Mitsubishi FG15N-35NM, FD20N-35N Operation and Maintenance Manual 99710-7M110 Vol 2

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 99710-7M110 Vol 2

- Number of Pages: 130

- Size: 10.6MB

- Format: PDF

-

Model List:

- FG15N, FG15NM, FG18N, FG18NM, FG20CN, FG20CNM, FG20N, FG20NM, FG25N, FG25NM, FG30N, FG30NM, FG33N, FG35N, FG35NM, FD20N, FD25N, FD30N, FD33N, FD35N

- 1. FOREWORD

- 2. HOW TO USE THIS MANUAL

- 2.1. Truck Models Covered in This Manual

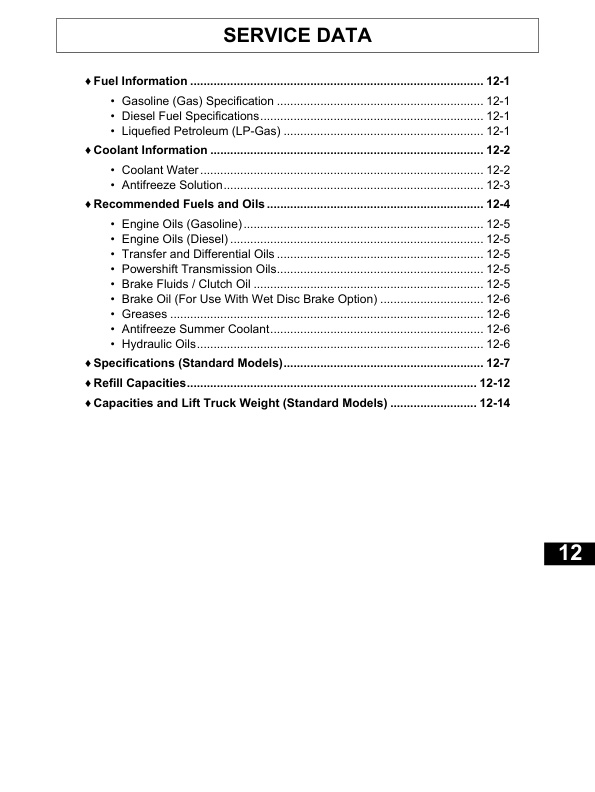

- 3. CHAPTER INDEX

- 4. TABLE OF CONTENTS

- 5. SAFETY RULES FOR LIFT TRUCK OPERATORS

- 5.1. General

- 5.2. Warning Decals, Location

- 5.3. Decals for Dual Fuel Only

- 5.4. Warning Decals, Description

- 5.4.1. Parking Brake

- 5.4.2. No Rider

- 5.4.3. Backup Alarm

- 5.4.4. For Safety Observe the Following Warnings

- 5.4.5. Radiator Cap

- 5.4.6. Cooling Fan

- 5.4.7. Overhead Guard

- 5.4.8. No One under / on Forks

- 5.4.9. Load Backrest Extension

- 5.4.10. Crush Points

- 5.4.11. Capacity Plate

- 5.4.12. Inspection / Lubrication Chart

- 5.4.13. Tipover Warnings

- 5.4.14. Maintenance Procedure

- 5.4.15. LPG Fuel Cylinder Replacement

- 5.4.16. Gasoline / LPG Changeover

- 5.5. Safety Rules

- 5.5.1. Authorized and trained operators only

- 5.5.2. Dress properly for the job

- 5.5.3. Always be alert

- 5.5.4. No smoking while refueling

- 5.5.5. Know all signals and traffic rules

- 5.5.6. Unauthorized addition or modification is prohibited

- 5.5.7. Know the lift truck and attachments

- 5.5.8. Avoid being splashed by scalding hot coolant

- 5.5.9. Turn OFF the key switch before servicing

- 5.5.10. Lift truck exhaust fumes contain carbon monoxide and could kill you

- 5.5.11. Inspect the lift truck prior to operation

- 5.5.12. DO NOT operate an unsafe lift truck

- 5.5.13. DO NOT remove the overhead guard

- 5.5.14. DO NOT operate the lift truck under the influence of drugs or alcohol

- 5.5.15. Keep the operators compartment clean

- 5.5.16. LP-Gases are flammable.

- 5.5.17. The back-up alarm must activate when traveling in reverse

- 5.5.18. Operate only in approved areas

- 5.5.19. Sit in the operators seat when starting the engine

- 5.5.20. DO NOT operate a damaged or defective lift truck

- 5.5.21. Face the lift truck when mounting and dismounting

- 5.5.22. Adjust the operators seat before operating the lift truck

- 5.5.23. Always check overhead clearance

- 5.5.24. Use lights in dark, dim areas

- 5.5.25. When operating the lift truck, BE SURE to fasten the seat belt

- 5.5.26. Stay within the confines of the lift truck

- 5.5.27. Always be aware of floor capacity

- 5.5.28. Avoid off-center loading

- 5.5.29. Stay under the overhead guard

- 5.5.30. Check fork locking pins for engagement

- 5.5.31. Be careful of forks that extend beyond the load

- 5.5.32. Check work places for high risk

- 5.5.33. Slow down for wet and slippery surfaces

- 5.5.34. When handling ECM, VCM, DCM and OCM

- 5.6. Operating Precautions

- 5.6.1. DO NOT allow any riders

- 5.6.2. Position levers correctly for starting

- 5.6.3. DO NOT pass another lift truck

- 5.6.4. DO NOT indulge in stunt driving or horseplay

- 5.6.5. Take care when turning with a load

- 5.6.6. Obey all traffic regulations and warning signs, including authorized plant speed limits

- 5.6.7. Always look in the direction of travel

- 5.6.8. Travel in REVERSE if forward visibility is blocked

- 5.6.9. Travel safely on grades with a loaded lift truck

- 5.6.10. Travel safely on grades with an empty lift truck

- 5.6.11. Be particularly careful when driving up or down a steep slope

- 5.6.12. Starting the lift truck on an upgrade carefully

- 5.6.13. Be careful of drive end swing when turning while operating with load end leading

- 5.6.14. DO NOT operate the lift truck under windy conditions

- 5.7. Working Precautions

- 5.7.1. Keep out

- 5.7.2. A helper must NOT be near the lift truck

- 5.7.3. Be careful of changes in capacity

- 5.7.4. Watch out for pedestrians at all times

- 5.7.5. Use the proper attachment

- 5.7.6. DO NOT speed when approaching loads

- 5.7.7. Ensure the load isnt too high

- 5.7.8. DO NOT move when someones next to the lift truck

- 5.7.9. Handle only stable and safely arranged loads

- 5.7.10. Stay clear of pinch points

- 5.7.11. DO NOT allow unloading from raised loads

- 5.7.12. Inspect a trailer before entering

- 5.7.13. DO NOT use damaged pallets

- 5.7.14. DO NOT abuse forks

- 5.7.15. DO NOT use lift truck improperly

- 5.7.16. Operate the direction lever smoothly

- 5.7.17. Always stay within the capacity

- 5.7.18. Park in authorized areas only

- 5.7.19. Watch out for personnel

- 5.7.20. DO NOT lift personnel except on a securely attached, specially designed work platform

- 5.7.21. Park disabled lift truck safely

- 5.8. LP-Gas

- 6. KNOW YOUR LIFT TRUCK

- 6.1. Serial Number and Capacity Plate

- 6.2. Electrical Components

- 6.3. Model View

- 6.3.1. MC Model

- 6.3.2. FC Model

- 6.4. Driving Switches and Controls

- 6.4.1. Key Switch

- 6.4.2. Direction Lever (Powershift)

- 6.4.3. Inching Pedal (Powershift)

- 6.4.4. Turn Signal / Light Switch

- 6.4.5. Steering Tilt Lever

- 6.5. Instrument Panel

- 6.5.1. LCD Screen

- 6.5.2. Warning Lamps and Indicators

- 6.5.3. Basic Screen Display

- 6.5.4. Basic Operation

- 6.5.5. When an Error Occurs

- 6.5.6. Optional Functions

- 6.5.7. Optional Functions for Use With Wet Disc Brake

- 6.6. Integrated Presence System

- 6.6.1. Mast Interlock System (MC Model)

- 6.6.2. Mast Interlock System (FC Model)

- 6.6.3. Mast Interlock System Functions

- 6.6.4. Driving Interlock System

- 6.6.5. Driving Interlock System Functions

- 6.6.6. Neutral System

- 6.6.7. Neutral System Functions

- 6.6.8. Seat Belt Warning Lamp

- 6.6.9. Seat Belt Warning Functions

- 6.6.10. Parking Brake Warning Buzzer and Lamp

- 6.6.11. Parking Brake Warning Functions

- 6.7. Parking Brake Dragging Warning

- 6.8. Operating Switches and Controls (MC Model)

- 6.8.1. Lift Lever

- 6.8.2. Tilt Lever

- 6.8.3. Attachment Lever

- 6.9. Operating Switches and Controls (FC Model)

- 6.9.1. Lift Lever

- 6.9.2. Tilt Lever

- 6.9.3. Attachment Lever A/B (Optional)

- 6.9.4. Selector Switch Between Forth and Fifth Attachment

- 6.9.5. Other Controls (Standard)

- 6.9.6. Emergency Stop Button

- 6.9.7. Forward and Back Adjustment Stopper Knob

- 6.9.8. Up and Down Adjustment Stopper Knob

- 6.9.9. Other Controls (Optional)

- 6.9.10. Lowering Speed Selector Switch (Optional)

- 6.9.11. Mast Vertical Switch (Optional)

- 6.9.12. Direction Switch (Optional)

- 6.10. Operators Seat

- 6.10.1. Seat Adjustment

- 6.10.2. Forward and Back Adjustment

- 6.10.3. Adjustment of Suspension (FC Model)

- 6.10.4. Lumbar Support Adjustment (FC Model)

- 6.10.5. Pocket for the Manual

- 6.10.6. Operator Presence Switch and Buzzer

- 6.10.7. How to Tip the Seat Forward

- 6.11. Seat Belt

- 6.12. Fork Locking Pins

- 6.13. Changing Forks

- 6.14. Drawbar Pin

- 6.15. Assist Grip

- 6.16. Engine Hood

- 6.16.1. Hood Latch

- 6.17. Hydraulic Tank Oil Level / Filler Hole

- 6.18. Fuel Filler

- 6.19. Brake Tank Oil Level / Air Breather

- 7. HOW TO AVOID A TIPOVER HOW TO SURVIVE ONE

- 7.1. Know What Lift Truck Stability Is

- 7.2. Center of Gravity (CG)

- 7.3. Stability and Center of Gravity (Top View)

- 7.4. Stability and Center of Gravity (Side View)

- 7.5. Lift Truck Stability Base

- 7.6. Capacity (Weight and Load Center)

- 7.7. Capacity Plate

- 7.7.1. For Example

- 7.8. Dos and Donts to Avoid Tipover

- 7.8.1. Fasten the seat belt

- 7.8.2. DO NOT jump off your lift truck if it starts to tip over

- 7.8.3. DO watch Tail swing

- 7.8.4. DO check surface strengths

- 7.8.5. DO avoid fast starts, turns and sudden stops

- 7.8.6. DO NOT elevate forward tilted loads

- 7.8.7. Travel at a reduced speed on rough surfaces

- 7.8.8. DO avoid slippery surfaces

- 7.8.9. Only stable or safely arranged loads must be handled

- 7.8.10. DO NOT travel with forks higher than 15 to 20 cm (6 to 8 in.) above the ground

- 7.8.11. DO NOT make fast or sharp turns with a loaded or unloaded lift truck

- 7.8.12. DO NOT turn sharply, even with an empty raised mast, to avoid a tipover

- 7.8.13. DO wear a hard hat

- 7.8.14. Be aware of the stability of an empty lift truck

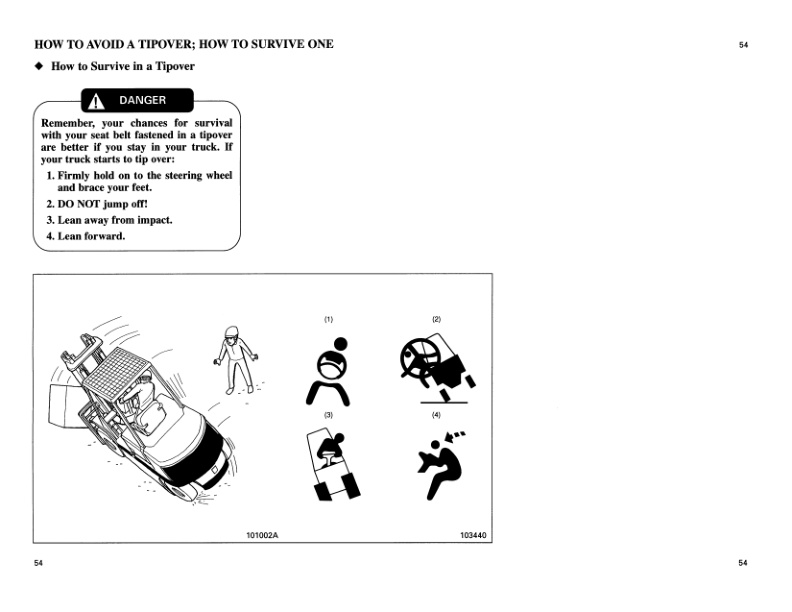

- 7.9. How to Survive in a Tipover

- 8. REFUELING

- 8.1. Gasoline and Diesel Engine Equipped

- 8.2. LP-Gas Engine Equipped

- 8.2.1. For Standard LP-Gas Tank

- 9. OPERATION

- 9.1. New Lift Truck Break-in

- 9.2. Before Starting Engine

- 9.2.1. FC model

- 9.2.2. MC model

- 9.2.3. Gasoline / LP-Gas Dual Fuel Type

- 9.2.4. FC Model

- 9.2.5. Seat Adjustment

- 9.3. Starting Gasoline Engine

- 9.3.1. If the engine wont start

- 9.4. Starting LP-Gas Engine

- 9.5. Starting Diesel Engine

- 9.5.1. If the engine wont start

- 9.6. Engine Wont Start

- 9.6.1. When Engine Is Flooded

- 9.6.2. When Engine Is Started After Long Recess

- 9.7. After Starting Engine

- 9.8. Before Moving Lift Truck

- 9.9. Lift Truck Operation

- 9.9.1. Changing Speed

- 9.9.2. Changing Direction

- 9.9.3. Operating Techniques

- 9.9.4. Steering (Turning)

- 9.9.5. Inching

- 9.10. Stopping Lift Truck

- 9.11. Parking Lift Truck (After Stopping)

- 9.12. Leaving Lift Truck (FC Model)

- 9.12.1. For Use With Wet Disc Brake Option

- 10. OPERATING TECHNIQUES

- 10.1. Stacking Methods

- 10.1.1. Stacking Different Loads in Size

- 10.1.2. Stacking Small Identical Loads

- 10.1.3. Stacking Large Identical Loads

- 10.2. Handling Loads Safely

- 10.2.1. Handle ONLY stable loads to prevent the load from falling

- 10.3. Correct Operating Steps

- 10.4. Incorrect Operating Steps

- 10.4.1. Example 1

- 10.5. Inching Into and Lifting the Load

- 10.6. Traveling With the Load

- 10.7. Unloading

- 10.8. Working on Grades

- 10.8.1. Normal Travel position

- 10.8.2. Traveling on a Grade

- 10.8.3. Stopping on a Grade

- 10.8.4. Starting on a Grade (Engine Stalls on a Grade)

- 11. STORING THE LIFT TRUCK

- 11.1. End of Each Shift Storage

- 11.2. Long Term Storage

- 11.2.1. Fuel System

- 11.2.2. Hydraulic System

- 11.2.3. Engine Cooling System

- 11.2.4. Engine Cylinders

- 11.2.5. Battery

- 11.2.6. Controller

- 11.2.7. Other

- 12. TRANSPORTATION HINTS

- 12.1. Lift Truck Loading and Shipping

- 12.2. Lift Truck Lifting and Tiedown Information

- 13. SPECIAL SITUATIONS

- 13.1. Care in Cold Weather

- 13.1.1. Fuel Oils and Lubrication Oils

- 13.1.2. Battery

- 13.1.3. Engine Coolant

- 13.2. Care in Hot Weather

- 13.2.1. Fuel Oils and Lubrication Oils

- 13.2.2. Battery

- 13.2.3. Engine Coolant

- 13.3. Severe Dust or Lint Conditions

- 14. TROUBLESHOOTING

- 14.1. Stalled Engine

- 14.2. Starting With Jumper Cables

- 14.3. If Lamps Wont Glow

- 14.3.1. How to Check Fuses and Lamps

- 14.4. If the Water Temperature Gauge Shows Red Zone

- 14.5. If Torque Converter Oil Temperature Warning Lamp Glows (Powershift)

- 14.6. Trouble With the LP-Gas Equipment

- 14.7. If the Lift Truck Wont Change Direction

- 14.8. If the Lift Truck Wont Move

- 14.9. If the Mast and Attachments Stop Moving

- 14.10. If the Mast and Attachments Malfunction (FC Model)

- 14.11. If a Tire Blew Out

- 14.11.1. If a Tire Blew Out During Traveling or Operation

- 14.12. Changing Tires

- 14.12.1. Before Changing a Tire

- 14.12.2. To Remove Wheel

- 14.12.3. To Raise Front Wheel

- 14.12.4. To Raise Rear Wheel

- 14.12.5. To Install Wheel

- 14.12.6. To Add Air to Tires

- 14.12.7. Dual Tire (Optional)

- 14.13. Error Codes and Explanations

- 15. MAINTENANCE

- 15.1. General

- 15.2. Inspection Precautions

- 15.3. Maintenance Schedule

- 15.3.1. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 15.3.2. Every 50 Service Hours or Weekly, Whichever Comes First

- 15.3.3. One Month (30 days) or 200 Service Hours After Delivery of a New Truck, Whichever Comes First

- 15.3.4. Every 200 Service Hours or Monthly, Whichever Comes First

- 15.3.5. Every 500 Service Hours or 3 Months, Whichever Comes First

- 15.3.6. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 15.3.7. Every 2000 Service Hours or 1 year, Whichever Comes First

- 15.4. Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

- 15.4.1. Faulty Operation Found the Day Before

- 15.4.2. Oil, Fuel or Coolant Leaks

- 15.4.3. Head Lamp and Working Lamp (if equipped)

- 15.4.4. Load Backrest Extension

- 15.4.5. Tilt Cylinder Socket Bolts

- 15.4.6. Overhead Guard

- 15.4.7. Assist Grip

- 15.4.8. Accelerator Pedal

- 15.4.9. Brake Pedal

- 15.4.10. Inching Pedal

- 15.4.11. Parking Brake Lever

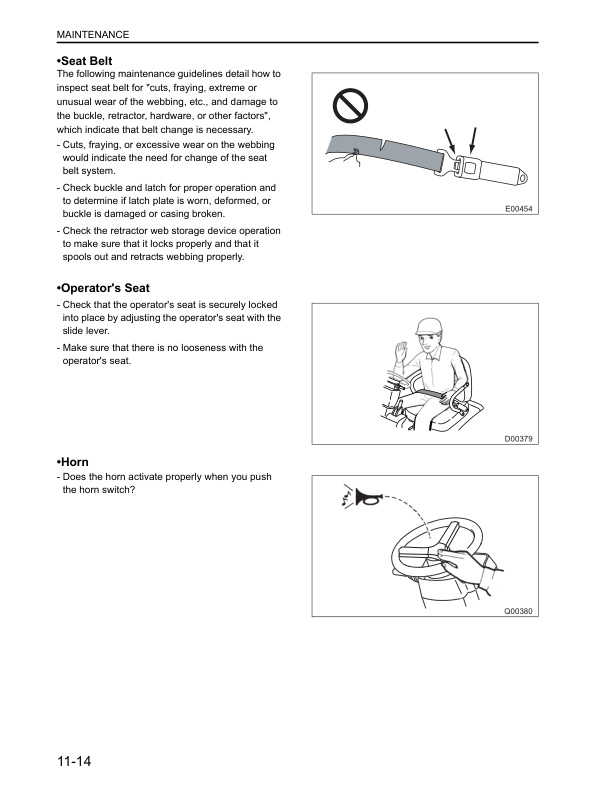

- 15.4.12. Parking Brake System

- 15.4.13. Seat Belt

- 15.4.14. Operators Seat

- 15.4.15. Steering Wheel and Column

- 15.4.16. Stop Lamps

- 15.4.17. Lamps of Instrument Panel

- 15.4.18. Lift Chains

- 15.4.19. Engine (Exhaust, Noise and Vibration)

- 15.4.20. Mast Strip Sliding Surfaces

- 15.4.21. Back-up Lamps (If Equipped)

- 15.4.22. Engine Oil

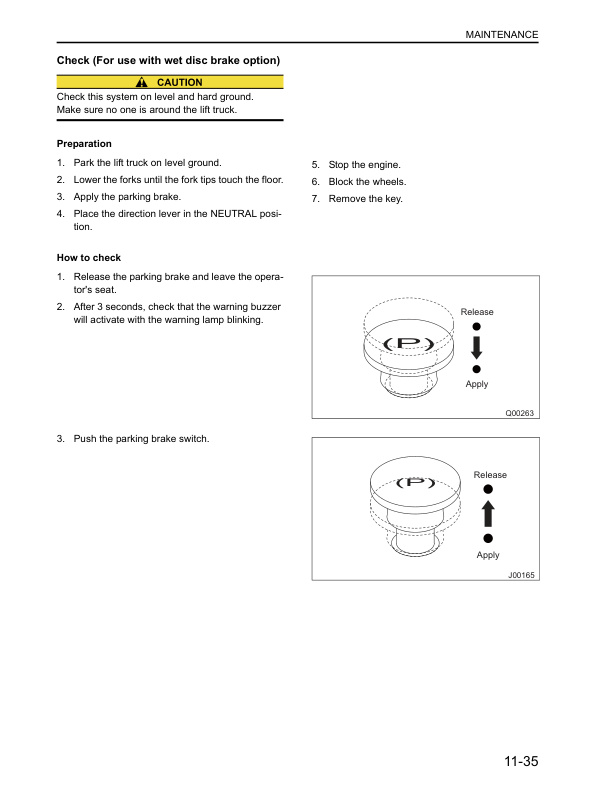

- 15.4.23. Engine Coolant

- 15.4.24. Hydraulic Oil

- 15.4.25. Powershift Transmission

- 15.4.26. Service Brakes

- 15.4.27. Brake Oil

- 15.4.28. Wheel Nuts

- 15.4.29. Tires and Rims

- 15.4.30. Mast and Forks

Mitsubishi Operation Manual PDF

Mitsubishi FB13-20TCB, FB16-20TBCB Operation and Maintenance Manual 99750-27100

Mitsubishi Operation Manual PDF

Mitsubishi FB14-20A(C)NT, FB16-20A(C)N Operation and Maintenance Manual 654390 EN A

Mitsubishi Operation Manual PDF

Mitsubishi ESR, EDR, ESS Reach Trucks Operation and Maintenance Manual WEBU6685-02

Mitsubishi Operation Manual PDF

Mitsubishi FB10 to FB25 Operation and Maintenance Manual 99750-12101

Mitsubishi Operation Manual PDF

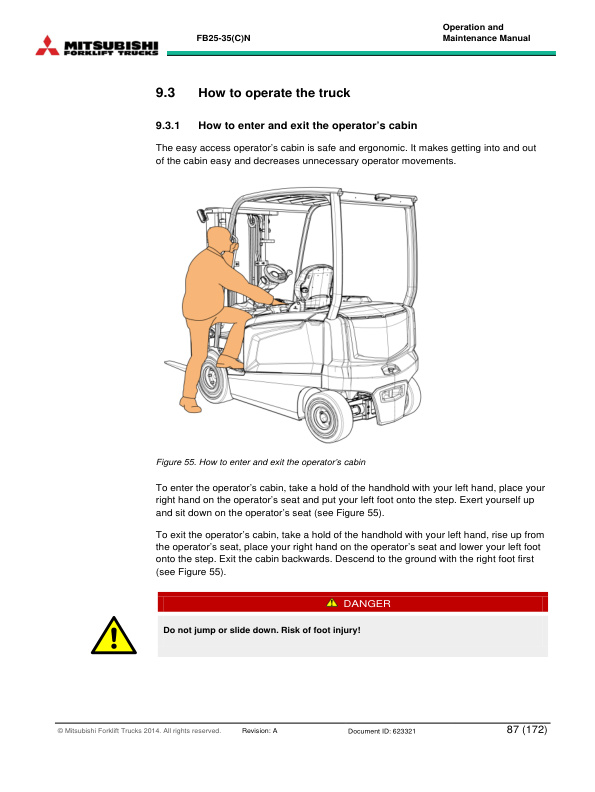

Mitsubishi FB25-35(C)N Operation and Maintenance Manual 623321 EN

Mitsubishi Operation Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Operation and Maintenance Manual 99750-7B111

Mitsubishi Operation Manual PDF

Mitsubishi ESR15N2-ESR23N2, EDR18N2 Operating Instructions 51620220

Mitsubishi Operation Manual PDF

Mitsubishi FB16N, FB18N, FB20CN Forklift Trucks Operation and Maintenance Manual 99750-56100

Mitsubishi Operation Manual PDF

Mitsubishi EDR 18N, ESR 20N, ESR 23N Operating and Maintenance Instructions 51326240

Mitsubishi Operation Manual PDF

Mitsubishi FB10-25H Operation and Maintenance Manual 99750-11110