Mitsubishi FBC25OBC Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 343

- Size: 7.7MB

- Format: PDF

-

Model List:

- FBC25OBC Forklift

- 1. FOREWARD

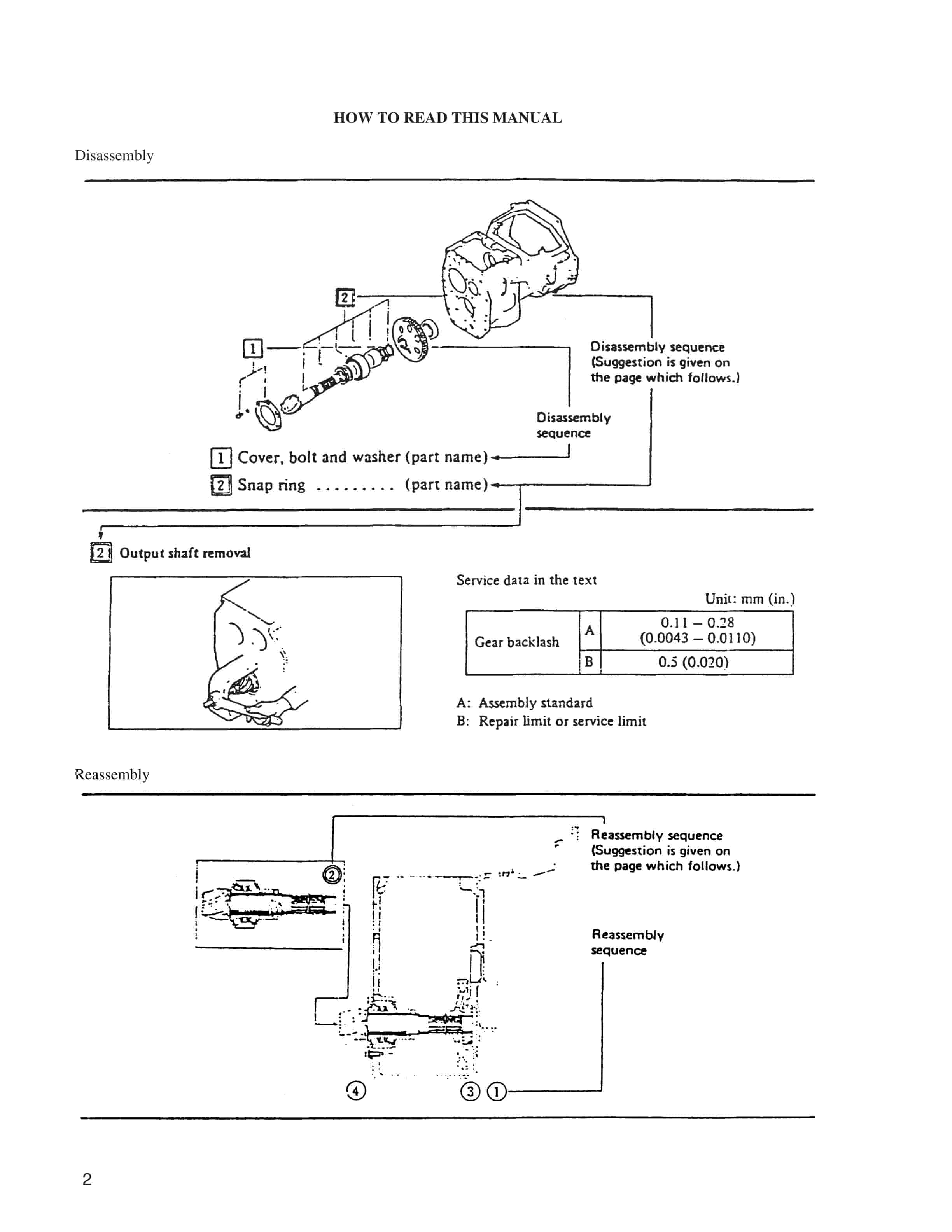

- 1.1. How To Read This Manual

- 2. BRAKE SYSTEM

- 2.1. DESCRIPTION

- 2.1.1. Automatic adjusting device

- 2.1.2. Brake pedal and associated parts

- 2.1.3. Parking brake lever mechanism

- 2.2. DISASSEMBLY AND REASSEMBLY

- 2.2.1. Master cylinder

- 2.2.2. Wheel brakes

- 2.3. INSPECTION AND ADJUSTMENT

- 2.3.1. Automatic adjusting device

- 2.3.2. Manual adjustment

- 2.3.3. Bleeding air out of the brake fluid line

- 2.3.4. Brake test

- 3. GENERAL INFORMATION

- 3.1. MODEL VIEW

- 3.2. TRUCK MODELS COVERED

- 3.3. NAME PLATE AND SERIAL NUMBER LOCATIONS

- 3.4. SPECIFICATIONS

- 4. HYDRAULIC SYSTEM

- 4.1. DESCRIPTION

- 4.1.1. Hydraulic Tank

- 4.1.2. Hydraulic Pump

- 4.1.3. Control Valve

- 4.1.4. Tilt Cylinders

- 4.2. REMOVAL AND INSTALLATION

- 4.2.1. Hydraulic Pump

- 4.2.2. Control Valve

- 4.2.3. Tilt Cylinders

- 4.3. DISASSEMBLY AND REASSEMBLY

- 4.3.1. Hydraulic Pump

- 4.3.2. Control Valve (MC)

- 4.3.3. Tilt Cylinders

- 4.4. INSPECTION AND ADJUSTMENT

- 4.4.1. Hydraulic Tank

- 4.4.2. Hydraulic Pump

- 4.4.3. Control Valve

- 5. INSPECTION GUIDE

- 5.1. PREFACE TO INSPECTION GUIDE

- 5.2. INSPECTION GUIDE

- 6. MAST AND FORKS

- 6.1. MAST MODEL DESIGNATION

- 6.1.1. Mast Model Number Location

- 6.1.2. Mast Model Number Coding

- 6.1.3. Mast Types

- 6.2. DESCRIPTION

- 6.2.1. Dual-stage panoramic mast

- 6.2.2. Dual-stage full free-lift panoramic mast

- 6.2.3. Triple-stage full free-lift panoramic mast

- 6.2.4. Hook device

- 6.2.5. Lift Cylinders

- 6.2.6. Flow regulator valve

- 6.2.7. Down safety valves

- 6.3. REMOVAL AND INSTALLATION

- 6.3.1. Mast and lift bracket assembly

- 6.3.2. Lift cylinders

- 6.3.3. Element mast piping

- 6.4. DISASSEMBLY AND REASSEMBLY

- 6.4.1. Dual-stage panoramic mast

- 6.4.2. Dual-stage full free-lift panoramic mast

- 6.4.3. Triple-stage full free-lift panoramic mast

- 6.4.4. Lift Cylinders

- 6.4.5. Flow regulator valve

- 6.4.6. Down safety valves

- 6.5. INSPECTION AND ADJUSTMENT

- 6.5.1. Lift chains, chain wheels and chain wheel supports

- 6.5.2. Lift chain tension

- 6.5.3. Longitudinal clearance adjustment on mast and lift bracket rollers

- 6.5.4. Mast strip adjustment

- 6.5.5. Lateral clearance adjustment on outer mast and inner mast rollers

- 6.5.6. Lateral clearance adjustment on outer mast and middle mast rollers

- 6.5.7. Lateral clearance adjustment on middle mast and inner mast rollers

- 6.5.8. Lateral clearance adjustment on lift bracket rollers

- 6.5.9. Mast cushion deflection inspection

- 6.5.10. Lift cylinder stroke adjustment

- 6.5.11. Hook device inspection

- 6.5.12. Pulley hose inspection

- 6.5.13. Flow regulator valve adjustment

- 6.5.14. Testing

- 7. REAR AXLE

- 7.1. DESCRIPTION

- 7.2. REMOVAL AND INSTALLATION

- 7.2.1. Rear Tires and Rear Axle

- 7.3. DISASSEMBLY AND REASSEMBLY

- 7.3.1. Disassembly

- 7.3.2. Reassembly

- 7.4. INSPECTION AND ADJUSTMENT

- 7.4.1. Toe-in adjustment

- 7.4.2. Minimum Turning Radius Adjustment

- 8. REDUCTION DIFFERENTIAL AND FRONT AXLE

- 8.1. DESCRIPTION

- 8.2. REMOVAL AND INSTALLATION

- 8.2.1. Front tires

- 8.3. DISASSEMBLY AND REASSEMBLY

- 8.3.1. Front axle

- 8.3.2. Reduction gear and differential

- 8.4. INSPECTION AND ADJUSTMENT

- 8.4.1. Side bearing preload and adjustment

- 8.4.2. Reduction gear backlash adjustment

- 8.4.3. Face runout measurement

- 8.4.4. Tooth contact adjustment

- 8.5. TRANSFER CASE

- 8.5.1. Disassembly

- 8.5.2. Reassembly

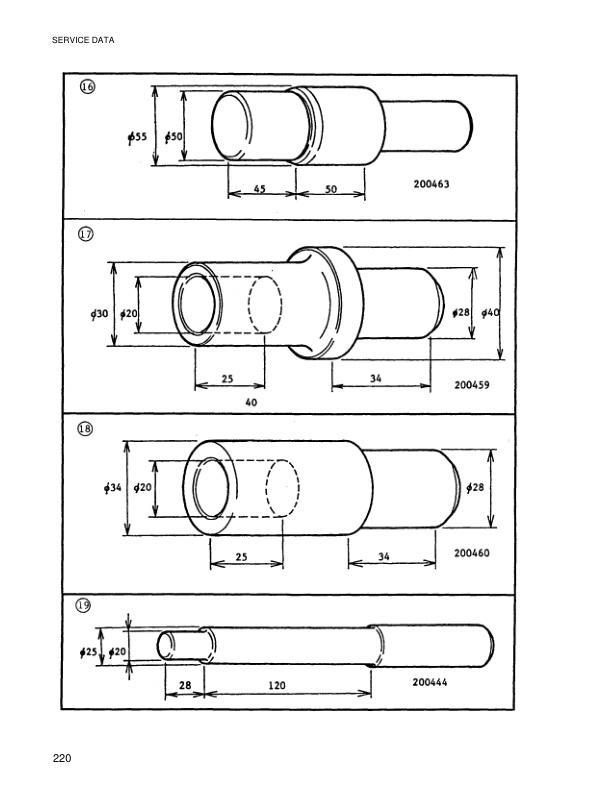

- 9. SERVICE DATA

- 9.1. MAINTENANCE STANDARDS

- 9.1.1. Reduction differential and front axle

- 9.1.2. Rear axle

- 9.1.3. Brake system

- 9.1.4. Steering system

- 9.1.5. Hydraulic system

- 9.1.6. Masts and forks

- 9.2. TIGHTENING TORQUE CHART

- 9.3. MAINTENANCE SCHEDULE

- 9.4. PERIODICAL REPLACEMENT PARTS

- 9.5. LUBRICATION CHART

- 9.6. FUEL AND LUBRICANT SPECIFICATIONS

- 9.7. RECOMMENDED BRANDS OF LUBRICANTS

- 9.8. WEIGHT OF MAJOR COMPONENTS

- 9.9. SPECIAL SERVICE TOOLS

- 10. STEERING SYSTEM

- 10.1. DESCRIPTION

- 10.1.1. Removal of steering pump/motor removal assembly

- 10.1.2. Steer pump disassembly

- 10.1.3. Steer pump reassembly

- 10.2. REMOVAL AND INSTALLATION

- 10.2.1. Steering gear and power cylinder

- 10.3. DISASSEMBLY AND REASSEMBLY

- 10.3.1. Steering gear

- 10.3.2. Power cylinder

- 10.4. INSPECTION AND ADJUSTMENT

- 10.4.1. Steering wheel free play

- 10.4.2. Steering effort

- 10.5. HYDRAULIC PRESSURE MEASUREMENT AND ADJUSTMENT

- 11. TROUBLESHOOTING

- 11.1. TRANSFER GEAR, REDUCTION DIFFERENTIAL AND FRONT AXLE

- 11.2. REAR AXLE

- 11.3. BRAKE SYSTEM

- 11.4. STEERING SYSTEM

- 11.5. HYDRAULIC SYSTEM

- 11.6. MASTS AND FORKS

- 12. COMPONENT ASSEMBLY AND ADJUSTMENT

- 12.1. Component Location

- 12.2. Dashboard and Seat

- 12.3. Console Box Assembly

- 12.4. Combination Meter Assembly

- 12.5. Controller Compartment

- 12.5.1. Contractors-RB (Regenerative Braking), 1A, FW (Field Weakening), PS (Power Steering) and Pump (Hydraulic)

- 12.5.2. Contractor – FR (Forward/Reverse)

- 12.5.3. EV100 LX Traction Logic Card and Hydraulic Logic Card Checks and Adjustments

- 12.5.4. EV100 LX Handset

- 12.5.5. Brake Bracket

- 12.5.6. Pump Contactor Hydraulic Control Adjustment-Lift Switch

- 12.5.7. SCR Hydraulic Control Adjustment

- 13. DESCRIPTION OF LIFT TRUCK CIRCUIT

- 13.1. EV100 LX Control Panel

- 13.1.1. Control Panel Layout

- 13.1.2. Component Identification

- 13.1.3. Test Points

- 13.1.4. Logic Switch Sequence

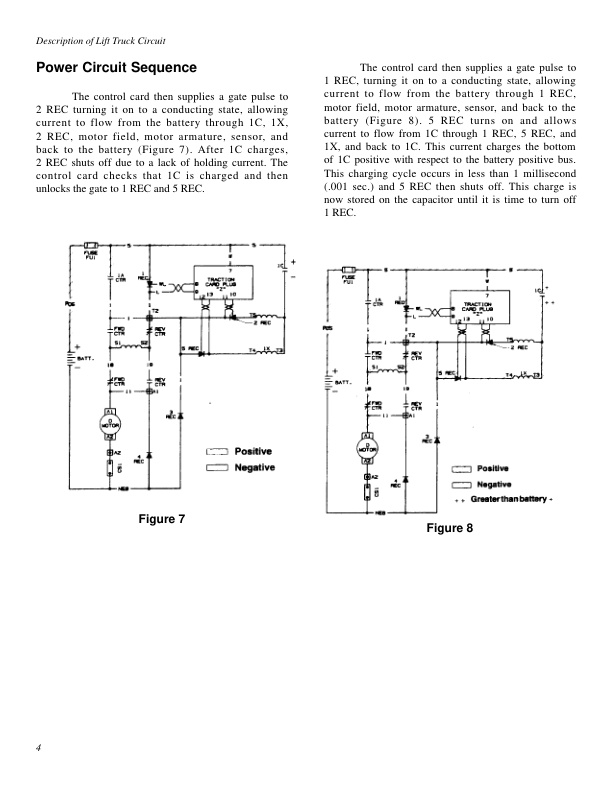

- 13.1.5. Power Circuit Sequence

- 13.1.6. Traction Control Logic Flow Chart

- 13.1.7. Control Features

- 13.2. Console

- 13.2.1. Hour Meter

- 13.2.2. Fault Indicator

- 13.2.3. Battery Discharge Indicator (BDI)

- 13.2.4. Brake Fluid Level Warning Circuit

- 13.2.5. Motor Protection Circuits

- 13.3. Horn Circuit

- 13.4. Options

- 13.4.1. Optional Backup Alarm

- 13.4.2. Optional Warning Light or Strobe

- 13.4.3. Optional Head Lamps, Working Lamps Tail Lamps-36/48V

- 13.4.4. Optional Head Lamps, Working Lamps Tail Lamps-12V

- 13.4.5. Optional Stop Light-36/48V

- 13.4.6. Optional Stop Light-12V

- 14. FOREWARD

- 15. GENERAL INFORMATION

- 15.1. Truck Models

- 15.2. External View

- 15.3. Name Plate and Serial Number Locations

- 15.4. Technical Data

- 15.4.1. General

- 15.4.2. Basic Dimensions

- 15.4.3. Performance

- 15.4.4. Control

- 15.4.5. Power Line

- 15.4.6. Axles Wheels

- 15.4.7. Brake System

- 15.4.8. Steering System

- 15.4.9. Steering Motor

- 15.4.10. Steering Pump

- 15.4.11. Power Steering

- 15.4.12. Hydraulic System

- 15.4.13. Hydraulic Pressure for Attachment

- 15.4.14. Battery

- 15.5. Description

- 15.6. Storage

- 15.7. Maintenance

- 15.7.1. Motor Maintenance Schedule

- 15.7.2. Bearings

- 15.7.3. Insulation

- 15.7.4. Brushes

- 15.7.5. Commutator

- 15.7.6. Mechanical

- 15.7.7. Cleaning

- 15.8. Traction, Pump and Steering Disassembly

- 15.8.1. Failure

- 15.8.2. Renewal Parts

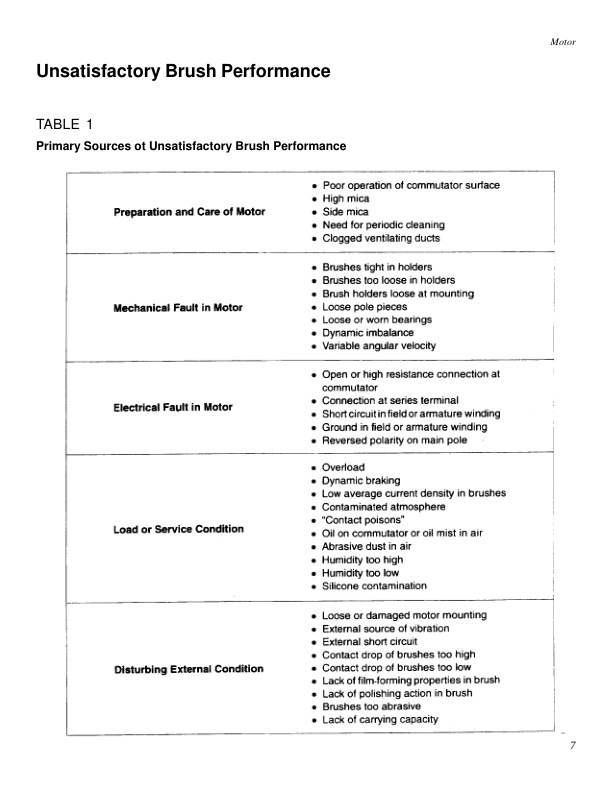

- 15.9. Unsatisfactory Brush Performance

- 15.9.1. Table 1 Primary Sources of Unsatisfactory Brush Performance

- 15.9.2. Table 2 Indications Appearing at Brushes

- 15.9.3. Table 3 Indications Appearing as Heat

- 15.9.4. Table 4 Indications Appearing at Commutator Surface

- 15.10. Commutator Check Chart

- 15.10.1. Satisfactory Commutator Surfaces

- 15.10.2. Poor Commutator Surfaces

- 15.10.3. Causes of Poor Commutator Conditions

- 16. RECOMMENDED REASSEMBLY PRACTICE

- 17. TESTING EQUIPMENT RECOMMENDATIONS

- 18. TROUBLESHOOTING

- 18.1. Introduction

- 18.2. Tools and Required Equipment

- 18.3. Frame Resistance Check

- 18.4. SCR Gerneral Maintenance

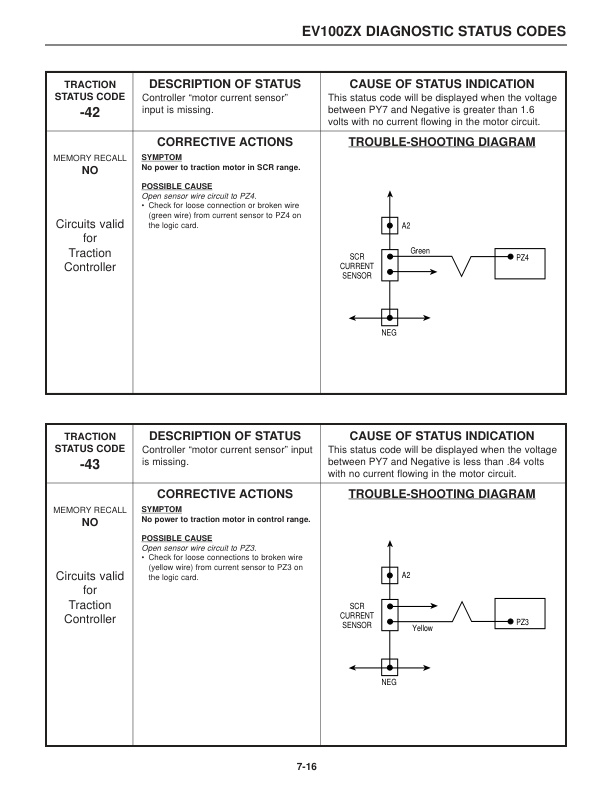

- 18.5. Status Code Descriptions

- 18.6. Status Code Instructions

- 18.7. Component Check

- 18.7.1. Control Card

- 18.7.2. Capacitor 1C

- 18.7.3. Contractors F/R (Forward/Reverse), 1A, PS (Power Steering), FW (Field Weakening), RB (Regenerative Braking) and Pump (Hydraulic

- 18.7.4. Potentiometer in Accelerator

- 18.7.5. SCRs (1 REC, REC and REC)

- 18.7.6. Rectifiers (3 REC, 4 REC, and Diode Blocks)

- 18.7.7. Thermal Protector (TP)

- 18.7.8. Filter Block (23 FIL, etc.)

- 18.7.9. Choke and Reactor T3-T4

- 18.8. Replacement of EV100 LX Components

- 18.8.1. Stud Semiconductors

- 18.8.2. Module Semiconductors

- 18.8.3. Capacitor

- 18.8.4. REC, 23 REC, and 25 REC

- 18.8.5. Filter Mounting Block

- 18.9. Secondary Troubleshooting

- 18.9.1. Table 1 Failures that Cause Reduced or No Motor Torque with SCR Control

- 18.9.2. Table 2 Failures that Cause Full or No Motor Torque with SCR Control

- 18.9.3. Table 3 Misoperation of Other Features

- 18.10. EV100 LX Hygraulic Pump Control Troubleshooting

- 18.10.1. Table 4 Failures that Cause Reduced or No Motor Torque with SCR Control

- 18.10.2. Table 5 Failures that Cause No Motor Torque with SCR Control

- 18.11. Power Cable Connections

- 18.12. Traction Control Card Wire Harness Connections

- 18.12.1. Panel Connector

- 18.12.2. TB Connections

- 18.12.3. A B Plugs

- 18.13. Hydraulic Pump SCR Control Card Wire Harness Connections

- 18.13.1. Panel Connector

- 18.13.2. TB Connections

- 18.13.3. A B Plugs

- 18.14. Traction Control Components

- 18.14.1. Potentiometer (for Accelerator)

- 18.14.2. Acclerator Switch

- 18.14.3. Brake Switch

- 18.15. Pump Driver

- 18.16. Hydraulic Control Components

- 18.16.1. Hydraulic Control Switch (Standard)

- 18.16.2. Hydraulic Control Switch (Tilt/Auxiliary)

- 18.16.3. Hydraulic Control Switch (Lift)

- 18.16.4. Potentiometer (for SCR Hydraulic Control)

- 18.17. Options

- 18.17.1. Relay for 12-Volt Stop Lamp

- 18.17.2. Volt DC/Dc Convertor

- 18.18. Console

- 18.19. EV100LX Electrical Schematic – Trucks Equipped with Contactor Hydraulics

- 18.20. EV100LX Electrical Schematic – Trucks Equipped with Optional SCR Hyrdaulics

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101