Mitsubishi PW23 Operating and Maintenance Instructions 51261759

$30.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 51261759

- Number of Pages: 126

- Size: 2.4MB

- Format: PDF

-

Model List:

- PW23

- 1. Foreword

- 2. Table of contents

- 3. A Compliance with regulations – Legal requirements and common sense

- 4. B Recognition and avoidance of risks

- 5. C Proper use

- 5.1. General

- 5.2. Proper use

- 5.3. Permissible usage conditions

- 5.4. Duties of the operator

- 5.5. Installing attachments and/or attaching accessory parts

- 5.6. Nameplate

- 5.7. General instructions for operating personnel and the owner

- 6. D Description of vehicle

- 6.1. Description of use

- 6.2. Description of components and functions

- 6.2.1. Overview of components

- 6.2.2. Functional description

- 6.3. Technical data

- 6.3.1. Performance data

- 6.3.2. Dimensions

- 6.3.3. Weights

- 6.3.4. Tires

- 6.3.5. US standards

- 6.3.6. Usage conditions

- 6.3.7. Electrical requirements

- 6.4. Position of signs and nameplates

- 6.4.1. Nameplate

- 7. E Operation

- 7.1. Important general issues affecting safe operation and use of the industrial truck

- 7.1.1. Training, certification, and approval to operate the industrial truck

- 7.1.2. Damage and repairs to the industrial truck

- 7.1.3. Aspects related to loading

- 7.1.4. Operating environment

- 7.1.5. Safety devices and warning labels

- 7.2. Description of indicators and controls

- 7.2.1. Battery discharge indicator

- 7.3. Starting the industrial truck

- 7.3.1. Safety regulations for industrial truck operators

- 7.3.2. General operation of the industrial truck

- 7.3.3. Ensuring that the industrial truck is properly equipped

- 7.3.4. Safe loading and transporting

- 7.3.5. Preventing overturning and tipping

- 7.3.6. Supervising and securing the industrial truck

- 7.3.7. Lifting people

- 7.3.8. Daily checks and actions before startup

- 7.3.9. Preparing for operation

- 7.3.10. Switching off and securing the industrial truck

- 7.3.11. Battery discharge monitor

- 7.4. Operation of the industrial truck

- 7.4.1. Safety regulations applicable when operating the industrial truck

- 7.4.2. EMERGENCY STOP, driving, steering, and braking

- 7.4.2.1. EMERGENCY STOP

- 7.4.2.2. Forced braking

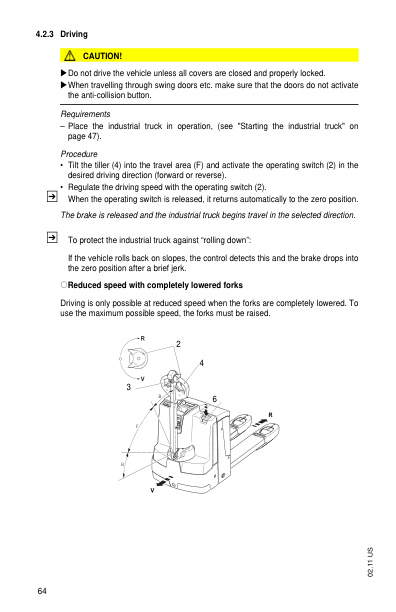

- 7.4.2.3. Driving

- 7.4.2.4. Slow travel

- 7.4.2.5. Steering

- 7.4.2.6. Braking

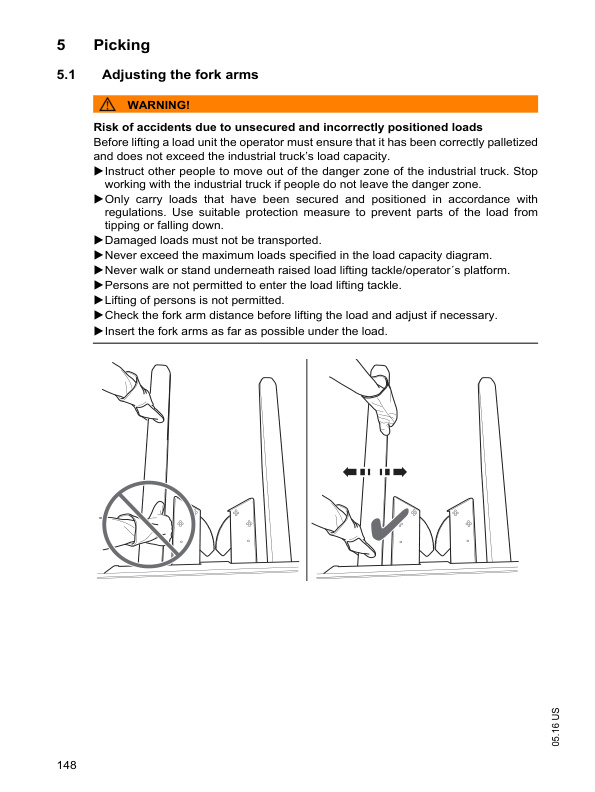

- 7.4.3. Picking up, transporting, and putting down load units

- 7.5. Moving the industrial truck without independent drive

- 7.6. Optional equipment

- 7.6.1. Emergency mode with service key GF60

- 7.6.2. CanCode keypad

- 7.6.2.1. Code lock

- 7.6.2.2. Parameters

- 7.6.2.3. Parameter settings

- 7.6.3. Setting the drive parameter with CanCode

- 7.6.4. Parameters

- 7.6.5. CanDis instrument display

- 7.6.5.1. Discharge monitoring function

- 7.6.5.2. Operating hours indicator

- 7.6.5.3. Event messages

- 7.6.5.4. Power on test

- 7.6.6. ISM access module ()

- 8. F Battery – maintenance, charging, and changing

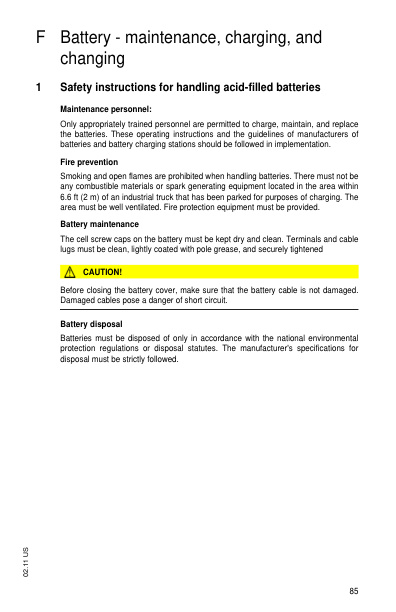

- 8.1. Safety instructions for handling acid-filled batteries

- 8.2. Battery types

- 8.3. Uncovering the battery

- 8.4. Charging the battery

- 8.4.1. Charging the battery with a stationary charger

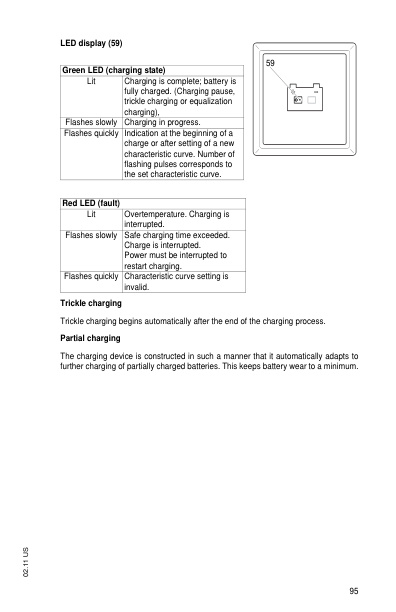

- 8.4.2. Charging the battery with an integrated charger

- 8.5. Removing and installing the battery

- 8.5.1. Replacing the battery (lifting up)

- 8.5.2. Battery extraction from the side

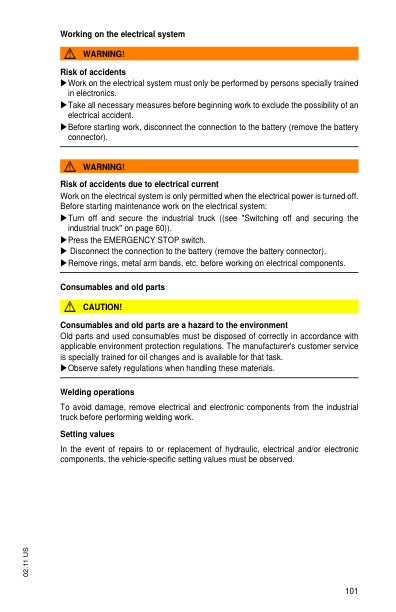

- 9. G Industrial truck maintenance and troubleshooting

- 9.1. Operating safety and environmental protection

- 9.2. Safety regulations for maintenance

- 9.3. Maintenance and inspection

- 9.4. Maintenance check list

- 9.4.1. Owner

- 9.4.1.1. Standard equipment

- 9.4.2. Maintenance department

- 9.4.2.1. Standard equipment

- 9.4.2.2. Optional equipment

- 9.5. Consumables and lubrication chart

- 9.5.1. Handling consumables safely

- 9.5.2. Lubrication chart

- 9.5.3. Consumables

- 9.6. Description of maintenance and servicing jobs

- 9.6.1. Preparing the industrial truck for maintenance and servicing

- 9.6.2. Removing the front cover

- 9.6.3. Remove the drive cover.

- 9.6.4. Checking the electrical fuses

- 9.6.5. Restarting the industrial truck after maintenance and servicing work

- 9.7. Extended shutdown of the industrial truck

- 9.7.1. Actions to be taken before shutting down the vehicle

- 9.7.2. Actions to be taken during decommissioning

- 9.7.3. Restarting the industrial truck after shutdown

- 9.8. Safety check after time and unusual events

- 9.9. Permanent decommissioning and disposal

- 9.10. Troubleshooting

- 9.10.1. Industrial truck does not move

- 9.10.2. Load cannot be raised

- 10. H Transport and initial startup

- 10.1. Handling by crane

- 10.2. Transport

- 10.3. Initial startup

Mitsubishi Operation Manual PDF

Mitsubishi EP10CB-35CB, EP20-25LCB Lift Trucks Operation and Maintenance Manual OCFEM-M22C0-200

Mitsubishi Operation Manual PDF

Mitsubishi ESR15N2-ESR23N2, EDR18N2 Operating Instructions 51620220

Mitsubishi Operation Manual PDF

Mitsubishi EOP15N3 Operating and Maintenance Instructions 51481376

Mitsubishi Operation Manual PDF

Mitsubishi FB16K to FB35K PAC Operation and Maintenance Manual 99750-52140

Mitsubishi Operation Manual PDF

Mitsubishi ESR15N2, ESR 18N2 Operating and Maintenance Instructions 51423155

Mitsubishi Operation Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Operation and Maintenance Manual 99750-7B100

Mitsubishi Operation Manual PDF

Mitsubishi FB10CB-35CB, FB20-25LCB Forklift Trucks Operation and Maintenance Manual OMFEM-M22C0-200

Mitsubishi Operation Manual PDF

Mitsubishi FB16N, FB18N, FB20CN Forklift Trucks Operation and Maintenance Manual 99750-56100

Mitsubishi Operation Manual PDF

Mitsubishi FB16PNT, FB18PNT, FB20PNT Forklift Trucks Operation and Maintenance Manual 99750-7P110

Mitsubishi Operation Manual PDF

Mitsubishi OPB10P, OPBM10P, OPBH12PH Operation and Maintenance Manual OM19GBOR1AA7