Mitsubishi FG40N1-55N1, FG40NM1-55NM1 Chassis and Mast Service Manual 99739-7B120

$50.00

- Type Of Manual: Service Manual

- Manual ID: 99739-7B120

- Number of Pages: 644

- Size: 34.3MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- FG40N1, FG45N1, FG50CN1, FG50N1, FG55N1, FD40NM1, FD45NM1, FD50CNM1, FD50NM1, FD55NM1

- 1. Vol 1

- 1.1. FOREWORD

- 1.2. HOW TO USE THIS MANUAL

- 1.3. CHANGE LOG

- 1.4. CHAPTER 1 GENERAL INFORMATION

- 1.4.1. Model View

- 1.4.1.1. Model View

- 1.4.2. Forklift Truck Models Covered

- 1.4.2.1. ForkliftTruck Models Covered

- 1.4.3. Serial Number Locations

- 1.4.3.1. Serial Number Locations

- 1.4.4. Dimensions

- 1.4.4.1. Dimensions

- 1.4.5. Technical Data

- 1.4.5.1. Technical Data

- 1.4.5.2. Performance

- 1.4.6. Performance

- 1.4.6.1. Performance

- 1.5. CHAPTER 2 COOLING SYSTEM

- 1.5.1. Specifications

- 1.5.1.1. Specifications

- 1.5.2. Structure

- 1.5.2.1. Structure

- 1.5.3. Removal and Installation

- 1.5.3.1. Fan Belt Removal

- 1.5.4. Inspection and Adjustment

- 1.5.4.1. Fan Belt

- 1.5.4.2. Radiator

- 1.5.4.3. Upper Hose, Lower Hose

- 1.5.4.4. Coolant

- 1.5.5. Troubleshooting

- 1.5.5.1. Troubleshooting

- 1.6. CHAPTER 3 ELECTRIC SYSTEM

- 1.6.1. Chassis Electrical Devices Wiring Outline

- 1.6.1.1. Gasoline Model

- 1.6.1.2. Diesel Model

- 1.6.1.3. Gasoline and Diesel Models

- 1.6.1.4. Power Relay Supersession

- 1.6.2. Structure

- 1.6.2.1. Console Box

- 1.6.2.2. Main Electrical Components

- 1.6.2.3. Table of Lamps

- 1.6.3. Console Box

- 1.6.3.1. Disassembly

- 1.6.4. Battery Maintenance

- 1.6.4.1. State of Charge and Electrolyte Specific Gravity (S.G.) Adjustment

- 1.6.4.2. Specific Gravity Reading and State of Charge

- 1.6.4.3. Charging Precautions

- 1.6.5. Instrument Panel

- 1.6.5.1. Instrument Panel Screen Components

- 1.6.5.2. Basic Screen Display

- 1.6.5.3. Basic Operation

- 1.6.5.4. When an Error Occurs

- 1.6.5.5. Warning Lamps

- 1.6.5.6. Optional Functions

- 1.6.5.7. Hour Meters

- 1.6.5.8. Troubleshooting

- 1.6.6. Wire Color

- 1.6.6.1. Wire Color

- 1.6.6.2. List of Wire Colors

- 1.6.7. Troubleshooting

- 1.6.7.1. Starter System

- 1.6.7.2. Gauges

- 1.6.7.3. Lighting System

- 1.6.7.4. Short Horn Service Life

- 1.6.7.5. Horn Contact Ring Failures

- 1.7. CHAPTER 4 CONTROLLERS

- 1.7.1. Outline

- 1.7.1.1. Outline

- 1.7.2. Main Functions of Controllers

- 1.7.2.1. Main Functions of Controllers

- 1.7.2.2. Instrument Panel

- 1.7.2.3. VCM (Vehicle Control Module) 4

- 1.7.2.4. ECM (Gasoline Engine Control Module)

- 1.7.2.5. DCM (Diesel Engine Control Module)

- 1.7.2.6. Remote Input/Output Units

- 1.7.2.7. OCM (Optional Control Module)

- 1.7.2.8. GSE Connector

- 1.7.3. Service Tool Functions

- 1.7.3.1. Service Tool Menus

- 1.7.3.2. Service Tool Box

- 1.7.4. Mast Interlock System

- 1.7.4.1. Function

- 1.7.4.2. Mast Interlock System of VCM-4 Controller, Checking Procedure

- 1.7.4.3. Active Test Inspection Procedure

- 1.7.5. Driving Interlock System

- 1.7.5.1. Function

- 1.7.5.2. Driving Interlock System, Checking Procedure

- 1.7.5.3. Active Test Inspection Procedure

- 1.7.6. Seat Belt Warning Lamp

- 1.7.6.1. Function

- 1.7.6.2. Seat Belt Warning Lamp Checking Procedure

- 1.7.7. Parking Brake Warning Buzzer and Lamp

- 1.7.7.1. Function

- 1.7.7.2. Parking Brake Warning Buzzer/Lamp Checking Procedure

- 1.7.7.3. Parking Brake Warning Buzzer/Lamp Checking Procedure with Key in OFF Position

- 1.7.8. Harness Code List

- 1.7.8.1. Harness Code List

- 1.7.9. Controller Output Details

- 1.7.9.1. VCM-4 Controller

- 1.7.9.2. Seat Switch/Seat Belt Switch

- 1.7.9.3. Parking Brake Switch

- 1.7.9.4. Direction Lever

- 1.7.9.5. Speed Sensor

- 1.7.9.6. T/M Solenoid

- 1.7.9.7. Unload Solenoid

- 1.7.9.8. Lift Lock Solenoid

- 1.7.9.9. Warning Buzzer

- 1.7.9.10. Warning Buzzer Relay

- 1.7.9.11. Warning Buzzer Circuit

- 1.7.9.12. Instrument Panel

- 1.7.9.13. OCM

- 1.7.9.14. Service Brake Solenoid

- 1.7.9.15. Parking Brake Solenoid

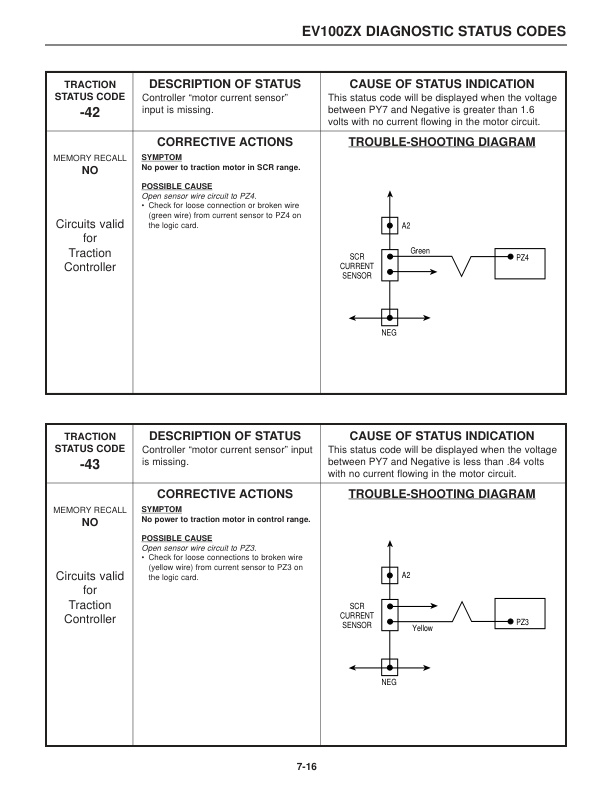

- 1.7.10. Error Codes and Troubleshooting

- 1.7.10.1. Error Code Display

- 1.7.10.2. Diagnosis Table (F Code)

- 1.7.10.3. Error Codes and Troubleshooting

- 1.7.11. Locations of Sensors and Switches

- 1.7.11.1. Locations of Sensors and Switches

- 1.8. CHAPTER 5 POWER TRAIN

- 1.8.1. Removal and Installation (MC Models)

- 1.8.1.1. Removal and Installation of Engine and Transmission Assembly (LPG Models)

- 1.8.1.2. Removal and Installation of Engine and Transmission Assembly (Diesel Models)

- 1.8.2. Removal and Installation (FC Models)

- 1.8.2.1. Removal of Engine and Transmission Assembly

- 1.8.2.2. Suggestions for Replacing Wet Disc Brake Oil and Filter

- 1.8.3. Removal and Installation (Wet disc brake)

- 1.8.3.1. Removal of Engine and Transmission Assembly

- 1.8.4. Service Data

- 1.8.4.1. Service Data

- 1.9. CHAPTER 6 POWERSHIFT TRANSMISSION

- 1.9.1. Structure

- 1.9.1.1. Transmission

- 1.9.1.2. Power Transmission Path

- 1.9.1.3. Torque Converter

- 1.9.1.4. Powershift Transmission Control

- 1.9.1.5. Control Valve

- 1.9.1.6. Main Regulator Valve

- 1.9.1.7. Parking Brake Activation

- 1.9.1.8. Releasing parking brake with the release bolt

- 1.9.1.9. Schematic Diagram of Powershift Transmission Hydraulic System

- 1.9.1.10. Powershift Transmission External View

- 1.9.2. Removal and Installation

- 1.9.2.1. Removal

- 1.9.2.2. Installation

- 1.9.3. Transmission Exterior Parts

- 1.9.3.1. Disassembly

- 1.9.3.2. Reassembly

- 1.9.4. Torque Converter

- 1.9.4.1. Disassembly

- 1.9.4.2. Inspection and Repair

- 1.9.4.3. Reassembly

- 1.9.5. Transmission

- 1.9.5.1. Disassembly

- 1.9.5.2. Inspection and Repair

- 1.9.5.3. Reassembly

- 1.9.6. F2 Clutch Pack Assembly

- 1.9.6.1. Disassembly

- 1.9.6.2. Inspection and Repair

- 1.9.6.3. Reassembly

- 1.9.7. F1 Clutch Pack Assembly

- 1.9.7.1. Disassembly

- 1.9.7.2. Inspection and Repair

- 1.9.7.3. Reassembly

- 1.9.8. R1 Clutch Pack Assembly

- 1.9.8.1. Disassembly

- 1.9.8.2. Inspection and Repair

- 1.9.8.3. Reassembly

- 1.9.9. Parking Brake Assembly

- 1.9.9.1. Disassembly

- 1.9.9.2. Inspection and Repair

- 1.9.9.3. Reassembly

- 1.9.10. Gear Pump Assembly

- 1.9.10.1. Disassembly

- 1.9.10.2. Inspection and Repair

- 1.9.10.3. Reassembly

- 1.9.11. Control Valve

- 1.9.11.1. Disassembly

- 1.9.11.2. Inspection and Repair

- 1.9.11.3. Reassembly

- 1.9.12. Main Regulator Valve

- 1.9.12.1. Disassembly

- 1.9.12.2. Inspection and Repair

- 1.9.12.3. Reassembly

- 1.9.13. Inspection and Adjustment

- 1.9.13.1. Oil Pressure Measurement

- 1.9.13.2. Brake Inching Pedal Adjustment

- 1.9.13.3. Inching Cable, Adjustment

- 1.9.14. Troubleshooting

- 1.9.14.1. Troubleshooting

- 1.9.14.2. DTC F-85, F-87, F-93

- 1.9.14.3. Diagnostic Trouble Code DTC-F88

- 1.9.15. Service Data

- 1.9.15.1. Service Data

- 2. Vol 2

- 2.1. CHAPTER 7 FRONT AXLE AND REDUCTION DIFFERENTIAL

- 2.1.1. Specifications

- 2.1.1.1. Specifications

- 2.1.2. Structure

- 2.1.2.1. Standard Model (with Drum Brake)

- 2.1.2.2. Option Model (with Wet Disc Brake)

- 2.1.3. Removal and Installation

- 2.1.3.1. Front Wheels (Common to Standard and Option Truck)

- 2.1.3.2. Shoe and Lining (Standard Truck)

- 2.1.3.3. Wet Disc Brake Assembly (Option Truck)

- 2.1.3.4. Front Axle Assembly (Standard Truck)

- 2.1.3.5. Front Axle Assembly (Option Truck)

- 2.1.3.6. Removal and Installation of Each Assembly (Standard Truck)

- 2.1.3.7. Removal and Installation of Each Assembly (Option Truck)

- 2.1.4. Disassembly and Reassembly

- 2.1.4.1. Tube Assembly and Final Reduction (Standard Truck)

- 2.1.4.2. Tube Assembly and Final Reduction (Option Truck)

- 2.1.4.3. Wear Gauge for Wet Disc Brakes

- 2.1.4.4. Reduction Differential (Common to Standard and Option Truck)

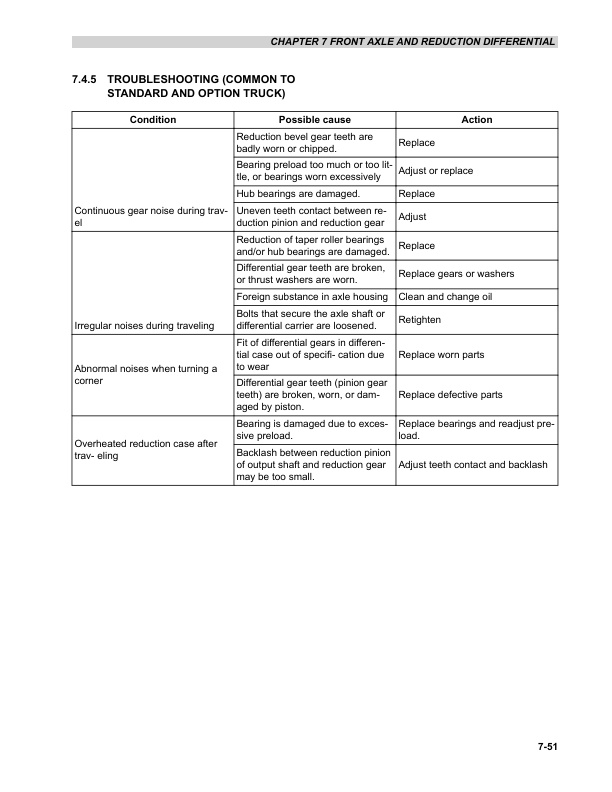

- 2.1.4.5. Troubleshooting (Common to Standard and Option Truck)

- 2.1.4.6. Service Data

- 2.2. CHAPTER 8 REAR AXLE

- 2.2.1. Structure and Functions

- 2.2.1.1. Rear Axle in General

- 2.2.1.2. Structure of Each Component

- 2.2.1.3. Steering Cylinder

- 2.2.2. Removal and Installation

- 2.2.2.1. Rear Wheel and Rear Axle Assembly

- 2.2.3. Disassembly and Reassembly

- 2.2.3.1. Disassembly and Reassembly of Wheel Hub

- 2.2.3.2. Disassembly and Reassembly of Knuckle (King Pin)

- 2.2.3.3. Disassembly and Reassembly of Steering Cylinder

- 2.2.3.4. Disassembly and Reassembly of Tie Rod

- 2.2.4. Troubleshooting

- 2.2.4.1. Troubleshooting

- 2.2.5. Service Data

- 2.2.5.1. Service Data

- 2.3. CHAPTER 9 BRAKE SYSTEM

- 2.3.1. Structure

- 2.3.1.1. Brake System (Dry type brake)

- 2.3.1.2. Wheel Brakes (Dry type brake)

- 2.3.1.3. Parking Brake Valve (Dry type brake)

- 2.3.1.4. Brake System (Wet type brake)

- 2.3.1.5. Wet Disc Brake Assembly

- 2.3.1.6. Parking Brake Valve (Wet type brake)

- 2.3.1.7. Auto Deceleration Valve (Wet type brake)

- 2.3.2. Disassembly and Reassembly

- 2.3.2.1. Wheel Brakes (Dry type brake)

- 2.3.2.2. Wheel Cylinder (Dry type brake)

- 2.3.2.3. Parking Brake Valve (Dry type brake)

- 2.3.2.4. Wet Disc Brake Assembly

- 2.3.2.5. Parking Brake Valve (Wet type brake)

- 2.3.3. Inspection and Adjustment

- 2.3.3.1. Automatic Adjuster Test (Dry type brake)

- 2.3.3.2. Manual Adjustment (Dry type brake)

- 2.3.3.3. Brake Pedal Adjustment (Common to dry and wet type)

- 2.3.3.4. Brake Lines Bleeding (Dry type brake)

- 2.3.3.5. Braking Performance Test (Dry type brake)

- 2.3.3.6. Procedure for Flushing and Air Bleeding after Assembly (Wet type brake)

- 2.3.3.7. Braking performance test (Wet type brake)

- 2.3.3.8. Oil Pressure Measurement (Dry type brake)

- 2.3.3.9. Oil Pressure Measurement (Wet type brake)

- 2.3.3.10. Parking Brake Emergency Release (Common to dry and wet type)

- 2.3.4. Troubleshooting

- 2.3.4.1. Troubleshooting

- 2.3.4.2. Brake Light Staying On

- 2.3.5. Service Data

- 2.3.5.1. Service Data

- 2.4. CHAPTER 10 STEERING SYSTEM

- 2.4.1. Structure and Functions

- 2.4.1.1. Steering System

- 2.4.1.2. Steering Valve

- 2.4.1.3. Steering Column

- 2.4.2. Disassembly and Reassembly

- 2.4.2.1. Valves, Hoses and Pipes, Disassembly and Reassembly

- 2.4.2.2. Removal and Installation of Steering Wheel and Steering Valve

- 2.4.2.3. Steering Wheel

- 2.4.2.4. Steering Valve

- 2.4.2.5. Tilt Lock Lever

- 2.4.3. Steering Valve

- 2.4.3.1. Disassembly Procedure

- 2.4.3.2. Reassembly Sequence

- 2.4.4. Troubleshooting

- 2.4.4.1. Troubleshooting

- 2.4.5. Service Data

- 2.4.5.1. Service Data

- 2.4.6. STC (Snap-to-Connect)

- 2.4.6.1. Installing and Removing STC Connector

- 2.4.6.2. Connection and Latching Check

- 2.4.6.3. STC Components

- 2.5. CHAPTER 11 HYDRAULIC SYSTEM

- 2.5.1. Structure and Functions

- 2.5.1.1. Outline

- 2.5.1.2. Hydraulic Circuit Diagram (for models with MC control valve)

- 2.5.1.3. Hydraulic Circuit Diagram (for models with FC control valve)

- 2.5.1.4. Hydraulic Tank

- 2.5.1.5. Hydraulic Pump (Gear Pump)

- 2.5.1.6. Control Valve

- 2.5.1.7. Flow Regulator Valve (models with FC control valve only)

- 2.5.1.8. Down Safety Valve

- 2.5.1.9. Lift Cylinder

- 2.5.1.10. Tilt Cylinder

- 2.5.2. Disassembly and Reassembly

- 2.5.2.1. Hydraulic Pump

- 2.5.2.2. Lift Cylinder

- 2.5.2.3. Tilt Cylinder

- 2.5.2.4. Flow Regulator Valve

- 2.5.2.5. Piping

- 2.5.2.6. Suction Strainer and Return Filter

- 2.5.3. Inspection and Adjustment

- 2.5.3.1. Hydraulic Tank

- 2.5.3.2. Control Valve

- 2.5.3.3. Natural Descent Test

- 2.5.3.4. Natural Forward Tilt Test

- 2.5.4. Troubleshooting

- 2.5.4.1. Troubleshooting

- 2.5.5. Service Data

- 2.5.5.1. Service Data

- 2.5.6. MC Control Valve

- 2.5.6.1. Outline

- 2.5.6.2. Names of Parts

- 2.5.6.3. Control Valve Operation

- 2.5.6.4. Pressure Control (Relief) Valve Operation

- 2.5.6.5. Flow Regulating Valve (FRV)

- 2.5.6.6. Cautions for use

- 2.5.7. FC Control Valve

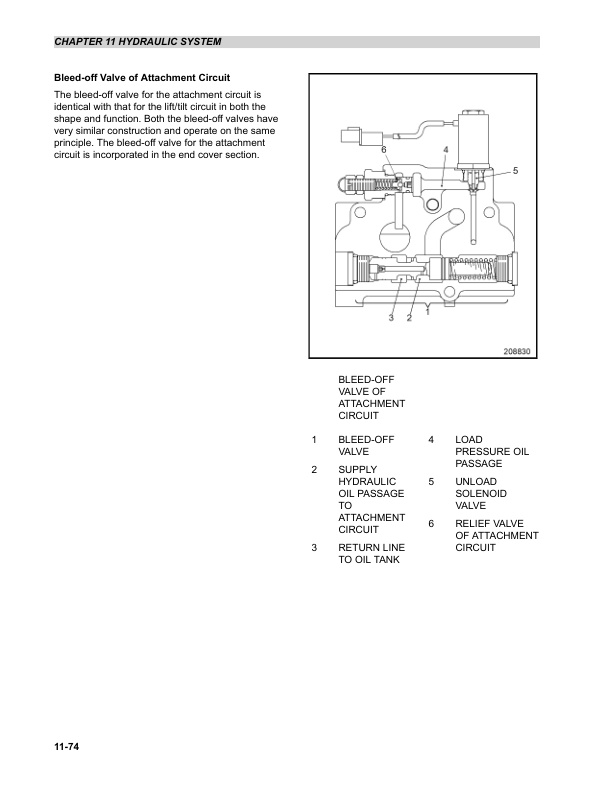

- 2.5.7.1. Structure and Functions

- 2.5.7.2. Procedures and Suggestions for Removal and Installation

- 2.5.7.3. Disassembly and Reassembly

- 2.5.8. Hydraulic Oil Tank Breather

- 2.5.8.1. Hydraulic Oil Tank Breather

- 2.6. CHAPTER 12 MAST AND FORKS

- 2.6.1. Simplex Mast

- 2.6.1.1. Mast System

- 2.6.2. Structure and Functions

- 2.6.2.1. Simplex Mast (Dual Panoramic 5V40C to 5V50C)

- 2.6.2.2. Mast Operation

- 2.6.3. Removal and Installation

- 2.6.3.1. Mast and Lift Bracket Assembly

- 2.6.4. Disassembly and Reassembly

- 2.6.4.1. Simplex Mast Disassembly

- 2.6.4.2. Simplex Mast Reassembly

- 2.6.5. Removal and Installation of Mast Rollers and Strips without Removing

- 2.6.5.1. Simplex Mast

- 2.6.6. Inspection and Adjustment (Simplex Mast)

- 2.6.6.1. Inspection and Adjustment (Simplex Mast)

- 2.6.6.2. Forks

- 2.6.6.3. Chain Tension Inspection and Adjustment

- 2.6.6.4. Chain Elongation Measurement

- 2.6.6.5. Clearance Adjustment between Lift Bracket Roller and Inner Mast

- 2.6.6.6. Mast Roller Clearance Adjustment

- 2.6.6.7. Mast Strip Clearance Inspection and Adjustment

- 2.6.6.8. Mast Tilt Angle Adjustment

- 2.6.6.9. Right and Left Lift Cylinder Stroke Inspection and Adjustment

- 2.6.7. Troubleshooting (Simplex Mast)

- 2.6.7.1. Troubleshooting (Simplex Mast)

- 2.6.8. Service Data (Simplex Mast)

- 2.6.8.1. Service Data (Simplex Mast)

- 2.6.9. Duplex Mast

Rate this product

You may also like

Mitsubishi Service Manual PDF

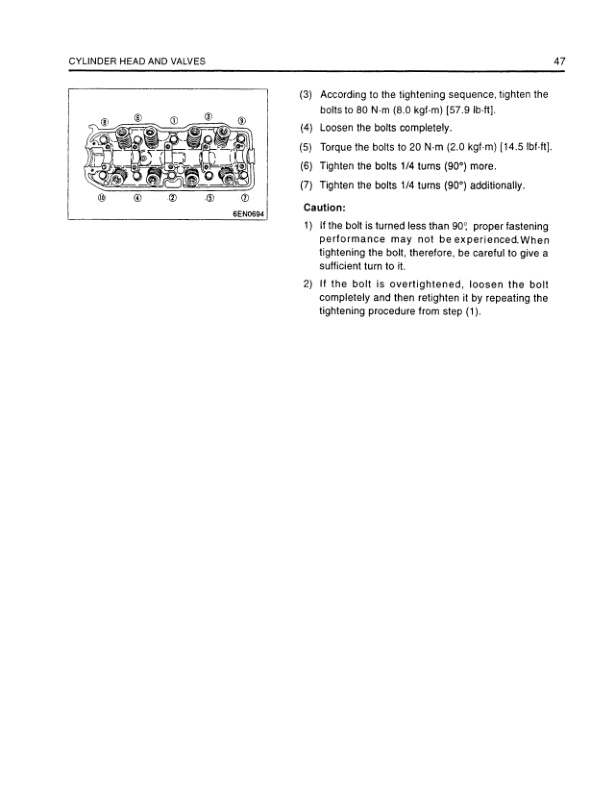

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-14110

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

$50.00

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00