Caterpillar EP10CB-35CB Mechanical Systems Service Manual SCKEM-J22C0-203

$50.00

- Type Of Manual: Service Manual

- Manual ID: SCKEM-J22C0-203

- Number of Pages: 290

- Size: 35.6MB

- Format: PDF

-

Model List:

- EP10CB, EP15CB, EP18CB, EP20CB, EP25CB, EP20LCB, EP25LCB, EP30CB, EP35CB

- 1. FOREWORD

- 2. GENERAL INFORMATION

- 2.1. HOW TO USE THIS MANUAL

- 2.1.1. Outline of This Manual

- 2.1.2. Description

- 2.1.3. Technical Term Definitions

- 2.1.4. Symbols Used in Exploded Views

- 2.2. IDENTIFICATION INFORMATION

- 2.2.1. Model Classification Number

- 2.2.2. Identification Number

- 2.3. DANGER / WARNING / CAUTION AND INSTRUCTION LABELS

- 2.3.1. Layout

- 2.3.2. Danger / Warning / Caution Labels

- 2.3.3. Instruction Label

- 2.4. TRUCK SPECIFICATIONS

- 2.5. UNIT SPECIFICATIONS

- 2.5.1. Front Axle

- 2.5.2. Reduction Gear and Differential Gear

- 2.5.3. Rear Axle

- 2.5.4. Brake System

- 2.5.5. Steering System

- 2.5.6. Hydraulic System

- 3. ANZEN (SAFETY)

- 3.1. SAFETY INSTRUCTIONS

- 3.1.1. Introduction

- 3.1.2. Protective Gear

- 3.1.3. Organize the Work Area

- 3.1.4. Maintenance Precautions (Before Starting to Work)

- 3.1.5. Maintenance Precautions (While Working)

- 3.1.6. When Working in a Group

- 3.1.7. Maintenance Precautions (After Servicing)

- 3.1.8. Modifications to the Truck Might Void Your Warranty

- 3.1.9. Implementation of Modifications

- 3.1.10. Jacking Up or Hoisting the Truck

- 3.1.11. Removing and Reinstalling Tires and Rims

- 3.1.12. Mast Inspection

- 3.1.13. Electrical System

- 3.1.14. Fire Hazards

- 3.1.15. Transporting

- 3.1.16. Others

- 3.2. BASIC SERVICING KNOWLEDGE

- 3.2.1. Jacking

- 3.2.2. Towing

- 3.2.3. Lifting

- 3.2.4. Installing Bearings

- 3.2.5. O-rings

- 3.2.6. Oil Seals

- 3.2.7. Snap Rings

- 3.2.8. Using Loctite and ThreeBond

- 3.2.9. Cleaning

- 3.3. STANDARD BOLT TIGHTENING TORQUE

- 4. MAINTENANCE

- 4.1. LUBRICATION

- 4.1.1. Lubrication Schedule Chart

- 4.1.2. Lubrication and Quantity

- 4.2. PERIODIC INSPECTIONS

- 4.3. PERIODIC MAINTENANCE SCHEDULE

- 4.4. PRE-OPERATION INSPECTION (DAILY INSPECTION)

- 4.5. INSPECTION WORK

- 4.5.1. Opening and Closing the Battery Cover

- 4.5.2. Exchanging of Battery

- 4.5.3. Fuse

- 4.5.4. Replacement of Brake Fluid

- 4.5.5. Replacement of Hydraulic Oil

- 4.5.6. Replacement and Cleaning of Filter

- 4.5.7. Lubrication Point

- 4.5.8. Greasing Point

- 4.6. SERVICE DATA

- 5. TROUBLESHOOTING

- 5.1. FRONT AXLE (INCLUDING FRONT WHEELS)

- 5.1.1. Axle

- 5.1.2. Reduction Gear and Differential Gear

- 5.2. REAR AXLE (INCLUDING REAR WHEELS)

- 5.3. BRAKE SYSTEM

- 5.3.1. Service Brake

- 5.3.2. Parking Brake

- 5.4. STEERING SYSTEM

- 5.5. HYDRAULIC SYSTEM

- 5.5.1. Hydraulic Pump (Gear Pump)

- 5.5.2. Control Valve

- 5.5.3. Tilt Cylinder

- 5.5.4. Relief Valve

- 5.5.5. Lift (Mast) Cylinder

- 5.6. LOADING SYSTEM

- 6. REMOVAL INSTALLATION

- 6.1. SERVICE INFORMATION

- 6.2. SERVICE DATA

- 6.2.1. Tightening Torque

- 6.2.2. Adjustment Value

- 6.3. FORK

- 6.3.1. Removal

- 6.3.2. Installation

- 6.4. LIFT BRACKET

- 6.4.1. Removal

- 6.4.2. Installation

- 6.4.3. Adjustment

- 6.5. MAST

- 6.5.1. Removal

- 6.5.2. Installation

- 6.6. FLOOR

- 6.6.1. Removal

- 6.6.2. Installation

- 6.7. COVERS

- 6.7.1. Removal

- 6.7.2. Installation

- 6.8. BATTERY

- 6.8.1. Removal

- 6.8.2. Installation

- 6.9. SEAT

- 6.9.1. Removal

- 6.9.2. Installation

- 6.10. BATTERY COVER

- 6.10.1. Removal

- 6.10.2. Installation

- 6.11. OVERHEAD GUARD

- 6.11.1. Removal

- 6.11.2. Installation

- 6.12. TILT CYLINDER

- 6.12.1. Removal

- 6.12.2. Installation

- 6.13. HYDRAULIC PUMP

- 6.13.1. Removal

- 6.13.2. Installation

- 6.14. HYD MOTOR

- 6.14.1. Removal

- 6.14.2. Installation

- 6.15. TRV MOTOR

- 6.15.1. Removal

- 6.15.2. Installation

- 6.16. FRONT TIRE

- 6.16.1. Removal

- 6.16.2. Installation

- 6.17. FRONT AXLE

- 6.17.1. Removal

- 6.17.2. Installation

- 6.18. HYDRAULIC OIL TANK

- 6.18.1. Removal

- 6.18.2. Installation

- 6.19. COUNTERWEIGHT

- 6.19.1. Removal

- 6.19.2. Installation

- 6.20. REAR TIRE

- 6.20.1. Removal

- 6.20.2. Installation

- 6.21. REAR AXLE

- 6.21.1. Removal

- 6.21.2. Installation

- 6.22. CONTROLLERS

- 6.22.1. Removal

- 6.22.2. Installation

- 6.23. TRANSFORMER (OPTION BUILT-IN CHARGER)

- 6.23.1. Removal

- 6.23.2. Installation

- 6.24. PS PUMP

- 6.24.1. Removal

- 6.24.2. Installation

- 6.25. PS MOTOR

- 6.25.1. Removal

- 6.25.2. Installation

- 7. FRONT AXLE

- 7.1. SERVICE DATA

- 7.1.1. Tightening torque

- 7.1.2. Adjustment value

- 7.2. CONSTRUCTION

- 7.2.1. to 1.75 ton

- 7.2.2. , 2.5 ton

- 7.2.3. , 3.5 ton

- 7.2.4. Front Axle

- 7.2.5. Reduction Gear and Differential Gear (ASSY)

- 7.3. FRONT AXLE ASSY

- 7.3.1. Disassembly Drawing

- 7.3.2. Removal

- 7.3.3. Inspection

- 7.3.4. Installation

- 7.4. REDUCTION GEAR AND DIFFERENTIAL GEAR (ASSY)

- 7.4.1. Disassembly Drawing

- 7.4.2. Disassembly

- 7.4.3. Assembly

- 7.4.4. Inspection

- 7.5. INSPECTION AND REPLACEMENT OF FRONT AXLE OIL

- 7.5.1. Oil Level Check

- 7.5.2. OIl Replacement and Refillment

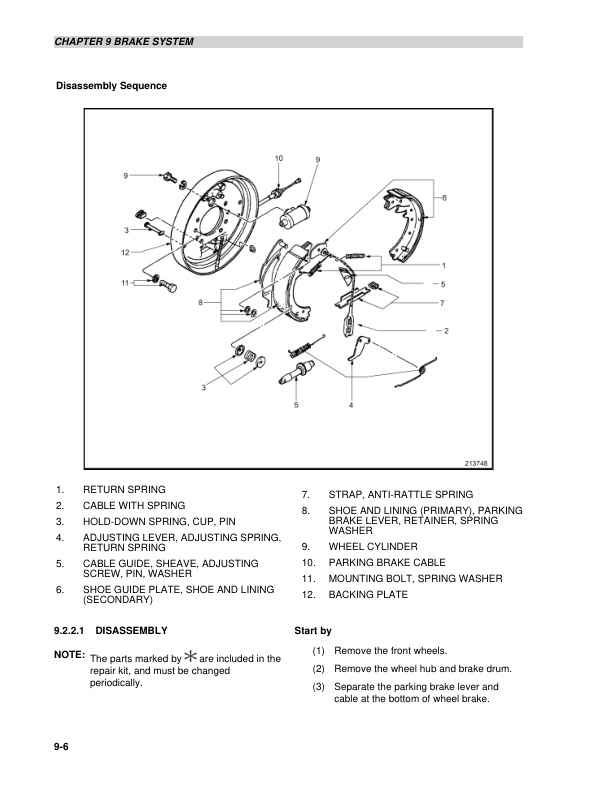

- 8. BRAKE SYSTEM

- 8.1. SERVICE DATA

- 8.1.1. Adjusting Value

- 8.1.2. Tightening Torque

- 8.2. SERVICE INFORMATION

- 8.3. SERVICE BRAKE

- 8.3.1. Construction

- 8.3.2. Disassembly

- 8.3.3. Inspection

- 8.3.4. Installation

- 8.3.5. Adjustment

- 8.4. BRAKE PEDAL

- 8.4.1. Layout

- 8.4.2. Removal and Installation

- 8.4.3. Adjustment

- 8.4.4. Construction

- 8.4.5. Disassembly and Assembly

- 8.4.6. Adustment and Inspection

- 8.5. MASTER CYLINDER

- 8.5.1. Disassembly Drawing

- 8.5.2. Inspection

- 8.6. BRAKE PIPING

- 8.6.1. Layout

- 8.6.2. Inspection

- 8.6.3. Adjustment

- 8.7. PARKING BRAKE

- 8.7.1. Layout

- 8.7.2. Inspection

- 8.7.3. Adjustment

- 9. STEERING SYSTEM

- 9.1. SERVICE DATA

- 9.1.1. Tightening Torque

- 9.1.2. Adjustment Value

- 9.2. SERVICE INFORMATION

- 9.3. STEERING LINKAGE

- 9.3.1. Layout

- 9.3.2. Exploded Views

- 9.3.3. Wheel

- 9.3.4. Gas Spring

- 9.4. PS HYDRAULIC PIPING

- 9.4.1. Layout

- 9.4.2. Precautions

- 9.5. HYDRAULIC SYSTEM

- 9.5.1. PS Valve

- 9.5.2. PS Correction Valve

- 9.5.3. PS Cylinder

- 9.5.4. PS Pump

- 9.6. INSPECTION OF HYDRAULIC PRESSURE

- 9.6.1. Preparation Work

- 9.6.2. Inspection

- 10. REAR AXLE

- 10.1. SERVICE DATA

- 10.1.1. Standard value

- 10.1.2. Tightening torque

- 10.1.3. Adjustment

- 10.2. REAR AXLE HUB

- 10.2.1. Disassembly

- 10.2.2. Inspection

- 10.2.3. Assembly

- 10.2.4. Adjustment

- 10.3. TIE ROD

- 10.3.1. Disassembly

- 10.3.2. Inspection

- 10.3.3. Reassembly

- 10.4. KNUCKLE, KING PIN, TIRE ANGLE SENSOR

- 10.4.1. Disassembly

- 10.4.2. Inspection

- 10.4.3. Assembly

- 10.4.4. Adjustment

- 10.5. STEERING CYLINDER

- 10.5.1. Disassembly

- 10.5.2. Inspection

- 10.5.3. Reassembly

- 11. HYDRAULIC SYSTEM

- 11.1. SERVICE DATA

- 11.1.1. Hydraulic Oil and Oil Level

- 11.1.2. Accumulator (Smooth Running System) Specification

- 11.1.3. Adjustment Value

- 11.1.4. Tightening Torque

- 11.2. SERVICE INFORMATION

- 11.3. HYDRAULIC CIRCUIT DIAGRAM

- 11.3.1. Standard Specification

- 11.3.2. Proportional Valve Specification

- 11.3.3. Smooth Running System and Automatic Tilt Horizontal Stop Specifications (Optional)

- 11.3.4. Attachment Specification

- 11.4. HYDRAULIC PIPING

- 11.4.1. Layout

- 11.4.2. Piping Components

- 11.4.3. Accumulator COMP.

- 11.4.4. Inspection

- 11.5. HYDRAULIC PUMP

- 11.5.1. External View

- 11.5.2. Service Information

- 11.6. CONTROL VALVE

- 11.6.1. External View

- 11.6.2. Construction

- 11.6.3. Removal and Reinstallation

- 11.6.4. Disassembly and Reassembly

- 11.7. HYD LEVER

- 11.7.1. Standard Lever

- 11.7.2. Single Hydraulic Lever (Optional)

- 11.8. CYLINDERS

- 11.8.1. Tilt Cylinder

- 11.8.2. Lift Cylinder

- 11.8.3. Full-Free Cylinder (2F/3F Mast)

- 11.8.4. Bleeding

- 11.8.5. Down Safety Valve

- 11.9. INSPECTION AND ADJUSTMENT

- 11.9.1. In Case of Emergency (Forks/Mast Cannot Be Lowered)

- 11.9.2. Hydraulic Pressure Inspection and Adjustment

- 11.9.3. Accumulator Inspection and Adjustment (Smooth Running System)

- 11.10. OPTIONAL EQUIPMENT

- 11.10.1. Layout

- 11.10.2. Relief Valve

- 12. LOADING MECHANISM

- 12.1. SERVICE DATA

- 12.1.1. Adjustment Value

- 12.1.2. Standard Value for Maintenance

- 12.1.3. Adjustment

- 12.1.4. Tightening Torque

- 12.2. FORK

- 12.2.1. Inspection

- 12.3. LIFT BRACKET

- 12.3.1. Disassembly

- 12.3.2. Inspection

- 12.3.3. Adjustment

- 12.3.4. Precautions When Assembling

- 12.4. MAST

- 12.4.1. Disassembly

- 12.4.2. Inspection

- 12.4.3. Assembly

- 12.4.4. Adjustment

- 12.4.5. Inspection of Natural Drop and Natural Tilt

Caterpillar Service Manual PDF

Caterpillar 1.4 Liter (4G33) Gasoline Engine Service Manual SENB8525

Caterpillar Service Manual PDF

Caterpillar 5V15D to 5V35D Mast Supplement Service Manual 99739-351S0

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Troubleshooting Service Manual 99799-67104

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Operation and Maintenance Manual Service Manual 99799-67105

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-85100

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Specifications Service Manual 99799-64101

Caterpillar Service Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110

Caterpillar Service Manual PDF

Caterpillar 5M15D to 5M35D Mast Supplement Service Manual 99739-351T0