Mitsubishi EOP15P Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 405

- Size: 6.7MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- EOP15P Forklift

- 1. APPENDIX

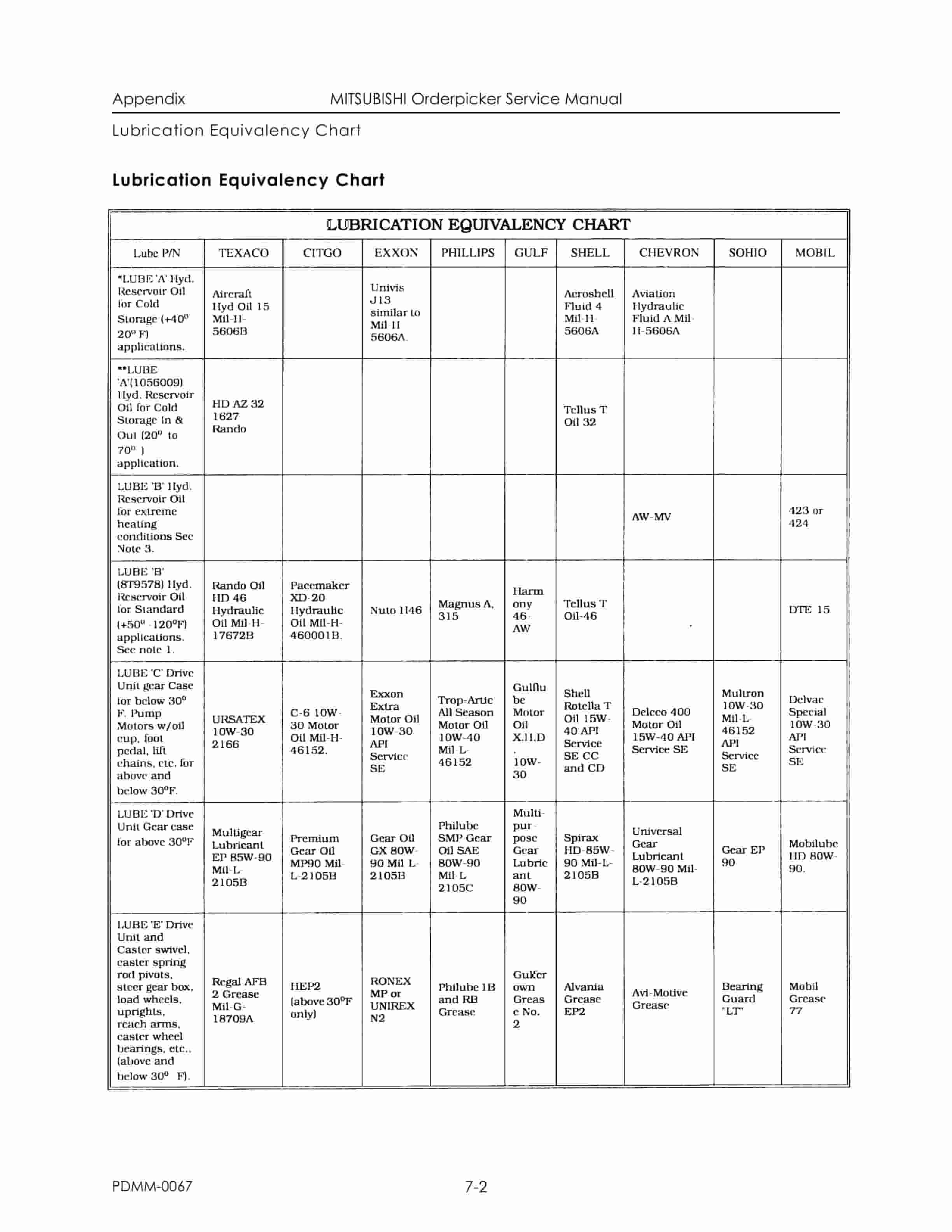

- 1.1. Lubrication Equivalency Chart

- 1.2. Standard Torque Data For Bolts

- 1.3. Conversion Table

- 1.4. Schematic – Electrical

- 1.5. Schematic – Hydraulic

- 1.6. Decal Replacement

- 1.7. Pin-By-Pin Description/Function

- 1.8. Fault Codes/Component Associatiion

- 1.9. Brush Replacement

- 2. DESCRIPTION

- 2.1. Truck Overview

- 2.1.1. Capacity

- 2.1.2. Controls

- 2.1.3. Indicators

- 2.2. Vehicle Specifications

- 2.3. Specification Plate

- 2.4. Mechanical

- 2.4.1. Chassis

- 2.4.2. Mast Assembly

- 2.4.3. Operators Compartment

- 2.4.4. Steering

- 2.4.5. Drive Unit

- 2.5. Hydraulic

- 2.5.1. Lift/Lower System

- 2.6. Electrical

- 2.6.1. General

- 2.6.2. System Displays

- 2.6.3. Electronic Control System

- 2.6.4. Travel System

- 2.6.5. Electric Steering

- 2.6.6. Options

- 3. MAINTENANCE

- 3.1. General Maintenance Instructions

- 3.1.1. Maintenance Practices

- 3.1.2. Jacking Truck

- 3.1.3. Welding Procedures

- 3.1.4. Electrostatic Discharge Damage

- 3.1.5. Shunt Locations

- 3.2. Planned Maintenance

- 3.2.1. Introduction

- 3.2.2. Maintenance Manual

- 3.2.3. Planned Maintenance Schedule

- 3.2.4. Time Requirements

- 3.2.5. Inspection Schedule

- 3.3. Batteries

- 3.3.1. Battery Cleaning

- 3.3.2. Battery Electrical Leakage To Frame Test

- 3.3.3. Battery Discharge Indicator (BDI)

- 3.3.4. Battery Charging

- 3.3.5. Motor Cleaning

- 3.3.6. Brush Care

- 3.3.7. Motor Overheating

- 3.3.8. Motor Stud Terminals

- 3.3.9. Motor Test for Open Circuits

- 3.4. Hydraulic

- 3.4.1. Oil Selection

- 3.4.2. Changing Reservoir Fluid

- 3.4.3. Changing Reservoir Filter

- 3.4.4. Bleeding Hydraulic System

- 3.5. Adjustment and Repair

- 3.5.1. Power Section

- 3.5.2. Lift/Lower System

- 3.5.3. Steering

- 4. OPERATING INSTRUCTIONS

- 4.1. EV100LX Operator System Display

- 4.1.1. Display Test

- 4.1.2. Hour Meter

- 4.1.3. Battery Discharge Indicator

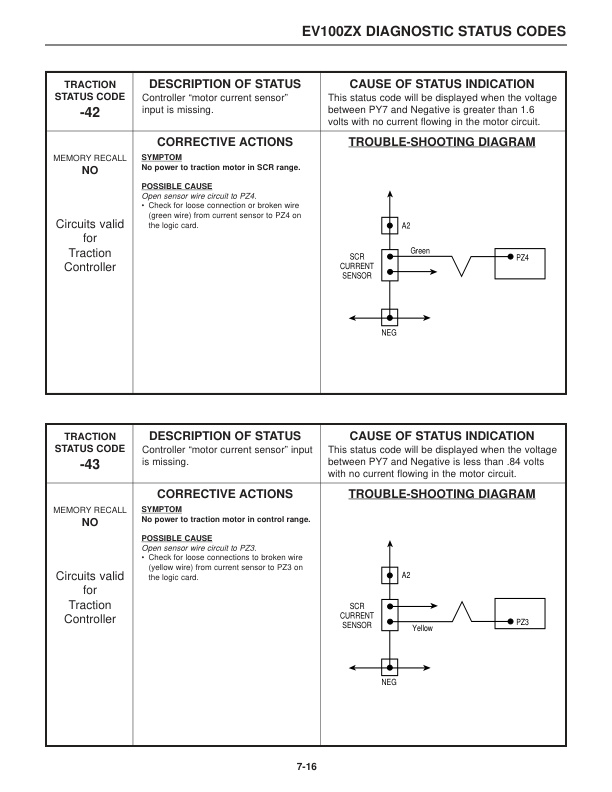

- 4.1.4. Status Codes

- 4.1.5. Informational Messages

- 4.1.6. Performance Limiting Codes

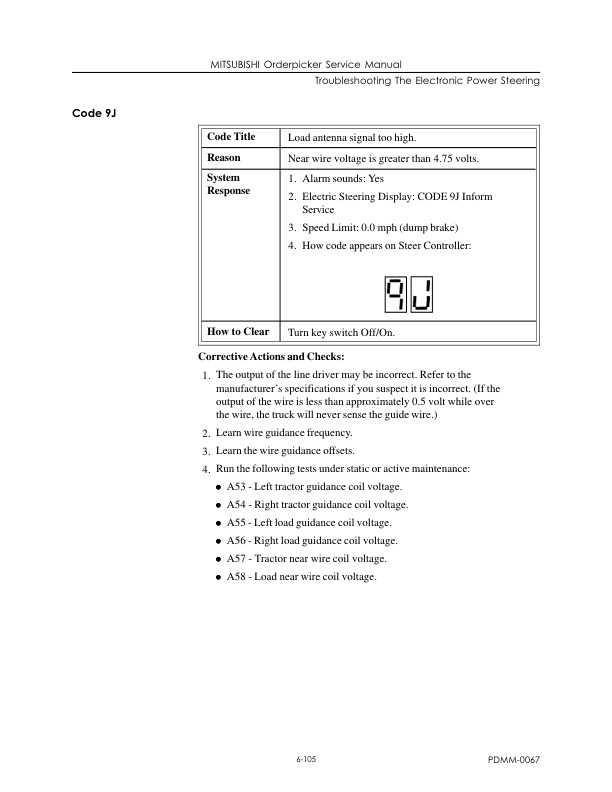

- 4.1.7. Fault Codes (For trucks with electronic power steering and wire guidance)

- 4.1.8. Audible Alarm (For trucks with electronic power steering)

- 4.2. Operators Daily Checklist

- 4.2.1. Visual Checks

- 4.2.2. Operational Checks

- 4.2.3. Start Up Procedure

- 4.2.4. Forward/Reverse Travel

- 4.2.5. Braking

- 4.2.6. Plugging

- 4.2.7. Parking

- 4.3. Electronic Power Steering Modes of Operation

- 4.3.1. Run Mode

- 4.3.2. Configure Mode

- 4.3.3. Maintenance Mode

- 4.3.4. Learn Mode

- 4.3.5. Piezo Sounder

- 4.3.6. Passwords

- 4.3.7. Entering CONFIG or MAINT Mode

- 4.3.8. Configure Mode

- 4.3.9. Maintenance Mode

- 5. THEORY OF OPERATION

- 5.1. EV100LX Control Panel

- 5.1.1. System Components

- 5.1.2. Control Features

- 5.1.3. Basic SCR Controller Circuit Operation

- 5.1.4. Wiring Conventions

- 5.1.5. Operation of The Travel System

- 5.2. Lift/Lower System

- 5.2.1. System Overview

- 5.2.2. Unique System Features

- 5.3. Braking

- 5.3.1. Process

- 5.4. Steering

- 5.4.1. Manual Cable Steering

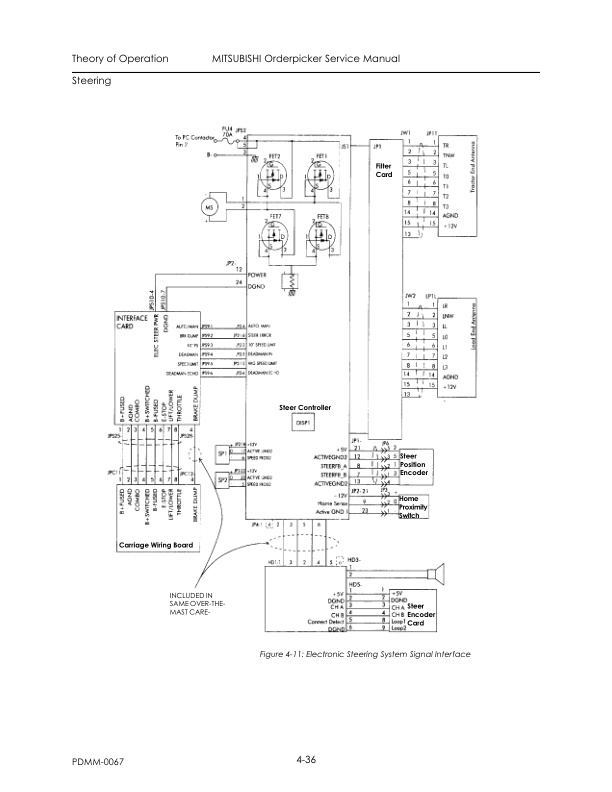

- 5.4.2. Electronic Power Steering

- 5.4.3. Electronic Power Steer System (Optional)

- 5.5. Wire Guidance

- 5.5.1. System Concept

- 5.5.2. Warehouse Installed Equipment (WIE)

- 5.5.3. Truck Installed Equipment (TIE)

- 5.6. Rail Guidance

- 5.6.1. Auto Steer Centering Description

- 5.6.2. Sequence of Operation

- 6. TROUBLESHOOTING

- 6.1. Introduction

- 6.2. Codes and Tests

- 6.2.1. Troubleshooting Procedure

- 6.2.2. Electrical

- 6.2.3. Hydraulics

- 6.3. Troubleshooting EV100LX Control System

- 6.3.1. Handset

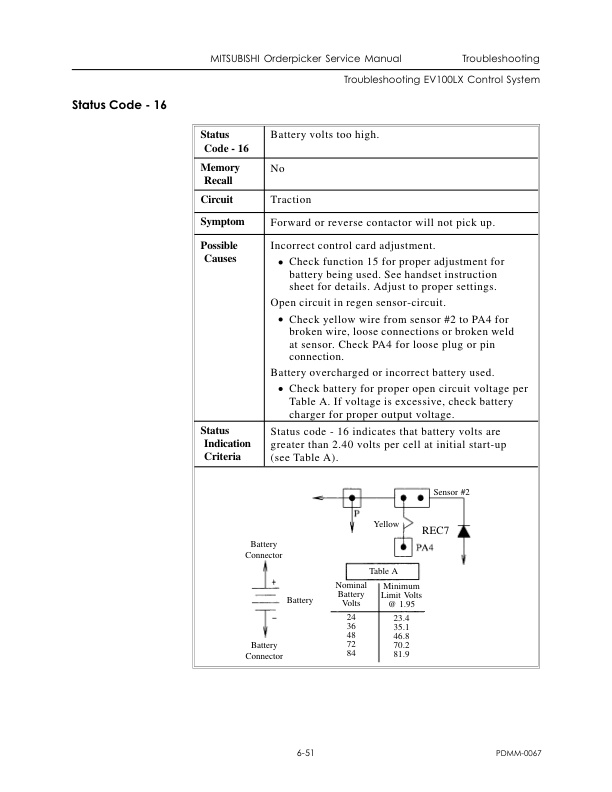

- 6.3.2. GE Status Codes

- 6.4. Troubleshooting The Interface Card System

- 6.4.1. LEARN (Interface Card Setup) Procedure and Troubleshooting

- 6.4.2. Initial Precautions

- 6.4.3. Setup Procedure

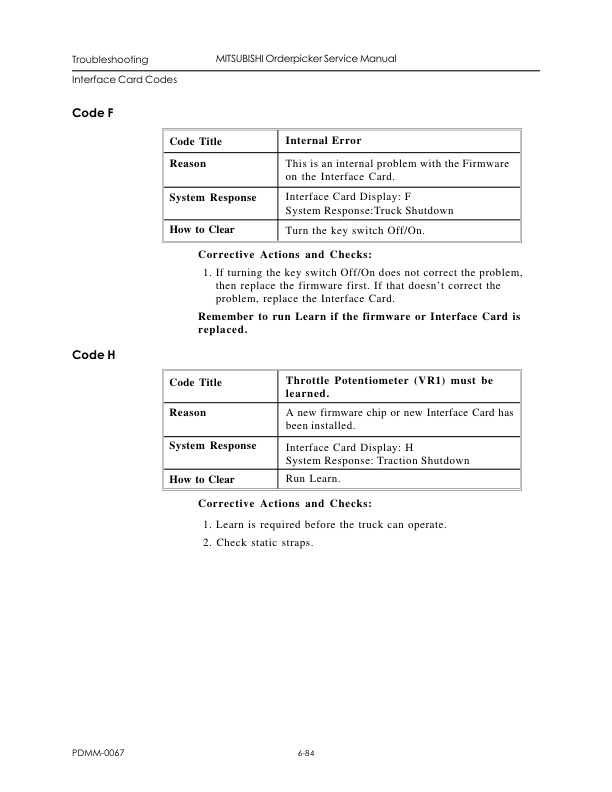

- 6.5. Interface Card Codes

- 6.6. Troubleshooting The Electronic Power Steering System

- 6.6.1. Maintenance Mode – Static

- 6.6.2. Maintenance Mode – Active

- 6.6.3. Electronic Power Steering Systems

- 6.7. Analog Input Tests

- 6.8. Digital Input Tests

- 6.9. Digital Output Tests

- 7. UNPACKING AND INSPECTION

- 7.1. Receiving Truck

- 7.1.1. Reasons For Visual Inspections

- 7.1.2. What to Look For

- 7.1.3. Visual Inspection/Conditions

- 7.2. Installation Procedure

- 7.2.1. Cradled Trucks

- 7.2.1.1. Visual Inspections

- 7.2.2. Uncradling

- 7.2.2.1. Uprighting a Cradled Vehicle

- 7.2.2.2. Procedure 1

- 7.2.2.3. Procedure 2

- 7.2.3. Gasket Removal

- 7.2.4. Greasing Mast Uprights

- 7.2.5. Battery

- 7.2.5.1. Battery Charger

- 7.3. Functional Inspection

- 7.3.1. Vehicle Operation

- 7.3.2. Warranty

- 7.3.3. What To Look For

- 7.3.4. Functional Installation Checklist

- 7.4. Cold Storage Conditioning

- 7.4.1. Types of Oils

- 7.4.2. Classes of Cold Storage

- 7.4.3. Hydraulic System Oil Change Procedure

- 7.5. Storage

- 7.5.1. Storage Warranty

- 7.5.2. Hydraulic System

- 7.5.3. Hydraulic Cylinders

- 7.5.4. Lift/Steering Chains

- 7.5.5. Electronics

- 7.5.6. Battery

- 7.5.7. Greasing Mast Uprights

- 7.5.8. Vehicle – General

- 8. WARNING PAGES

- 8.1. Warning Pages

- 8.2. Manual Overview

- 8.3. Using the Manual

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-74120

$50.00