Mitsubishi S4S-E35AFL(F) Diesel Engine Service Manual SMEEG-CF14J-230

$50.00

- Type Of Manual: Service Manual

- Manual ID: SMEEG-CF14J-230

- Number of Pages: 222

- Size: 9.3MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- S4S-E35AFL(F) Diesel Engine

- 1. BINDING

- 2. INTRODUCTION

- 2.1. How to use this manual

- 2.1.1. Methods of presentation

- 2.1.2. Terms used in this manual

- 2.1.3. Abbreviations

- 2.1.4. Units of measurement

- 2.2. Safety Cautions

- 2.2.1. Fire and explosion

- 2.2.2. Stay clear of all rotating and moving parts

- 2.2.3. Be careful of burns

- 2.2.4. Be careful of exhaust fume poisoning

- 2.2.5. Protect ears from noises

- 2.2.6. Be careful of falling down

- 2.2.7. Be careful of handling fuel, engine oil and LLC

- 2.2.8. Service battery

- 2.2.9. When abnormality occurs

- 2.2.10. Other cautions

- 2.2.11. About warning labels

- 3. GENERAL CONTENTS

- 4. GENERAL

- 4.1. External view (in-line fuel injection pump and distributor-type fuel injection pump)

- 4.1.1. S4S in-line fuel injection pump specification

- 4.1.2. S4S-DT in-line fuel injection pump specification

- 4.1.3. S4S distributor-type fuel injection pump specification

- 4.1.4. S4S-DT distributor-type fuel injection pump specification

- 4.2. System flow diagrams

- 4.2.1. Fuel system – flow diagram

- 4.2.2. Lubrication system – flow diagram

- 4.2.3. Cooling system – flow diagram

- 4.2.4. Inlet and exhaust system – flow diagram

- 4.3. Engine serial number location

- 4.4. Main specifications

- 4.4.1. S4S in-line fuel injection pump specification (varies depending on the specification)

- 4.4.2. S4S distributor-type fuel injection pump specification (varies depending on the specification)

- 4.5. Tips on disassembling and reassembling

- 4.5.1. Disassembling

- 4.5.2. Reassembling

- 5. SERVICE DATA

- 5.1. Maintenance service data

- 5.1.1. General

- 5.1.2. Basic engine

- 5.1.3. Fuel system

- 5.1.4. Lubrication system

- 5.1.5. Cooling system

- 5.1.6. Inlet and exhaust system

- 5.1.7. Electrical system

- 5.2. Tightening torque table

- 5.2.1. Major bolt tightening torque

- 5.2.2. Standard bolt and nut tightening torque

- 5.2.3. Standard stud tightening torque

- 6. SERVICE TOOLS

- 6.1. Special tool

- 7. DETERMINATION OF OVERHAUL

- 7.1. Determining overhaul timing

- 7.2. Testing compression pressure

- 8. DISASSEMBLY OF BASIC ENGINE

- 8.1. Disassembling and inspecting cylinder head and valve mechanism

- 8.1.1. Removing rocker shaft assembly

- 8.1.2. Disassembling rocker shaft assembly

- 8.1.3. Removing cylinder head bolt

- 8.1.4. Removing cylinder head assembly

- 8.1.5. Removing valve and valve spring

- 8.1.6. Removing valve stem seal

- 8.2. Disassembling and inspecting flywheel

- 8.2.1. Removing flywheel

- 8.2.2. Removing flywheel housing

- 8.3. Disassembling and inspecting gear case, timing gear and camshaft

- 8.3.1. Removing crankshaft pulley

- 8.3.2. Removing cover

- 8.3.3. Removing timing gear case

- 8.3.4. Measuring timing gear backlash

- 8.3.5. Measuring idler gear and camshaft gear end play

- 8.3.6. Removing fuel injection pump

- 8.3.7. Removing oil pan

- 8.3.8. Removing oil strainer

- 8.3.9. Removing oil pump gear

- 8.3.10. Removing idler gear

- 8.3.11. Removing camshaft

- 8.3.12. Separating camshaft gear

- 8.3.13. Installing camshaft gear and thrust plate

- 8.3.14. Removing front plate

- 8.3.15. Removing oil pump

- 8.4. Disassembling and inspecting piston, connecting rod, crankshaft and crankcase

- 8.4.1. Removing connecting rod cap

- 8.4.2. Removing carbon deposits from the upper part of cylinder

- 8.4.3. Pulling out piston

- 8.4.4. Removing piston ring

- 8.4.5. Removing piston pin and piston

- 8.4.6. Removing main bearing cap

- 8.4.7. Removing crankshaft

- 8.4.8. Removing tappet

- 9. INSPECTION AND REPAIR OF BASIC ENGINE

- 9.1. Inspecting and repairing cylinder head and valve mechanism

- 9.1.1. Measuring clearance between rocker bushing and rocker shaft

- 9.1.2. Measuring valve stem outside diameter and valve guide inside diameter

- 9.1.3. Replacing valve guide

- 9.1.4. Inspecting valve face

- 9.1.5. Refacing valve face

- 9.1.6. Refacing valve seat

- 9.1.7. Replacing valve seat

- 9.1.8. Lapping valve and valve seat

- 9.1.9. Measuring perpendicularity and free length of valve spring

- 9.1.10. Measuring distortion of the bottom surface of the cylinder head

- 9.1.11. Measuring pushrod runout

- 9.1.12. Removing combustion jet

- 9.2. Inspecting and repairing flywheel

- 9.2.1. Measuring flatness of flywheel

- 9.2.2. Measuring flywheel face and radial runouts

- 9.2.3. Inspecting ring gear

- 9.2.4. Replacing ring gear

- 9.3. Inspecting and repairing timing gear and camshaft

- 9.3.1. Measuring timing gear backlash

- 9.3.2. Measuring idler gear and camshaft gear end play

- 9.3.3. Measuring cam lift

- 9.3.4. Measuring camshaft runout

- 9.3.5. Measuring camshaft journal outside diameter

- 9.3.6. Measuring camshaft hole (bushing) inside diameter

- 9.3.7. Replacing camshaft bushing

- 9.3.8. Measuring idler bushing inside diameter and idler shaft outside diameter

- 9.3.9. Replacing idler shaft

- 9.3.10. Measuring clearance between tappet and tappet guide hole

- 9.3.11. Inspecting tappet

- 9.3.12. Inspecting V-belt groove wear

- 9.4. Inspecting and repairing piston, connecting rod, crankshaft and crankcase

- 9.4.1. Measuring crankcase top surface distortion

- 9.4.2. Measuring cylinder inside diameter

- 9.4.3. Measuring piston outside diameter

- 9.4.4. Measuring piston ring end gap

- 9.4.5. Measuring clearance between piston ring groove and piston ring

- 9.4.6. Measuring piston pin bore diameter and piston pin outside diameter

- 9.4.7. Measuring piston protrusion

- 9.4.8. Measuring clearance between connecting rod bearing and crankpin

- 9.4.9. Measuring clearance between connecting rod bushing and piston pin

- 9.4.10. Replacing connecting rod bushing

- 9.4.11. Inspecting connecting rod bend and twist

- 9.4.12. Inspecting connecting rod bearing

- 9.4.13. Measuring connecting rod end play

- 9.4.14. Weight difference of connecting rod assembly in one engine

- 9.4.15. Measuring crankshaft journal outside diameter

- 9.4.16. Measuring crankshaft crankpin outside diameter

- 9.4.17. Grinding crankshaft

- 9.4.18. Measuring crankshaft end play

- 9.4.19. Measuring crankshaft runout

- 9.4.20. Replacing crankshaft gear

- 9.4.21. Inspecting oil seal contact surface

- 9.4.22. Installing oil seal sleeve

- 9.4.23. Removing oil seal sleeve

- 9.4.24. Inspecting main bearing surface

- 9.4.25. Measuring clearance between main bearing and crankshaft journal

- 10. REASSEMBLY OF BASIC ENGINE

- 10.1. Reassembling piston, connecting rod, crankshaft and crankcase

- 10.1.1. Installing main bearing

- 10.1.2. Installing thrust plate

- 10.1.3. Installing tappet

- 10.1.4. Installing crankshaft

- 10.1.5. Installing main bearing caps

- 10.1.6. Inserting side seal

- 10.1.7. Installing main bearing cap bolt

- 10.1.8. Measuring crankshaft end play

- 10.1.9. Reassembling piston and connecting rod

- 10.1.10. Installing piston ring

- 10.1.11. Preparation for installing pistons

- 10.1.12. Installing connecting rod bolt and connecting rod bearing

- 10.1.13. Installing pistons

- 10.1.14. Installing connecting rod cap

- 10.2. Reassembling timing gear and camshaft

- 10.2.1. Installing oil pump

- 10.2.2. Installing front plate

- 10.2.3. Installing camshaft gear and thrust plate

- 10.2.4. Installing camshaft

- 10.2.5. Installing idler gear

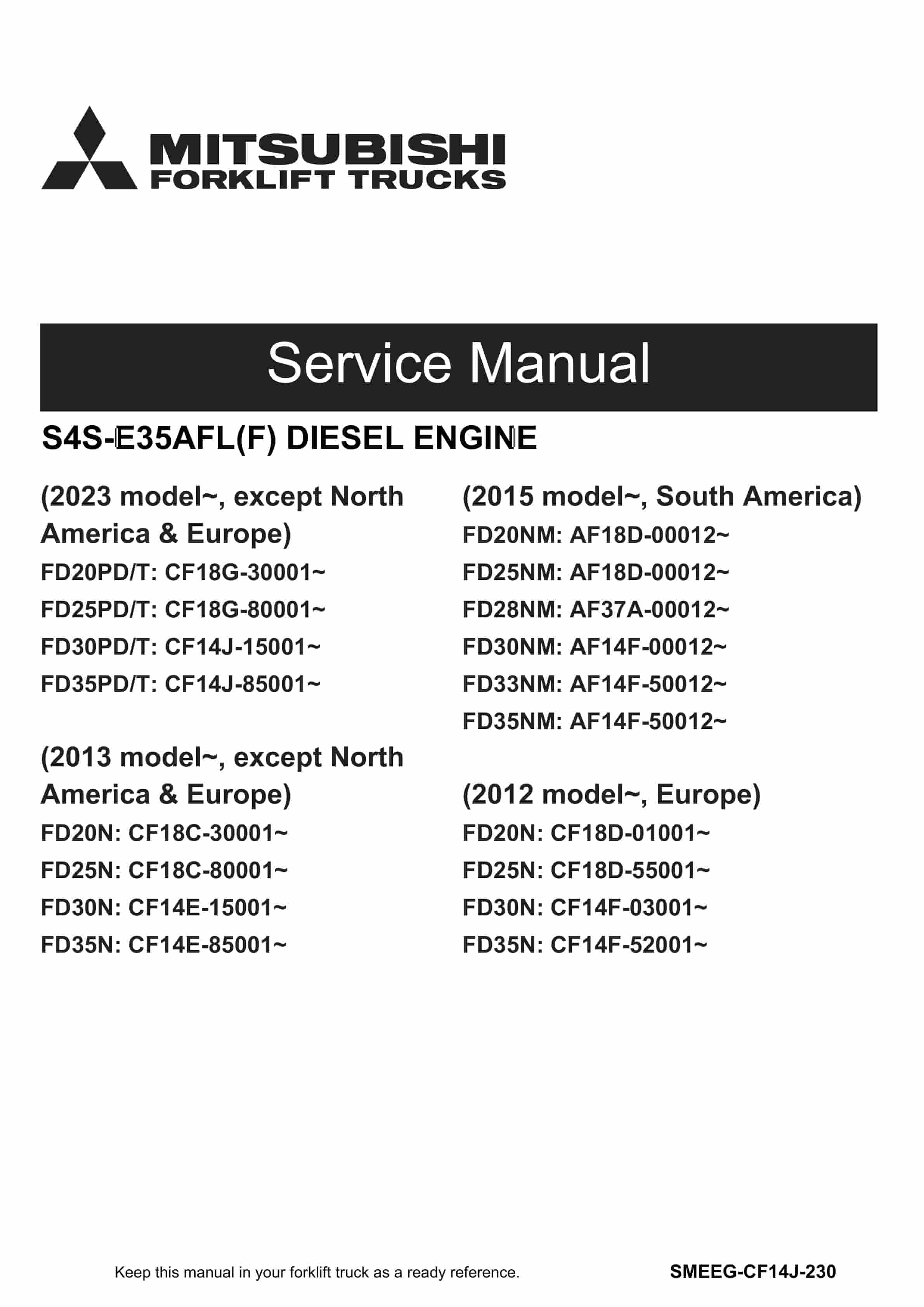

- 10.2.6. Installing oil pump gear

- 10.2.7. Installing fuel injection pump

- 10.2.8. Inspecting and adjusting timing gear after installation

- 10.2.9. Installing front oil seal

- 10.2.10. Installing timing gear case

- 10.2.11. Installing oil strainer

- 10.2.12. Installing oil pan

- 10.2.13. Installing cover

- 10.2.14. Installing crankshaft pulley

- 10.3. Reassembling flywheel

- 10.3.1. Installing oil seal

- 10.3.2. Installing flywheel housing

- 10.3.3. Installing flywheel

- 10.4. Reassembling cylinder head and valve mechanism

- 10.4.1. Cleaning cylinder head bottom surface

- 10.4.2. Installing valve stem seal

- 10.4.3. Installing valve and valve spring

- 10.4.4. Installing cylinder head gasket

- 10.4.5. Installing cylinder head assembly

- 10.4.6. Tightening cylinder head bolts

- 10.4.7. Inserting pushrod

- 10.4.8. Reassembling rocker shaft assembly

- 10.4.9. Installing rocker shaft assembly

- 10.4.10. Determining top dead center of No.1 cylinder compression stroke

- 10.4.11. Adjusting valve clearance

- 10.4.12. Installing rocker cover

- 11. FUEL SYSTEM

- 11.1. Removing fuel system

- 11.1.1. Removing fuel filter and fuel pipe

- 11.1.2. Removing fuel injection pipe, fuel leak-off pipe and fuel injection nozzle

- 11.1.3. Removing fuel injection pump

- 11.2. Disassembling, inspecting and reassembling fuel system

- 11.2.1. Disassembling and inspecting fuel filter (in-line type fuel injection pump)

- 11.2.2. Disassembling and inspecting fuel filter

- 11.2.3. Changing fuel filter

- 11.2.4. Disassembling and inspecting fuel injection nozzle (swirl chamber type)

- 11.2.5. Disassembling and inspecting fuel injection nozzle (direct injection type)

- 11.2.6. Inspecting and adjusting fuel injection valve opening pressure

- 11.2.7. Inspecting fuel spray pattern of fuel injection nozzle

- 11.2.8. Cleaning and inspecting nozzle tip

- 11.2.9. Reassembling fuel injection nozzle (swirl chamber type)

- 11.2.10. Reassembling fuel injection nozzle (direct injection type)

- 11.2.11. Inspecting and cleaning gauze filter of distribute type fuel injection pump (Bosch)

- 11.3. Installing fuel system

- 11.3.1. Installing fuel injection pump

- 11.3.2. Checking fuel injection timing (in-line fuel injection pump type)

- 11.3.3. Inspecting fuel injection timing (distributor-type fuel injection pump)

- 11.3.4. Installing fuel injection pipe, fuel leak-off pipe and fuel injection nozzle

- 11.3.5. Installing fuel filter and fuel pipe

- 12. LUBRICATION SYSTEM

- 12.1. Removing lubrication system

- 12.1.1. Removing oil filter and relief valve

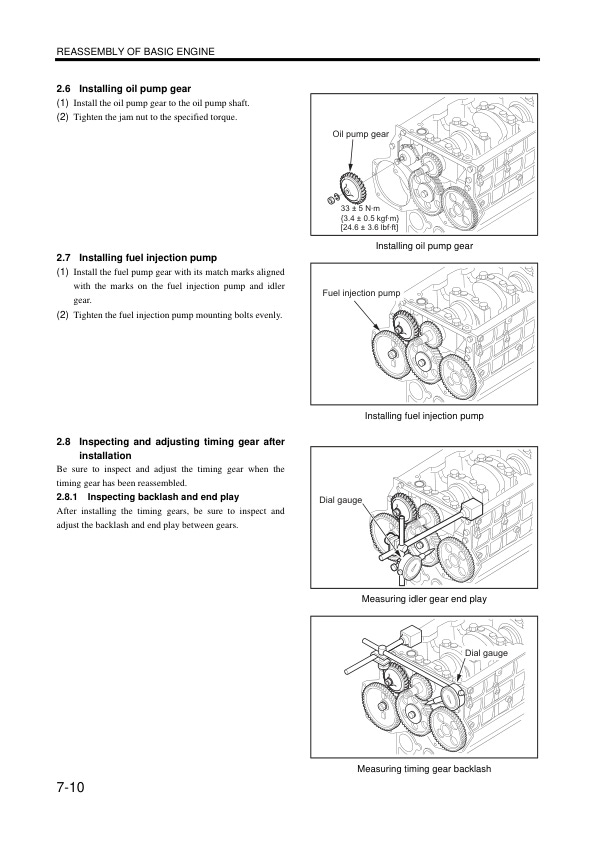

- 12.1.2. Removing oil cooler

- 12.1.3. Removing oil pump, oil pan and oil strainer

- 12.2. Disassembling, inspecting and reassembling lubrication system

- 12.2.1. Disassembling and inspecting oil pump

- 12.2.2. Inspecting oil pump

- 12.2.3. Reassembling oil pump

- 12.2.4. Disassembling and inspecting oil cooler

- 12.2.5. Inspecting oil filter

- 12.2.6. Inspecting relief valve

- 12.2.7. Inspecting safety valve (for the engine with oil cooler)

- 12.3. Installing lubrication system

- 12.3.1. Installing oil pump, oil pan and oil strainer

- 12.3.2. Installing oil cooler

- 12.3.3. Installing oil filter and relief valve

- 13. COOLING SYSTEM

- 13.1. Removing cooling system

- 13.1.1. Removing cooling fan, fan pulley and V-belt

- 13.1.2. Removing thermostat

- 13.1.3. Removing water pump

- 13.2. Disassembling, inspecting and reassembling cooling system

- 13.2.1. Disassembling and inspecting thermostat

- 13.2.2. Inspecting thermostat

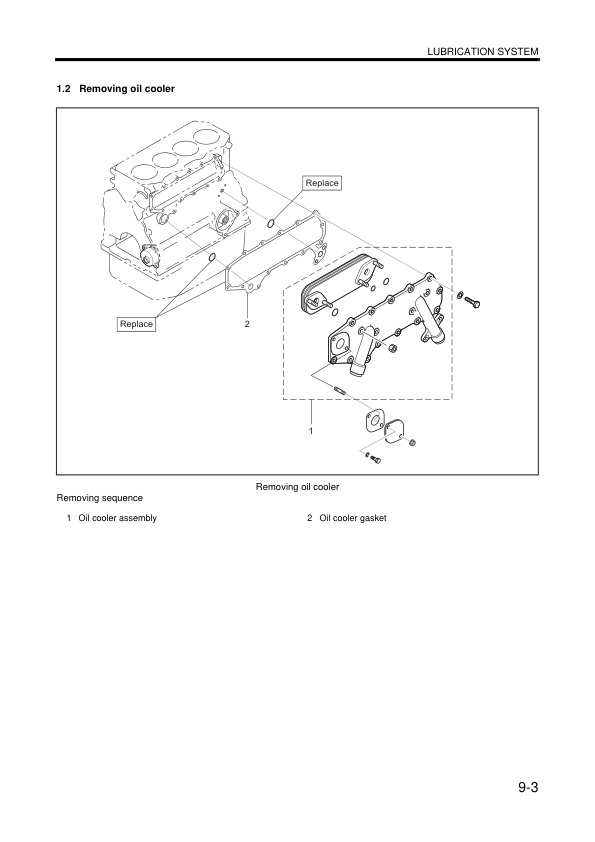

- 13.2.3. Disassembling water pump

- 13.2.4. Inspecting water pump

- 13.3. Installing cooling system

- 13.3.1. Installing water pump

- 13.3.2. Installing thermostat

- 13.3.3. Installing cooling fan, fan pulley and V-belt

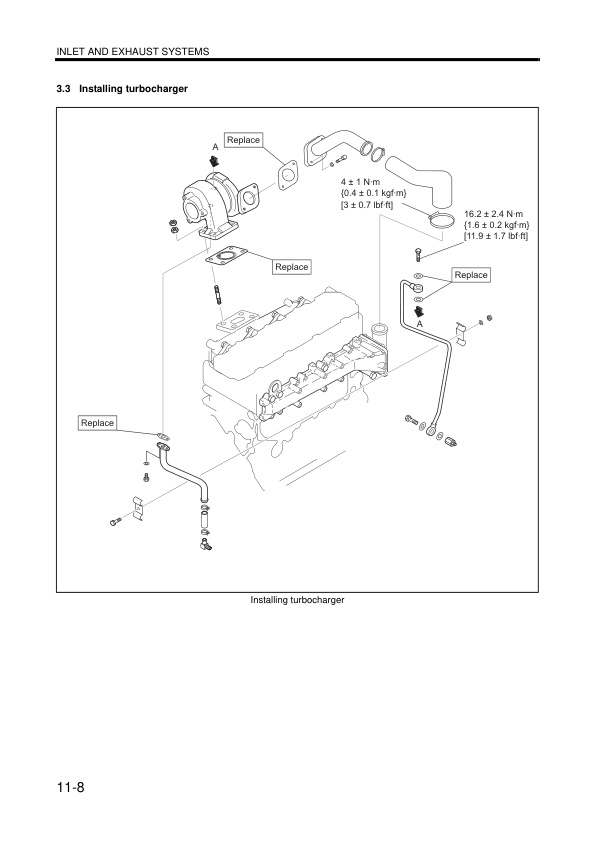

- 14. INLET AND EXHAUST SYSTEMS

- 14.1. Removing turbocharger, inlet and exhaust systems

- 14.1.1. Removing turbocharger

- 14.1.2. Removing inlet manifold

- 14.1.3. Removing exhaust manifold

- 14.2. Disassembling, inspecting and reassembling inlet and exhaust systems

- 14.2.1. Measuring exhaust manifold distortion

- 14.3. Installing turbocharger, inlet and exhaust systems

- 14.3.1. Installing exhaust manifold

- 14.3.2. Installing inlet manifold

- 14.3.3. Installing turbocharger

- 15. ELECTRICAL SYSTEM

- 15.1. Removing electrical system

- 15.1.1. Removing starter

- 15.1.2. Inspection before removing alternator

- 15.1.3. Removing alternator (12V-50A)

- 15.1.4. Removing alternator (12V-75A, option)

- 15.1.5. Removing glow plug

- 15.2. Disassembling, inspecting and reassembling electrical system

- 15.2.1. Inspection before disassembling starter

- 15.2.2. Disassembling and inspecting starter

- 15.2.3. Inspecting and repairing starter

- 15.2.4. Reassembling starter

- 15.2.5. Disassembling and inspecting alternator

- 15.2.6. Inspecting and repairing alternator

- 15.2.7. Reassembling alternator

- 15.2.8. Heating test of glow plug

- 15.2.9. Inspecting air heater

- 15.2.10. Inspecting magnetic valve (stop solenoid, distributor-type)

- 15.2.11. Installing magnetic valve (stop solenoid)

- 15.2.12. Installing stop solenoid (RUN-ON type, for in-line pump type)

- 15.3. Installing electrical system

- 15.3.1. Installing glow plug

- 15.3.2. Installing alternator (12V-50A)

- 15.3.3. Installing alternator (12V-75A, option)

- 15.3.4. Installing starter

- 16. ADJUSTMENT AND OPERATION

- 16.1. Adjusting engine

- 16.1.1. Inspecting and adjusting valve clearance

- 16.1.2. Draining fuel system

- 16.1.3. Bleeding fuel system

- 16.1.4. Inspecting V-belt and adjusting V-belt tension

- 16.1.5. Inspecting V-belt

- 16.1.6. Adjusting V-belt tension

- 16.2. Break-in operation

- 16.2.1. Starting up

- 16.2.2. Inspecting engine condition after starting up

- 16.2.3. Break-in operation time

- 16.2.4. Inspection and adjustment after break-in operation

- 16.3. Performance test (JIS standard)

Rate this product

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-56103

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

$50.00