Caterpillar NOL10P, NOM10P, NOH12PH Service Manual SM20GBEPC3

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM20GBEPC3

- Number of Pages: 376

- Size: 15.5MB

- Format: PDF

-

Model List:

- NOL10P, NOM10P, NOH12PH

- 1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1. Introduction

- 1.1.1. General

- 1.1.2. The trucks

- 1.1.3. Genuine Parts

- 1.1.4. Authorised service personnel.

- 1.1.5. Symbol key

- 1.2. Safety

- 1.2.1. General

- 1.2.2. Safety instructions

- 1.2.3. Truck modification

- 1.2.4. Lifting the truck

- 1.2.5. Welding on truck

- 1.3. Environmental considerations

- 1.3.1. We respect the environment

- 1.4. Preparations

- 1.4.1. Service

- 1.4.2. Troubleshooting

- 1.5. Truck data

- 1.5.1. Machine plates

- 1.5.2. Safety and warning signs

- 1.5.3. Type designation

- 1.5.4. Truck types

- 1.5.5. Dimensions and weights

- 1.6. Component placement

- 1.6.1. NOL10P

- 1.6.2. NOM10P

- 1.6.3. NOH12PH

- 1.7. Component specification

- 1.7.1. Drive motor

- 1.7.2. Electric brake

- 1.7.3. Gearbox

- 1.7.4. Hydraulic unit

- 1.7.5. Control system for traction and pump motors

- 1.7.6. Steering servo motor

- 1.7.7. Controller system for steering

- 1.8. Recommended consumable materials

- 1.8.1. Oil and grease types

- 1.9. Standards and abbreviations

- 1.9.1. General

- 1.9.2. Screw types and tensile grades

- 1.9.3. Tightening torques for screws and nuts

- 1.9.4. Tightening torque for hydraulic couplings

- 1.9.5. Tightening torque for banjo screws with rubber-steel washer

- 1.9.6. Tightening torque, conversion table

- 1.10. Code explanations

- 1.10.1. Colour coding according to NCS

- 1.10.2. Colour codes for wiring diagrams

- 1.10.3. Designations for electrical components in electrical diagram

- 1.10.4. Standard abbreviations and units

- 1.10.5. Acronyms and abbreviations

- 2. SPECIAL TOOLS

- 2.1. List of tools

- 3. SERVICE

- 3.1. Service inspection

- 3.1.1. Daily/Weekly inspection

- 3.1.2. General

- 3.1.3. First service (200 hours)

- 3.1.4. Service intervals

- 3.1.5. Verification of safety functions

- 3.1.6. Check list

- 3.2. Lubrication

- 3.2.1. Lubrication chart, symbol chart

- 4. CHASSIS

- 4.1. Design and function

- 4.1.1. Machine housing

- 4.1.2. Overhead guard

- 4.1.3. Battery locking

- 4.1.4. Covers and panels

- 4.2. Repair and maintenance instructions

- 4.2.1. Before work is performed

- 4.2.2. Removal and installation of the overhead guard

- 4.2.3. Panels and housing

- 4.2.4. Removal and installation of the battery rollers

- 4.2.5. Dismounting and installing the presence sensor in the operators platform

- 4.2.6. Tilt the truck before changing wheels

- 4.2.7. Load wheel replacement, NOL10P

- 4.2.8. Load wheel replacement, NOM10P/NOH12PH

- 4.2.9. Adjustment of stabilising lugs, NOH12PH

- 5. DRIVE UNIT

- 5.1. Design and function

- 5.1.1. Description

- 5.1.2. Drive motor

- 5.1.3. Gearbox

- 5.1.4. Drive wheel

- 5.2. Repair and maintenance instructions

- 5.2.1. Before work is performed

- 5.2.2. Servicing and maintenance

- 5.3. Drive unit, NOL10P/NOM10P

- 5.3.1. Traction motor

- 5.3.2. Gearbox

- 5.3.3. Drive wheels

- 5.4. Drive unit, NOH12PH

- 5.4.1. Drive motor

- 5.4.2. Gearbox

- 5.4.3. Drive wheel

- 5.5. Diagnostics and troubleshooting

- 5.5.1. Troubleshooting

- 5.5.2. Troubleshooting chart

- 6. MAST SYSTEM

- 6.1. Design and function

- 6.1.1. Fixation of the mast

- 6.1.2. Operators platform

- 6.1.3. Mast switch in mast

- 6.2. Repair and maintenance instructions

- 6.2.1. Before work is performed

- 6.2.2. Operators platform

- 6.2.3. Fork carriage

- 6.2.4. Lift chains

- 6.2.5. Control of initial lift stroke

- 6.2.6. Inspection of forks

- 6.2.7. Emergency lowering valve

- 6.3. Diagnostics and trouble shooting

- 6.3.1. Troubleshooting

- 7. STEERING

- 7.1. Design and function

- 7.1.1. General

- 7.1.2. Steering

- 7.1.3. Signal path, steering

- 7.2. Repair and maintenance instructions

- 7.2.1. Before work is performed

- 7.2.2. Steering wheel

- 7.2.3. Steering servo motor

- 7.2.4. Replacement of sensor for steering

- 7.2.5. Installations, adjustments and testing

- 7.3. Diagnostics and trouble shooting

- 7.3.1. Troubleshooting

- 8. HYDRAULIC SYSTEM

- 8.1. Design and function

- 8.1.1. Description, NOL10P

- 8.1.2. Description, NOM10P/NOH12PH

- 8.1.3. Functions

- 8.1.4. Hydraulic diagram

- 8.1.5. Hydraulic unit, compact (NOL10P)

- 8.1.6. Hydraulic unit, pump motor (NOM10P/NOH12PH)

- 8.1.7. Valve unit (NOM10P/NOH12PH)

- 8.1.8. Tank unit with return filter (NOM10P/NOH12PH)

- 8.1.9. Cylinders

- 8.1.10. Conduit components

- 8.1.11. Other components

- 8.1.12. Hydraulic oil

- 8.2. Repair and maintenance instructions

- 8.2.1. Before work is performed

- 8.2.2. General rules

- 8.2.3. Installation

- 8.2.4. Connections

- 8.2.5. Dismounting and mounting of hydraulic hoses

- 8.3. Hydraulic unit, compact (NOL10P)

- 8.3.1. Dismounting and mounting

- 8.3.2. Start-up

- 8.3.3. Replacing the filter

- 8.3.4. Changing the oil

- 8.3.5. Checking the hydraulic oil level

- 8.3.6. Hydraulic motor

- 8.3.7. Pump, hydraulic unit

- 8.3.8. Hydraulic unit valves

- 8.4. Hydraulic unit, pump motor (NOM10P/NOH12PH)

- 8.4.1. Removal and installation of the hydraulic unit (pump motor unit)

- 8.4.2. Removal and installation of the pump

- 8.4.3. Removal and installation of the motor bearing

- 8.4.4. Start after work with the pump motor unit

- 8.5. Valve unit (NOM10P/NOH12PH)

- 8.5.1. Overview

- 8.5.2. Tightening torque

- 8.5.3. Removal and installation of valve unit

- 8.5.4. Start after work with the valve unit

- 8.5.5. Pressure limitation, control and setting

- 8.5.6. Check of lowering speed

- 8.6. Tank and filter unit (NOM10P/NOH12PH)

- 8.6.1. General

- 8.6.2. Replacing the air filter

- 8.6.3. Replacing the oil filter

- 8.6.4. Intake

- 8.6.5. Hydraulic oil level check

- 8.6.6. Removal and installation of the hydraulic tank

- 8.7. Diagnostics and troubleshooting

- 8.7.1. Troubleshooting

- 8.7.2. Troubleshooting, hydraulics functions, NOL10P

- 8.7.3. Troubleshooting, hydraulics functions, NOM10P/NOH12PH

- 9. CYLINDERS

- 9.1. Design and function

- 9.1.1. Descriptions

- 9.1.2. Damping

- 9.1.3. Hose break valve

- 9.2. Repair and maintenance instructions

- 9.2.1. Before work is performed

- 9.2.2. Bleeding of the hydraulic cylinders without a bleed air screw

- 9.2.3. Bleeding of the hydraulic cylinders with air bleed screw, NO

- 9.2.4. Work with hose break valve/lowering brake valve in cylinders

- 9.2.5. Replace seals, lift cylinder

- 9.3. Cylinders, NO

- 9.3.1. Dismounting and mounting, lift cylinder

- 9.3.2. Dismounting and mounting, initial cylinder (option)

- 9.4. Cylinders, NOM10P/NOH12PH

- 9.4.1. Removing and installing the free lift cylinder, DTFV mast

- 9.4.2. Removing and installing the mast lift cylinder, TV-mast

- 9.4.3. Removing and installing the mast lift cylinder, DTFV-mast

- 9.4.4. Removing and installing the initial cylinder

- 9.4.5. Aeration of the initial cylinder

- 10. ELECTRICAL SYSTEM

- 10.1. Introduction

- 10.1.1. Description of components

- 10.2. Safety

- 10.2.1. Safety instructions

- 10.2.2. Electronic controllers

- 10.2.3. Safety checks

- 10.2.4. Steering servo system

- 10.2.5. Traction system

- 10.2.6. Hydraulic system

- 10.3. Design and function

- 10.3.1. Battery replacement

- 10.3.2. Battery capacity

- 10.3.3. Truck computer, ATC

- 10.4. Repair and maintenance instructions

- 10.4.1. Before work is performed

- 10.4.2. General operation

- 10.4.3. Connectors in cold store

- 10.4.4. Drive and pump control

- 10.4.5. Steering

- 10.4.6. Wiring diagram

- 10.4.7. Insulation resistance

- 10.4.8. Main controller unit ATC, operation

- 10.4.9. Hydraulic system

- 10.4.10. Brake system

- 10.4.11. Traction system

- 10.4.12. Cold resistance values

- 10.5. Diagnostics and trouble shooting

- 10.5.1. Error codes/Warnings

- 11. SPEED CONTROL AND BRAKE SYSTEMS

- 11.1. Design and function

- 11.1.1. General

- 11.1.2. Speed and brake control

- 11.1.3. Electric brakes

- 11.1.4. Brake button

- 11.1.5. Motor brake

- 11.2. Repair and maintenance instructions

- 11.2.1. Before work is performed

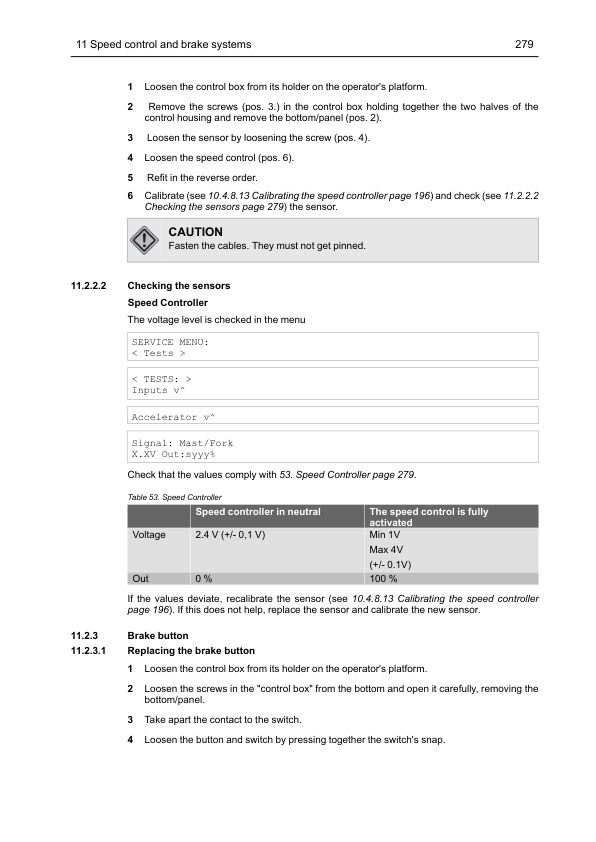

- 11.2.2. Speed Controller

- 11.2.3. Brake button

- 11.2.4. Removal and installation of the left hand control

- 11.2.5. Electric brakes

- 11.3. Diagnostics and trouble shooting

- 11.3.1. Troubleshooting the brakes

- 12. MISCELLANEOUS

- 12.1. Stability support system, S3-1

- 12.1.1. Speed restriction based on the steering angle, S3-1

- 12.1.2. Activation of S3-1

- 12.1.3. Dynamic curve control, S3-1

- 12.1.4. Activation of S3-1 DCC

- 12.1.5. Setting S3-1 DCC

- 12.2. Weight and height system, S3-2

- 12.2.1. Design and function

- 12.2.2. Activation of S3-2

- 12.2.3. Calibration of S3-2

- 12.2.4. Monitoring, weight measurement

- 12.3. Lift and running stop

- 12.4. Walk beside, option, only NOL10P

- 12.4.1. Design and function

- 12.4.2. Activation

- 12.4.3. Setting the speed

- 12.5. Step warning

- 12.5.1. Design and function

- 12.5.2. Activation

- 12.6. Double controls

- 12.6.1. Design and function

- 12.6.2. Maintenance and repair instructions

- 12.6.3. Diagnostics and trouble shooting

- 12.7. Wire guidance

- 12.7.1. Wire guidance antenna

- 12.7.2. Steering lock, wire guidance, NOM10P, NOH12PH

- 12.7.3. Removing/installing the antenna

- 12.7.4. Select setting

- 12.7.5. Calibration

- 12.7.6. Calibration, manual

- 12.7.7. Trouble shooting

- 12.8. End of Aisle

- 12.8.1. General

- 12.8.2. Introduction

- 12.8.3. Installation

- 12.8.4. Settings

- 12.8.5. End of Aisle magnetic system troubleshooting

- 12.9. Rail guidance

- 12.9.1. Design and function

- 12.9.2. Repair and maintenance instructions

- 12.9.3. Diagnostics and trouble shooting

- 12.10. Descent with the help of safety line, option NOM10P/NOH12PH

- 12.11. Mast lowering NOM10P/NOH12PH

- 12.12. Delivery mode, NOM10P/NOH12PH

- 12.13. Mast raising, NOM10P/NOH12PH

- 12.14. PPS, Personnel Protection System

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-64103

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Disassembly and Assembly Service Manual 99799-67102

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 4G15, 4G63, 4G64, 6G72 Engine Service Manual 99719-34130

Caterpillar Service Manual PDF

Caterpillar 5V15D to 5V35D Mast Supplement Service Manual 99739-351S0

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Troubleshooting Service Manual 99799-67104

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Operation and Maintenance Manual Service Manual 99799-67105

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Specifications Service Manual 99799-67101