Mitsubishi S4S Diesel Engine Service Manual 99616-87100

$30.00

- Type Of Manual: Service Manual

- Manual ID: 99616-87100

- Number of Pages: 190

- Size: 19.5MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- S4S Diesel Engine

- 1. Foreword

- 1.1. HOW TO USE THIS MANUAL

- 1.1.1. Description format

- 1.1.2. Terms used in this manual

- 1.1.3. Abbreviations and Standards

- 1.1.4. Unit of Measurement

- 1.2. Safety Cautions

- 1.2.1. Fire and Explosion Precautions

- 1.2.2. Stay Away From Rotating and Moving Parts

- 1.2.3. Be Careful of Exhaust Gas Poisoning

- 1.2.4. Be Careful of Hearing Loss

- 1.2.5. Be Careful of Falling

- 1.2.6. Be Careful When Handling Fuel, Engine Oil or Coolant

- 1.2.7. Be Careful of Burns

- 1.2.8. Battery

- 1.2.9. When Abnormality Occurs

- 1.2.10. Other Cautions

- 1.2.11. Warning Labels

- 1.2.12. Points on Disassembling and Assembling

- 2. GENERAL CONTENTS

- 3. Chapter 1 GENERAL

- 3.1. External View

- 3.2. Outline of Systems

- 3.2.1. Outline of Fuel System

- 3.2.2. Outline of Lubrication System

- 3.2.3. Outline of Cooling System

- 3.2.4. Outline of Inlet and Exhaust System

- 3.3. Engine Serial Number

- 3.4. Specifications

- 4. Chapter 2 SERVICE DATA

- 4.1. Maintenance Service Data

- 4.1.1. Maintenance Service Data of Engine General

- 4.1.2. Maintenance Service Data of Basic Engine

- 4.1.3. Maintenance Service Data of Fuel System

- 4.1.4. Maintenance Service Data of Lubrication System

- 4.1.5. Maintenance Service Data of Cooling System

- 4.1.6. Maintenance Service Data of Inlet and Exhaust System

- 4.1.7. Maintenance Service Data of Electrical System

- 4.2. Tightening Torque Table

- 4.2.1. Tightening Torque Spec for Basic Engine

- 4.2.2. Tightening Torque Spec for Fuel System

- 4.2.3. Tightening Torque Spec for Lubrication System

- 4.2.4. Tightening Torque Spec for Cooling System

- 4.2.5. Tightening Torque Spec for Inlet and Exhaust System

- 4.2.6. Tightening Torque Spec for Electrical System

- 4.2.7. Tightening Torque for Standard Bolts

- 4.2.8. Tightening Torque for Standard Stud Bolts

- 5. Chapter 3 SERVICE TOOLS

- 5.1. Special Tools

- 6. Chapter 4 OVERHAUL INSTRUCTIONS

- 6.1. Determining Overhaul Timing

- 6.2. Compression Pressure – Measure

- 7. Chapter 5 DISASSEMBLY OF BASIC ENGINE

- 7.1. Cylinder Heads and Valve Mechanisms – Disassemble and Inspect

- 7.1.1. Inspection of Valve Clearance

- 7.1.2. Rocker Shaft Assembly – Remove

- 7.1.3. Cylinder Head Bolt – Remove

- 7.1.4. Cylinder Head Assembly – Remove

- 7.1.5. Measurement of Valve Sinkage

- 7.1.6. Valve and Valve Spring – Remove

- 7.2. Rear Mechanism – Disassemble and Inspect

- 7.2.1. Flywheel Face and Radial Runout – Measure

- 7.2.2. Flywheel – Remove

- 7.2.3. Oil Seal Case – Remove

- 7.2.4. Rear Plate – Remove

- 7.3. Front Mechanism – Disassemble and Inspect

- 7.3.1. Crankshaft Pulley – Remove

- 7.3.2. Timing Gear Case – Remove

- 7.3.3. Timing Gear Backlash – Measure

- 7.3.4. Idler Gear and Camshaft End Play – Measure

- 7.3.5. Fuel Injection Pump – Remove

- 7.3.6. Oil Pan – Remove

- 7.3.7. Oil Strainer – Remove

- 7.3.8. Oil Pump Gear – Remove

- 7.3.9. Idler Gear – Remove

- 7.3.10. PTO Drive Gear – Remove

- 7.3.11. Camshaft – Remove

- 7.3.12. Camshaft Gear – Replace

- 7.3.13. Front Plate – Remove

- 7.3.14. Oil Pump – Remove

- 7.4. Piston, Connecting Rod, Crankshaft and Crankcase – Disassemble and Inspect

- 7.4.1. Piston Protrusion – Measure

- 7.4.2. Carbon Deposits from the Upper Part of Cylinder – Remove

- 7.4.3. Connecting Rod End Play – Measure

- 7.4.4. Connecting Rod Cap – Remove

- 7.4.5. Piston – Remove

- 7.4.6. Piston Ring – Remove

- 7.4.7. Piston Pin and Piston – Remove

- 7.4.8. Crankshaft End Play – Measure

- 7.4.9. Main Bearing Cap – Remove

- 7.4.10. Crankshaft – Remove

- 7.4.11. Tappet – Remove

- 8. Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

- 8.1. Cylinder Head and Valve Mechanism – Inspect and Repair

- 8.1.1. Clearance Between Rocker Bushing and Rocker Shaft – Measure

- 8.1.2. Valve Stem Outside Diameter and Valve Guide Inside Diameter – Measure

- 8.1.3. Valve Guide – Replace

- 8.1.4. Valve Face – Inspect

- 8.1.5. Valve Face – Reface

- 8.1.6. Valve Seat Ring – Reface

- 8.1.7. Valve Seat – Replace

- 8.1.8. Valve and Valve Seat Ring – Lap

- 8.1.9. Squareness and Free Length of Valve Spring – Measure

- 8.1.10. Push rod Runout – Measure

- 8.1.11. Distortion of Cylinder Head Bottom Surface – Measure

- 8.1.12. Combustion Jet – Replace

- 8.2. Rear Mechanism – Inspect and Repair

- 8.2.1. Flatness of Flywheel – Measure

- 8.2.2. Ring Gear – Inspect

- 8.2.3. Ring Gear – Replace

- 8.3. Front Mechanism – Inspect and Repair

- 8.3.1. Idler Bushing Inside Diameter and Idler Shaft Outside Diameter – Measure

- 8.3.2. Idler Shaft – Replace

- 8.3.3. Cam Lift of Cam Shaft Lobe – Measure

- 8.3.4. Camshaft Runout – Measure

- 8.3.5. Camshaft Journal Outside Diameter – Measure

- 8.3.6. Belt Groove Wear – Inspect

- 8.4. Piston and Connecting Rod – Inspect and Repair

- 8.4.1. Piston – Inspect Visually

- 8.4.2. Piston Weight

- 8.4.3. Piston Outside Diameter – Measure

- 8.4.4. Piston Ring Groove – Inspect

- 8.4.5. Piston Pin Bore Diameter and Piston Pin Outside Diameter – Measure

- 8.4.6. Standard for Piston Ring Replacement

- 8.4.7. Clearance Between Connecting Rod Bearing and Crankpin – Measure

- 8.4.8. Clearance Between Connecting Rod Bushing and Piston Pin – Measure

- 8.4.9. Connecting Rod Bushing – Replace

- 8.4.10. Connecting Rod Assembly Weight Rank

- 8.4.11. Connecting Rod Bearing – Inspect

- 8.4.12. Connecting Rod Bend and Twist – Inspect

- 8.5. Crankcase and Crankshaft – Inspect and Repair

- 8.5.1. Cylinder Inside Diameter – Measure

- 8.5.2. Crankcase Top Surface Distortion – Measure

- 8.5.3. Crankpin and Journal Outside Diameters – Measure

- 8.5.4. Width of Crankpin and Rearmost Crank Main Journal – Measure

- 8.5.5. Crankshaft – Grind

- 8.5.6. Crankshaft Runout – Measure

- 8.5.7. Crankshaft Gear – Inspect

- 8.5.8. Crankshaft Gear – Replace

- 8.5.9. Oil Seal Contact Surface – Inspect

- 8.5.10. Oil Seal Sleeve – Replace

- 8.5.11. Main Bearing – Inspect

- 8.5.12. Clearance Between Main Bearing and Crank Journal – Measure

- 8.5.13. Thrust Plate – Inspect

- 8.5.14. Tappet – Inspect

- 9. Chapter 7 ASSEMBLY OF BASIC ENGINE

- 9.1. Piston, Connecting rod, Crankshaft and Crankcase – Assemble

- 9.1.1. Crankcase – Turn Over (Upend)

- 9.1.2. Tappet – Install

- 9.1.3. Upper Main Bearing – Install

- 9.1.4. Rear Upper Thrust Plate – Install

- 9.1.5. Crankshaft – Install

- 9.1.6. Lower Main Bearing Shell and Lower Thrust Plate – Install

- 9.1.7. Main Bearing Cap – Install

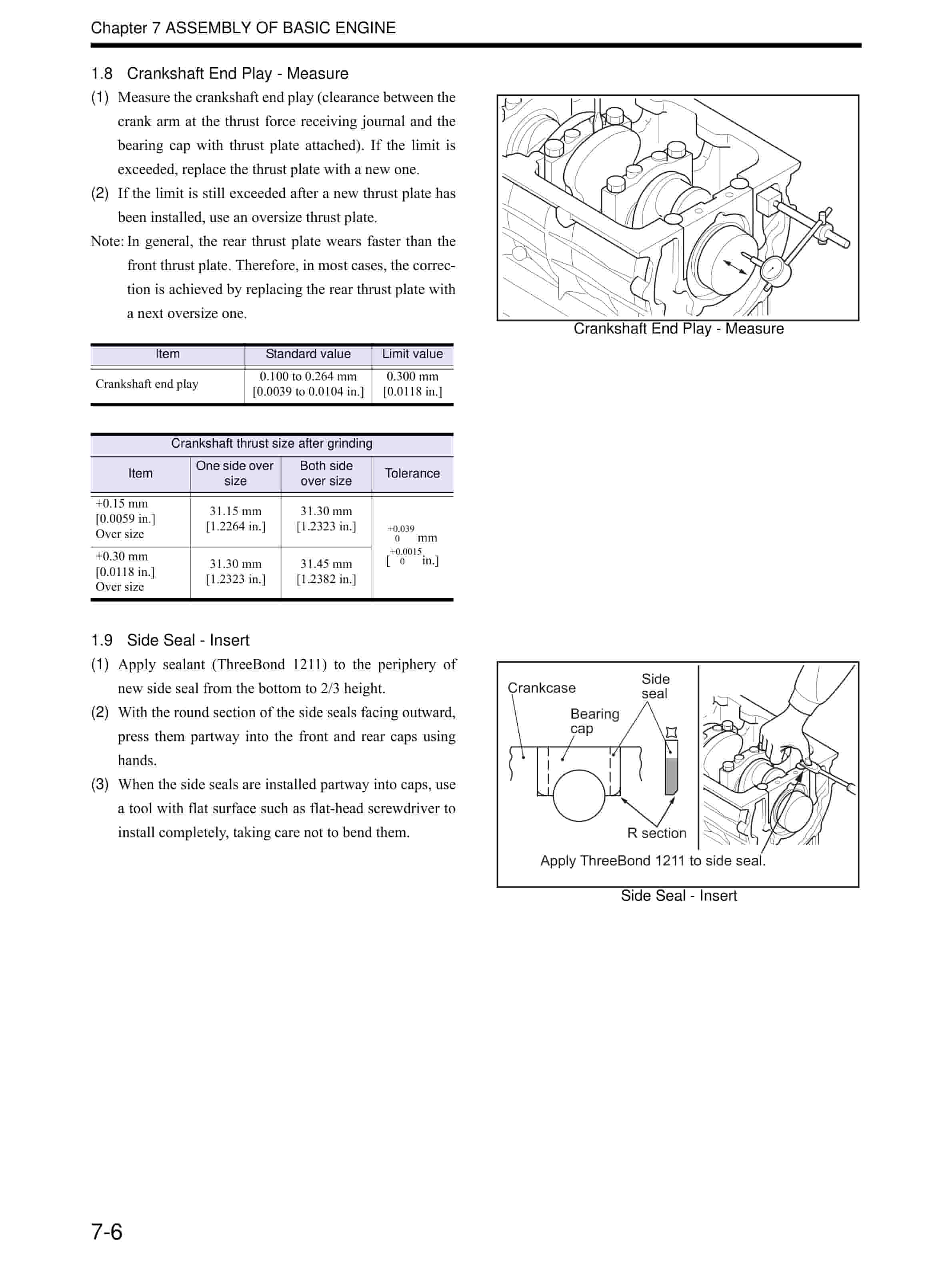

- 9.1.8. Crankshaft End Play – Measure

- 9.1.9. Side Seal – Insert

- 9.1.10. Piston and Connecting Rod – Assemble

- 9.1.11. Piston Ring – Install

- 9.1.12. Piston Installation – Prepare

- 9.1.13. Connecting rod bolt and Upper connecting rod bearing – Install

- 9.1.14. Piston – Install

- 9.1.15. Connecting Rod Cap – Install

- 9.1.16. Connecting Rod End Play – Measure

- 9.1.17. Piston Protrusion – Measure

- 9.2. Front Mechanism – Assemble

- 9.2.1. Oil Pump – Install

- 9.2.2. Front Plate – Install

- 9.2.3. Camshaft – Install

- 9.2.4. PTO Drive Gear – Install

- 9.2.5. Idler Gear – Install

- 9.2.6. Oil Pump Gear – Install

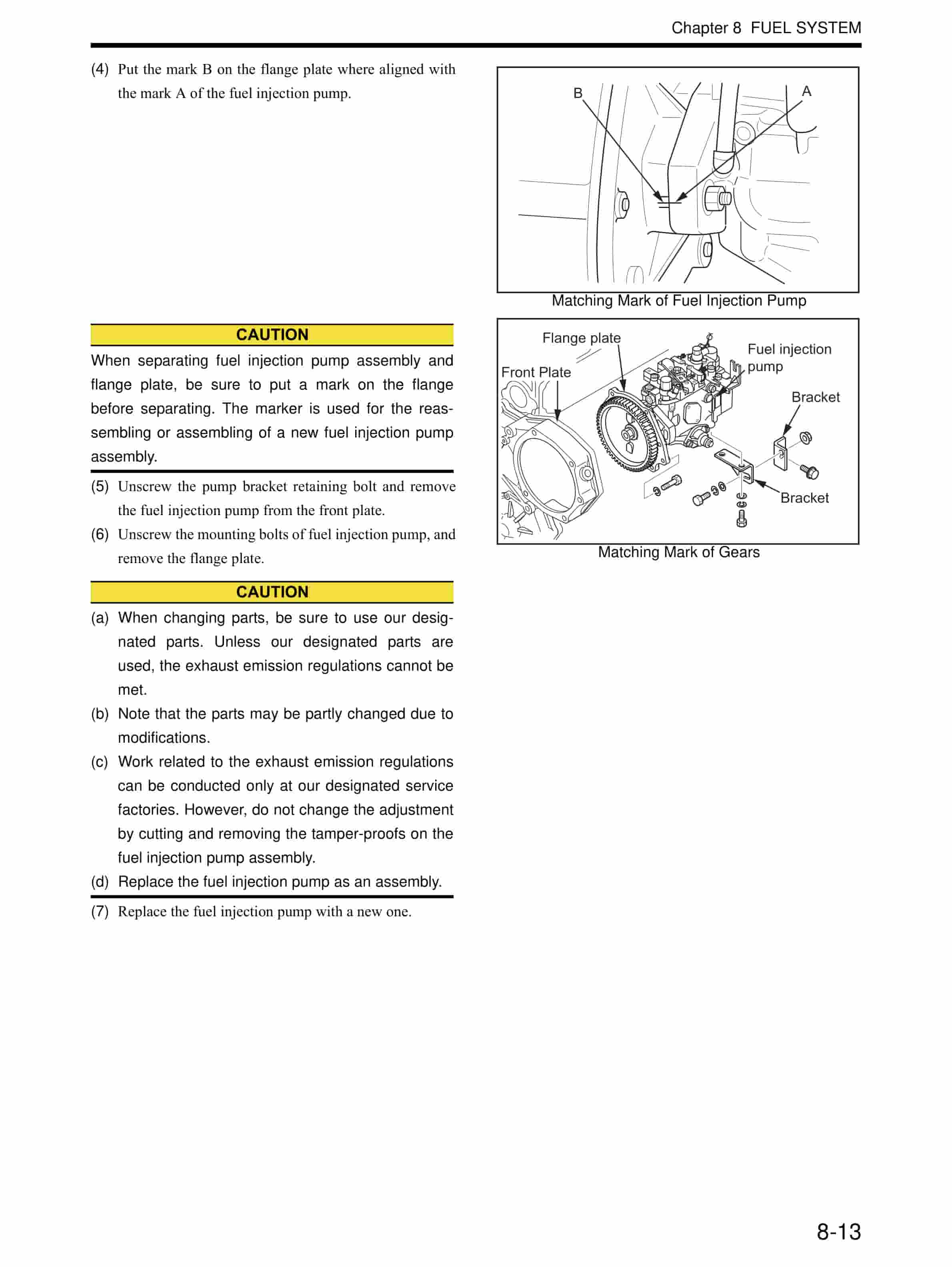

- 9.2.7. Fuel Injection Pump – Install

- 9.2.8. Timing Gear Backlash – Measure

- 9.2.9. Idler Gear End Play – Measure

- 9.2.10. Camshaft End Play – Measure

- 9.2.11. Front Oil Seal – Install

- 9.2.12. Timing Gear Case – Install

- 9.2.13. Oil Strainer – Install

- 9.2.14. Oil Pan – Install

- 9.2.15. Crankcase – Turn Over

- 9.2.16. Cover – Install

- 9.2.17. Crankshaft Pulley – Install

- 9.3. Rear Mechanism – Assemble

- 9.3.1. Rear Plate – Install

- 9.3.2. Oil Seal – Install

- 9.3.3. Flywheel – Install

- 9.3.4. Flywheel Face and Radial Runout – Measure

- 9.4. Cylinder Head and Valve Mechanism – Assemble

- 9.4.1. Cylinder Head – Assemble

- 9.4.2. Measurement of Valve Sinkage

- 9.4.3. Cylinder Head Gasket – Install

- 9.4.4. Cylinder Head Assembly – Install

- 9.4.5. Cylinder Head Bolt – Tighten

- 9.4.6. Push Rod – Insert

- 9.4.7. Rocker Shaft Assembly – Install

- 9.4.8. Valve Clearance – Check and Adjust

- 9.4.9. Rocker Cover – Install

- 10. Chapter 8 FUEL SYSTEM

- 10.1. Fuel System – Remove and Inspect

- 10.2. Fuel System – Disassemble, Inspect and Assemble

- 10.2.1. Fuel Filter (Paper Element) – Disassemble, Inspect and Assemble

- 10.2.2. Fuel Injection Nozzle – Disassemble and Inspect

- 10.2.3. Fuel Injection Nozzle – Inspect and Adjust

- 10.2.4. Fuel Injection Nozzle – Assemble

- 10.2.5. Gauze Filter of Distribute Type Fuel Injection Pump – Inspect and Clean

- 10.3. Fuel System – Install

- 10.3.1. Fuel Injection Timing – Check

- 11. Chapter 9 LUBRICATION SYSTEM

- 11.1. Lubrication System – Remove and Inspect

- 11.2. Lubrication System – Disassemble, Inspect and Assemble

- 11.2.1. Oil Pump – Disassemble and Inspect

- 11.2.2. Oil Pump – Inspect

- 11.2.3. Oil Pump – Assemble

- 11.2.4. Oil Filter – Inspect

- 11.2.5. Relief Valve – Inspect

- 11.3. Lubrication System – Install

- 12. Chapter 10 COOLING SYSTEM

- 12.1. Cooling System – Remove and Inspect

- 12.2. Cooling System – Disassemble, Inspect and Assemble

- 12.2.1. Thermostat – Disassemble and Inspect

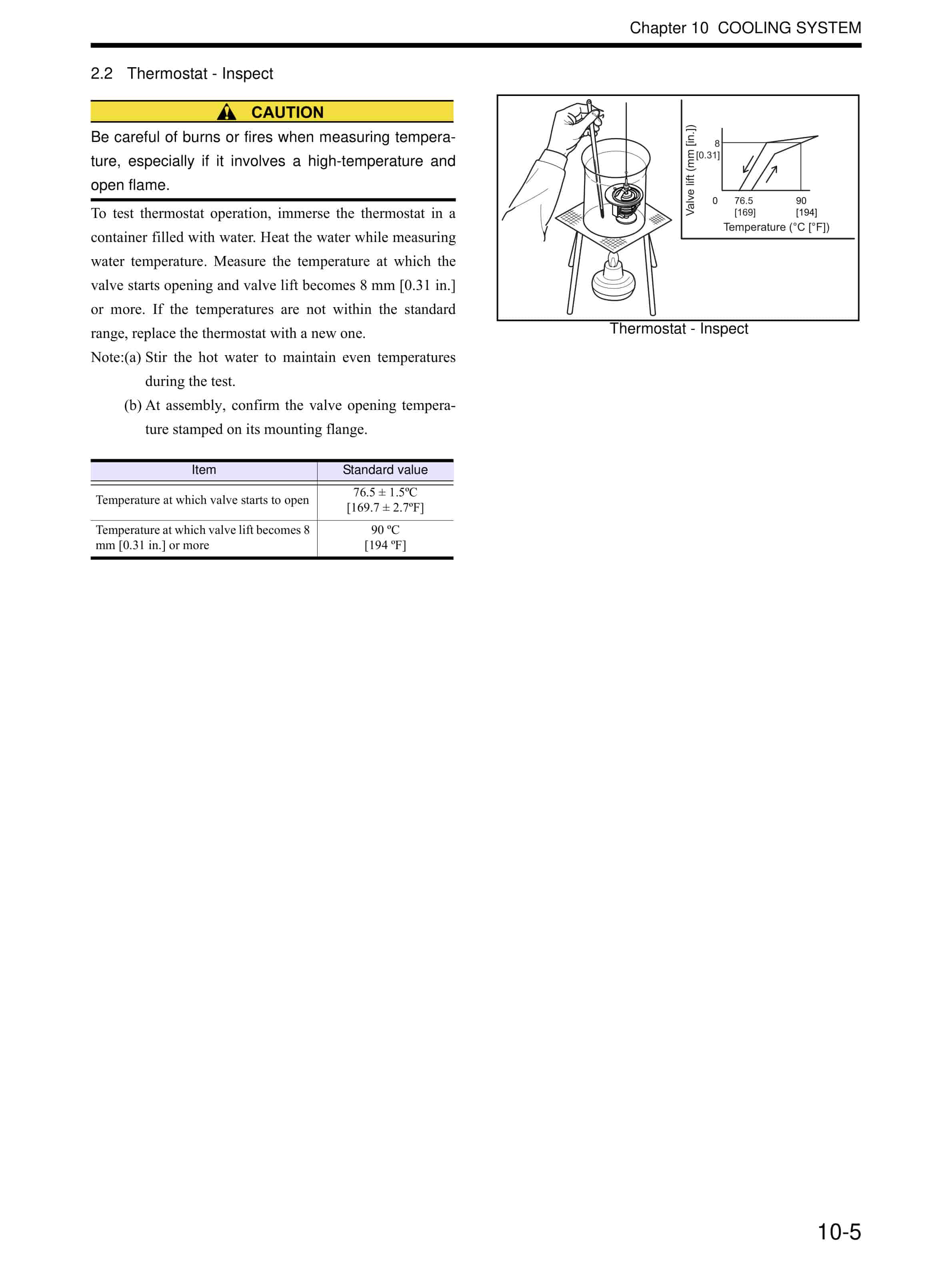

- 12.2.2. Thermostat – Inspect

- 12.2.3. Water pump – Disassemble and Inspect

- 12.3. Cooling System – Install

- 13. Chapter 11 INLET AND EXHAUST SYSTEMS

- 13.1. Inlet and Exhaust Systems – Remove and Inspect

- 13.2. Inlet and Exhaust Systems – Disassemble, Inspect and Assemble

- 13.2.1. Exhaust Manifold Distortion – Measure

- 13.3. Inlet and Exhaust Systems – Install

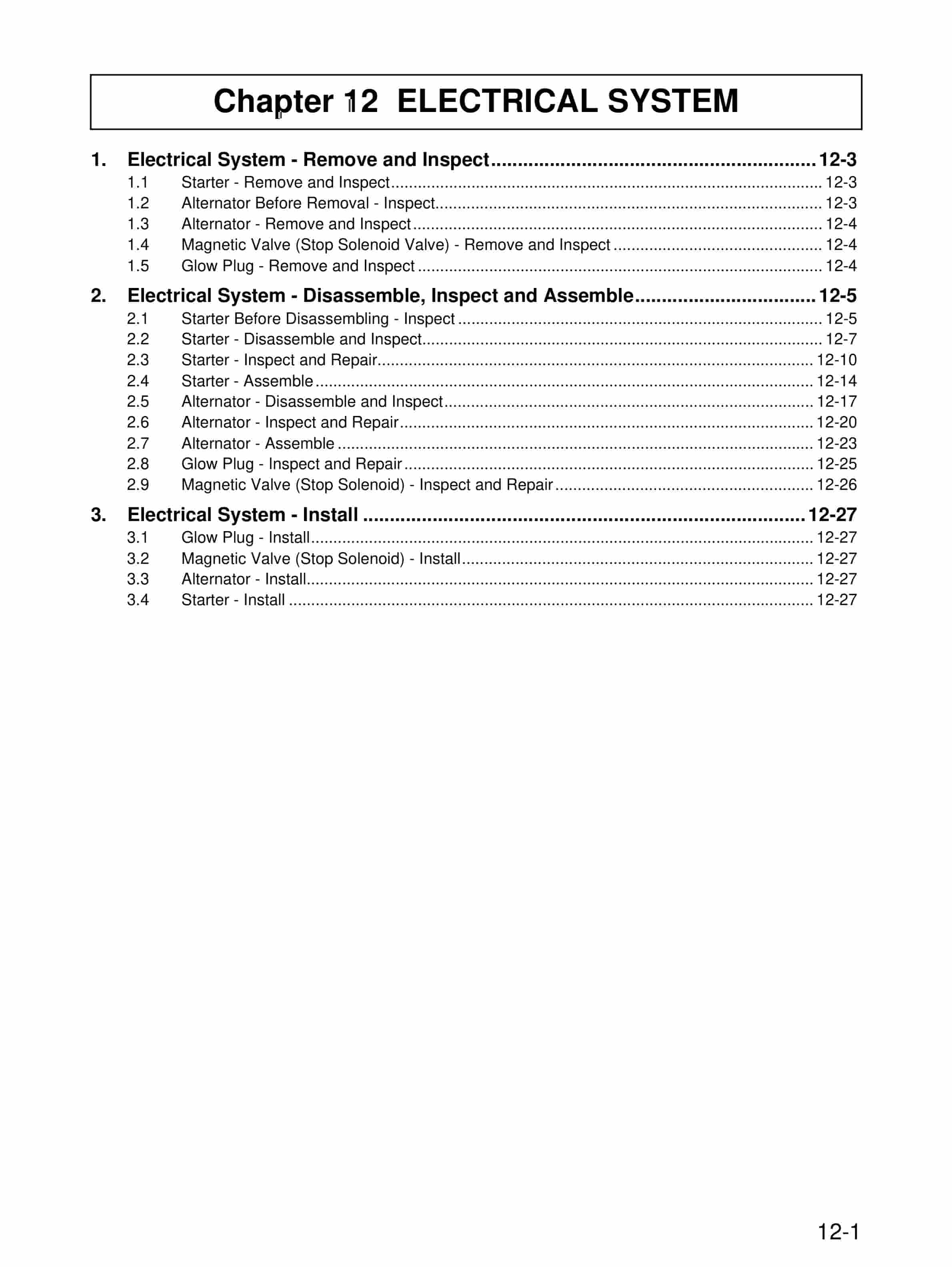

- 14. Chapter 12 ELECTRICAL SYSTEM

- 14.1. Electrical System – Remove and Inspect

- 14.1.1. Starter – Remove and Inspect

- 14.1.2. Alternator Before Removal – Inspect

- 14.1.3. Alternator – Remove and Inspect

- 14.1.4. Magnetic Valve (Stop Solenoid Valve) – Remove and Inspect

- 14.1.5. Glow Plug – Remove and Inspect

- 14.2. Electrical System – Disassemble, Inspect and Assemble

- 14.2.1. Starter Before Disassembling – Inspect

- 14.2.2. Starter – Disassemble and Inspect

- 14.2.3. Starter – Inspect and Repair

- 14.2.4. Starter – Assemble

- 14.2.5. Alternator – Disassemble and Inspect

- 14.2.6. Alternator – Inspect and Repair

- 14.2.7. Alternator – Assemble

- 14.2.8. Glow Plug – Inspect and Repair

- 14.2.9. Magnetic Valve (Stop Solenoid) – Inspect and Repair

- 14.3. Electrical System – Install

- 14.3.1. Glow Plug – Install

- 14.3.2. Magnetic Valve (Stop Solenoid) – Install

- 14.3.3. Alternator – Install

- 14.3.4. Starter – Install

- 15. Chapter 13 ADJUSTMENT AND OPERATION

- 15.1. Engine – Adjust

- 15.1.1. Valve Clearance – Check

- 15.1.2. Fuel System – Drain

- 15.1.3. Fuel System – Bleed Air

- 15.1.4. Belt and Belt Tension – Inspect and Adjust

- 15.2. Break-in Operation

- 15.2.1. Engine Start-up

- 15.2.2. Break-in Operation

- 15.3. Performance Test

- 15.3.1. Engine Equipment Condition

- 15.3.2. Test Items and Purposes

- 15.3.3. Other Inspections

- 15.3.4. Engine Output Adjustment

- 16. Back cover

- 17. Rear cover

Rate this product

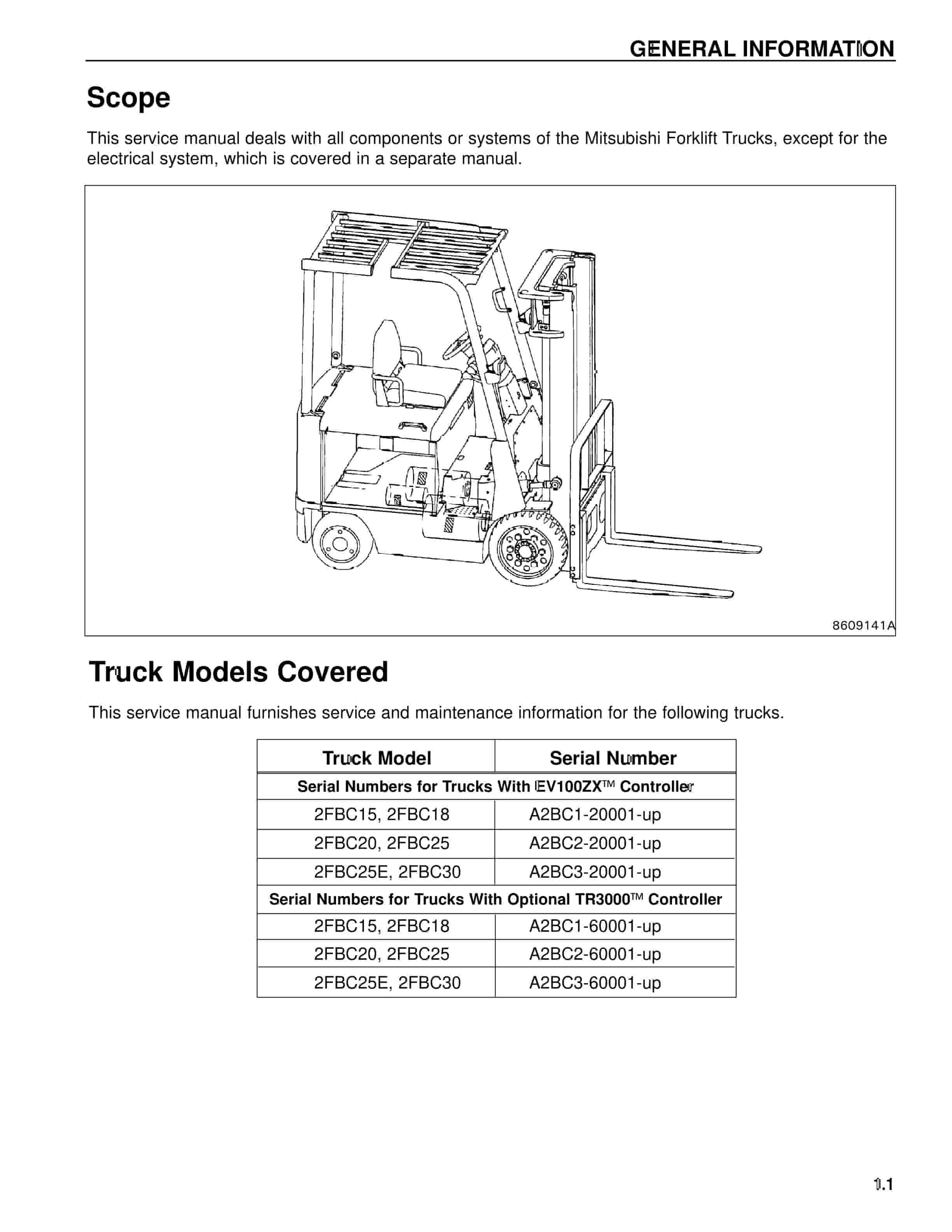

You may also like

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-56103

$50.00