Mitsubishi 2FBC20 Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 570

- Size: 6.4MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

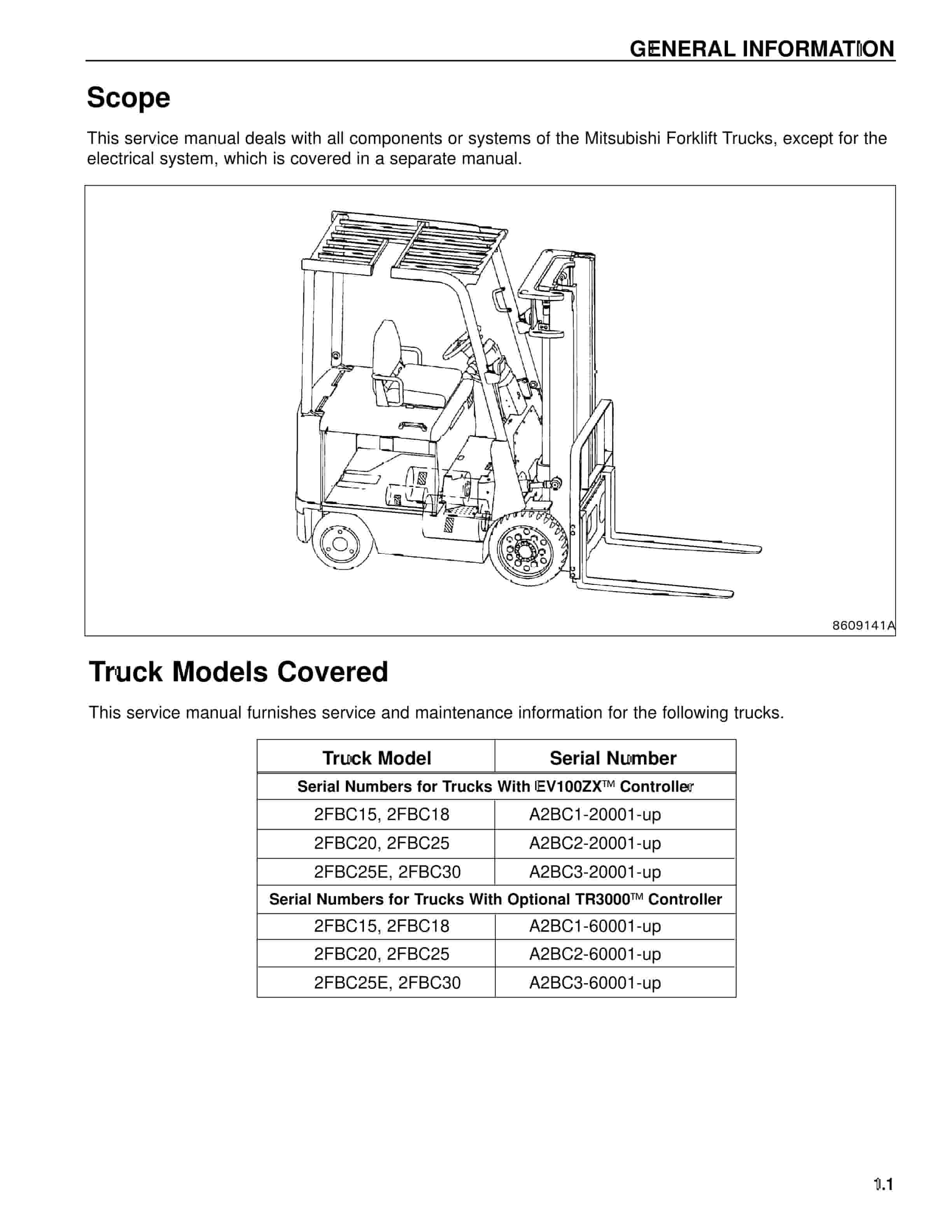

Model List:

- 2FBC20 Forklift

- 1. GENERAL INFORMATION

- 1.1. Truck Models Covered

- 1.2. Nameplate and Serial Number Locations

- 1.3. Dimensions

- 1.3.1. Dimensions Chart

- 1.4. General Information (Standard Models)

- 2. BRAKE SYSTEM

- 2.1. Description

- 2.1.1. Automatic Adjusting Device

- 2.1.2. General Information

- 2.2. Master Cylinder

- 2.2.1. Disassembly

- 2.2.2. Inspection after Disassembly

- 2.2.3. Reassembly

- 2.3. Service Brakes

- 2.3.1. Disassembly

- 2.3.2. Inspection after Disassembly

- 2.3.3. Reassembly

- 2.4. Wheel Cylinders

- 2.4.1. Disassembly

- 2.4.2. Inspection after Disassembly

- 2.4.3. Reassembly

- 2.4.4. Inspection and Adjustment

- 3. Front Axle and Reduction Differential Maintainance

- 3.1. Maintenance Service Data

- 3.1.1. Front Axle and Reduction Differential

- 3.1.2. Transfer Case

- 3.1.3. Rear Axle

- 3.1.4. Brake System

- 3.1.5. Steering System

- 3.1.6. Hydraulic System

- 3.1.7. Mast and Forks (Simplex Mast)

- 3.2. Tightening Torques for Standard Bolts and Nuts

- 3.2.1. Fine Thread – With Spring Washer

- 3.2.2. Fine Thread – Without Spring Washer

- 3.2.3. Coarse Thread – With Spring Washer

- 3.2.4. Coarse Thread – Without Spring Washer

- 3.3. Maintenance Chart

- 3.4. Periodic Replacement Parts

- 3.5. Lubrication Information

- 3.5.1. Lubrication Chart

- 3.5.2. Fuel and Lubricant Specifications

- 3.5.3. Recommended Brands of Lubricants

- 3.6. Weight of Major Components (Approximate)

- 3.7. Special Service Tools

- 3.7.1. Special Tool Illustrations

- 3.8. Inspection Guide

- 4. Front Axle

- 4.1. Front Axle

- 4.1.1. Description

- 4.1.2. Front Wheels

- 4.1.3. Installation

- 4.1.4. Disassembly

- 4.1.5. Inspection after Disassembly

- 4.1.6. Reassembly

- 4.2. Reduction Differential

- 4.2.1. Description

- 4.2.2. Disassembly

- 4.2.3. Inspection after Disassembly

- 4.2.4. Reassembly

- 4.2.5. Inspection and Adjustment

- 5. Hydraulic System

- 5.1. Hydraulic System

- 5.1.1. Description

- 5.1.2. Removal and Installation Warning

- 5.2. Hydraulic Pump

- 5.2.1. Removal

- 5.2.2. Installation

- 5.2.3. Disassembly

- 5.2.4. Inspection after Disassembly

- 5.2.5. Reassembly

- 5.2.6. Inspection after Reassembly

- 5.3. Priority Valve

- 5.3.1. Disassembly

- 5.3.2. Reassembly

- 5.4. Control Valve

- 5.4.1. Removal

- 5.4.2. Installation

- 5.4.3. Disassembly

- 5.4.4. Inspection after Disassembly

- 5.4.5. Reassembly

- 5.5. Lift and Tilt Cylinders

- 5.5.1. Removal

- 5.5.2. Disassembly

- 5.5.3. Precautions for Reassembly

- 5.5.4. Flow Regulator Valve

- 5.6. Inspection and Adjustment

- 5.6.1. Hydraulic Tank

- 5.6.2. Control Valve

- 5.6.3. Lift and Tilt Cylinders

- 6. Mast and Forks Earlier Version

- 6.1. Description

- 6.1.1. Components

- 6.1.2. Mast and Forks

- 6.1.3. Mast and Lift Bracket Assembly

- 6.2. Removal Installation

- 6.3. Disassembly

- 6.4. Inspection after Disassembly

- 6.5. Reassembly

- 6.6. Inspection and Adjustment

- 6.6.1. Chain Tension Adjustment

- 6.6.2. Clearance Adjustment on Lift Bracket

- 6.6.3. Mast Clearance Adjustment

- 6.6.4. Main Roller Shim Replacement

- 6.6.5. Mast Adjustment Chart

- 7. Mast and Forks Later Version

- 7.1. Description

- 7.2. Removal and Installation

- 7.3. Disassembly

- 7.4. Reassembly

- 7.5. Inspection and Adjustment

- 7.5.1. Chain Tension Adjustment

- 7.5.2. Clearance Adjustment on Lift Bracket

- 7.5.3. Mast Clearance Adjustment

- 7.5.4. Main Roller Shim Replacement

- 7.5.5. Mast Strip Adjustment

- 7.5.6. Tilt Angle Adjustment

- 7.5.7. Lift Cylinder Stroke Adjustment

- 7.5.8. Bleeding Lift Cylinders

- 7.6. Service Data

- 7.7. Troubleshooting

- 8. Rear Axle

- 8.1. Description

- 8.2. Rear Wheels

- 8.2.1. Removal

- 8.2.2. Installation

- 8.3. Rear Axle

- 8.3.1. Removal

- 8.3.2. Installation

- 8.3.3. Disassembly

- 8.3.4. Inspection after Disassembly

- 8.3.5. Reassembly

- 8.4. Inspection and Adjustment

- 8.4.1. Minimum Turning Radius Adjustment

- 9. Steering System

- 9.1. Steering System

- 9.1.1. Description

- 9.2. Steering Gear

- 9.2.1. Removal

- 9.2.2. Installation

- 9.2.3. Disassembly

- 9.2.4. Reassembly

- 9.3. Steer Pump

- 9.3.1. Removal

- 9.3.2. Installation

- 9.3.3. Disassembly

- 9.3.4. Reassembly

- 10. Transfer Case Earlier Version

- 10.1. Description

- 10.1.1. Earlier Version

- 10.1.2. Later Version

- 10.2. Disassembly

- 10.2.1. Removal Sequence

- 10.3. Reassembly

- 11. TROUBLESHOOTING FRONT AXLE REDUCTION DIFFERENTIAL

- 11.1. Front Axle and Reduction Differential

- 11.2. Brake System

- 11.3. Steering System

- 11.4. Hydraulic System

- 11.5. Rear Axle

- 11.6. Mast and Forks

- 12. CHECKS REPAIRS

- 12.1. CHECKS REPAIRS

- 12.1.1. General Information

- 12.1.2. Electric Truck Motors and Controls

- 12.1.3. Unsatisfactory Brush Performance

- 12.1.4. Commutator Surfaces

- 12.1.5. Motor Winding Specifications

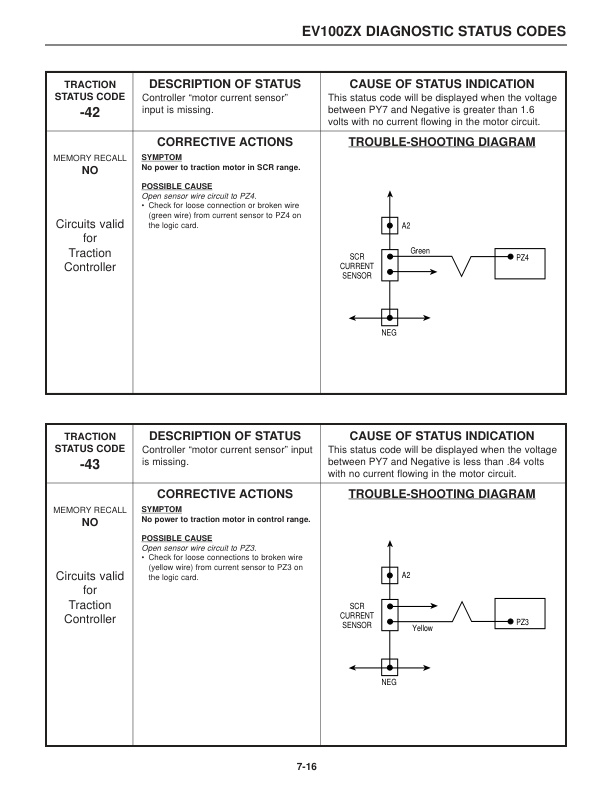

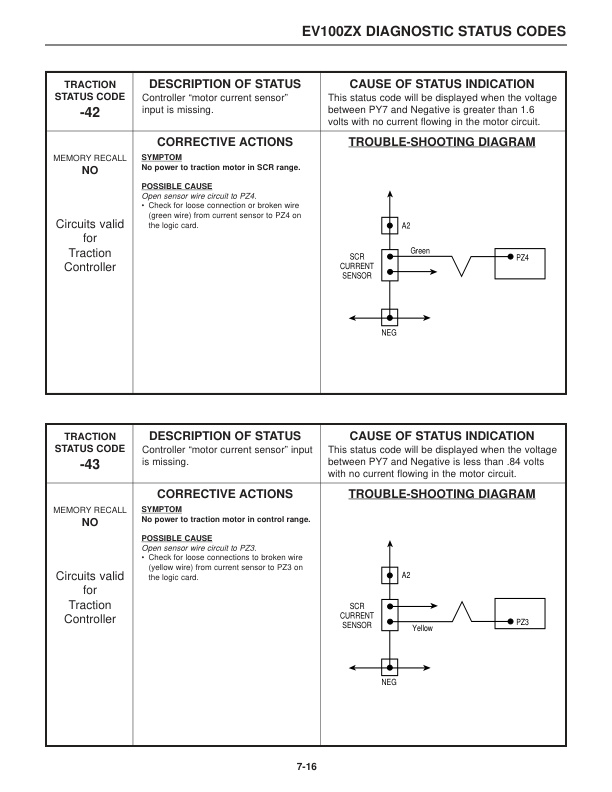

- 13. EV100ZX DIAGNOSTIC STATUS CODES

- 13.1. DIAGNOSTIC STATUS CODES

- 13.1.1. Basic Checks

- 13.1.2. On Board Diagnostics

- 13.1.3. Status Codes

- 14. EV100ZX SCR Motor Controller

- 14.1. GENERAL INFORMATION FEATURES

- 14.1.1. Safety Precautions

- 14.1.2. Glossary

- 14.1.3. Nameplate and Serial Number Locations

- 14.1.4. EV100ZX Motor Controller without SCR Hydraulics

- 14.1.5. EV100ZX Motor Controller with Optional SCR Hydraulics

- 14.1.6. Basics of Circuit Operation

- 14.1.7. Traction Control Logic Flow Chart

- 14.1.8. Console (Display)

- 14.1.9. Features of the EV100ZX Control Systems

- 14.1.10. General Maintenance for the EV100ZX Motor Controller

- 14.1.11. Trouble-shooting the EV100ZX Motor Controller

- 14.1.12. EV100ZX SCR Control Wiring Schematic without SCR Hydraulics

- 14.1.13. EV100ZX SCR Control Wiring Schematic with SCR Hydraulics

- 14.1.14. EV100ZX SCR Control Wiring Schematic for Optional Equipment

- 15. HANDSET

- 15.1. HANDSET

- 15.1.1. General Information

- 15.1.2. Function Numbers (Traction)

- 15.1.3. Function Set-Up Procedures for Optional SCR Hydraulics

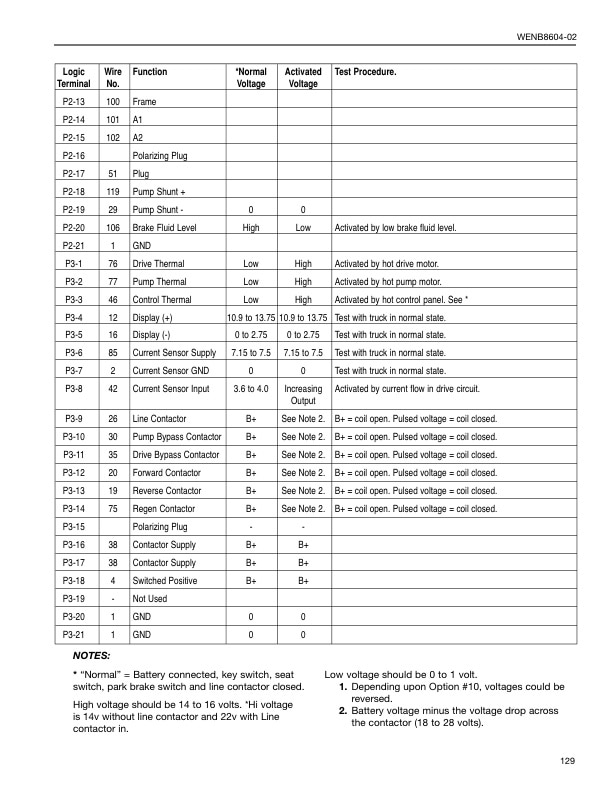

- 16. Main Logic Card

- 16.1. LOGIC CARD CONNECTIONS TROUBLESHOOTING BY SYMPTOM

- 16.1.1. Main Logic Card

- 16.1.2. Component Locations

- 16.1.3. Terminal Connections for ZX Logic Cards

- 16.1.4. EV100ZX Logic Card Specifications

- 16.1.5. EV100ZX Current Limit Curves

- 16.1.6. Secondary Troubleshooting

- 16.1.7. Hydraulic Pump Control Troubleshooting

- 17. THEORY OF OPERATION

- 17.1. THEORY OF OPERATION

- 17.1.1. Electronic Speed Controls

- 17.1.2. Flyback Current from the Motor

- 17.1.3. Control Cards

- 17.1.4. Sequence of Operation

- 17.1.5. SCR Control (Hydraulic Pump Motor)

- 17.1.6. Contactors

- 17.1.7. Circuit Protection

- 17.1.8. Truck Mangement Module (TMM1)

- 17.1.9. Instrument Panel Display

- 17.1.10. Power Cable Connections

- 17.1.11. Traction Control Card Wire Harness Connections

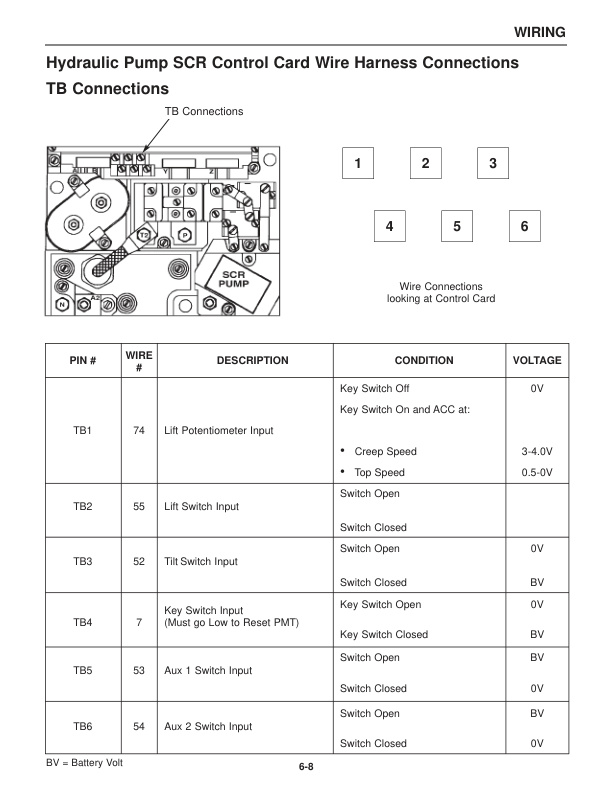

- 17.1.12. Control Card Wire Harness Connections for Optional Hydraulic Pump SCR

- 17.1.13. Pump Driver

- 17.1.14. Pump Time Delay

- 18. Circuit Tests

- 18.1. CIRCUIT TESTS

- 19. Electrical Testing

- 19.1. ELECTRICAL TESTING

- 19.1.1. Testing Transistors

- 19.1.2. Electrical System Adjustments

- 20. Hydraulics

- 20.1. HYDRAULICS

- 20.1.1. Actuation Circuit

- 20.1.2. Capacitor Charging Circuit

- 20.1.3. Hydraulic Pump Motor Circuit

- 20.1.4. Lift Circuit

- 21. Operation and Test Equipment

- 21.1. SYSTEMS OPERATION AND TEST EQUIPMENT

- 21.1.1. Conductor And Switch Continuity Tests

- 21.1.2. Contactor

- 21.1.3. Driver Board Tests

- 21.1.4. Traction Motor Current Sensor Test

- 22. Systems Operation -Test Equipment

- 22.1. SYSTEMS OPERATION AND TEST EQUIPMENT

- 22.1.1. Conductor And Switch Continuity Tests

- 22.1.2. Contactor

- 22.1.3. Driver Board Tests

- 22.1.4. Traction Motor Current Sensor Test

- 23. Systems Operation

- 23.1. SYSTEMS OPERATION

- 23.1.1. Glossary

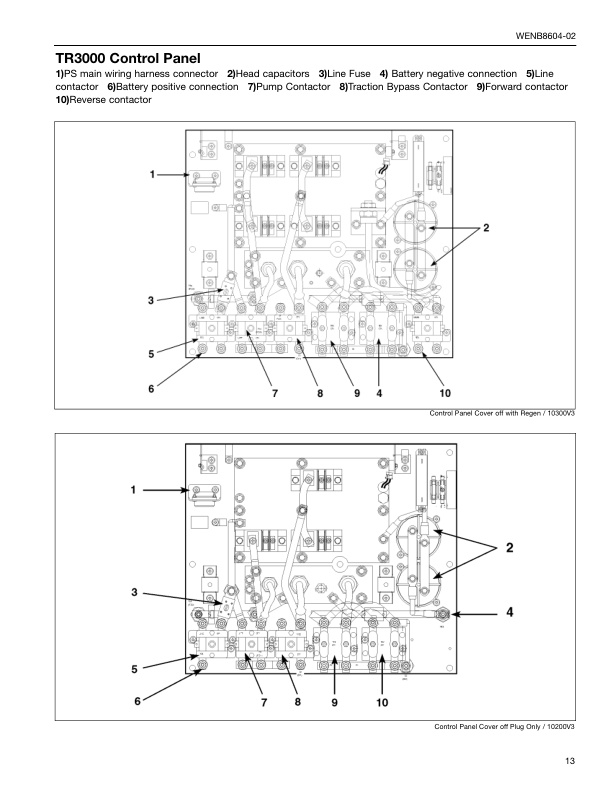

- 23.1.2. Location of Control Panel Components

- 23.1.3. Symbol Library

- 23.1.4. General Information

- 23.1.5. Programmable Setup Options

- 23.1.6. Accessing Programmable Setup Options

- 23.1.7. Operational Circuit Elements

- 23.1.8. Run-Time Diagnostics

- 23.1.9. Chat Mode

- 23.1.10. Contactors

- 23.1.11. Accelerator Control

- 23.1.12. Circuits

- 23.1.13. Drive Circuit

- 23.1.14. Power Transistors

- 24. Testing and Adjusting

- 24.1. TESTING AND ADJUSTING

- 24.1.1. Accessing Stored Fault Codes

- 25. TR3000 CONTROL

- 25.1. GENERAL INFORMATION

- 25.1.1. Mitsubishi Forklift Truck Important Safety Information

- 25.1.2. Specifications

- 26. Troubleshooting Charts

- 26.1. TROUBLESHOOTING CHARTS

- 27. Troubleshooting

- 27.1. TROUBLESHOOTING

- 27.1.1. Troubleshooting Checklist

- 27.1.2. Control And Power System Operational Checks

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100

$50.00