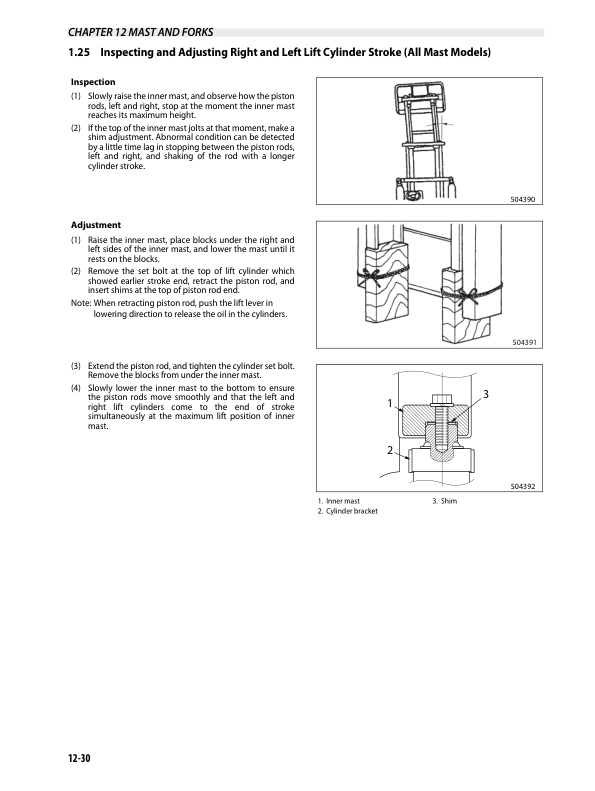

Mitsubishi FG15N-35CN, FD20N-35N Chassis and Mast Service Manual 99719-M9140 Vol 1

$50.00

- Type Of Manual: Service Manual

- Manual ID: 99719-M9140 Vol 1

- Number of Pages: 631

- Size: 36.7MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- FG15N, FG18N, FG20CN, FG20N, FG25N, FG28N, FG30N, FG33N, FG35CN, FD20N, FD25N, FD28N, FD30N, FD33N, FD35N

- 1. M9140_VOL1_FG15N_SERVICE_2014-07E1_MIT_50949

- 2. M9140_VOL2_FG15N_SERVICE_2014-07E1_MIT_50950

- 3. M9140_VOL3_FG15N_SERVICE_2014-07E1_MIT_50951

- 3.1. FOREWORD

- 3.1.1. Safety

- 3.1.2. Symbols and Abbreviations

- 3.1.3. Units

- 3.2. TABLE OF CONTENTS

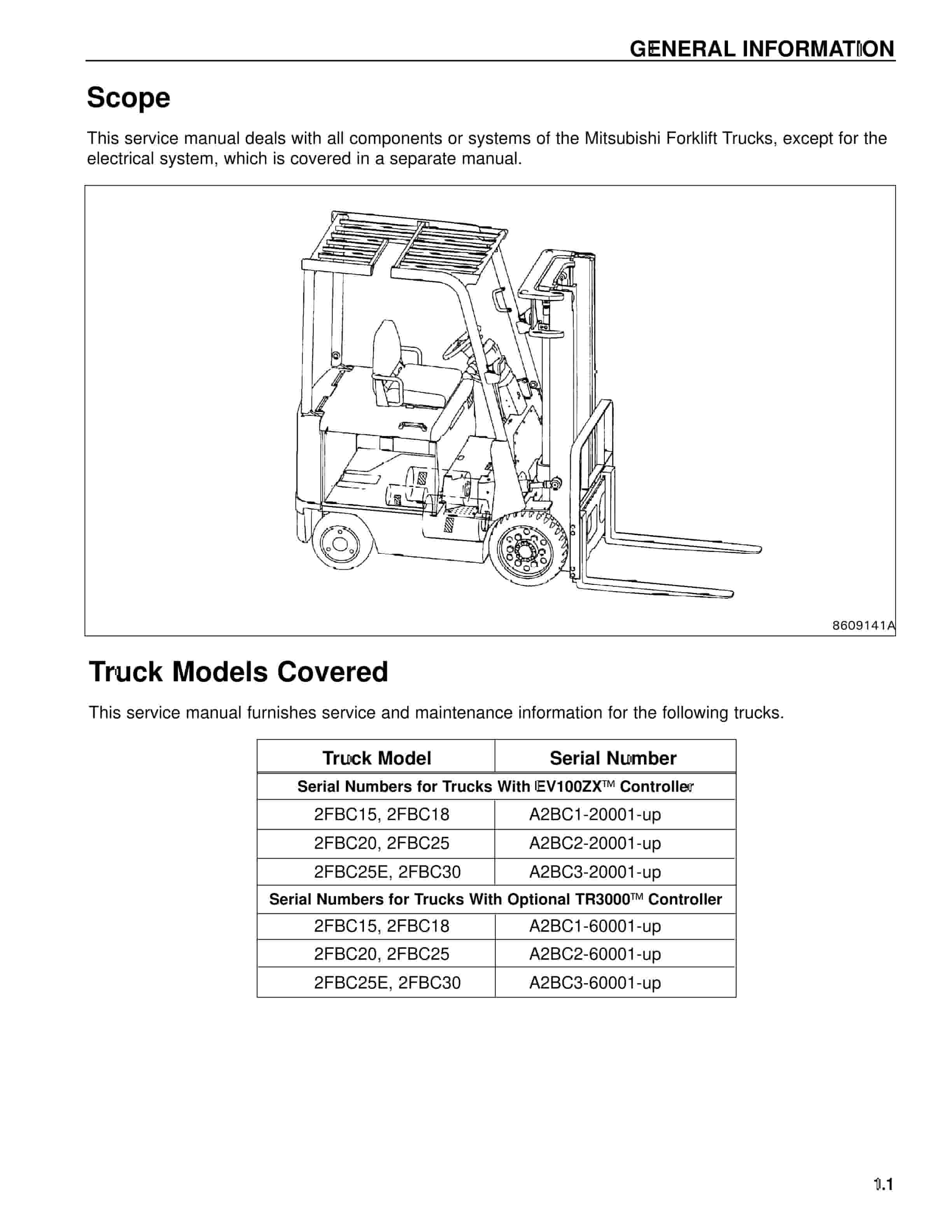

- 3.3. Chapter 1 GENERAL INFORMATION

- 3.3.1. Model View

- 3.3.2. Truck Models Covered

- 3.3.3. Serial Number Locations

- 3.3.4. Dimensions

- 3.3.5. Technical Data

- 3.4. Chapter 2 COOLING SYSTEM

- 3.4.1. Specification

- 3.4.2. Structure

- 3.4.3. Removing Fan Belt

- 3.4.3.1. Preparation

- 3.4.3.2. Removal Sequence

- 3.4.3.3. Suggestions for Removal

- 3.4.4. Installing Fan Belt

- 3.4.5. Inspecting and Adjusting Cooling System

- 3.4.5.1. Inspecting Fan Belt

- 3.4.5.2. Adjusting Fan Belt Tension

- 3.4.5.3. Connecting Radiator Hoses

- 3.4.5.4. Coolant

- 3.4.5.5. Radiator Cap

- 3.5. Chapter 3 ELECTRICAL SYSTEM

- 3.5.1. Electrical Components and Wiring Outline

- 3.5.1.1. Locations of Electrical Components

- 3.5.2. Console Box

- 3.5.2.1. Console Box Outline

- 3.5.2.2. Disassembling Console Box

- 3.5.2.3. Assembling Console Box

- 3.5.3. Meter Panel

- 3.5.3.1. Disassembling Meter Panel

- 3.5.3.2. Assembling Meter Panel

- 3.5.3.3. Bulb Replacement

- 3.5.4. Main Electrical Components

- 3.5.4.1. Meter Panel

- 3.5.4.2. Key Switch

- 3.5.4.3. Key Switch (Anti-Restart Switch)

- 3.5.4.4. Light Switch and Turn Signal Switch

- 3.5.4.5. Direction (FNR) Switch

- 3.5.4.6. Select Switch

- 3.5.4.7. Horn

- 3.5.4.8. Tank Unit

- 3.5.4.9. Brake Oil Sensor

- 3.5.4.10. Stop Light Switch

- 3.5.4.11. Thermoswitch (Engine Coolant Temperature)

- 3.5.4.12. Thermoswitch (T/C Oil)

- 3.5.4.13. Speed Sensor (Pulse Generator)

- 3.5.4.14. Parking Brake Switch

- 3.5.4.15. Relay Box

- 3.5.4.16. Fuse Box

- 3.5.4.17. QGS Controller (Diesel Model)

- 3.5.4.18. Rear Combination Light

- 3.5.4.19. Rear Combination Harness

- 3.5.4.20. List of Lights

- 3.5.5. Battery and Maintenance

- 3.5.5.1. State of Charge and Electrolyte Specific Gravity (S.G.) Adjustment

- 3.5.5.2. Specific Gravity Reading and State of Charge

- 3.5.5.3. Precautions for Battery Charging

- 3.5.6. Wire Color

- 3.5.6.1. List of Wire Color Codes

- 3.5.7. Troubleshooting

- 3.5.7.1. Starter System

- 3.5.7.2. Gauges

- 3.5.7.3. Lighting System

- 3.5.7.4. Alarm Unit

- 3.5.7.5. Battery

- 3.5.7.6. Horn Testing Procedures

- 3.5.8. Fuel Pressure Sensor Harness

- 3.5.8.1. Wire Harness

- 3.5.8.2. Converting the Year 2005/2006 Chassis Harness to 2004 Chassis Harness

- 3.5.8.3. Year 2005/2006 RELATIVE Fuel Pressure Sensor

- 3.5.8.4. Terminal Positions

- 3.5.8.5. Change the Wire Positions

- 3.5.8.6. Fuel Pressure Sensor Connector Kit P/N 91A04-06960

- 3.5.8.7. Change Pins

- 3.5.9. Wiring Harness Service Parts

- 3.5.9.1. Pick Tool Part

- 3.5.9.2. ETC Connector Assembly Part No. SE000218

- 3.5.9.3. ETC Pin Terminal W/ 6 Lead Part No. SE000219

- 3.5.9.4. Ignition Coil Connector Part No. 91A04-06590

- 3.5.9.5. Water Temp Sensor Connector Part No. 91A04-06410

- 3.5.9.6. Alternator Connector Part No. 91A04-06420

- 3.5.9.7. Air Flow Meter Connector Part No. 91A04-06580

- 3.5.9.8. LP Injector Driver Connector Part No. 05110-81230

- 3.5.9.9. Fuel Pressure Jumper Harness Part No. 91820-03200

- 3.5.9.10. Gasoline Injector Connector Part No. 91820-01840

- 3.5.9.11. Fuel Pressure Connector Part No. 91820-01850

- 3.5.9.12. Fuel Pressure Connector Part No. 91A04-06960

- 3.5.9.13. GSE Connector

- 3.5.9.14. Throttle Position Sensor

- 3.5.9.15. Soldering Procedure

- 3.5.9.16. Pin Removal Procedure

- 3.5.9.17. Pin Removal Procedure

- 3.5.10. Electrical Wiring Diagram

- 3.6. Chapter 4 CONTROLLER

- 3.6.1. Outline

- 3.6.2. Main Functions of Controllers

- 3.6.2.1. Meter Panel

- 3.6.2.2. VCM (Vehicle Control Module)

- 3.6.2.3. ECM (Engine Control Module)

- 3.6.2.4. GSE Connector

- 3.6.3. Service Tool

- 3.6.3.1. Service Tool Menus

- 3.6.3.2. Toolbox

- 3.6.3.3. Mot File Download Process

- 3.6.3.4. Check Main C Relay Circuit with Diagnostics Program

- 3.6.3.5. Programming Travel Speed

- 3.6.4. Mast Interlock System

- 3.6.4.1. Mast Interlock Function

- 3.6.4.2. Checking Procedure of Mast Interlock System

- 3.6.4.3. Active Test Inspection Procedure

- 3.6.5. Driving Interlock System

- 3.6.5.1. Controller Function

- 3.6.5.2. Checking the Operation of Driving Interlock Function

- 3.6.5.3. Active Test Inspection Procedure

- 3.6.6. Seat Belt Warning Light

- 3.6.6.1. Operation of Seat Belt Warning Light

- 3.6.6.2. Checking the Operation of Seat Belt Warning Light

- 3.6.7. Parking Brake Warning Buzzer and Light

- 3.6.7.1. Operation of Parking Brake Warning Buzzer and Light

- 3.6.7.2. Parking Brake Warning Buzzer

- 3.6.7.3. Checking the Operation of Parking Brake Warning Buzzer/Light with Key in OFF Position

- 3.6.8. Harness Codes

- 3.6.9. Controller Output Details

- 3.6.9.1. VCM (Vehicle Control Module)

- 3.6.9.2. Seat Switch

- 3.6.9.3. Parking Brake Switch

- 3.6.9.4. Direction Lever Switch

- 3.6.9.5. Vehicle Speed Sensor

- 3.6.9.6. T/M Solenoid

- 3.6.9.7. Unload Solenoid

- 3.6.9.8. Lift Lock Solenoid

- 3.6.9.9. Warning Buzzer

- 3.6.9.10. Warning Buzzer Relay

- 3.6.9.11. Warning Buzzer Circuit

- 3.6.9.12. Meter Panel

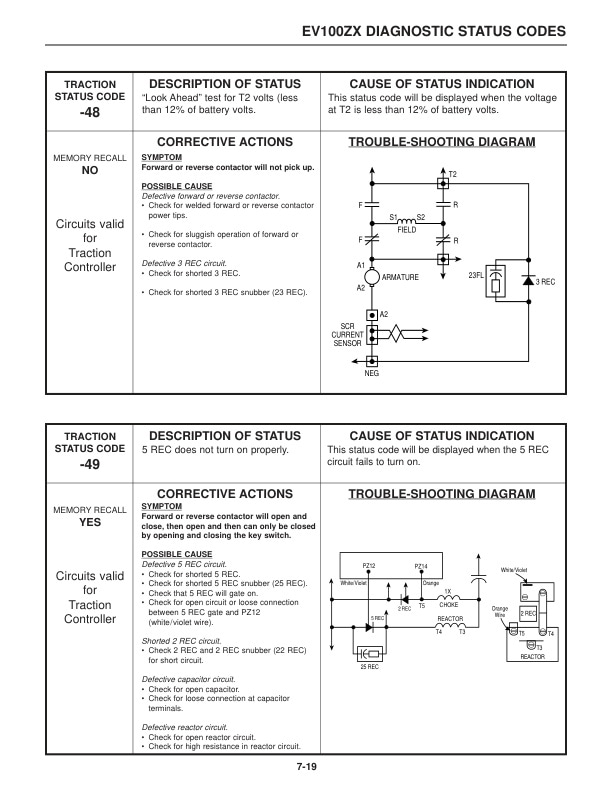

- 3.6.10. Truck Status Display and Troubleshooting

- 3.6.10.1. Truck Status Display

- 3.6.10.2. Diagnosis Table (F Code)

- 3.6.10.3. LED Blink Pattern

- 3.6.10.4. Diagnostic Codes and Troubleshooting

- 3.6.11. Common Diagnostic Codes

- 3.6.11.1. F85(T/M Forward Travel Solenoid Warning) and F87 (T/M Backward Travel Solenoid Warning) Displayed

- 3.6.11.2. E-23 (Throttle Sensor Warning)

- 3.6.11.3. E-24 (Accelerator Sensor Warning)

- 3.6.11.4. E-27 (POS Sensor Warning)

- 3.6.11.5. E-30 (ECCS C/U System Warning)

- 3.6.11.6. E-31 (Throttle Control Warning)

- 3.6.11.7. E-35 (LPG Fuel Injection Disconnection Warning)

- 3.6.11.8. E-38 (LPG Vaporizer Diagnostic Result Warning)

- 3.6.11.9. E-42 (Gas Air-Fuel Ratio Malfunction) and E-43 (LPG Air-Fuel Ratio MalFunction)

- 3.7. Chapter 5 POWER TRAIN

- 3.7.1. Removing and Installing Engine and Transmission Assembly (For Gasoline engine Trucks)

- 3.7.1.1. Removal Sequence of Overhead Guard, Covers, and Air Cleaner

- 3.7.1.2. Suggestions for Removal of Overhead Guard, Cover, and Air Cleaner

- 3.7.1.3. Removal Sequence of Controls

- 3.7.1.4. Suggestion for Removal of Controls

- 3.7.1.5. Installation Sequence of Overhead Guard, Covers, Air Cleaner, and Controls

- 3.7.1.6. Preparation for Removal of LPG System (Dual Fuel Gasoline and LPG Model)

- 3.7.1.7. Removal Sequence of LPG System (Dual Fuel Gasoline and LPG Model)

- 3.7.1.8. Installation Sequence of LPG System (Dual Fuel Gasoline and LPG Model)

- 3.7.1.9. Preparation for Removal of Radiator and Pipes

- 3.7.1.10. Removal Sequence of Radiator and Pipes

- 3.7.1.11. Suggestion for Removal of Radiator and Pipes

- 3.7.1.12. Installation Sequence of Radiator and Pipes

- 3.7.1.13. Preparation for Removal of Engine and Transmission Assembly

- 3.7.1.14. Removal Sequence of Engine and Transmission Assembly

- 3.7.1.15. Suggestions for Removal of Engine and Transmission Assembly

- 3.7.1.16. Installation Sequence of Engine and Transmission Assembly

- 3.7.1.17. Suggestions for Installation of Engine and Transmission Assembly

- 3.7.1.18. Removing and Installing of Engine and Transmission Assembly (For Diesel Engine Trucks)

- 3.7.1.19. Removal Sequence of Overhead Guard, Covers, and Air Cleaner

- 3.7.1.20. Suggestions for Removal of Overhead Guard, Covers, and Air Cleaner

- 3.7.1.21. Removal Sequence of Controls

- 3.7.1.22. Suggestions for Removal and Installation

- 3.7.1.23. Preparation for Removal of Radiator and Pipes

- 3.7.1.24. Removal Sequence of Radiator and Pipes

- 3.7.1.25. Suggestion for Removal of Radiator and Pipes

- 3.7.1.26. Installation Sequence of Radiator and Pipes

- 3.7.1.27. Preparation for Removal of Engine and Transmission Assembly

- 3.7.1.28. Removal Sequence of Engine and Transmission Assembly

- 3.7.1.29. Suggestions for Removal of Engine and Transmission Assembly

- 3.7.1.30. Installation of Engine and Transmission Assembly

- 3.7.1.31. Suggestion for Installation of Engine and Transmission Assembly (Those Not Shared with Gasoline Engine Trucks)

- 3.8. Chapter 6 POWERSHIFT TRANSMISSION

- 3.8.1. Structure

- 3.8.1.1. External View of Torque Converter Transmission

- 3.8.1.2. External View of Control Valve

- 3.8.1.3. Transmission Components

- 3.8.1.4. Torque Converter Components

- 3.8.1.5. Torque Converter Drive Control Components

- 3.8.1.6. Schematic Diagram of Powershift Transmission Hydraulic System

- 3.8.2. Removing Transmission

- 3.8.2.1. Suggestions for Removal

- 3.8.3. Installing Transmission

- 3.8.3.1. Suggestions for Installation

- 3.8.4. Disassembling Torque Converter Transmission

- 3.8.4.1. Preparation

- 3.8.4.2. Removing Transmission Accessories

- 3.8.4.3. Removing Oil Pump

- 3.8.4.4. Removing Transmission Housing

- 3.8.4.5. Removing Input Shaft, Idler Shaft and Output Gear

- 3.8.4.6. Disassembling Transmission Housing

- 3.8.4.7. Disassembling Torque Converter Housing

- 3.8.4.8. Disassembling Idler Shaft

- 3.8.4.9. Disassembling Output Gear

- 3.8.4.10. Disassembling Forward Side Input Shaft Gear Assembly

- 3.8.4.11. Disassembling Reverse Side Input Shaft Gear

- 3.8.4.12. Disassembling Oil Pump

- 3.8.5. Assembling Torque Converter Transmission

- 3.8.5.1. Assembling Transmission Housing

- 3.8.5.2. Assembling Idler Shaft Assembly

- 3.8.5.3. Assembling Output Gear Assembly

- 3.8.5.4. Inspecting Input Shaft Gear Assembly

- 3.8.5.5. Assembling Forward Side Input Shaft Gear Assembly

- 3.8.5.6. Assembling Reverse Side Input Shaft Gear Assembly

- 3.8.5.7. Assembling and Installing Oil Pump Assembly

- 3.8.5.8. Assembling Torque Converter Housing

- 3.8.5.9. Installing Transmission Housing

- 3.8.5.10. Installing Servo Case Assembly

- 3.8.5.11. Installing Transmission Accessories

- 3.8.6. Disassembling Control Valve

- 3.8.6.1. Removing Control Valve Accessories

- 3.8.6.2. Removing Valve Body Plate

- 3.8.6.3. Removing Plugs

- 3.8.6.4. Removing Strainer

- 3.8.6.5. Disassembling Regulator Valve Section

- 3.8.6.6. Disassembling Accumulator Valve Section

- 3.8.6.7. Disassembling Inching Valve Section

- 3.8.6.8. Removing Oil Seal and Plug

- 3.8.7. Assembling Control Valve

- 3.8.7.1. Assembly Sequence of Control Valve

- 3.8.7.2. Suggestions for Assembly

- 3.8.7.3. Washing and Inspecting

- 3.8.7.4. Installing Valve Plug and Oil Seal

- 3.8.7.5. Assembling Inching Valve Section

- 3.8.7.6. Assembling Accumulator Valve Section

- 3.8.7.7. Assembling Regulator Valve Section

- 3.8.7.8. Installing Strainer

- 3.8.7.9. Installing Plug

- 3.8.7.10. Installing Valve Body Plate and Breather Cover

- 3.8.7.11. Assembling Control Valve Accessories

- 3.8.8. Inspection and Adjustment

- 3.8.8.1. Oil Pressure Measurement

- 3.8.8.2. Adjusting Brake (Inching) Pedal

- 3.8.8.3. Adjusting Inching Cable

- 3.8.8.4. Increasing the Inching Pedal Return Spring Tension

- 3.8.9. Troubleshooting

- 3.8.10. Service Data

- 3.8.10.1. Pump Boss

- 3.8.10.2. Pilot Boss

- 3.8.10.3. Oil Pump

- 3.8.10.4. Flexible Plate

- 3.8.10.5. Clutches

- 3.8.10.6. Input Shaft

- 3.9. Chapter 7 FRONT AXLE AND REDUCTION DIFFERENTIAL

- 3.9.1. Structure

- 3.9.1.1. Ton Class

- 3.9.1.2. Ton Class

- 3.9.1.3. Ton Class

- 3.9.2. Removing Front Wheels

- 3.9.2.1. Preparation

- 3.9.2.2. Removal

- 3.9.2.3. Suggestion for Removal

- 3.9.3. Installing Front Wheels

- 3.9.4. Removing Front Axle and Reduction Differential

- 3.9.4.1. Preparation

- 3.9.4.2. Removal Sequence

- 3.9.4.3. Suggestions for Removal

- 3.9.5. Installing Front Axle

- 3.9.6. Disassembling Front Axle

- 3.9.6.1. Disassembly Sequence

- 3.9.6.2. Suggestions for Disassembly

- 3.9.7. Inspection and Repair After Disassembling Front Axle

- 3.9.8. Assembling Front Axle

- 3.9.9. Disassembling Reduction Differential

- 3.9.9.1. Disassembly Sequence

- 3.9.9.2. Suggestions for Disassembly

- 3.9.10. Inspection and Repair After Disassembling Reduction Differential

- 3.9.11. Assembling Reduction Differential

- 3.9.11.1. Assembly Sequence

- 3.9.11.2. Suggestions for Assembly

- 3.9.11.3. Adjustment

- 3.9.12. Troubleshooting

- 3.9.13. Service Data

- 3.9.13.1. Hub and Wheels

- 3.9.13.2. Reduction Differential

- 3.10. Chapter 8 REAR AXLE

- 3.10.1. Structure

- 3.10.1.1. Main Components of Rear Axle

- 3.10.1.2. Specifications for Wheel Alignment and Steering Angle

- 3.10.1.3. Main Components of Wheel Hub

- 3.10.1.4. Main Components of King Pin

- 3.10.1.5. Main Components of Tie Rod

- 3.10.1.6. Main Components of Steering Cylinder

- 3.10.2. Removing Rear Wheels

- 3.10.3. Installing Rear Wheels

- 3.10.4. Removing Rear Wheels and Rear Axle Assembly

- 3.10.4.1. Removal Sequence

- 3.10.4.2. Suggestions for Removal

- 3.10.5. Installing Rear Wheels

- 3.10.6. Disassembling Wheel Hub

- 3.10.6.1. Disassembly Sequence

- 3.10.6.2. Suggestions for Disassembly

- 3.10.7. Inspection and Repair After Disassembly

Rate this product

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-74120

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-56103

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00