Mitsubishi FB 40-50 Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 434

- Size: 26.0MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- FB 40-50

- 1. EN

- 1.1. Drive Brake

- 1.1.1. Parking Brake, Mechanical

- 1.1.2. Foot Brake

- 1.1.3. Parking Brake, Hydraulic

- 1.1.4. Multi-Plate Brake

- 2. EN

- 2.1. Parking Brake, Mechanical

- 2.1.1. Disassembly

- 2.1.2. Assembly

- 3. EN

- 3.1. Foot Brake

- 3.1.1. Disassembly

- 3.1.2. Assembly

- 4. EN

- 4.1. Parking Brake, Hydraulic

- 4.1.1. Spring-loaded brake disassembly

- 4.1.2. Spring-loaded brake assembly

- 5. EN

- 5.1. Multi-Plate Brake

- 5.1.1. Replacing the Multi-Plates

- 6. EN

- 6.1. Controls

- 6.1.1. CANCODE

- 6.1.2. ISM Access Module (see ISM service manual)

- 6.1.3. ISM component assembly

- 6.2. Truck Lighting

- 6.2.1. Beacon (LED)

- 6.3. Misc. Electrical

- 6.3.1. Fuses

- 6.3.2. Connector Overview / Connector Layout

- 6.3.3. On-Board Power Supply

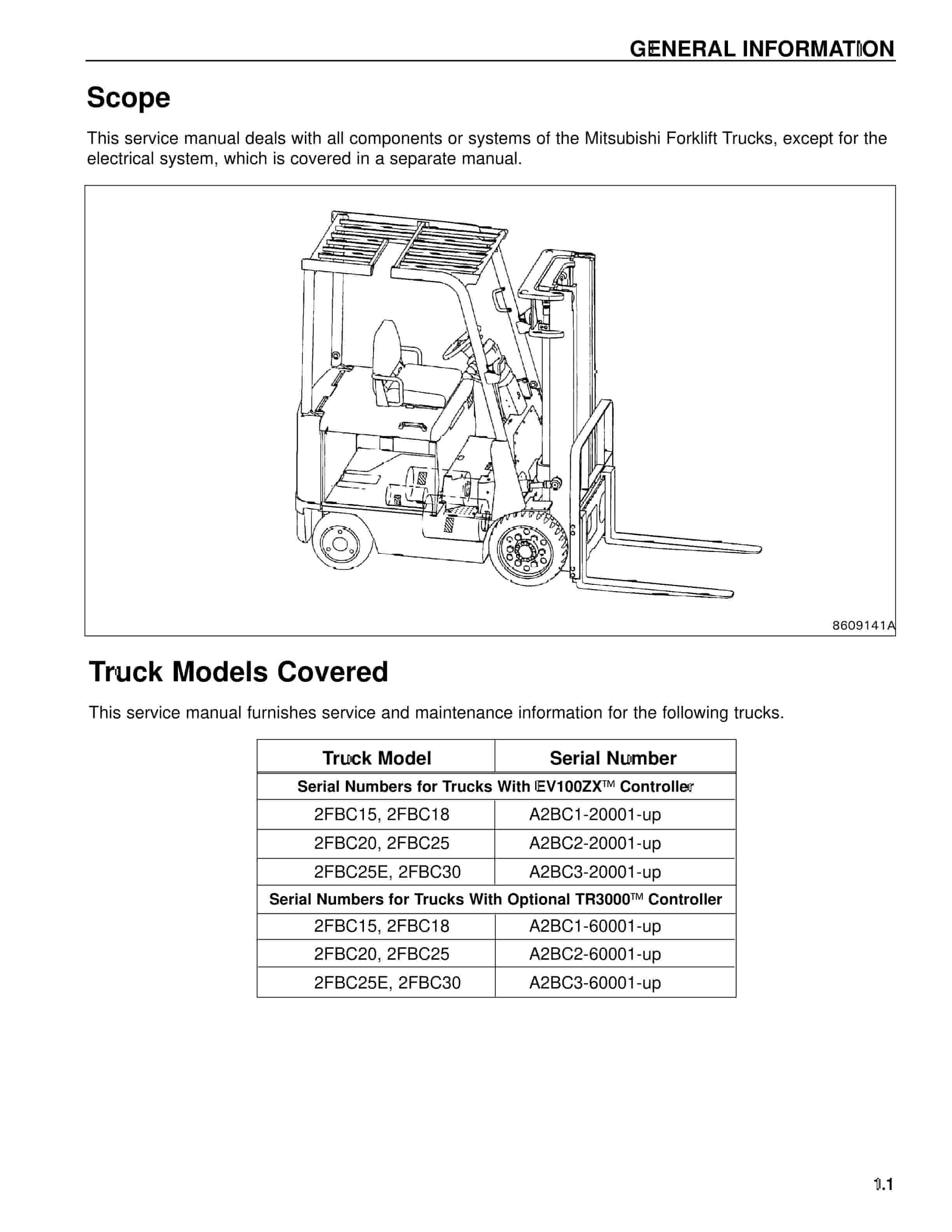

- 6.3.4. Saab Connector PIN Layout

- 6.3.5. DC/DC converter iCE-PIO

- 6.3.6. DC/DC converter iCE-POC

- 6.4. Traction and Hydraulic Controllers

- 6.4.1. Drive Lift Controller

- 7. EN_.pdf

- 7.1. Code Lock / CanCode

- 7.1.1. Overview

- 7.1.2. Functions

- 7.1.3. User mode

- 7.1.4. Master mode

- 7.1.5. Code lock error messages

- 7.1.6. Code Combinations

- 7.1.7. Auxiliary Functions

- 7.1.8. Technical Specifications

- 7.1.9. Connector pin assignment

- 7.1.10. Status Display for the Various LEDs

- 7.1.11. Entry confirmation

- 7.1.12. Flow diagram

- 7.1.13. Parameters

- 8. EN_LED Konzernrundumleuchte

- 8.1. Beacon LED

- 8.1.1. Operating Mode Programming

- 8.1.2. Connector

- 9. EN

- 9.1. On-Board Power Supplies

- 10. EN.pdf

- 10.1. Connector Overview

- 10.2. Connector layout

- 11. EN_Pin_Belegung_saab

- 11.1. Pin Layout for Saab Connectors

- 11.1.1. pin connector

- 11.1.2. pin connector

- 11.1.3. pin connector

- 11.1.4. pin connector

- 11.1.5. pin connector

- 11.1.6. pin connector

- 11.1.7. pin connector

- 12. EN

- 12.1. Installation of ISM components FB40-50

- 12.1.1. Description

- 12.1.2. Requirements

- 12.1.3. Mounting position of the ISM components

- 13. EN

- 13.1. Mechanical Transmission

- 13.1.1. Transmission

- 13.2. Drive System

- 13.2.1. Drive Unit

- 13.2.2. Thermal Sensor

- 13.2.3. Wheel Bolts

- 13.3. Electrical System

- 13.3.1. Drive Lift Controller

- 13.3.2. DC/DC Converter iCE-PIO

- 13.3.3. DC/DC Converter iCE-POC

- 14. EN

- 14.1. Drive Lift Controller

- 14.1.1. Settings / diagnostics

- 14.1.2. Overview

- 14.1.3. Minimum diagnostics

- 14.1.4. Heartbeat indicator LED H4, H5, H6, 1H11 and 1H10

- 14.1.5. Error flashing code

- 14.1.6. Diagnostic display LED H3 and H7

- 14.1.7. LED H3 for fuse box 1

- 14.1.8. LED H7 for fuse box 2

- 14.1.9. Disassembly

- 14.1.10. Dismantling the controller

- 14.1.11. Controller assembly

- 15. EN

- 15.1. iCE-PIO / iCE-POC

- 15.1.1. Diagnostics

- 15.1.2. Overview

- 15.1.3. iCE-PIO minimum diagnostics

- 15.1.4. Heartbeat indicator LED 5H19

- 15.1.5. Error flashing code

- 15.1.6. Diagnostic indicator LED 5H18

- 15.1.7. iCE-POC minimum diagnostics

- 16. EN

- 16.1. Ü1 Über1 – Thermal Sensor (KTY 84-130) 1B7 / 2B4

- 17. EN

- 17.1. Drive Unit

- 17.1.1. Disassembly

- 18. EN

- 18.1. Transmission

- 18.1.1. RH transmission disassembly

- 18.1.2. Assembly

- 18.1.3. LH transmission disassembly

- 18.1.4. Assembly

- 19. EN

- 19.1. Wheel Bolts

- 19.1.1. Disassembly

- 20. EN

- 20.1. Operator Position

- 20.1.1. Armrest

- 20.2. Labelling / Documentation

- 20.2.1. Operating Instructions

- 20.2.2. Circuit Diagrams

- 21. EN

- 21.1. Circuit Diagrams

- 21.1.1. Electrical System

- 21.1.2. Hydraulics

- 22. EN

- 22.1. Armrest

- 22.1.1. Gas pressure spring / Bowden cable disassembly

- 23. EN

- 23.1. Mast, Mechanical

- 23.1.1. Mast Rollers (for masts with angled backing rollers see service manual G 6233.01)

- 23.1.2. Mast Rollers (mast without roller recess)

- 23.1.3. Chains (for chain elongation testing see service manual G 6355.01)

- 23.1.4. Securing the Mast

- 23.2. Load Handler

- 23.2.1. Forks (see service manual G1 6401.01)

- 23.3. Hydraulic System …

- 23.3.1. Valve Block

- 23.3.2. Hydraulic Unit

- 23.3.3. Hydraulic Reservoir

- 23.3.4. Thermal Sensor

- 23.4. Controls

- 23.4.1. Solopilot

- 23.4.2. Multipilot

- 24. _EN

- 24.1. SOLO-PILOT, assembly and disassembly

- 24.1.1. Disassembly

- 24.1.2. Description

- 25. _EN

- 25.1. MULTI-PILOT, assembly and disassembly

- 25.2. Disassembly

- 25.3. Description

- 26. _EN

- 26.1. Securing the Mast

- 26.1.1. Securing the mast with a chain

- 26.1.2. Chain lock (detailed image)

- 27. EN ohne Rollenausschnitt

- 27.1. Mast Roller Disassembly – Mast Without Roller Recess

- 27.1.1. Required tools and materials

- 27.1.2. Preparing the truck

- 27.1.3. Jacking up the truck

- 27.1.4. Disassembly preparation

- 27.1.5. Fork carriage disassembly

- 27.1.6. Undoing the hose connections

- 27.1.7. Piston rod disassembly

- 27.2. Mast Roller Assembly – Mast Without Roller Recess

- 27.2.1. Piston rod assembly

- 27.2.2. Fork carriage assembly

- 27.2.3. Safety and functional test

- 28. EN

- 28.1. Hydraulic Unit

- 28.1.1. Disassembly

- 28.1.2. Assembly

- 29. EN

- 29.1. Ü1 Über1 – EFG 4 EFG 5 Hydraulic Reservoir

- 29.1.1. Ü2 Über2 –

- 30. EN

- 30.1. FB 40-50 Manifold

- 30.1.1. Safety valve test

- 31. EN

- 31.1. Commissioning

- 31.1.1. Commissioning (see Operating Instructions, Chapter C)

- 31.2. Maintenance

- 31.3. – Notes on how to avoid malfunctions and material damage when cleaning an industrial truck See service manual Z 0000.15

- 31.4. – Notes on how to avoid accidents and material damage during maintenance, test and repair work on industrial trucks with electronic components See service manual J 6900-09

- 31.4.1. Regular inspection in accordance with FEM 4.004

- 31.4.2. Maintenance Checklist B

- 31.4.3. Maintenance Checklist C

- 32. EN

- 32.1. Electrical System

- 32.1.1. Steering Actual Value Sensor (3U9)

- 32.1.2. Setpoint Sensor RSC 28 MH (3U10)

- 32.1.3. Thermal Sensor (3B26)

- 32.2. Steer Axle

- 32.2.1. Steer Axle

- 32.3. Mechanical Components

- 32.3.1. Steering Column

- 32.4. Steering

- 32.4.1. Steering Controller Assembly (3U8)

- 32.4.2. Steering Controller ICE-EPS (3U8)

- 32.4.3. Electric Steering

- 33. EN

- 33.1. Actual Value Sensor (3U9)

- 33.1.1. Disassembly

- 33.1.2. Assembly

- 33.2. Actual value sensor (3U9) with electric steering

- 33.2.1. Disassembly

- 33.2.2. Assembly

- 33.2.3. Travel speed as a function of the steer wheel angle

- 34. EN

- 34.1. Steering Controller Assembly

- 35. EN

- 35.1. ICE-EPS Steering Controller

- 35.1.1. Notes on how to avoid accidents and material damage

- 35.1.2. ICE-EPS Steering Controller

- 35.1.3. Performance Data

- 35.1.4. Settings and Diagnostics

- 36. EN

- 36.1. FB40-50 Steer Axle

- 36.2. FB 40S-50S Steer Axle

- 37. EN

- 37.1. Electric Steering

- 38. EN

- 38.1. Steering Column with Electro-Hydraulic Steering

- 38.2. Steering Column with Hydraulic Steering

- 39. Anordnung von Komponenten FB40-50 EN

- 39.1. Ü1 Über1 – FB40-50

- 39.1.1. Ü2 Über2 – Counterweight

- 39.1.2. Ü2 Über2 – Drive Compartment

- 39.1.3. Ü2 Über2 – Operator Position

- 40. Anziehdrehmomente_EN

- 40.1. General Screw Torques

- 40.2. General Screw Torques (Nm)

- 40.3. General Screw Torques (lbf ft)

- 40.4. General Screw Torques

- 40.5. General Screw Torques (Nm)

- 40.6. General Screw Torques (lbf ft)

- 41. Beschreibung IDA_EN

- 41.1. Ü1 Über1 – IDA Description

- 41.1.1. Ü2 Über2 – Display

- 41.1.2. Ü2 Über2 – Display and Keypad Layout

- 41.1.3. Ü2 Über2 – Connecting the IDA to the Truck

- 41.1.4. Ü2 Über2 – Updating the Content of the IDA

- 41.1.5. Ü2 Über2 – Updating the IDA

- 41.1.6. Ü2 Über2 – Commissioning with the IDA

- 42. Einstieg FB 40-50

- 42.1. Safety Information

- 42.2. Component Layout

- 42.3. Technical Specifications

- 42.4. Operating Instructions

- 42.5. Circuit Diagrams (Electrical / Hydraulic)

- 42.6. Parameters

- 42.7. Event Message

- 42.8. General Tightening Torques

- 43. Ereignismeldungen EN

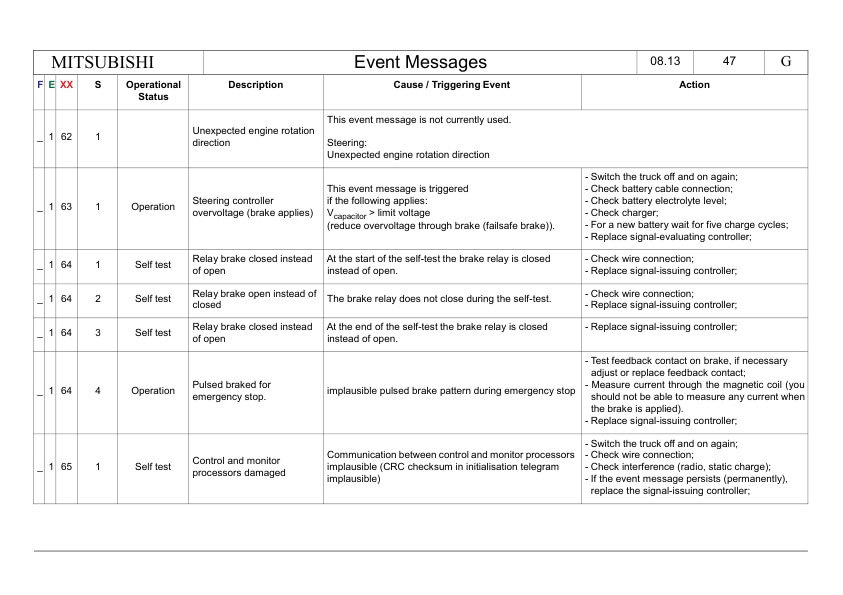

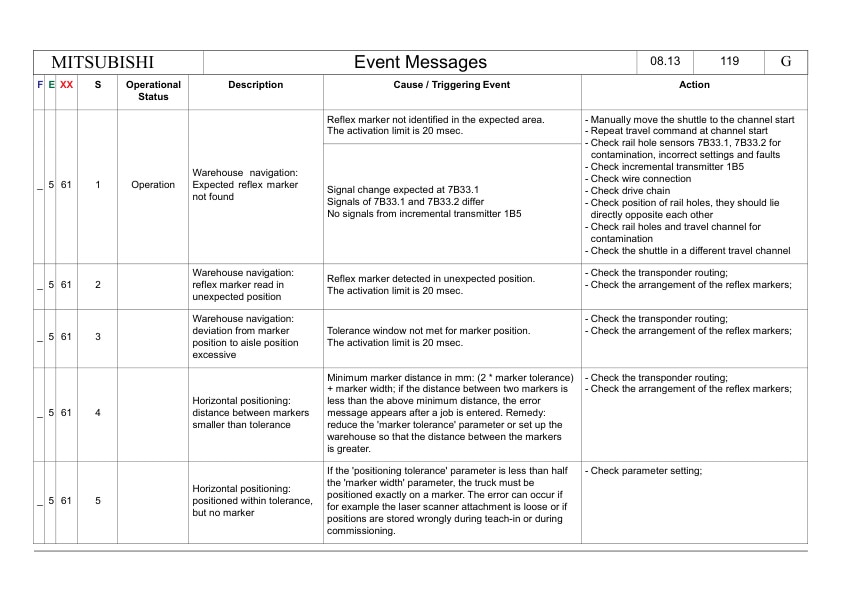

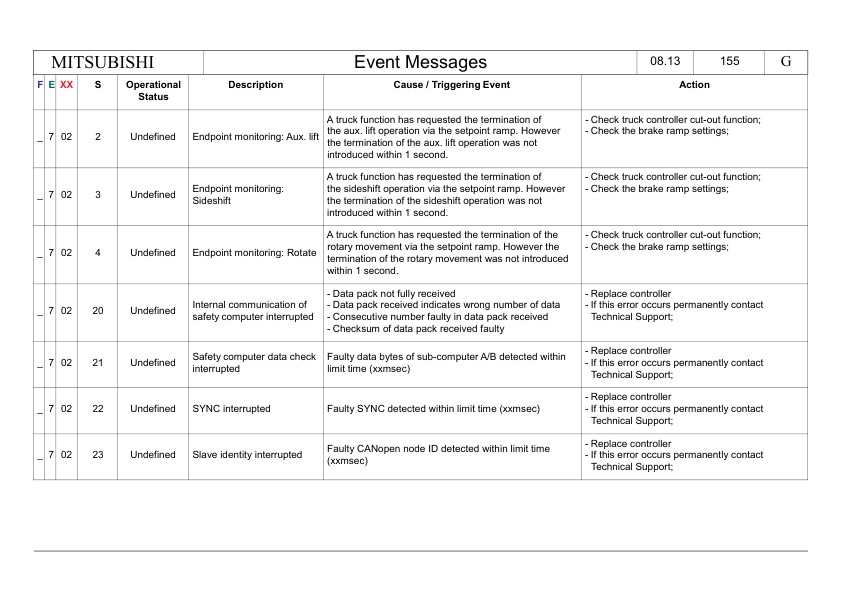

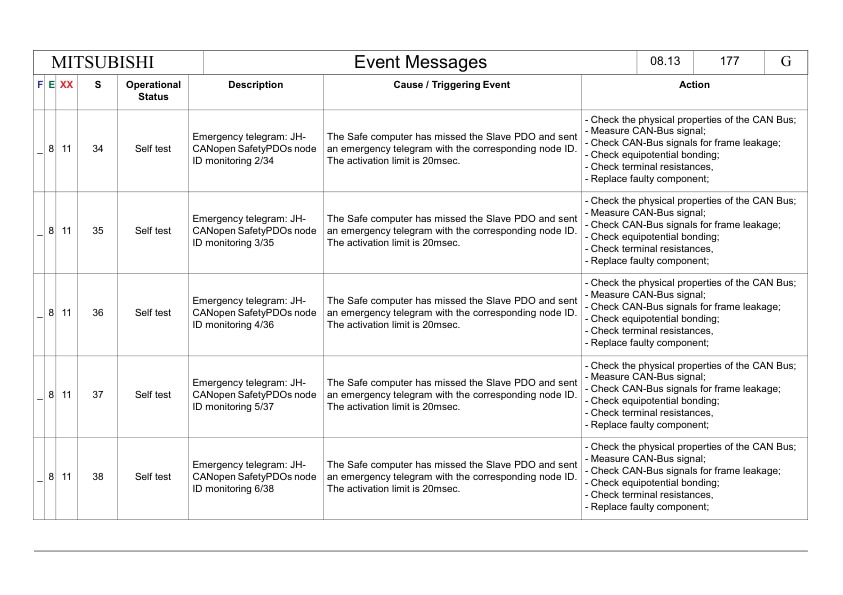

- 43.1. Event Messages

- 43.1.1. Event numbering display

- 43.1.2. Display system

- 43.1.3. Description / cause / action and effects

- 43.2. Event messages table

- 43.3. CAN-Bus node IDs

- 44. G 623301_GB

- 44.1. Ü1 Über1 – Hoist Frames with Angled Rollers

- 44.1.1. Ü2 Über2 – Condition Assessment

- 44.1.2. Ü2 Über2 – Test Measurements

- 44.1.3. Ü2 Über2 – Roller Components

- 44.1.4. Ü2 Über2 – Adjustment

- 44.1.5. Ü2 Über2 – Setting Instructions

- 45. G 6355_01_EN.PDF

- 45.1. Load Chains (Cleaning, Inspection and Lubrication)

- 45.2. Cleaning

- 45.3. Inspection

- 45.3.1. Checking the chain wear level

- 45.3.2. Checking chains for corrosion

- 45.3.3. Checking the wear limit of link plate height H

- 45.3.4. Checking chains for elongation

- 45.4. Lubrication

- 45.4.1. General Instructions

- 45.4.2. Lubricants

- 46. G1 640101_EN(06.05)

- 46.1. Technical Specifications

- 47. J 6900_09_GB

- 47.1. Instructions for the prevention of accidents and damage to equipment when performing servicing, checking and repair operations on fork lift trucks equipped with electronic assemblies

- 47.1.1. Safety measures

- 47.1.2. Electric welding operations

- 47.1.3. Correct handling of electronic printed circuit boards

- 47.1.4. Handling of electronic components (MOS-components, E-PROM and others)

- 47.1.5. Changing the EPROM

- 47.1.6. Installation of heat-sensitive components

- 47.1.7. Cleaning operations

- 48. Parameter FB 40-50 DE_EN_MCFE

- 48.1. Ü2 Über2 – Einstellung der Parameter und Optionen/ Adjustment of the Parameters and Options

- 48.1.1. Ü3 Über3 – Einstellung der Parameter und Optionen/ Adjustment of the Parameters and Options

- 49. Technische Daten FB 40-50 EN

- 49.1. FB 40-50

- 49.1.1. Tightening torques in accordance with VDI 2230 (sheet 1)

- 49.1.2. Truck-Specific Torques

- 50. Z 0000_15_GB

- 50.1. Instructions for the prevention of functional failures and damage to equipment when performing cleaning operations on fork lift truck

- 50.1.1. Cleaning operations, general

- 50.1.2. Cleaning and servicing of chains

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-56103

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00