Mitsubishi PBP16N3, PBP18N3, PBP20N3, PBP20N3E, PBP20N3R Service Manual 660033 EN-A

$50.00

- Type Of Manual: Service Manual

- Manual ID: 660033

- Language: EN-A

- Number of Pages: 289

- Size: 10.7MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- PBP16N3, PBP18N3, PBP20N3, PBP20N3E, PBP20N3R

- 1. Table of contents

- 2. Foreword

- 3. How to read this manual

- 3.1. Safety-related signs

- 3.2. Safety symbols

- 3.3. Units

- 3.4. Interactive links

- 4. Safety instructions

- 4.1. General safety instructions

- 4.2. Safety requirements for industrial trucks

- 4.3. Repairs and structural modifications

- 4.4. Instructions for site supervision

- 4.5. Service area safety

- 4.6. Occupational safety

- 4.7. Personal safety

- 4.8. Work safety

- 4.9. Operating temperature

- 5. General information

- 5.1. Truck models covered by this manual

- 5.2. Transportation

- 5.2.1. Lifting the truck

- 5.2.1.1. Jack points

- 5.2.1.2. Hoist points

- 5.2.2. Towing the truck

- 5.2.3. Brake release

- 5.3. Operating position

- 5.4. Operating direction

- 5.5. Special tools

- 5.6. Assembly and commissioning

- 5.7. Order spare parts

- 6. Main components

- 6.1. Identification plates and stickers

- 6.2. Operating devices

- 6.3. Tiller arm

- 6.3.1. Tiller arm controls

- 6.3.2. Tiller arm positions

- 6.4. Truck covers

- 6.5. Battery compartment

- 6.6. Control panel

- 6.6.1. Emergency stop button

- 6.6.2. Key switch

- 6.6.3. Multi-functional display

- 6.7. Foldable operator platform

- 6.8. Load handling

- 6.8.1. Hydraulic cylinders

- 6.9. Electric system

- 6.9.1. Electrical operation

- 6.9.1.1. Overview

- 6.9.1.2. How to use the schematic diagram

- 6.9.1.3. Power source

- 6.9.1.4. Safety circuit (emergency stop button)

- 6.9.1.5. Key switch

- 6.9.1.6. Traction

- 6.9.1.7. AC motor operation

- 6.9.2. Traction and pump controller

- 6.9.2.1. Traction and pump controller connectors

- 6.9.2.2. CNA external connector

- 6.9.2.3. Description of the power connections

- 6.9.3. Horn

- 6.9.4. Sensors

- 6.9.5. Fuses

- 6.9.6. Relays and contactors

- 6.9.7. Display connector

- 6.10. Hydraulic operation

- 6.10.1. Hydraulic aggregate

- 6.10.1.1. Pump motor

- 6.10.2. Hydraulic symbols

- 6.10.3. Hydraulic operation overview

- 6.10.4. Hydraulic operation lifting/lowering

- 6.10.5. Additional hydraulic functions with lifting forks

- 6.11. Drive unit

- 6.11.1. Traction motor

- 6.11.2. Magnetic brake

- 6.11.2.1. Service brake

- 6.11.2.2. Parking brake

- 6.11.2.3. Emergency braking

- 6.12. Wheels

- 6.13. Truck suspension

- 7. Maintenance

- 7.1. Safety instructions for maintenance

- 7.2. Maintenance intervals

- 7.3. Opening the covers

- 7.3.1. Remove the front cover

- 7.3.2. Remove the control panel

- 7.3.3. Remove the top cover

- 7.3.4. Open the battery cover

- 7.4. Drive unit

- 7.4.1. Transmission gear

- 7.4.1.1. Fastening of the transmission gear

- 7.4.1.2. Leakage check of the transmission gear

- 7.4.2. Slewing bearing

- 7.4.3. Magnetic brake

- 7.4.3.1. Measure the thickness of the brake disc

- 7.4.3.2. Measure the coil resistance

- 7.4.4. Drive unit suspension

- 7.4.4.1. Inspect the drive unit suspension

- 7.4.4.2. Lubricate the drive unit suspension

- 7.5. Hydraulics

- 7.5.1. Hydraulic system maintenance

- 7.5.2. Hydraulic filters

- 7.5.3. Solenoid valve functionality check

- 7.5.4. Leakage check of the hydraulic system

- 7.5.5. Hoses and cylinders

- 7.5.6. Hydraulic oil tank

- 7.5.6.1. Hydraulic oil change

- 7.5.6.2. Oil level

- 7.5.6.3. Clean the oil tank

- 7.6. Lifting system

- 7.6.1. Check the cylinders and piston rods

- 7.6.2. Lifting test

- 7.6.3. Fork inspection

- 7.6.4. Examine the load backrest for cracks

- 7.7. Lifting forks

- 7.7.1. Examine the welding in lifting carriage for cracks

- 7.7.2. Examine the rollers, pins and welds for cracking and damage

- 7.7.3. Lifting chains

- 7.7.3.1. Chain tension

- 7.7.3.2. Chain lubrication

- 7.7.3.3. Chain wear measurement

- 7.7.3.4. Check the chain anchors and locking pins

- 7.8. Wheels

- 7.8.1. Before you replace the wheels

- 7.8.2. Traction wheel

- 7.8.2.1. Remove the traction wheel

- 7.8.2.2. Replace the wheel shaft bolts

- 7.8.2.3. Install the traction wheel

- 7.8.3. Castor wheel

- 7.8.3.1. Replace the castor wheel

- 7.8.3.2. Adjust the castor wheel

- 7.8.3.3. Inspect the castor wheel suspension

- 7.8.4. Load wheels

- 7.8.4.1. Replace the load wheels

- 7.9. Electrics

- 7.9.1. Electrical connections tightening torques

- 7.9.2. Discharge the controllers

- 7.9.3. Contactor functionality check

- 7.9.4. Test the functionality of sensors

- 7.9.4.1. Traction motor sensors

- 7.9.4.2. Tiller arm sensor

- 7.9.4.3. Operator platform sensors

- 7.9.4.4. Battery cover sensor

- 7.9.4.5. Lifting fork limit sensor

- 7.9.4.6. Lifting forks down sensor

- 7.9.5. Test the functionality of switches and buttons

- 7.9.5.1. Emergency stop button

- 7.9.5.2. Key switch functionality check

- 7.9.5.3. Tiller arm control buttons

- 7.9.6. Test the functionality of the horn

- 7.9.6.1. Horn

- 7.9.6.2. Horn diode

- 7.9.7. Wiring harnesses and cables

- 7.9.8. Examine and clear the alarm history

- 7.9.9. Insulation resistance test

- 7.9.9.1. Test voltage

- 7.9.9.2. Check the insulation tester

- 7.9.9.3. Measure the insulation resistance

- 7.10. General

- 7.10.1. How to clean the truck

- 7.10.2. Lubrication

- 7.10.3. Examine the welding in the truck frame for cracking

- 7.10.4. Examine the truck frame and the lifting carriage

- 7.10.5. Examine the gas springs

- 7.10.6. Examine the condition and position of the identification plates

- 7.10.7. Examine the covers

- 7.10.8. Safety functions

- 8. Battery maintenance

- 8.1. Lead-acid batteries

- 8.1.1. Safety with lead-acid batteries

- 8.1.2. General information

- 8.1.3. Requirements for battery charging areas

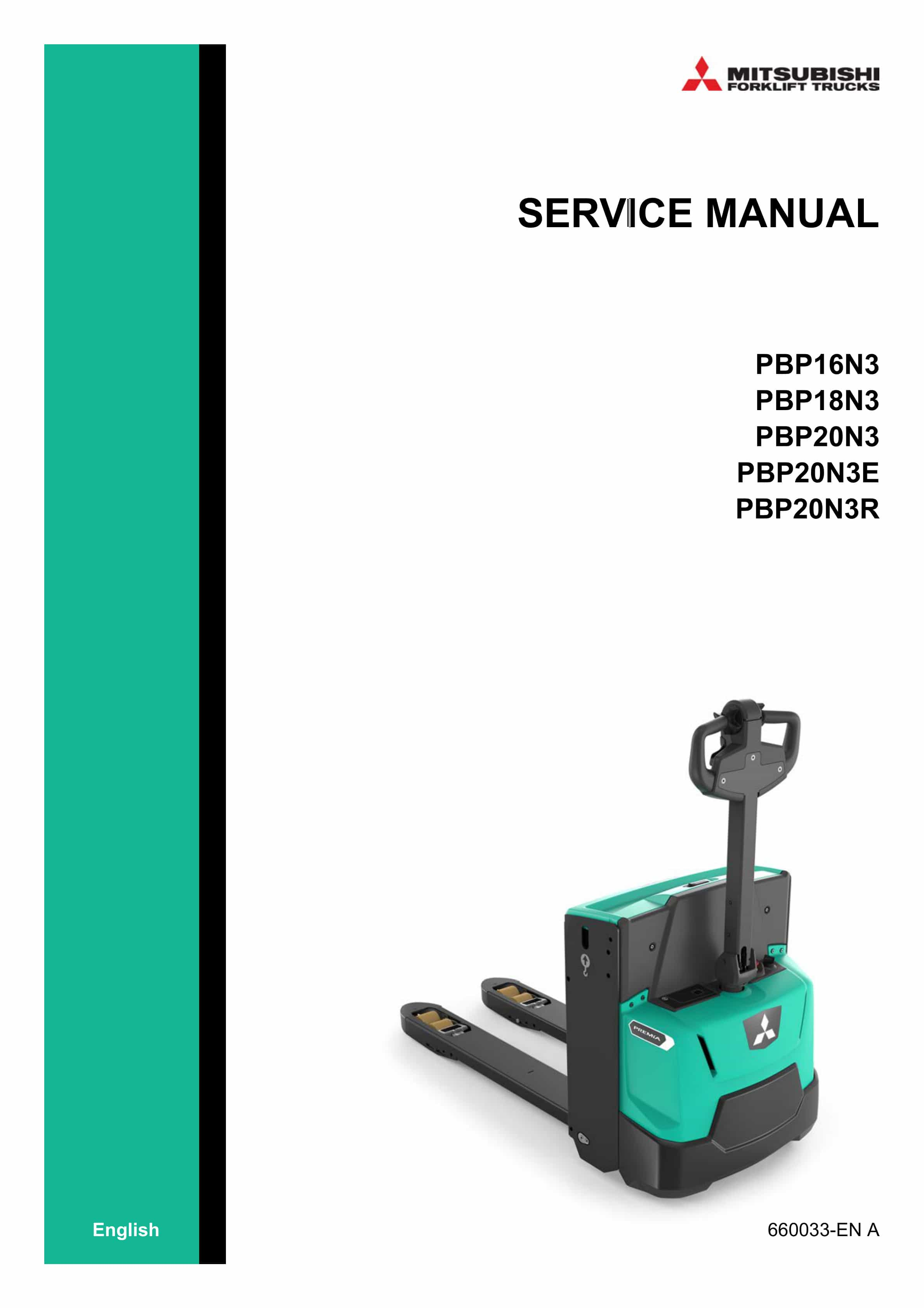

- 8.1.4. Charge the battery with the external charger

- 8.1.5. Charge the battery with the internal charger

- 8.1.6. Battery maintenance

- 8.1.6.1. General maintenance

- 8.1.6.2. How to clean the battery

- 8.1.6.3. Daily maintenance

- 8.1.6.4. Weekly maintenance

- 8.1.6.5. Monthly maintenance

- 8.1.6.6. Annual maintenance

- 8.1.7. Malfunctions

- 8.1.8. Acquire a new battery

- 8.1.9. Storage

- 8.2. Lithium-ion batteries

- 8.2.1. General information

- 8.2.2. Safety signs

- 8.2.3. Requirements for battery charging areas

- 8.2.4. Charge the battery

- 8.2.4.1. Recharging a lithium-ion battery

- 8.2.4.2. Charge the battery with the external charger

- 8.2.4.3. Charge the battery with the internal charger

- 8.2.4.4. Opportunity charging

- 8.2.4.5. Battery balancing

- 8.2.5. Battery maintenance

- 8.2.5.1. Examine the battery

- 8.2.5.2. How to clean the battery

- 8.2.5.3. Malfunctions

- 8.2.5.4. Service and repair

- 8.2.6. Acquire a new battery

- 8.2.7. Storage

- 8.3. Replace the battery

- 8.3.1. General safety instructions

- 8.3.2. Replace the battery with a lifting device

- 8.3.3. Replace the battery with a battery change device

- 8.4. Battery cover maintenance

- 8.4.1. Remove the rubber absorbers of the battery cover

- 8.4.2. Remove the battery cover lock

- 9. Repair

- 9.1. Repair drive unit

- 9.1.1. Remove the drive unit

- 9.1.2. Disassemble the drive unit

- 9.1.3. Measuring the run-out of the connecting face of the motor

- 9.1.4. Assemble the drive unit

- 9.2. Repair foldable operator platform

- 9.2.1. Remove the foldable operator platform

- 9.2.2. Replace the rubber absorbers of the foldable operator platform

- 9.2.3. Replace the gas springs of the platform

- 9.2.4. Replace the slide bearing of the platform

- 9.3. Repair tiller arm

- 9.3.1. Remove the steering assembly

- 9.3.2. Remove the tiller arm

- 9.3.3. Replace the gas spring of the tiller arm

- 9.3.4. Remove the tiller head

- 9.3.4.1. Replace the acceleration controllers

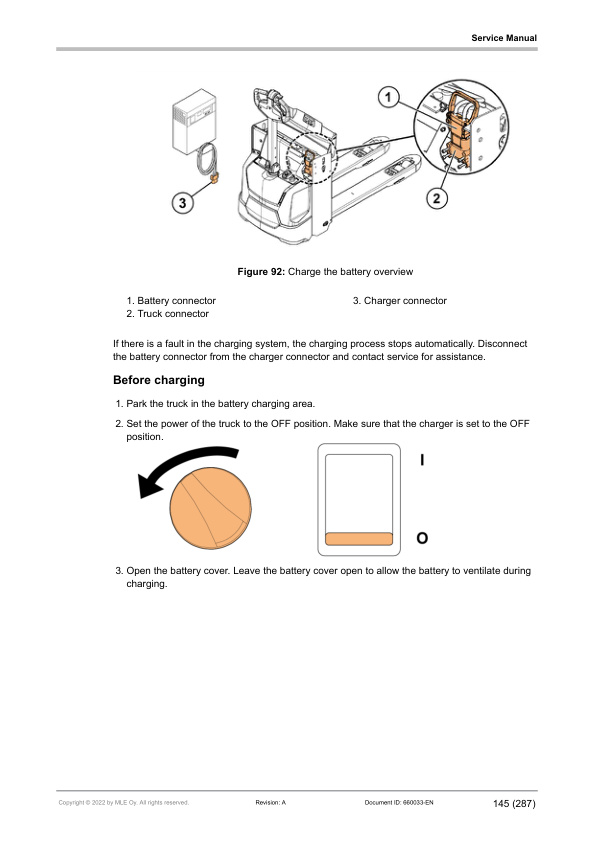

- 9.3.4.2. Replace the safety stop button

- 9.3.4.3. Replace the low speed button

- 9.3.4.4. Replace the tiller sensor box

- 9.3.4.5. Replace the lifting/lowering buttons

- 9.3.4.6. Replace the horn buttons

- 9.4. Repair hydraulic system

- 9.4.1. Disassemble the hydraulic aggregate

- 9.4.2. Set the lifting pressure

- 9.4.3. Disassemble the lifting fork valve

- 9.5. Repair lifting system

- 9.5.1. Disassemble the linkage mechanism

- 9.5.2. Remove the hydraulic cylinder

- 9.5.3. Replace the sealing housing of the hydraulic cylinder

- 9.5.4. Replace the slide bearings of the hydraulic cylinder

- 9.6. Repair lifting forks assembly

- 9.6.1. Disassemble the lifting fork carriage

- 9.6.2. Main rollers of the lifting fork carriage

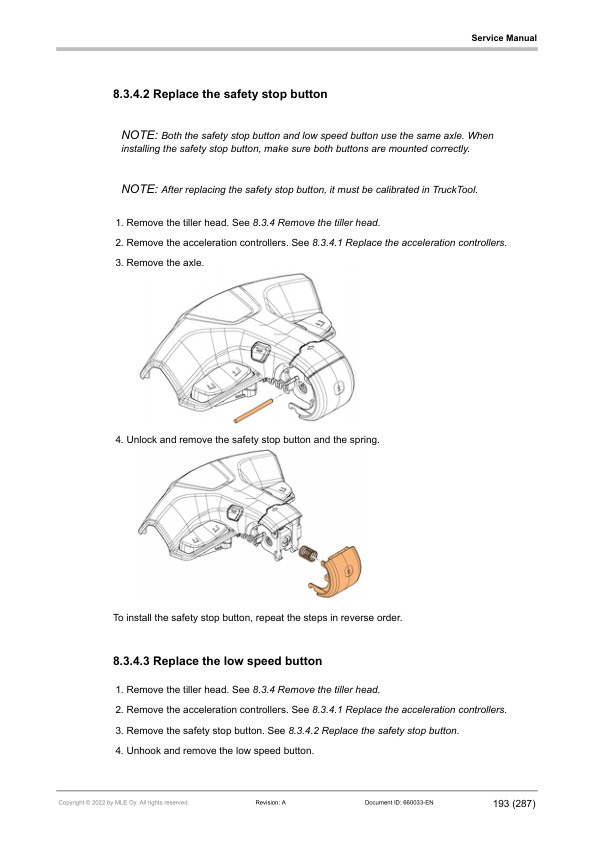

- 9.6.2.1. Adjust the main rollers of the lifting fork carriage

- 9.6.2.2. Disassemble the main rollers of the lifting fork carriage

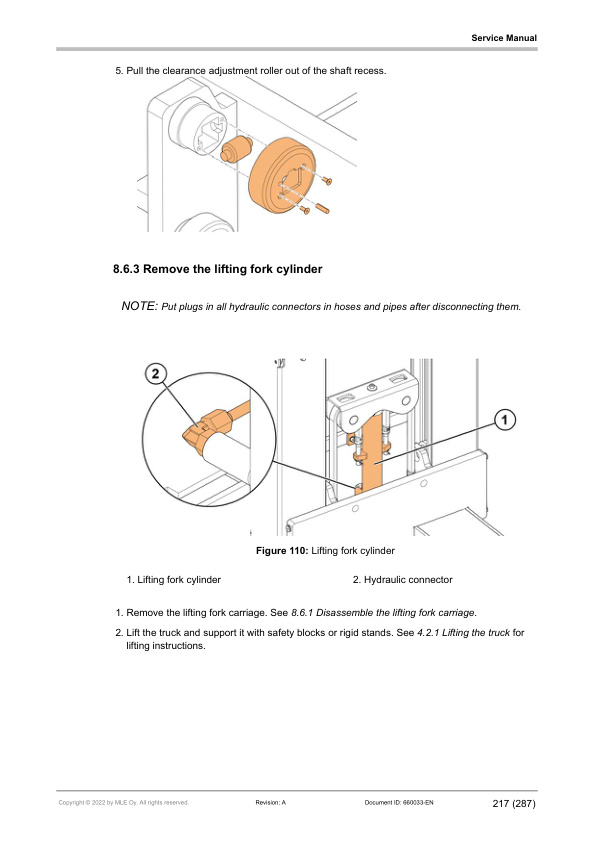

- 9.6.3. Remove the lifting fork cylinder

- 9.6.4. Replace the sealing housing of the lifting fork cylinder

- 9.6.5. Adjust the lifting chains

- 9.6.6. Replace the lifting chains

- 9.7. Repair truck suspension

- 9.7.1. Disassemble the castor wheel suspension

- 9.7.2. Disassemble the drive unit suspension

- 9.8. Repair electric system

- 9.8.1. Replace the fuses

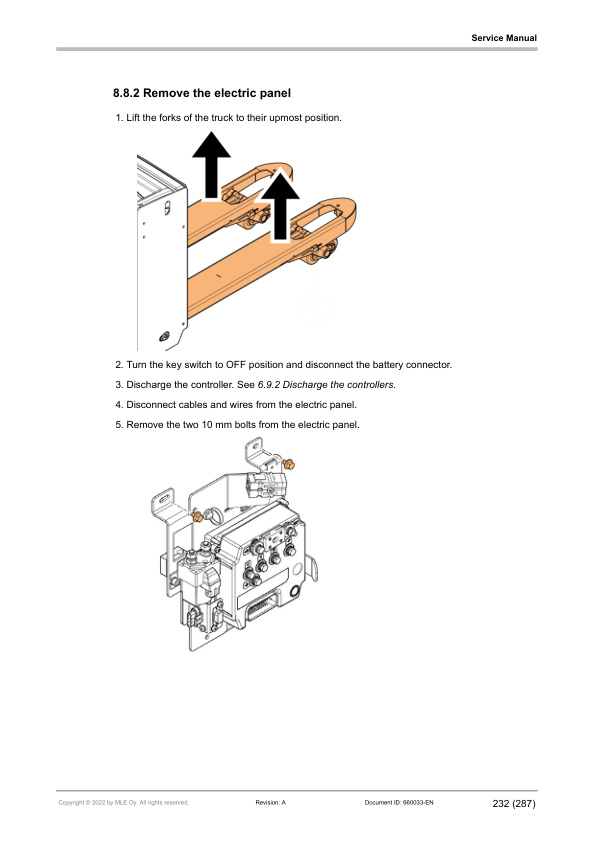

- 9.8.2. Remove the electric panel

- 9.8.3. Replace the contactor

- 9.8.4. Replace the traction and pump controller

- 9.8.5. Replace the truck connector

- 9.8.6. Install the traction motor cables

- 9.8.7. Replace the horn

- 9.9. Repair sensors and switches

- 9.9.1. Replace the rotation sensor

- 9.9.2. Replace the tiller arm sensor

- 9.9.3. Replace the operator platform sensors

- 9.9.4. Replace the battery cover sensor

- 9.9.5. Replace the lifting fork limit sensor

- 9.9.6. Replace the lifting forks down sensor

- 10. TruckTool Diagnostics

- 10.1. Overview

- 10.2. Location of the service socket

- 10.3. Parameter descriptions

- 11. Service data

- 11.1. Special tightening torques

- 11.2. Tightening torques for standard bolts and nuts

- 11.3. Oils and lubricants

- 11.3.1. Channels of the lifting structure

- 11.3.2. Lifting chain

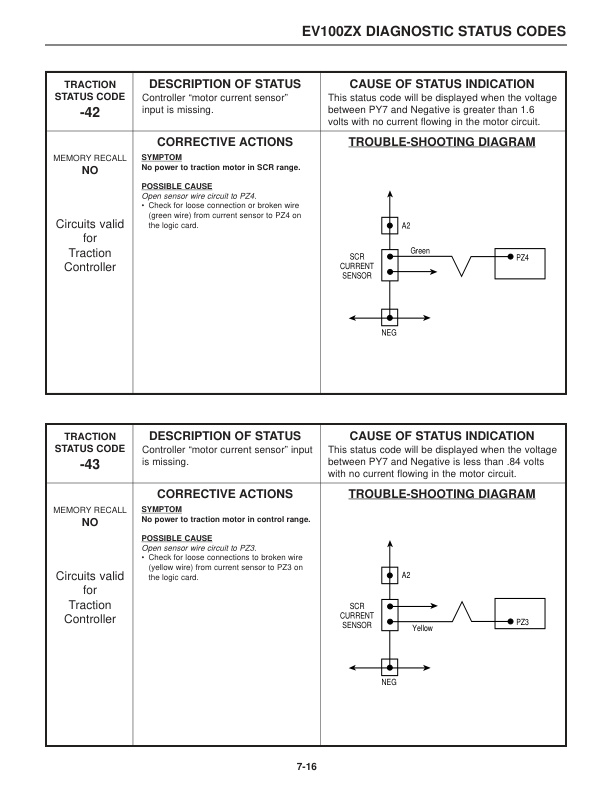

- 11.4. Troubleshooting

- 12. Options

- 12.1. Options overview

- 12.2. Load backrest

- 12.2.1. Install the load backrest

- 12.3. Pallet entry and exit rollers

- 12.3.1. Remove the pallet entry and exit rollers

- 12.4. Accessory rack

- 12.4.1. Install the accessory rack

- 12.4.2. Install the list bracket

- 12.4.3. Install the computer holder

- 12.4.4. Install the working light

- 12.5. Battery connector and cable

- 12.5.1. Replace battery connector and cable

- 12.6. Battery change device

- 12.7. Charger connector

- 12.7.1. Replace the charger connector

- 12.8. Internal charger and internal charger connector

- 12.8.1. Install the internal charger and charger connector

- 12.9. Voltage converter

- 12.9.1. Install the voltage converter

- 12.10. PIN code unit keyboard

- 12.10.1. Install the PIN code unit

- 12.10.2. Activate the truck with a PIN code

- 13. Technical specifications

- 13.1. Dimensions

- 13.2. Technical data

- 14. Declaration of Conformity

- 15. Stickers

- 16. Maintenance check list

- 17. Notes

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

$50.00

Mitsubishi Service Manual PDF

$50.00