Mitsubishi 2FBC25 Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 697

- Size: 7.3MB

- Format: PDF

-

Model List:

- 2FBC25 Forklift

- 1. GENERAL INFORMATION

- 1.1. Truck Models Covered

- 1.2. Nameplate and Serial Number Locations

- 1.3. Dimensions

- 1.3.1. Dimensions Chart

- 1.4. General Information (Standard Models)

- 2. Front Axle and Reduction Differential Troubleshooting

- 2.1. Front Axle and Reduction Differential

- 2.2. Brake System

- 2.3. Steering System

- 2.4. Hydraulic System

- 2.5. Rear Axle

- 2.6. Mast and Forks

- 3. Front Axle

- 3.1. Front Axle

- 3.1.1. Description

- 3.1.2. Front Wheels

- 3.1.3. Installation

- 3.1.4. Disassembly

- 3.1.5. Inspection after Disassembly

- 3.1.6. Reassembly

- 3.2. Reduction Differential

- 3.2.1. Description

- 3.2.2. Disassembly

- 3.2.3. Inspection after Disassembly

- 3.2.4. Reassembly

- 3.2.5. Inspection and Adjustment

- 4. Hydraulic System

- 4.1. Hydraulic System

- 4.1.1. Description

- 4.1.2. Removal and Installation Warning

- 4.2. Hydraulic Pump

- 4.2.1. Removal

- 4.2.2. Installation

- 4.2.3. Disassembly

- 4.2.4. Inspection after Disassembly

- 4.2.5. Reassembly

- 4.2.6. Inspection after Reassembly

- 4.3. Priority Valve

- 4.3.1. Disassembly

- 4.3.2. Reassembly

- 4.4. Control Valve

- 4.4.1. Removal

- 4.4.2. Installation

- 4.4.3. Disassembly

- 4.4.4. Inspection after Disassembly

- 4.4.5. Reassembly

- 4.5. Lift and Tilt Cylinders

- 4.5.1. Removal

- 4.5.2. Disassembly

- 4.5.3. Precautions for Reassembly

- 4.5.4. Flow Regulator Valve

- 4.6. Inspection and Adjustment

- 4.6.1. Hydraulic Tank

- 4.6.2. Control Valve

- 4.6.3. Lift and Tilt Cylinders

- 5. Maintenance Service Data Drive Unit

- 5.1. Maintenance Service Data

- 5.1.1. Front Axle and Reduction Differential

- 5.1.2. Transfer Case

- 5.1.3. Rear Axle

- 5.1.4. Brake System

- 5.1.5. Steering System

- 5.1.6. Hydraulic System

- 5.1.7. Mast and Forks (Simplex Mast)

- 5.2. Tightening Torques for Standard Bolts and Nuts

- 5.2.1. Fine Thread – With Spring Washer

- 5.2.2. Fine Thread – Without Spring Washer

- 5.2.3. Coarse Thread – With Spring Washer

- 5.2.4. Coarse Thread – Without Spring Washer

- 5.3. Maintenance Chart

- 5.4. Periodic Replacement Parts

- 5.5. Lubrication Information

- 5.5.1. Lubrication Chart

- 5.5.2. Fuel and Lubricant Specifications

- 5.5.3. Recommended Brands of Lubricants

- 5.6. Weight of Major Components (Approximate)

- 5.7. Special Service Tools

- 5.7.1. Special Tool Illustrations

- 5.8. Inspection Guide

- 6. Mast and Forks Early

- 6.1. Description

- 6.1.1. Components

- 6.1.2. Mast and Forks

- 6.1.3. Mast and Lift Bracket Assembly

- 6.2. Removal Installation

- 6.3. Disassembly

- 6.4. Inspection after Disassembly

- 6.5. Reassembly

- 6.6. Inspection and Adjustment

- 6.6.1. Chain Tension Adjustment

- 6.6.2. Clearance Adjustment on Lift Bracket

- 6.6.3. Mast Clearance Adjustment

- 6.6.4. Main Roller Shim Replacement

- 6.6.5. Mast Adjustment Chart

- 7. Mast and Forks Later

- 7.1. Description

- 7.2. Removal and Installation

- 7.3. Disassembly

- 7.4. Reassembly

- 7.5. Inspection and Adjustment

- 7.5.1. Chain Tension Adjustment

- 7.5.2. Clearance Adjustment on Lift Bracket

- 7.5.3. Mast Clearance Adjustment

- 7.5.4. Main Roller Shim Replacement

- 7.5.5. Mast Strip Adjustment

- 7.5.6. Tilt Angle Adjustment

- 7.5.7. Lift Cylinder Stroke Adjustment

- 7.5.8. Bleeding Lift Cylinders

- 7.6. Service Data

- 7.7. Troubleshooting

- 8. Steering System

- 8.1. Steering System

- 8.1.1. Description

- 8.2. Steering Gear

- 8.2.1. Removal

- 8.2.2. Installation

- 8.2.3. Disassembly

- 8.2.4. Reassembly

- 8.3. Steer Pump

- 8.3.1. Removal

- 8.3.2. Installation

- 8.3.3. Disassembly

- 8.3.4. Reassembly

- 9. Systems Operation

- 9.1. SYSTEMS OPERATION

- 9.1.1. Glossary

- 9.1.2. Location of Control Panel Components

- 9.1.3. Symbol Library

- 9.1.4. General Information

- 9.1.5. Programmable Setup Options

- 9.1.6. Accessing Programmable Setup Options

- 9.1.7. Operational Circuit Elements

- 9.1.8. Run-Time Diagnostics

- 9.1.9. Chat Mode

- 9.1.10. Contactors

- 9.1.11. Accelerator Control

- 9.1.12. Circuits

- 9.1.13. Drive Circuit

- 9.1.14. Power Transistors

- 10. Transfer Case Early

- 10.1. Description

- 10.1.1. Earlier Version

- 10.1.2. Later Version

- 10.2. Disassembly

- 10.2.1. Removal Sequence

- 10.3. Reassembly

- 11. Checks and repairs

- 11.1. CHECKS REPAIRS

- 11.1.1. General Information

- 11.1.2. Electric Truck Motors and Controls

- 11.1.3. Unsatisfactory Brush Performance

- 11.1.4. Commutator Surfaces

- 11.1.5. Motor Winding Specifications

- 12. Diagnostic Codes

- 12.1. DIAGNOSTIC STATUS CODES

- 12.1.1. Basic Checks

- 12.1.2. On Board Diagnostics

- 12.1.3. Status Codes

- 13. EV100ZX DIAGNOSTIC STATUS CODES

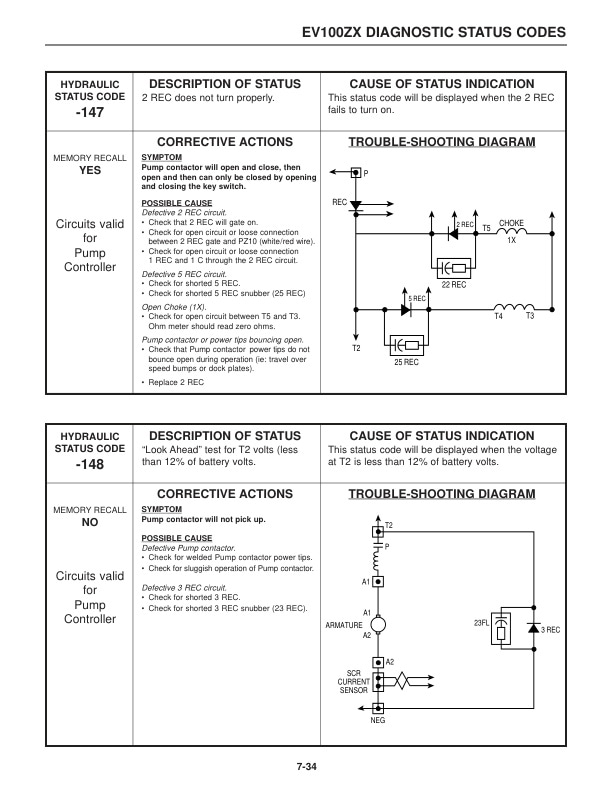

- 13.1. DIAGNOSTIC STATUS CODES

- 13.1.1. Basic Checks

- 13.1.2. On Board Diagnostics

- 13.1.3. Status Codes

- 14. EV100ZX SCR Motor Controller

- 14.1. GENERAL INFORMATION FEATURES

- 14.1.1. Safety Precautions

- 14.1.2. Glossary

- 14.1.3. Nameplate and Serial Number Locations

- 14.1.4. EV100ZX Motor Controller without SCR Hydraulics

- 14.1.5. EV100ZX Motor Controller with Optional SCR Hydraulics

- 14.1.6. Basics of Circuit Operation

- 14.1.7. Traction Control Logic Flow Chart

- 14.1.8. Console (Display)

- 14.1.9. Features of the EV100ZX Control Systems

- 14.1.10. General Maintenance for the EV100ZX Motor Controller

- 14.1.11. Trouble-shooting the EV100ZX Motor Controller

- 14.1.12. EV100ZX SCR Control Wiring Schematic without SCR Hydraulics

- 14.1.13. EV100ZX SCR Control Wiring Schematic with SCR Hydraulics

- 14.1.14. EV100ZX SCR Control Wiring Schematic for Optional Equipment

- 15. General Information (2)

- 15.1. CHECKS REPAIRS

- 15.1.1. General Information

- 15.1.2. Electric Truck Motors and Controls

- 15.1.3. Unsatisfactory Brush Performance

- 15.1.4. Commutator Surfaces

- 15.1.5. Motor Winding Specifications

- 16. Handset

- 16.1. HANDSET

- 16.1.1. General Information

- 16.1.2. Function Numbers (Traction)

- 16.1.3. Function Set-Up Procedures for Optional SCR Hydraulics

- 17. Hydraulics

- 17.1. HYDRAULICS

- 17.1.1. Actuation Circuit

- 17.1.2. Capacitor Charging Circuit

- 17.1.3. Hydraulic Pump Motor Circuit

- 17.1.4. Lift Circuit

- 18. Logic Card Connections and troubleshooting

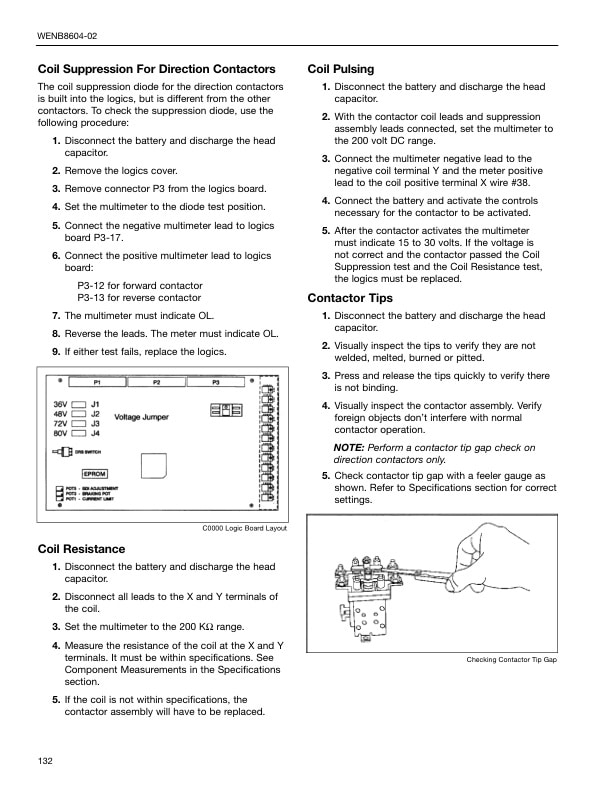

- 18.1. LOGIC CARD CONNECTIONS TROUBLESHOOTING BY SYMPTOM

- 18.1.1. Main Logic Card

- 18.1.2. Component Locations

- 18.1.3. Terminal Connections for ZX Logic Cards

- 18.1.4. EV100ZX Logic Card Specifications

- 18.1.5. EV100ZX Current Limit Curves

- 18.1.6. Secondary Troubleshooting

- 18.1.7. Hydraulic Pump Control Troubleshooting

- 19. THEORY OF OPERATION

- 19.1. THEORY OF OPERATION

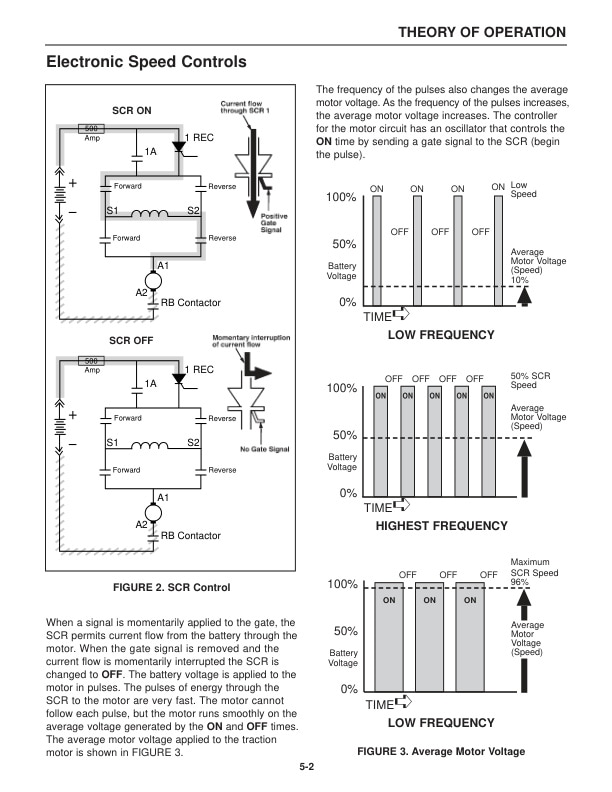

- 19.1.1. Electronic Speed Controls

- 19.1.2. Flyback Current from the Motor

- 19.1.3. Control Cards

- 19.1.4. Sequence of Operation

- 19.1.5. SCR Control (Hydraulic Pump Motor)

- 19.1.6. Contactors

- 19.1.7. Circuit Protection

- 19.1.8. Truck Mangement Module (TMM1)

- 19.1.9. Instrument Panel Display

- 20. Theroy of operation

- 20.1. THEORY OF OPERATION

- 20.1.1. Electronic Speed Controls

- 20.1.2. Flyback Current from the Motor

- 20.1.3. Control Cards

- 20.1.4. Sequence of Operation

- 20.1.5. SCR Control (Hydraulic Pump Motor)

- 20.1.6. Contactors

- 20.1.7. Circuit Protection

- 20.1.8. Truck Mangement Module (TMM1)

- 20.1.9. Instrument Panel Display

- 20.1.10. Power Cable Connections

- 20.1.11. Traction Control Card Wire Harness Connections

- 20.1.12. Control Card Wire Harness Connections for Optional Hydraulic Pump SCR

- 20.1.13. Pump Driver

- 20.1.14. Pump Time Delay

- 21. Circuit Testing

- 21.1. CIRCUIT TESTS

- 22. Circuit Tests

- 22.1. CIRCUIT TESTS

- 23. Component Testing

- 23.1. ELECTRICAL TESTING

- 23.1.1. Testing Transistors

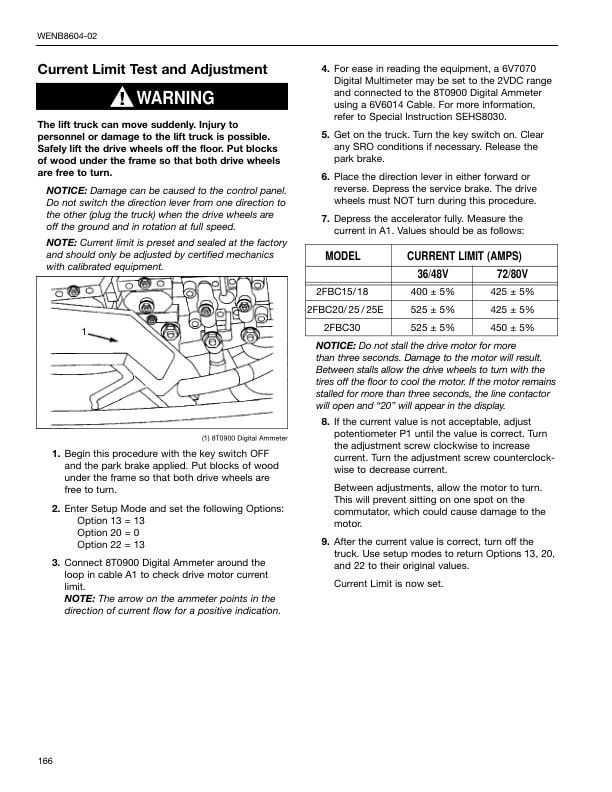

- 23.1.2. Electrical System Adjustments

- 24. Diagnostic Codes

- 24.1. TROUBLESHOOTING

- 24.1.1. Troubleshooting Checklist

- 24.1.2. Control And Power System Operational Checks

- 25. Electrical Testing

- 25.1. ELECTRICAL TESTING

- 25.1.1. Testing Transistors

- 25.1.2. Electrical System Adjustments

- 26. Hydraulics

- 26.1. HYDRAULICS

- 26.1.1. Actuation Circuit

- 26.1.2. Capacitor Charging Circuit

- 26.1.3. Hydraulic Pump Motor Circuit

- 26.1.4. Lift Circuit

- 27. System Operation and Testing

- 27.1. SYSTEMS OPERATION AND TEST EQUIPMENT

- 27.1.1. Conductor And Switch Continuity Tests

- 27.1.2. Contactor

- 27.1.3. Driver Board Tests

- 27.1.4. Traction Motor Current Sensor Test

- 28. System operation

- 28.1. SYSTEMS OPERATION

- 28.1.1. Glossary

- 28.1.2. Location of Control Panel Components

- 28.1.3. Symbol Library

- 28.1.4. General Information

- 28.1.5. Programmable Setup Options

- 28.1.6. Accessing Programmable Setup Options

- 28.1.7. Operational Circuit Elements

- 28.1.8. Run-Time Diagnostics

- 28.1.9. Chat Mode

- 28.1.10. Contactors

- 28.1.11. Accelerator Control

- 28.1.12. Circuits

- 28.1.13. Drive Circuit

- 28.1.14. Power Transistors

- 29. Systems Operation Testing

- 29.1. SYSTEMS OPERATION AND TEST EQUIPMENT

- 29.1.1. Conductor And Switch Continuity Tests

- 29.1.2. Contactor

- 29.1.3. Driver Board Tests

- 29.1.4. Traction Motor Current Sensor Test

- 30. Testing and adjusting

- 30.1. TESTING AND ADJUSTING

- 30.1.1. Accessing Stored Fault Codes

- 31. TR3000 CONTROL

- 31.1. GENERAL INFORMATION

- 31.1.1. Mitsubishi Forklift Truck Important Safety Information

- 31.1.2. Specifications

- 32. Troubleshooting Chart

- 32.1. TROUBLESHOOTING CHARTS

- 33. Troubleshooting

- 33.1. TROUBLESHOOTING

- 33.1.1. Troubleshooting Checklist

- 33.1.2. Control And Power System Operational Checks

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-14110

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105