIRCUIT

- 1.1.1.14. FANS, AUX.DEVICES

- 1.1.1.15. AUX.DEVICES

- 1.1.1.16. LAYOUT

- 1.1.1.17. LAYOUT

- 1.1.1.18. WIRE HARNESS W3 RL468152

- 2.

- 2.1. TS1050000

- 2.1.1. TEM AC SAUER DANFOSS

- 2.1.1.1. POWER SUPPLY 48V

- 2.1.1.2. MAIN CIRCUITS

- 2.1.1.3. DRIVE CIRCUIT

- 2.1.1.4. DRIVE CIRCUIT 2

- 2.1.1.5. STEERING CIRCUIT 1

- 2.1.1.6. HYDRAULIC CONTROL CIRCUIT

- 2.1.1.7. AUX DEVICES

- 2.1.1.8. STEERING CIRCUIT

- 2.1.1.9. CONTROL CIRCUIT

- 2.1.1.10. SIGNAL/LIGHT CIRCUITS

- 2.1.1.11. CSM FLASH LIGHTS WITH RUBBER BODY

- 2.1.1.12. 24V POWER SUPPLY / AUX DEVICES

- 2.1.1.13. MAIN WIRE HARNESS 479690

- 2.1.1.14. MAIN WIRE HARNESS 479690

- 2.1.1.15. PUSH WIRE HARNESS 480917

- 2.1.1.16. SUPPLY AND MOTOR CABLES 479691

- 2.1.1.17. INSTRUMENT PANEL WIRE HARNESS 479692

- 2.1.1.18. PIN CODE LUCK 480016

- 2.1.1.19. PEDALS 482458

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

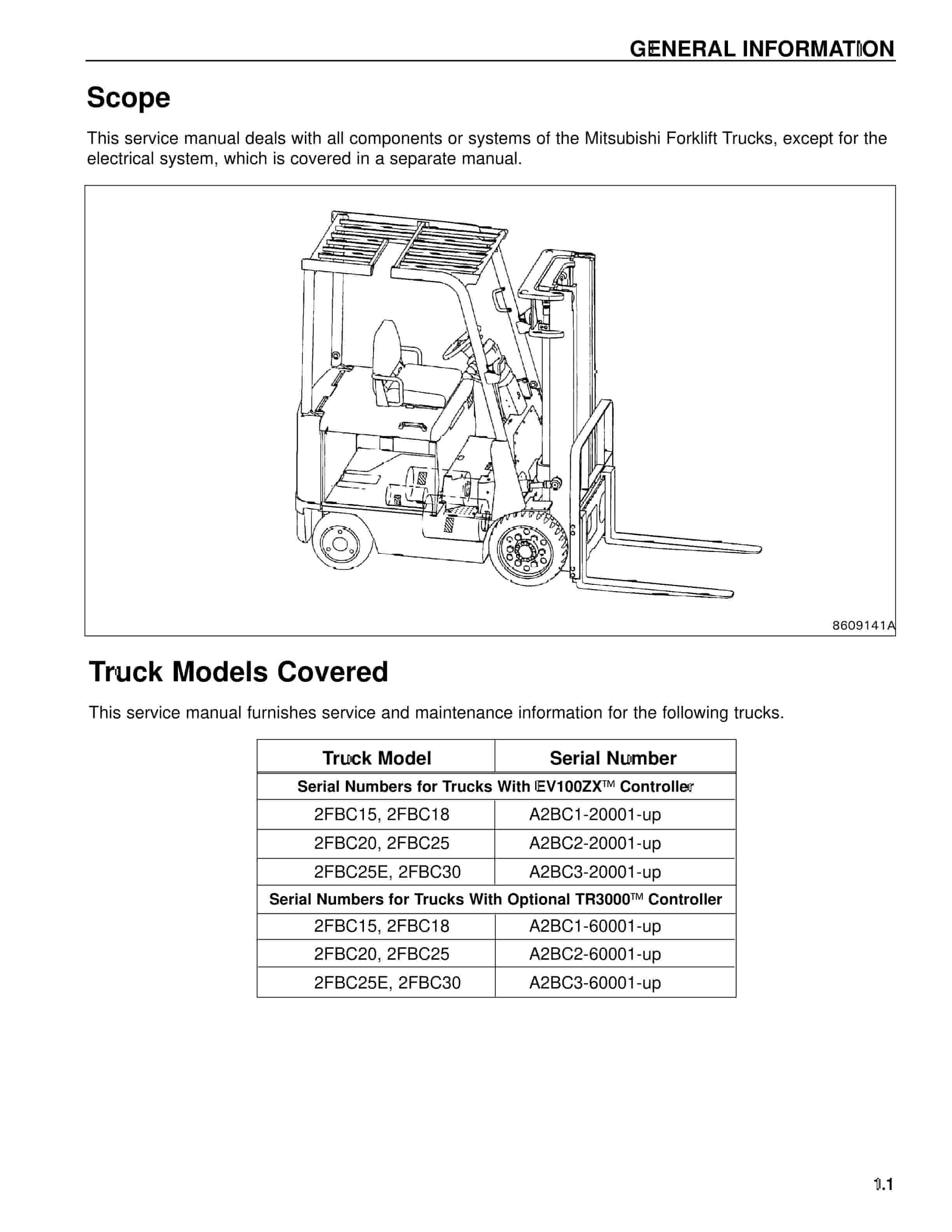

- 10.1. Table of Contents

- 10.2. Scope of this Manual

- 10.3. Related Documents

- 10.4. Intended Use of the AC SuperDrive

- 10.5. Product Identification

- 10.6. Technical Support

- 10.7. Product Warranty

- 10.8. Introduction

- 10.9. Tools and Equipment Required

- 10.10. Orientation

- 10.11. Clearances for Access and Air Circulation

- 10.12. Procedure

- 10.13. Introduction

- 10.14. Tools and Equipment Required

- 10.15. Motor and Battery Connections

- 10.15.1. General

- 10.15.2. Making Connections to Terminal Posts

- 10.15.3. Inrush Current Limiting Resistance

- 10.15.4. Main Contactor

- 10.15.5. Key Start Input

- 10.16. Control and I/O Connections

- 10.16.1. General

- 10.16.2. ID0 and ID1 Inputs

- 10.16.3. Encoder Signals

- 10.16.4. Temperature Sensor

- 10.16.5. CAN Bus Signals

- 10.16.6. Crimping Contacts onto Signal Conductors

- 10.16.7. Installing Crimped Contacts in Connector Housing

- 10.17. General

- 10.18. Checks Prior to Initial Powerup

- 10.19. Verifying AC SuperDrive Readiness for Operation

- 10.20. Configuring the AC SuperDrive for the Application

- 10.21. Final Operational Checks in Vehicle

- 10.22. Introduction

- 10.23. Periodic Preventive Maintenance

- 10.24. AC SuperDrive Replacement Procedure

- 10.24.1. Drive Removal

- 10.24.2. Drive Installation

- 10.25. Scope of the Troubleshooting Guide

- 10.26. Using the Troubleshooting Guide

- 10.26.1. Organization of Troubleshooting Guide

- 10.26.2. About Errors and Warnings

- 10.26.3. Error Logging

- 10.26.4. Using the Troubleshooting Charts

- 10.27. Information for OEMs Preparing User Documentation

- 10.28. Symptom Main Contactor doesnt close after switching on Key Switch

- 10.29. Symptom Fuse to Power Stage is blown

- 10.30. Symptom AC SuperDrive Status Indicator is blinking or off

- 10.31. Symptom Motor runs only at low speed and with a ticking sound

- 10.32. Error Code 1 Pulse Sensor Error

- 10.33. Error Code 2 Motor Temperature High

- 10.34. Warning Code 16 Power limited due to Motor Overtemp.

- 10.35. Error Code 4 Heatsink Temperature high

- 10.36. Warning Code 1 Power Limited due to Heatsink Overtemp.

- 10.37. Error Code 8 Overcurrent

- 10.38. Error Code 16 DC Bus High – hardware detected

- 10.39. Error Code 32 DC Bus High – software detected

- 10.40. Error Code 64 DC Bus Low

- 10.41. Error Code 128 No Charging DC Bus

- 10.42. Error Code 256 CAN – too many Errors

- 10.43. Error Code 512 CAN Watchdog Time-out

- 10.44. Error Code 1024 Missing Okay to Start from Truck Controller

- 10.45. Error Code 2048 Contradictory Commands from Truck Controller

- 10.46. Error Code 4096 Potentiometer Values Out of Range

- 10.47. Warning Code 2 Heatsink Temperature Sensor Open Circuit

- 10.48. Warning Code 4 Heatsink Temperature Sensor Short Circuit

- 10.49. Warning Code 8 Power limited – temp < -20 deg. C

- 10.50. Warning Code 32 Motor Temperature Sensor – Open Circuit

- 10.51. Warning Code 64 Motor Temperature Sensor – Short Circuit

- 10.52. Warning Code 128 Speed from Truck Controller Out of Range

- 10.53. Warning Code 256 Current Calibration Error

- 10.54. Warning Code 512 Reverted to Default Parameters

- 10.55. _UM.pdf

- 10.55.1. Scope of this Manual

- 10.55.2. Related Documents

- 10.55.3. Intended Use of the AC SuperDrive

- 10.55.4. Product Identification

- 10.55.5. Technical Support

- 10.55.6. Product Warranty

- 10.55.7. Introduction

- 10.55.8. Tools and Equipment Required

- 10.55.9. Orientation

- 10.55.10. Clearances for Access and Air Circulation

- 10.55.11. Procedure

- 10.55.12. Introduction

- 10.55.13. Tools and Equipment Required

- 10.55.14. Motor and Battery Connections

- 10.55.14.1. General

- 10.55.14.2. Making Connections to Terminal Posts

- 10.55.14.3. Inrush Current Limiting Resistance

- 10.55.14.4. Main Contactor

- 10.55.14.5. Key Start Input

- 10.55.15. Control and I/O Connections

- 10.55.15.1. General

- 10.55.15.2. ID0 and ID1 Inputs

- 10.55.15.3. Encoder Signals

- 10.55.15.4. Temperature Sensor

- 10.55.15.5. CAN Bus Signals

- 10.55.15.6. Crimping Contacts onto Signal Conductors

- 10.55.15.7. Installing Crimped Contacts in Connector Housing

- 10.55.16. General

- 10.55.17. Checks Prior to Initial Powerup

- 10.55.18. Verifying AC SuperDrive Readiness for Operation

- 10.55.19. Configuring the AC SuperDrive for the Application

- 10.55.20. Final Operational Checks in Vehicle

- 10.55.21. Introduction

- 10.55.22. Periodic Preventive Maintenance

- 10.55.23. AC SuperDrive Replacement Procedure

- 10.55.23.1. Drive Removal

- 10.55.23.2. Drive Installation

- 10.55.24. Obtaining Factory Repair

- 10.55.25. Scope of the Troubleshooting Guide

- 10.55.26. Using the Troubleshooting Guide

- 10.55.26.1. Organization of Troubleshooting Guide

- 10.55.26.2. About Errors and Warnings

- 10.55.26.3. Error Logging

- 10.55.26.4. Using the Troubleshooting Charts

- 10.55.27. Information for OEMs Preparing User Documentation

- 10.55.28. Symptom Main Contactor doesnt close after switching on Key Switch

- 10.55.29. Symptom Fuse to Power Stage is blown

- 10.55.30. Symptom AC SuperDrive Status Indicator is blinking or off

- 10.55.31. Symptom Motor runs only at low speed and with a ticking sound

- 10.55.32. Error Code 1 Pulse Sensor Error

- 10.55.33. Error Code 2 Motor Temperature High

- 10.55.34. Warning Code 16 Power limited due to Motor Overtemp.

- 10.55.35. Error Code 4 Heatsink Temperature high

- 10.55.36. Warning Code 1 Power Limited due to Heatsink Overtemp.

- 10.55.37. Error Code 8 Overcurrent

- 10.55.38. Error Code 16 DC Bus High – hardware detected

- 10.55.39. Error Code 32 DC Bus High – software detected

- 10.55.40. Error Code 64 DC Bus Low

- 10.55.41. Error Code 128 No Charging DC Bus

- 10.55.42. Error Code 256 CAN – too many Errors

- 10.55.43. Error Code 512 CAN Watchdog Time-out

- 10.55.44. Error Code 1024 Missing Okay to Start from Truck Controller

- 10.55.45. Error Code 2048 Contradictory Commands from Truck Controller

- 10.55.46. Error Code 4096 Potentiometer Values Out of Range

- 10.55.47. Warning Code 2 Heatsink Temperature Sensor Open Circuit

- 10.55.48. Warning Code 4 Heatsink Temperature Sensor Short Circuit

- 10.55.49. Warning Code 8 Power limited – temp < -20 deg. C

- 10.55.50. Warning Code 32 Motor Temperature Sensor – Open Circuit

- 10.55.51. Warning Code 64 Motor Temperature Sensor – Short Circuit

- 10.55.52. Warning Code 128 Speed from Truck Controller Out of Range

- 10.55.53. Warning Code 256 Current Calibration Error

- 10.55.54. Warning Code 512 Reverted to Default Parameters

- 10.55.54.1. Table of Contents

- 11.

- 12.

- 12.1. Table of Contents

- 12.2. Introduction

- 12.2.1. About APS Documentation

- 12.2.1.1. Scope of this Manual

- 12.2.1.2. Intended Use

- 12.2.1.3. Related Documents

- 12.2.2. About the Advanced Power Steering Unit

- 12.2.2.1. Intended Use

- 12.2.2.2. Safety Instructions

- 12.2.2.3. Technical Support

- 12.2.2.4. Product Warranty

- 12.3. APS Installation

- 12.3.1. Installing APS in Vehicle

- 12.3.1.1. Introduction

- 12.3.1.2. Installing the Actuator

- 12.3.1.3. Installing a Separately mounted Controller

- 12.3.2. Installing Steering Feedback Sensors

- 12.3.2.1. Introduction

- 12.3.2.2. Potentiometer

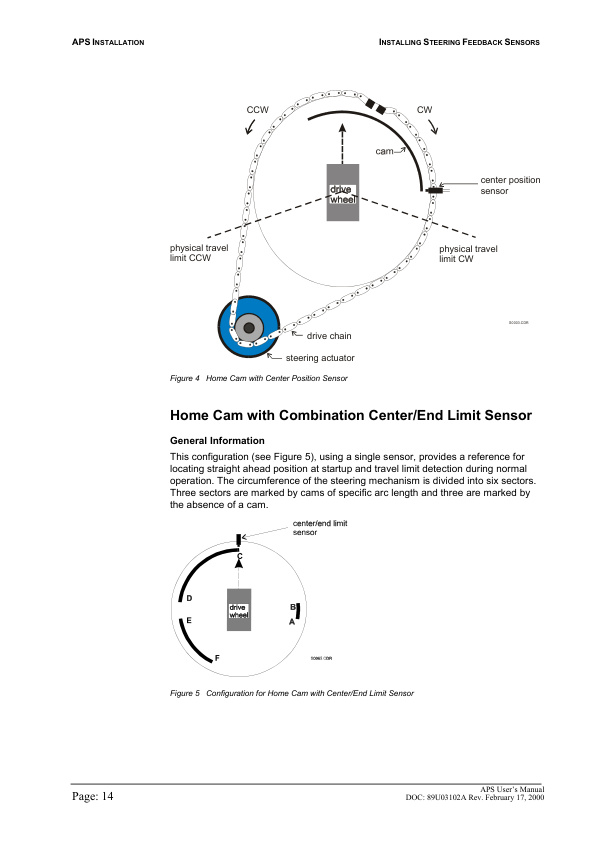

- 12.3.2.3. Home Cam with Center Position Sensor

- 12.3.2.4. Home Cam with Combination Center/End Limit Sensor

- 12.3.3. Installing Steering Input Sensors

- 12.3.3.1. Introduction

- 12.3.3.2. Stepper Motor

- 12.3.3.3. Joystick or Potentiometer

- 12.3.3.4. Encoder

- 12.3.4. Wiring the APS

- 12.3.4.1. Introduction

- 12.3.4.2. Tools and Equipment Required

- 12.3.4.3. Wiring the APS Mating Connector

- 12.3.4.4. Battery Power Connections

- 12.3.4.5. Sensor, Safety and Communications Wiring

- 12.3.4.6. Actuator to Separately Mounted Controller Cabling

- 12.4. Startup and Commissioning

- 12.4.1. Initial Startup

- 12.4.1.1. General Information

- 12.4.1.2. Checks Prior to Initial Powerup

- 12.4.1.3. Verifying APS Unit Readiness for Operation

- 12.4.1.4. Configuring the APS for the Application

- 12.4.1.5. Operational Checks in Vehicle

- 12.5. Maintenance

- 12.5.1. Maintenance Procedures

- 12.5.1.1. Introduction

- 12.5.1.2. Periodic Inspection and Preventive Maintenance

- 12.5.1.3. Steering Feedback Calibration

- 12.5.2. APS Replacement Procedures

- 12.5.2.1. Safety Information

- 12.5.2.2. APS with Integrated Controller

- 12.5.2.3. APS with Separately Mounted Controller

- 12.6. Troubleshooting

- 12.6.1. Introduction

- 12.6.1.1. Terms and Definitions

- 12.6.1.2. Troubleshooting Data Available from APS

- 12.6.2. The Troubleshooting Guide

- 12.6.2.1. General

- 12.6.2.2. Using the Troubleshooting Guide

- 12.6.2.3. General Troubleshooting Procedure

- 12.6.2.4. Information for OEMs Preparing User Documentation

- 12.6.2.5. LED status Indicator is Off

- 12.6.2.6. High Current Error

- 12.6.2.7. Voltage Error

- 12.6.2.8. High Temp Error

- 12.6.2.9. Watchdog Reset

- 12.6.2.10. Hardware Power Protection Trip

- 12.6.2.11. Safety Out Error

- 12.6.2.12. Steer Sensor Error

- 12.6.2.13. Switch Error

- 12.6.2.14. Feedback Sensor Error

- 12.6.2.15. EEPROM Error

- 12.6.2.16. Motor Error

- 12.6.2.17. Position Error

- 12.6.2.18. Communications Timeout Error

- 13.

- 13.1. Table of Contents

- 13.2. Introduction

- 13.2.1. About CANION Documentation

- 13.2.1.1. Scope of this Manual

- 13.3. Technical Description

- 13.3.1. Principles of Operation

- 13.3.1.1. Introduction

- 13.3.1.2. Introduction

- 13.3.1.3. CANION Software

- 13.4. Applications

- 13.4.1. Order Picker

- 13.4.2. Order Picker

- 13.4.2.1. Reach Truck

- 13.5. Interfacing to CANION

- 13.5.1. Interfacing Input Devices

- 13.5.1.1. General

- 13.5.2. Interfacing Input Devices

- 13.5.2.1. PWM Outputs

- 13.5.3. Interfacing Output Devices

- 13.5.3.1. Interfacing CANION in a Truck Can Network

- 13.5.4. Can Bus Communications

- 13.5.4.1. General Configuration

- 13.6. Installation and Wiring

- 13.6.1. CANION Installation

- 13.6.1.1. Mounting CANION in a Vehicle

- 13.6.2. CANION Installation

- 13.6.2.1. Introduction

- 13.7. Specifications

- 13.7.1. Electrical Power Inputs Outputs

- 14. _A-01_Foreword

- 15. _A-02_How to read this manual

- 16. _A-03_Safety instructions

- 17. _A-04_General information

- 18. _A-05_Forks

- 19. _A-06_Electrical operation

- 20. _A-07_Battery maintenance

- 21. _A-08_Electric system maintenance

- 22. _A-09_Parameter lists

- 23. _A-10_Fault and state reports

- 24. _A-11_Technical data

- 25. _A-12_Annex

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

$50.00