Mitsubishi FB40N, FB45N, FB50CN, FB50N, FB50NH, FB55NH Service Manual 656257 EN C

$50.00

- Type Of Manual: Service Manual

- Manual ID: 656257

- Language: EN C

- Number of Pages: 596

- Size: 31.3MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- FB40N, FB45N, FB50CN, FB50N, FB50NH, FB55NH

- 1. Table of contents

- 2. Foreword

- 3. How to read this manual

- 4. Safety-related signs

- 5. Safety symbols

- 6. Units

- 7. Interactive links

- 8. Safety instructions

- 9. General safety instructions

- 10. Safety requirements for industrial trucks

- 11. Repairs and structural modifications

- 12. Seat belt

- 13. Wheels

- 14. Service area safety

- 15. Personal safety

- 16. Work safety

- 17. Operating temperature

- 18. General information

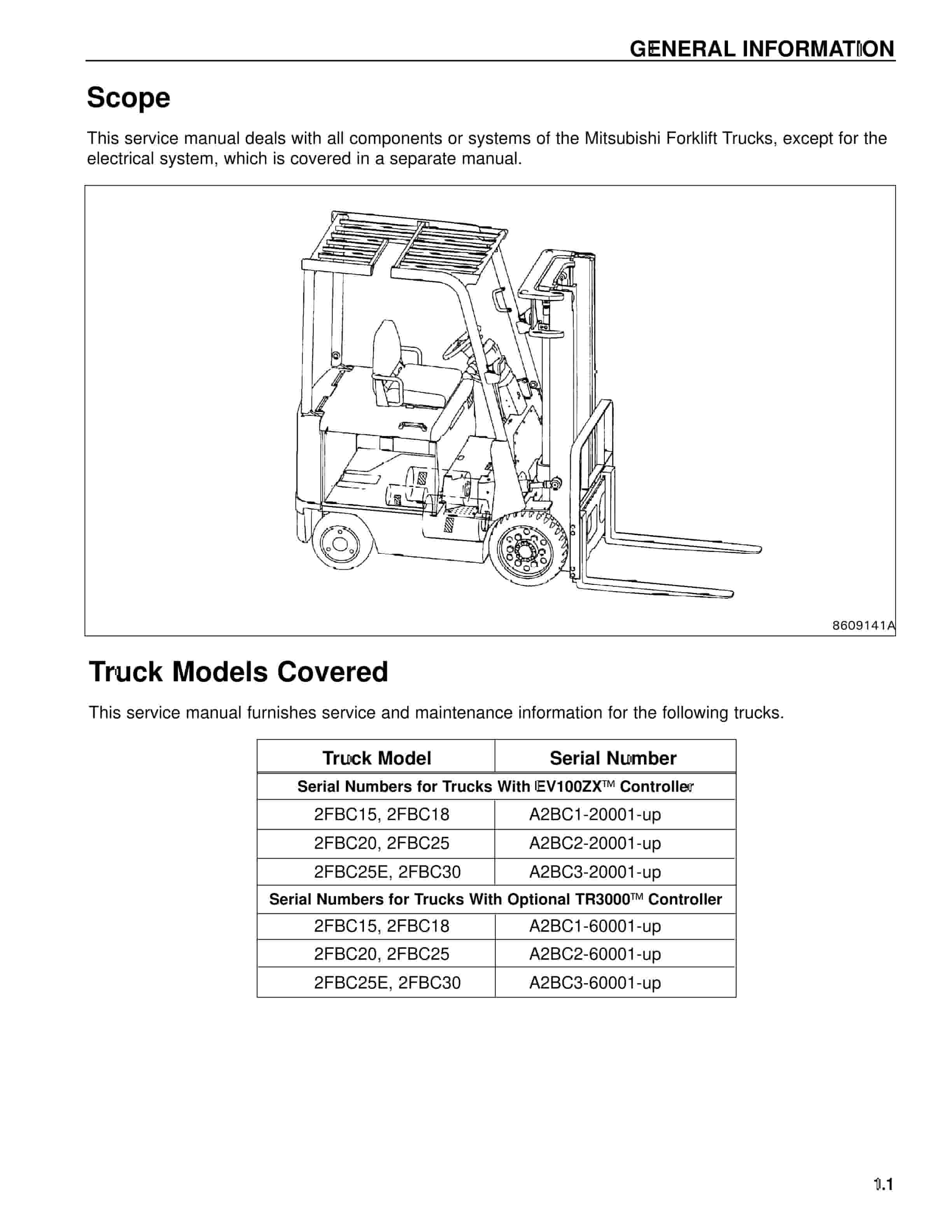

- 19. Truck models covered by this manual

- 20. Identification plates and stickers

- 21. Special tools

- 22. Operating position

- 23. Operating direction

- 24. Transportation

- 25. Lifting the truck

- 26. Jack points

- 27. Hoist points

- 28. Towing connection

- 29. Towing the truck

- 30. Brake release

- 31. Assembly and commissioning

- 32. Order spare parts

- 33. Main components

- 34. Truck covers

- 35. Overhead guard

- 36. Cabin

- 37. Manual holder

- 38. Emergency exits

- 39. Open the operator door

- 40. Open the rear window

- 41. Operators seat

- 42. Operating devices

- 43. Steering wheel

- 44. Mini steering wheel

- 45. Armrest

- 46. Armrest with fingertip controls

- 47. Dual joystick armrest

- 48. Control functions

- 49. Manual levers

- 50. Side control panel

- 51. Display panel

- 52. Emergency stop button

- 53. Key switch

- 54. Display control buttons

- 55. Truck display

- 56. Main view of the truck display

- 57. Hierarchy of the truck display menus

- 58. Pedals

- 59. Accelerator pedal

- 60. Brake pedal

- 61. Operator presence pedal (option)

- 62. Dual pedal

- 63. Pedal functionalities

- 64. Battery inspection hatch

- 65. Electric system

- 66. Electrical operation

- 67. Overview

- 68. How to use the schematic diagram

- 69. Power source

- 70. Safety circuit (emergency stop button)

- 71. Key switch

- 72. Traction

- 73. Controllers

- 74. Vehicle master controller

- 75. Vehicle master controller connectors

- 76. Traction controller

- 77. Traction controller connectors

- 78. Pump controller

- 79. Pump controller connectors

- 80. Steering controller

- 81. Steering controller connectors

- 82. Sensors and switches

- 83. Horn switch

- 84. Option panel

- 85. Fuses

- 86. Location of the fuses in the electric panel

- 87. Location of the fuses for optional equipment

- 88. Location of the fuses for heater and air conditioner

- 89. Location of the fuses for the oil cooler

- 90. Location of the fuses for easy charging

- 91. Relays and contactors

- 92. Main relays and contactors

- 93. Option panel relays

- 94. Air conditioning relays

- 95. Oil cooler relays

- 96. Easy charger fan relay

- 97. DC/DC converter

- 98. Armrest connector

- 99. Display connector

- 100. Steering feedback device

- 101. Hydraulic operation

- 102. Hydraulic operation overview

- 103. Hydraulic operation lifting/lowering

- 104. Hydraulic symbols

- 105. Hydraulic valve unit with fingertip controls

- 106. Manual lowering valve

- 107. Hydraulic valve unit with manual levers

- 108. Clamp release valve

- 109. Hydraulic supply system

- 110. Hydraulic flow distribution with additional hydraulic functions

- 111. Additional hydraulic functions in a truck with the armrest

- 112. Additional hydraulic functions in a truck with the manual levers

- 113. Drive axle

- 114. Brakes

- 115. Service brake

- 116. Parking brake

- 117. Rear axle

- 118. Load handling

- 119. Lifting carriage

- 120. Integrated sideshift carriage

- 121. Hook-on sideshift

- 122. Integrated fork positioner with sideshift

- 123. Load backrest

- 124. Mast

- 125. Simplex mast

- 126. Triplex mast

- 127. Mast chains

- 128. Main rollers

- 129. Mast cylinders

- 130. Free lift cylinder

- 131. Side cylinders

- 132. Tilt cylinders

- 133. Nominal capacity height indicator

- 134. Automated performance reduction based on lift height

- 135. Wheels

- 136. Solid rubber wheels

- 137. Pneumatic wheels

- 138. Cushion wheels

- 139. Maintenance

- 140. Maintenance intervals

- 141. Truck covers

- 142. Remove the pedal plate

- 143. Open the battery door

- 144. Remove the back cover

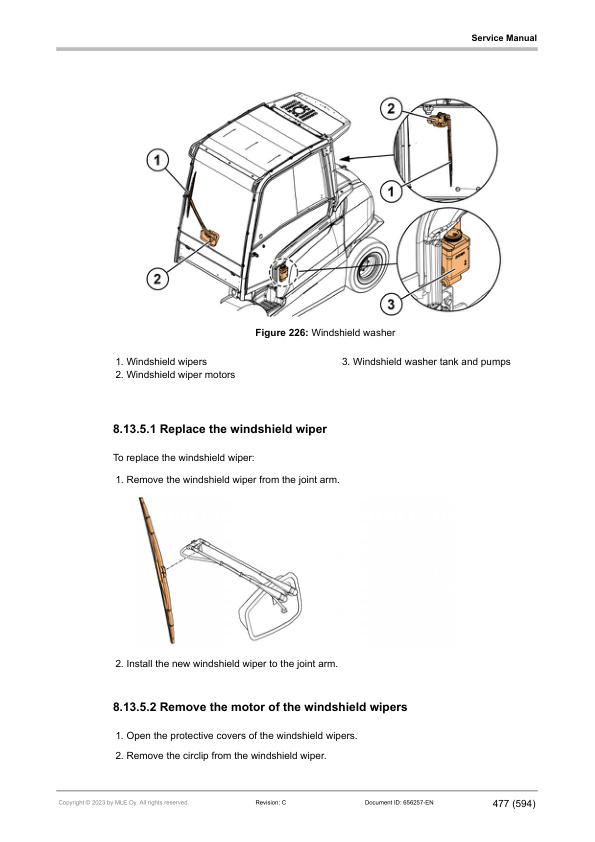

- 145. Remove the steering wheel cover

- 146. Remove the control panel

- 147. Remove the side control panel

- 148. Remove the front top side cover

- 149. Remove the air intake cover

- 150. Remove the interior panel

- 151. Remove the electric panel cover

- 152. Remove the step cover

- 153. Open the side door

- 154. Remove the right side cover

- 155. Cabin

- 156. Windshield washer tank

- 157. Examine the air filters of the heater

- 158. Replace the air filters of the air conditioner

- 159. Cabin seals

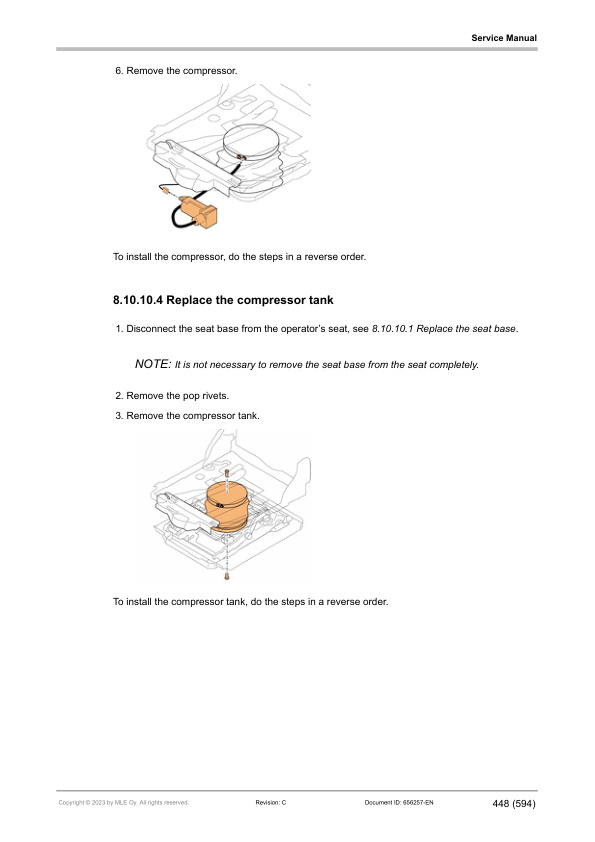

- 160. Air conditioner unit

- 161. Drive unit

- 162. Leakage check of the drive axle

- 163. Fastening of the drive axle

- 164. Lubricate the drive axle

- 165. Oil volume measurement

- 166. Oil draining

- 167. Oil filling

- 168. Test the parking brake

- 169. Maintenance of the parking brake and the service brake

- 170. Test the regenerative brake

- 171. Hydraulics

- 172. Hydraulic system maintenance

- 173. Leakage check of the hydraulic system

- 174. Replace the hydraulic oil return filter

- 175. Replace the air breather filter

- 176. Cleaning of the hydraulic oil suction filter

- 177. Remove the hydraulic oil suction filter

- 178. Oil level

- 179. Operation of the hydraulics

- 180. Relief valves

- 181. Hydraulic oil change

- 182. Hoses and cylinders

- 183. Lubricate the pump axle splines

- 184. Lubricate the steering unit pump axle splines

- 185. Clean the oil tank

- 186. Mast

- 187. Mounting of the mast

- 188. Wear level of the mast rollers and contact surfaces

- 189. Chain tension

- 190. Chain lubrication

- 191. Chain wear measurement

- 192. Check the chain anchors and locking pins

- 193. Check the cylinders and piston rods

- 194. Lifting and lowering speed

- 195. Lubrication of the mast channel surfaces

- 196. Lifting test

- 197. Examine the welding in the mast for cracks

- 198. Mounting of any attachments and load-carrying components

- 199. Examine the welding of the cylinders and masts for cracking

- 200. Examine the rollers, pins and welds for cracking and damage

- 201. Apply grease to the lubrication points of the tilt cylinder

- 202. Additional mast attachments

- 203. Lifting carriage

- 204. Examine the welding in lifting carriage for cracks

- 205. Examine the load backrest for cracks

- 206. Fork inspection

- 207. Maintenance of the integrated sideshift carriage

- 208. Check the sliding blocks

- 209. Adjust the lower hooks

- 210. Maintenance of the integrated fork positioner with sideshift

- 211. Check the sliding blocks

- 212. Rear axle

- 213. Lubricate the rear axle

- 214. Examine the operating condition of the bearings, check for looseness of the bearings

- 215. Examine the welds for cracks

- 216. Examine the mounting of the rear axle

- 217. Examine the condition of the rubber spring

- 218. Wheels

- 219. Damage and wear in the wheels

- 220. Before you replace the wheels

- 221. Front wheels

- 222. Remove the front wheel

- 223. Install the front wheel

- 224. Replace the wheel shaft bolts of the front wheel

- 225. Rear wheels

- 226. Remove the rear wheels

- 227. Install the rear wheels

- 228. Replace the wheel shaft bolts of the rear wheel

- 229. Electrics

- 230. Test the functionality of sensors

- 231. Traction motor sensors

- 232. Steering motor sensors

- 233. Pump motor sensors

- 234. Battery door sensor and side door sensor

- 235. Pressure sensor

- 236. Tilt angle sensor

- 237. Mast height sensor

- 238. Parking brake sensors

- 239. Rear axle sensor

- 240. Steering wheel sensor

- 241. Mini steering wheel sensors

- 242. Accelerator pedal sensor

- 243. Brake pedal sensor

- 244. Brake fluid level sensor

- 245. Operator presence pedal sensor

- 246. Dual pedal sensors

- 247. Manual lever sensors

- 248. Seat belt switch

- 249. Seat switch

- 250. Side control panel switches

- 251. Steering column driving direction selection switch

- 252. Clamp release switch

- 253. Autolight sensor

- 254. Steering wheel functions

- 255. Horn

- 256. Electrical connections tightening torques

- 257. Cables and wiring

- 258. Examine and clear the alarm history

- 259. Insulation resistance test

- 260. Test voltage

- 261. Check the insulation tester

- 262. Measure the insulation resistance

- 263. Discharge the controllers

- 264. Emergency stop button functionality check

- 265. Key switch functionality check

- 266. Replace the filter of the air intake

- 267. Safety

- 268. Inspect the seat belt

- 269. Functionality of the fire extinguisher

- 270. General

- 271. How to clean the truck

- 272. Lubrication

- 273. Examine the welding in the truck frame for cracking

- 274. Examine the truck frame and the lifting carriage

- 275. Examine the overhead guard for deformation, cracking and damage

- 276. Examine the gas springs

- 277. Examine the condition and position of the identification plates

- 278. Examine the covers

- 279. Safety functions

- 280. Examine the fastening of the steering wheel

- 281. Battery maintenance

- 282. Lead-acid batteries

- 283. Safety with lead-acid batteries

- 284. General information

- 285. Requirements for battery charging areas

- 286. Charge the battery

- 287. After the battery is charged

- 288. Charge the battery with easy charging

- 289. Before charging

- 290. After charging

- 291. Battery maintenance

- 292. General maintenance

- 293. How to clean the battery

- 294. Daily maintenance

- 295. Weekly maintenance

- 296. Monthly maintenance

- 297. Annual maintenance

- 298. Malfunctions

- 299. Acquire a new battery

- 300. Storage

- 301. Lithium-ion batteries

- 302. General information

- 303. Safety signs

- 304. Requirements for battery charging areas

- 305. Charge the battery

- 306. Recharging a lithium-ion battery

- 307. Before charging

- 308. After charging

- 309. Opportunity charging

- 310. Battery balancing

- 311. Battery maintenance

- 312. Examine the battery

- 313. How to clean the battery

- 314. Malfunctions

- 315. Service and repair

- 316. Acquire a new battery

- 317. Storage

- 318. Replace the battery

- 319. General safety instructions

- 320. Replace the battery with a lifting device

- 321. Remove the battery with the battery sideway exchange tools

- 322. Install a battery with the battery sideway exchange tools

- 323. Repair

- 324. Repair drive unit

- 325. Drive axle lifting and handling

- 326. Remove the drive axle

- 327. Remove the motor and cover of the drive axle

- 328. Replace the brake discs

- 329. Replace the hub and main seal

- 330. Install the motor and cover of the drive axle

- 331. Install the drive axle

- 332. Bleed the service brake

- 333. Repair rear axle

- 334. Remove the rear axle

- 335. Repair hydraulic system

- 336. Remove the pump motor

- 337. Disassemble the steering unit

- 338. Set the lifting pressure

- 339. Disassemble the coils

- 340. Disassemble the M1, M2 and M9 valves

- 341. Remove the clamp release valve

- 342. Repair mast

- 343. Using the mast bearing tool

- 344. Remove the mast

- 345. Disassemble the mast

- 346. Disassemble the simplex mast

- 347. Disassemble the triplex mast

- 348. Repair mast chains

- 349. Adjust the mast chains

- 350. Replace the mast chains

- 351. Repair free lift cylinder

- 352. Replace the free lift cylinder

- 353. Sealing housing of the free lift cylinder

- 354. Repair side cylinders

- 355. Replace the side cylinders

- 356. Sealing housing of the side cylinder

- 357. Repair tilt cylinders

- 358. Remove the tilt cylinders

- 359. Disassemble the tilt cylinder

- 360. Replace the main rollers of the mast

- 361. Repair lifting carriage

- 362. Remove the lifting carriage

- 363. Adjust the rollers of the lifting carriage

- 364. Replace the guidance rollers of the lifting carriage

- 365. Replace the main rollers of the lifting carriage

- 366. Replace the load backrest

- 367. Repair integrated sideshift carriage

- 368. Troubleshooting integrated sideshift carriage

- 369. Remove the load backrest

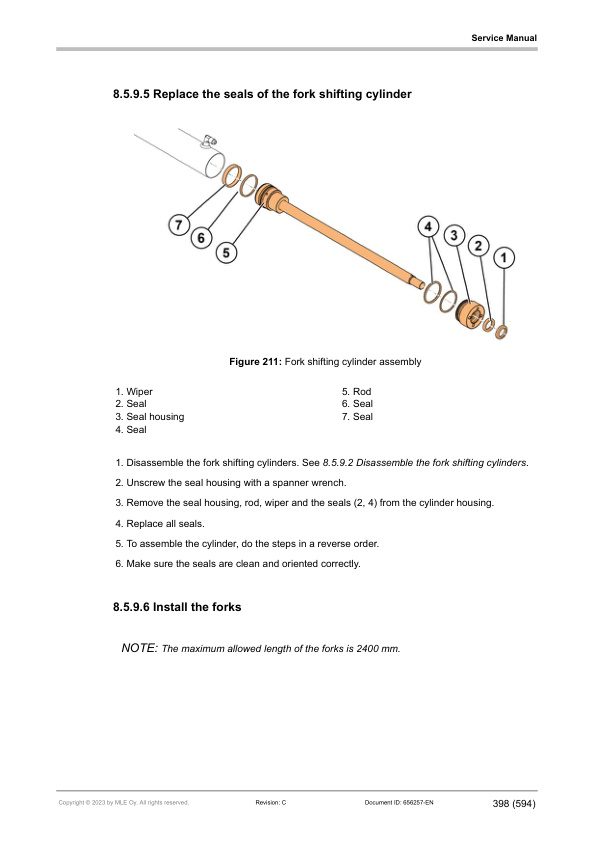

- 370. Disassemble the mobile frame

- 371. Replace the sliding blocks

- 372. Remove the piston of the integrated sideshift cylinder

- 373. Sealing housing of the integrated sideshift cylinder

- 374. Disassemble the upper sliding blocks and lower rollers

- 375. Repair hook-on sideshift carriage

- 376. Remove the hook-on sideshift frame

- 377. Remove the hook-on sideshift cylinder piston

- 378. Troubleshooting the fork positioner with sideshift

- 379. Repair integrated fork positioner with sideshift

- 380. Hydraulic system (Fork positioner)

- 381. Disassemble the fork shifting cylinders

Rate this product

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-56103

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

$50.00

Mitsubishi Service Manual PDF

$50.00