Mitsubishi FGC15N to FGC33N Chassis, Mast and Options Service Manual 99719-7C110

$50.00

- Type Of Manual: Service Manual

- Manual ID: 99719-7C110

- Number of Pages: 576

- Size: 10.2MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

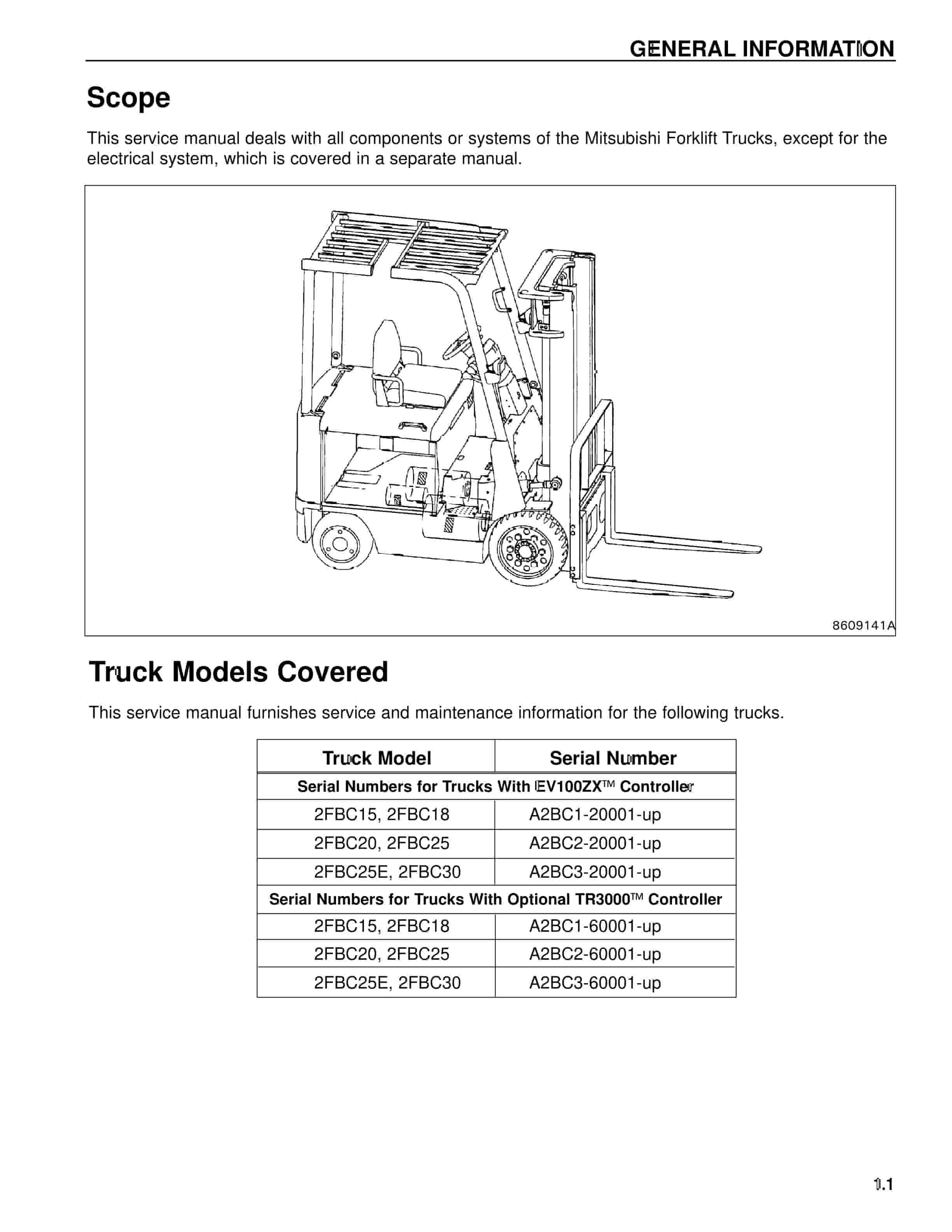

Model List:

- FGC15N, FGC18N, FGC20CN, FGC20N, FGC20N-HO, FGC25N, FGC25N-HO, FGC28N, FGC30N, FGC33N

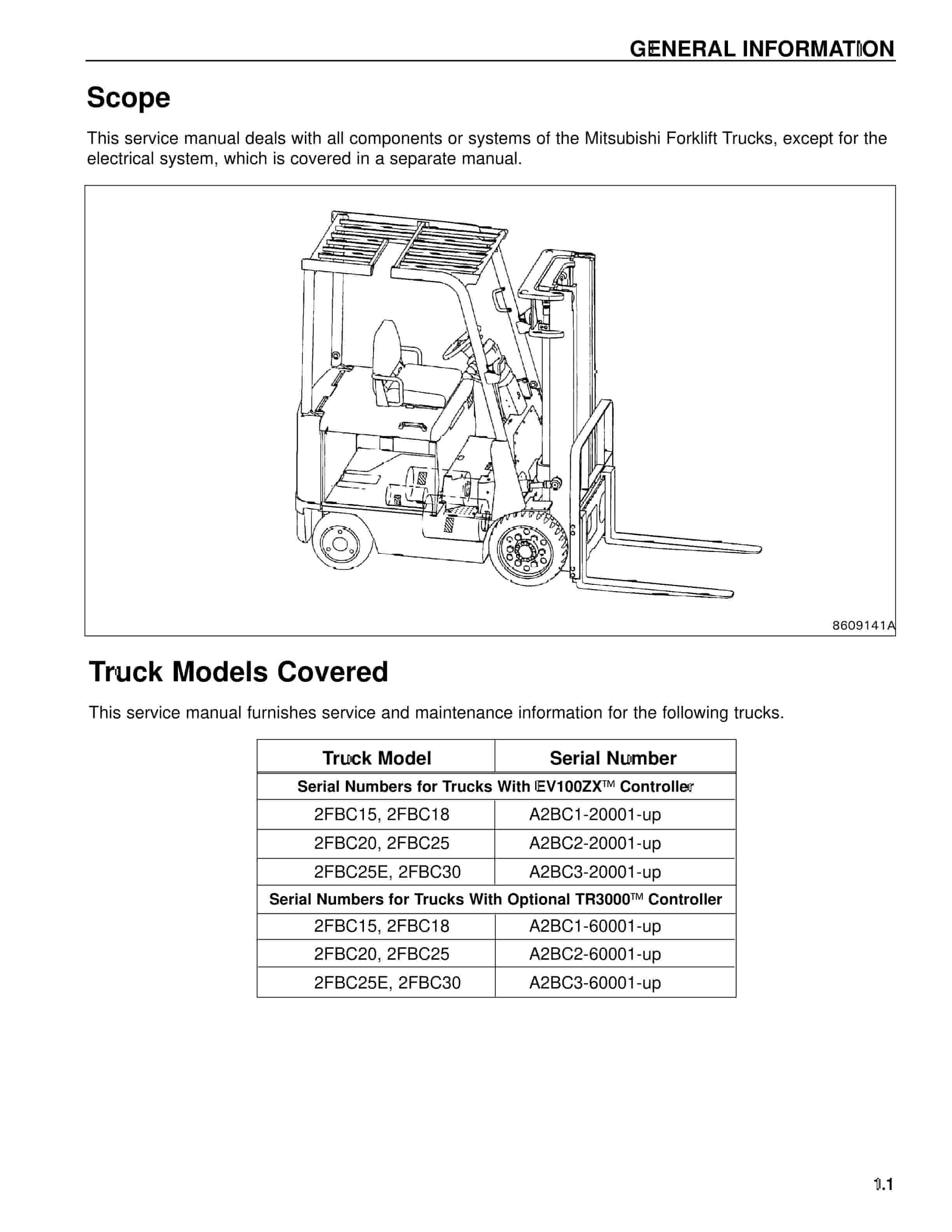

- 1. GENERAL INFORMATION

- 1.1. GENERAL INFORMATION

- 1.1.1. Model View

- 1.1.2. Truck Models Covered

- 1.1.3. Serial Number Locations

- 1.1.4. Dimensions

- 1.1.5. Technical Data

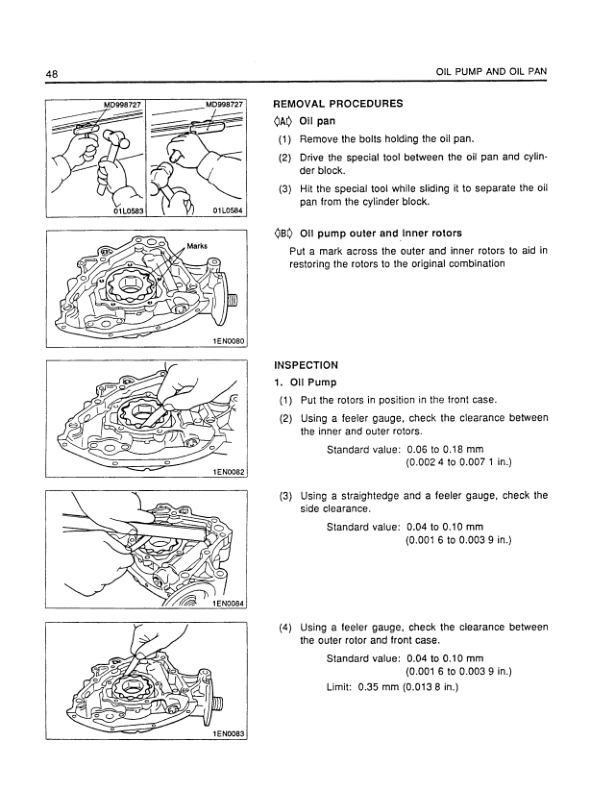

- 2. BRAKE SYSTEM

- 2.1. BRAKE SYSTEM

- 2.1.1. Structure

- 2.1.2. Disassembly and Reassembly

- 2.1.3. Inspection and Adjustment

- 2.1.4. Troubleshooting

- 2.1.5. Service Data

- 3. CONTROLERS

- 3.1. CONTROLLERS

- 3.1.1. Outline

- 3.1.2. Main Functions

- 3.1.3. Service Tool Functions

- 3.1.4. Locations of Sensors and Switches

- 4. COOLING SYSTEM

- 4.1. COOLING SYSTEM

- 4.1.1. Specification

- 4.1.2. Structure

- 4.1.3. Removal and Installation

- 4.1.4. Inspection and Adjustment

- 4.1.4.1. Unit Layout

- 4.1.4.2. Inspection and Adjustment

- 5. ELECTRICAL SYSTEM

- 5.1. ELECTRICAL SYSTEM

- 5.1.1. Chassis Electrical Devices Wiring Outline (No. 1)

- 5.1.2. Chassis Electrical Devices Wiring Outline (No. 2)

- 5.1.3. Structure

- 5.1.4. Console Box

- 5.1.5. Battery

- 5.1.6. Wire Color

- 5.1.7. Troubleshooting

- 5.1.8. Electrical Schematic ( 1 / 2 )

- 5.1.9. Electrical Schematic ( 2 / 2 )

- 6. FRONT AXLE AND REDUCTION DIFFERENTIAL

- 6.1. FRONT AXLE

- 6.1.1. Structure

- 6.1.2. Removal and Installation

- 6.1.3. Disassembly and Reassembly

- 6.1.4. Service Data

- 7. HYDRAULIC SYSTEM

- 7.1. HYDRAULIC SYSTEM

- 7.1.1. Structure and Functions

- 7.1.2. Disassembly and Reassembly

- 7.1.3. Inspection and Adjustment

- 7.1.4. Inspection and Adjustment

- 7.1.5. Troubleshooting

- 7.1.6. Service Data

- 7.1.7. Control Valve

- 7.1.8. Disassembly and Reassembly

- 8. MAST AND FORKS

- 8.1. MAST AND FORKS

- 8.1.1. Mast Systems

- 8.1.2. Structure

- 8.1.3. Removal and Installation

- 8.1.4. Disassembly and Reassembly

- 8.1.5. Duplex Mast

- 8.1.6. Triplex Mast

- 8.1.7. Inspection and Adjustment

- 8.1.8. Troubleshooting

- 8.1.9. Service Data

- 9. POWER TRAIN

- 9.1. POWER TRAIN

- 9.1.1. Removal and Installation

- 9.1.1.1. Removal of Engine and Transmission Assembly

- 9.1.1.2. Cooling, Exhaust and Hydraulic

- 9.1.1.3. Front Wheel and Front Axle Shaft

- 9.1.1.4. Engine and Transmission Assembly

- 9.1.2. Installation

- 10. POWERSHIFT TRANSMISSION

- 10.1. POWERSHIFT TRANSMISSION

- 10.1.1. Structure and Function

- 10.1.2. Removal and Installation

- 10.1.3. Control Valve

- 10.1.4. Input Shaft Assembly

- 10.1.5. Oil Pump Assembly

- 10.1.6. Inspection and Adjustment

- 10.1.7. Troubleshooting

- 10.1.8. Tightening Torque

- 10.1.9. Service Data

- 11. REAR AXLE

- 11.1. REAR AXLE

- 11.1.1. Structure and Functions

- 11.1.2. Removal and Installation

- 11.1.3. Disassembly and Reassembly

- 11.1.4. Troubleshooting

- 11.1.5. Service Data

- 12. REDUCTION DIFFERENTIAL

- 12.1. REDUCTION DIFFERENTIAL

- 12.1.1. Structure and Function

- 12.1.2. Removal and Installation

- 12.1.3. Disassembly and Reassembly

- 12.1.4. Inspection

- 12.1.5. Reassembly

- 12.1.6. Troubleshooting

- 13. SERVICE DATA

- 13.1. SERVICE DATA

- 13.1.1. Maintenance Schedule

- 13.1.2. Tightening Torques for Standard Bolts and Nuts

- 13.1.3. Parts to be Changed Periodically

- 13.1.4. Lubrication Instructions

- 13.1.5. Fuel and Lubricant Specifications

- 13.1.6. Refill Capacities

- 13.1.7. Weight of Components (Approximate)

- 13.1.8. Special Service Tool

- 14. STEERING SYSTEM

- 14.1. STEERING SYSTEM

- 14.1.1. Structure and Function

- 14.1.2. Steering Column

- 14.1.3. Disassembly and Reassembly

- 14.1.4. Removal and Installation of Steering Wheel and Steering Valve

- 14.1.5. Steering Valve

- 14.1.6. Troubleshooting

- 14.1.7. Service Data

- 15. ENGINE CONTROL

- 15.1. ENGINE CONTROL

- 15.1.1. PRECAUTIONS

- 15.1.1.1. General precautions for service operations

- 15.1.2. PREPARATION

- 15.1.2.1. Service Tools

- 15.1.3. DESCRIPTION

- 15.1.4. BASIC INSPECTION

- 15.1.4.1. Inspection of Idle Speed, Ignition Timing, and Air-fuel Ratio

- 15.1.4.2. Throttle Valve Closed Position Learning and Idle Air Volume Learning

- 15.1.4.3. Accelerator Pedal Released Position Learning

- 15.1.4.4. Fuel pressure inspection EC

- 15.1.5. TROUBLE DIAGNOSIS

- 15.1.5.1. How to Proceed with Trouble Diagnosis

- 15.1.5.2. Diagnosis Chart by Symptom

- 15.1.5.3. Component Parts Location

- 15.1.5.4. ECM Component

- 15.1.5.5. Circuit Diagram

- 15.1.5.6. ECM Terminal Layout

- 15.1.5.7. ECM Input/Output Signal Specifications

- 15.1.5.8. Service Tool (ST)

- 15.1.5.9. Self-Diagnosis Function (without ST)

- 15.1.5.10. ST Reference Value in Data Monitor

- 15.1.5.11. Fail-Safe Function

- 15.1.6. POWER SUPPLY AND GROUND SYSTEM

- 15.1.6.1. ECM Input/Output Signal Specifications

- 15.1.6.2. Circuit Diagram

- 15.1.7. CRANKSHAFT POSITION SENSOR (POS) SYSTEM

- 15.1.7.1. ECM Input/Output Signal Specifications

- 15.1.7.2. Circuit Diagram

- 15.1.7.3. Component Parts Inspection

- 15.1.8. CAMSHAFT POSITION SENSOR (PHASE) SYSTEM

- 15.1.8.1. ECM Input/Output Signal Specifications

- 15.1.8.2. Circuit Diagram

- 15.1.8.3. Component Parts Inspection

- 15.1.9. MASS AIR FLOW SENSOR SYSTEM

- 15.1.9.1. ST Data Monitor Display

- 15.1.9.2. ECM Input/Output Signal Specifications

- 15.1.9.3. Circuit Diagram

- 15.1.9.4. Component Parts Inspection

- 15.1.10. ENGINE COOLANT TEMPERATURE SENSOR SYSTEM

- 15.1.10.1. ST Data Monitor Display

- 15.1.10.2. ECM Input/Output Signal Specifications

- 15.1.10.3. Circuit Diagram

- 15.1.10.4. Component Parts Inspection

- 15.1.11. HEATED OXYGEN SENSOR SYSTEM

- 15.1.11.1. ST Data Monitor Display

- 15.1.11.2. ECM Input/Output Signal Specifications

- 15.1.11.3. Circuit Diagram

- 15.1.12. THROTTLE POSITION SENSOR SYSTEM

- 15.1.12.1. ST Data Monitor Display

- 15.1.12.2. ECM Input/Output Signal Specifications

- 15.1.12.3. Circuit Diagram

- 15.1.12.4. Component Parts Inspection

- 15.1.13. ACCELERATOR PEDAL POSITION SENSOR SYSTEM

- 15.1.13.1. ST Data Monitor Display

- 15.1.13.2. ECM Input/Output Signal Specifications

- 15.1.13.3. Circuit Diagram

- 15.1.13.4. Component Parts Inspection

- 15.1.14. INTAKE AIR TEMPERATURE SENSOR

- 15.1.14.1. ST Data Monitor Display

- 15.1.14.2. ECM Input/Output Signal Specifications

- 15.1.14.3. Circuit Diagram

- 15.1.14.4. Component Parts Inspection

- 15.1.15. PNP SWITCH SYSTEM

- 15.1.15.1. ST Data Monitor Display

- 15.1.15.2. ECM Input/Output Signal Specifications

- 15.1.15.3. Circuit Diagram

- 15.1.16. STOP LAMP SWITCH SYSTEM

- 15.1.16.1. ST Data Monitor Display

- 15.1.16.2. ECM Input/Output Signal Specifications

- 15.1.16.3. Circuit Diagram

- 15.1.16.4. Component Parts Inspection

- 15.1.17. ELECTRIC LOAD SWITCH SYSTEM

- 15.1.17.1. ST Data Monitor Display

- 15.1.17.2. ECM Input/Output Signal Specifications

- 15.1.17.3. Circuit Diagram

- 15.1.18. CAN COMMUNICATION SYSTEM

- 15.1.18.1. ECM Input/Output Signal Specifications

- 15.1.18.2. Circuit Diagram

- 15.1.19. IGNITION SYSTEM

- 15.1.19.1. ST Data Monitor Display

- 15.1.19.2. ECM Input/Output Signal Specifications

- 15.1.19.3. Circuit Diagram

- 15.1.19.4. Component Parts Inspection

- 15.1.20. FUEL INJECTOR SYSTEM

- 15.1.20.1. ST Data Monitor Display

- 15.1.20.2. ECM Input/Output Signal Specifications

- 15.1.20.3. Circuit Diagram

- 15.1.20.4. Component Parts Inspection

- 15.1.21. FUEL PUMP SYSTEM

- 15.1.21.1. ST Data Monitor Display

- 15.1.21.2. ECM Input/Output Signal Specifications

- 15.1.21.3. Circuit Diagram

- 15.1.21.4. Component Parts Inspection

- 15.1.22. THROTTLE CONTROL MOTOR SYSTEM

- 15.1.22.1. ECM Input/Output Signal Specifications

- 15.1.22.2. Circuit Diagram

- 15.1.22.3. Component Parts Inspection

- 15.1.23. HEATED OXYGEN SENSOR HEATER SYSTEM

- 15.1.23.1. ST Data Monitor Display

- 15.1.23.2. ECM Input/Output Signal Specifications

- 15.1.23.3. Circuit Diagram

- 15.1.23.4. Component Parts Inspection

- 15.1.24. PCV GAS RECIRCULATION DEVICE

- 15.1.24.1. System Diagram

- 15.1.24.2. Component Parts Inspection

- 15.1.25. FUEL CUT FUNCTION

- 15.1.25.1. Inspection Procedure

- 15.1.26. REMOVAL AND INSTALLATION OF ECM COMPONENTS

- 15.1.26.1. Removal and Installation of ECM

- 15.1.26.2. Removal and Installation of Crankshaft Position Sensor (POS)

- 15.1.26.3. Removal and Installation of Camshaft Position Sensor (PHASE)

- 15.1.26.4. Removal and Installation of Mass Air Flow Sensor

- 15.1.26.5. Removal and Installation of Engine Coolant Temperature Sensor

- 15.1.26.6. Removal and Installation of Heated Oxygen Sensor (with Heated Oxygen Sensor Heater)

- 15.1.26.7. Removal and Installation of Throttle Position Sensor (Electric Throttle Control Actuator Assembly)

- 15.1.26.8. Removal and Installation of Accelerator Pedal Position Sensor (Accelerator Pedal Assembly)

- 15.1.26.9. Removal and Installation of Intake Air Temperature Sensor (with Mass Air Flow Sensor)

- 15.1.26.10. Removal and Installation of Neutral Switch (M/T Model)

- 15.1.26.11. Removal and Installation of Ignition Coil (with Power Transistor)

- 15.1.26.12. Removal and Installation of Fuel Injector

- 15.1.26.13. Removal and Installation of Fuel Pump

- 15.1.26.14. Removal and Installation of Throttle Control Motor (Electric Throttle Control Actuator Assembly)

- 15.1.26.15. Removal and Installation of LPG Injector Holder

- 15.1.26.16. Removal and Installation of LPG Injector Drive Unit

- 15.1.27. SERVICE DATA AND SPECIFICATIONS (SDS)

- 15.1.27.1. Standard, Repair Limit

- 16. ENGINE ELECTRICAL

- 16.1. ENGINE ELECTRICAL SYSTEM

- 16.1.1. ADJUSTMENT VALUE

- 16.1.2. TROUBLE DIAGNOSIS

- 16.1.3. STARTER MOTOR

- 16.1.3.1. Starter Motor Specifications

- 16.1.3.2. Component Parts Location

- 16.1.3.3. Overhaul

- 16.1.3.4. Assembly Inspection

- 16.1.4. ALTERNATOR

- 16.1.4.1. Components of Alternator

- 16.1.4.2. Disassembly

- 16.1.4.3. Inspection

- 17. ENGINE FUEL

- 17.1. ENGINE FUEL

- 17.1.1. EMISSION CONTROL SYSTEM (ONLY FOR ELECTRONIC CONTROLLED TYPE)

- 17.1.2. UNIT LAYOUT

- 17.1.3. SERVICE DATA AND SPECIFICATIONS (SDS)

- 17.1.3.1. Electronic Control System Specifications

- 17.1.4. LPG FUEL SYSTEM TROUBLE DIAGNOSIS

- 17.1.5. DISASSEMBLY AND ASSEMBLY OF FUEL SYSTEM

- 17.1.5.1. Removal and Installation of LPG Injector Drive Unit Connector

- 17.1.5.2. Removal and Installation of Electronic Control Throttle Assembly

- 17.1.5.3. Removal and Installation of Gasoline Fuel Injector (Electronic Controlled Gasoline and Combined Use)

- 17.1.5.4. Injector Holder

- 17.1.6. VAPORIZER MECHANISM AND OPERATION

- 17.1.6.1. Primary (Decompression) Room

- 17.1.6.2. Description

- 18. ENGINE LUBRICATION AND COOLING SYSTEM

- 18.1. ENGINE LUBRICATION COOLING SYSTEMS

- 18.1.1. LUBRICATION SYSTEM

- 18.1.1.1. Specifications

- 18.1.1.2. Adjustment Value

- 18.1.1.3. Oil Pressure

- 18.1.1.4. Tightening Torque

- 18.1.1.5. Trouble Diagnosis

- 18.1.1.6. Lubrication Schematic Diagram

- 18.1.1.7. Oil Pump

- 18.1.2. ENGINE COOLANT SYSTEM

- 18.1.2.1. Specifications

- 18.1.2.2. Adjustment Value

- 18.1.2.3. Tightening Torque

- 18.1.2.4. Trouble Diagnosis

- 18.1.2.5. Cooling System Configuration

- 18.1.2.6. Water Pump

- 18.1.2.7. Thermostat

- 19. ENGINE MECHANICAL

- 19.1. ENGINE MECHANICAL

- 19.1.1. PRECAUTIONS

- 19.1.1.1. Precautions for Draining Engine Coolant

- 19.1.1.2. Precautions for Disconnecting Fuel Piping

- 19.1.1.3. Precautions for Removing and Disassembling

- 19.1.1.4. Precautions for Inspection, Correction, and Replacement

- 19.1.1.5. Precautions for Assembly and Installation

- 19.1.1.6. Parts Requiring Angle Tightening

- 19.1.1.7. Caution for Use of Power Tools

- 19.1.1.8. Precautions for Liquid Gasket Application

- 19.1.2. ENGINE OUTSIDE DRAWINGS

- 19.1.3. MAIN SPECIFICATIONS

- 19.1.4. ADJUSTMENT VALUE

- 19.1.5. TIGHTENING TORQUE

- 19.1.5.1. Standard Bolt Tightening Torque

- 19.1.5.2. Engine Part Tightening Torque

- 19.1.6. TROUBLE DIAGNOSIS

- 19.1.7. SERVICE TOOLS

- 19.1.8. REMOVAL AND INSTALLATION OF ENGINE

- 19.1.8.1. Removal

- 19.1.8.2. Installation

- 19.1.8.3. Inspection

- 19.1.9. ENGINE SERVICE

- 19.1.9.1. Engine Disassembly

- 19.1.9.2. Inspection and Correction

- 19.1.9.3. Engine Assembly

- 20. ENGINE TUNE-UP

- 20.1. ENGINE TUNE-UP

- 20.1.1. SPECIFICATIONS

- 20.1.2. TIGHTENING TORQUE

- 20.1.3. TROUBLE DIAGNOSIS

- 20.1.4. ENGINE INSPECTION AND ADJUSTMENT

- 20.1.4.1. Engine Body Related

- 20.1.4.2. Ignition and Fuel Systems

- 21. FOREWORD

- 21.1. FOREWORD

- 21.2. GROUP INDEX

- 22. GENERAL INFORMATION

- 22.1. GENERAL INFORMATION

- 22.1.1. HOW TO USE THIS MANUAL

- 22.1.1.1. Description

- 22.1.1.2. Definition of Terms

- 22.1.1.3. Definition of Units

- 22.1.1.4. Description

- 22.1.2. PRECAUTIONS FOR SAFETY AND QUALITY

- 22.1.2.1. Reduction of Risk Operation

- 22.1.2.2. Correct Operation

- 22.1.2.3. Precautions for Radio Equipment Installation

- 22.1.3. PRECAUTIONS

- 22.1.3.1. Precautions in Draining Engine Coolant

- 22.1.3.2. Precautions for Disconnecting Fuel Piping

- 22.1.3.3. Precautions for Removing and Disassembling

Rate this product

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101

$50.00

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

$50.00

Mitsubishi Service Manual PDF

$50.00