Mitsubishi S6S Diesel Engine Service Manual 99739-12110

$50.00

- Type Of Manual: Service Manual

- Manual ID: 99739-12110

- Number of Pages: 209

- Size: 31.0MB

- Format: PDF

-

Model List:

- S6S Diesel Engine

- 1. Vol 1

- 1.1. INTRODUCTION

- 1.1.1. How to use this manual

- 1.1.1.1. Methods of presentation

- 1.1.1.2. Terms used in this manual

- 1.1.1.3. Abbreviations

- 1.1.1.4. Units of measurement

- 1.1.2. Safety Cautions

- 1.1.2.1. Fire and explosion

- 1.1.2.2. Stay clear of all rotating and moving parts

- 1.1.2.3. Be careful of burns

- 1.1.2.4. Be careful of exhaust fume poisoning

- 1.1.2.5. Protect ears from noise

- 1.1.2.6. Be careful of falling down

- 1.1.2.7. Be careful of handling fuel, engine oil and LLC

- 1.1.2.8. Service battery

- 1.1.2.9. When abnormality occurs

- 1.1.2.10. Other cautions

- 1.1.2.11. About warning labels

- 1.1.2.12. Tips on disassembling and assembling

- 1.2. GENERAL CONTENTS

- 1.3. Chapter 1 GENERAL

- 1.3.1. External View

- 1.3.2. System flow diagrams

- 1.3.2.1. Outline of fuel system

- 1.3.2.2. Outline of lubrication system

- 1.3.2.3. Outline of cooling system

- 1.3.2.4. Outline of inlet and exhaust system

- 1.3.3. Engine serial number location

- 1.3.4. Main specifications

- 1.4. Chapter 2 SERVICE DATA

- 1.4.1. Maintenance service data

- 1.4.1.1. Engine general

- 1.4.1.2. Basic engine

- 1.4.1.3. Fuel system

- 1.4.1.4. Lubrication system

- 1.4.1.5. Cooling system

- 1.4.1.6. Inlet and exhaust system

- 1.4.1.7. Electrical system

- 1.4.2. Tightening torque table

- 1.4.2.1. Basic engine

- 1.4.2.2. Fuel system

- 1.4.2.3. Lubrication system

- 1.4.2.4. Cooling system

- 1.4.2.5. Inlet and exhaust system

- 1.4.2.6. Electrical system

- 1.4.2.7. Standard bolt and nut tightening torque

- 1.4.2.8. Standard stud tightening torque

- 1.5. Chapter 3 SERVICE TOOLS

- 1.5.1. Special tools

- 1.6. Chapter 4 OVERHAUL INSTRUCTIONS

- 1.6.1. Determining overhaul timing

- 1.6.2. Compression pressure – Measure

- 1.7. Chapter 5 DISASSEMBLY OF BASIC ENGINE

- 1.7.1. Cylinder heads and Valve mechanisms – Disassemble and Inspect

- 1.7.1.1. Valve clearance – Inspect

- 1.7.1.2. Rocker shaft assembly – Remove

- 1.7.1.3. Cylinder head bolt – Remove

- 1.7.1.4. Cylinder head assembly – Remove

- 1.7.1.5. Valve sinkage – Measure

- 1.7.1.6. Valve and Valve spring – Remove

- 1.7.2. Rear equipment – Disassemble and Inspect

- 1.7.2.1. Flywheel face and radial runouts – Measure

- 1.7.2.2. Flywheel – Remove

- 1.7.2.3. Rear plate – Remove

- 1.7.3. Front equipment – Disassemble and Inspect

- 1.7.3.1. Damper face and radial runouts – Measure

- 1.7.3.2. Damper and Crankshaft pulley – Remove

- 1.7.3.3. Timing gear case – Remove

- 1.7.3.4. Timing gear backlash – Measure

- 1.7.3.5. Idler gear and camshaft end play – Measure

- 1.7.3.6. Fuel injection pump – Remove

- 1.7.3.7. Oil pan – Remove

- 1.7.3.8. Oil strainer – Remove

- 1.7.3.9. Oil pump gear – Remove

- 1.7.3.10. Idler gear – Remove

- 1.7.3.11. Camshaft – Remove

- 1.7.3.12. Camshaft gear – Replace

- 1.7.3.13. Front plate – Remove

- 1.7.3.14. Oil pump – Remove

- 1.7.4. Piston, Connecting rod, Crankshaft and Crankcase – Disassemble and Inspect

- 1.7.4.1. Piston protrusion – Measure

- 1.7.4.2. Carbon deposits from the upper part of cylinder – Remove

- 1.7.4.3. End play of connecting rod big end – Measure

- 1.7.4.4. Connecting rod cap – Remove

- 1.7.4.5. Piston – Remove

- 1.7.4.6. Piston ring – Remove

- 1.7.4.7. Piston pin and Piston – Remove

- 1.7.4.8. Crankshaft end play – Measure

- 1.7.4.9. Main bearing cap – Remove

- 1.7.4.10. Crankshaft – Remove

- 1.7.4.11. Tappet – Remove

- 1.8. Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

- 1.8.1. Cylinder head and Valve mechanism – Inspect and Repair

- 1.8.1.1. Clearance between rocker bushing and rocker shaft – Measure

- 1.8.1.2. Valve stem outside diameter and Valve guide inside diameter – Measure

- 1.8.1.3. Valve guide – Replace

- 1.8.1.4. Valve face – Inspect

- 1.8.1.5. Valve face – Reface

- 1.8.1.6. Valve seat – Reface

- 1.8.1.7. Valve seat – Replace

- 1.8.1.8. Valve and Valve seat – Lap

- 1.8.1.9. Squareness and free length of valve spring – Measure

- 1.8.1.10. Pushrod runout – Measure

- 1.8.1.11. Distortion of cylinder head bottom surface – Measure

- 1.8.1.12. Combustion jet – Replace

- 1.8.2. Rear equipment – Inspect and Repair

- 1.8.2.1. Flatness of flywheel – Measure

- 1.8.2.2. Ring gear – Inspect

- 1.8.2.3. Ring gear – Replace

- 1.8.3. Front equipment – Inspect and Repair

- 1.8.3.1. Damper – Inspect visually

- 1.8.3.2. Idler bushing inside diameter and Idler shaft outside diameter – Measure

- 1.8.3.3. Idler shaft – Replace

- 1.8.3.4. Cam lift of camshaft – Measure

- 1.8.3.5. Camshaft runout – Measure

- 1.8.3.6. Camshaft journal outside diameter – Measure

- 1.8.3.7. Camshaft hole (bushing) inside diameter – Measure

- 1.8.3.8. Camshaft bushing – Replace

- 1.8.3.9. V-belt groove wear – Inspect

- 1.8.4. Piston and Connecting rod – Inspect and Repair

- 1.8.4.1. Piston – Inspect visually

- 1.8.4.2. Piston outside diameter – Measure

- 1.8.4.3. Piston ring groove – Inspect

- 1.8.4.4. Piston pin bore diameter and Piston pin outside diameter – Measure

- 1.8.4.5. Standard for piston ring replacement

- 1.8.4.6. Clearance between connecting rod bearing and crankpin – Measure

- 1.8.4.7. Clearance between connecting rod bushing and piston pin – Measure

- 1.8.4.8. Connecting rod bushing – Replace

- 1.8.4.9. Weight difference of connecting rod assembly in one engine

- 1.8.4.10. Connecting rod bearing – Inspect

- 1.8.4.11. Connecting rod bend and twist – Inspect

- 1.8.5. Crankcase and Crankshaft – Inspect and Repair

- 1.8.5.1. Cylinder inside diameter – Measure

- 1.8.5.2. Crankcase top surface distortion – Measure

- 1.8.5.3. Crankpin and Crank journal outside diameters – Measure

- 1.8.5.4. Crankpin and journal width – Measure

- 1.8.5.5. Crankshaft – Grind

- 1.8.5.6. Crankshaft runout – Measure

- 1.8.5.7. Crankshaft gear – Inspect

- 1.8.5.8. Crankshaft gear – Replace

- 1.8.5.9. Oil seal contact surface – Inspect

- 1.8.5.10. Oil seal sleeve – Install

- 1.8.5.11. Oil seal sleeve – Remove

- 1.8.5.12. Main bearing – Inspect

- 1.8.5.13. Clearance between main bearing and crank journal – Measure

- 1.8.5.14. Thrust plate – Inspect

- 1.8.5.15. Tappet – Inspect

- 1.9. Chapter 7 ASSEMBLY OF BASIC ENGINE

- 1.9.1. Piston, Connecting rod, Crankshaft and Crankcase – Assemble

- 1.9.1.1. Crankcase – Invert

- 1.9.1.2. Tappet – Install

- 1.9.1.3. Upper main bearing – Install

- 1.9.1.4. Rear upper thrust plate – Install

- 1.9.1.5. Crankshaft – Install

- 1.9.1.6. Lower main bearing and Lower thrust plate – Install

- 1.9.1.7. Main bearing cap – Install

- 1.9.1.8. Crankshaft end play – Measure

- 1.9.1.9. Side seal – Insert

- 1.9.1.10. Piston and Connecting rod – Assemble

- 1.9.1.11. Piston ring – Install

- 1.9.1.12. Piston installation – Prepare

- 1.9.1.13. Connecting rod bolt and Upper connecting rod bearing – Install

- 1.9.1.14. Piston – Install

- 1.9.1.15. Connecting rod cap – Install

- 1.9.1.16. End play of connecting rod big end – Measure

- 1.9.1.17. Piston protrusion – Measure

- 1.9.2. Front equipment – Assemble

- 1.9.2.1. Oil pump – Install

- 1.9.2.2. Front plate – Install

- 1.9.2.3. Camshaft – Install

- 1.9.2.4. Idler gear – Install

- 1.9.2.5. Oil pump gear – Install

- 1.9.2.6. Fuel injection pump – Install

- 1.9.2.7. Timing gear backlash – Measure

- 1.9.2.8. Idler gear end play – Measure

- 1.9.2.9. Camshaft end play – Measure

- 1.9.2.10. Front oil seal – Install

- 1.9.2.11. Timing gear case – Install

- 1.9.2.12. Oil strainer – Install

- 1.9.2.13. Oil pan – Install

- 1.9.2.14. Crankcase – Invert

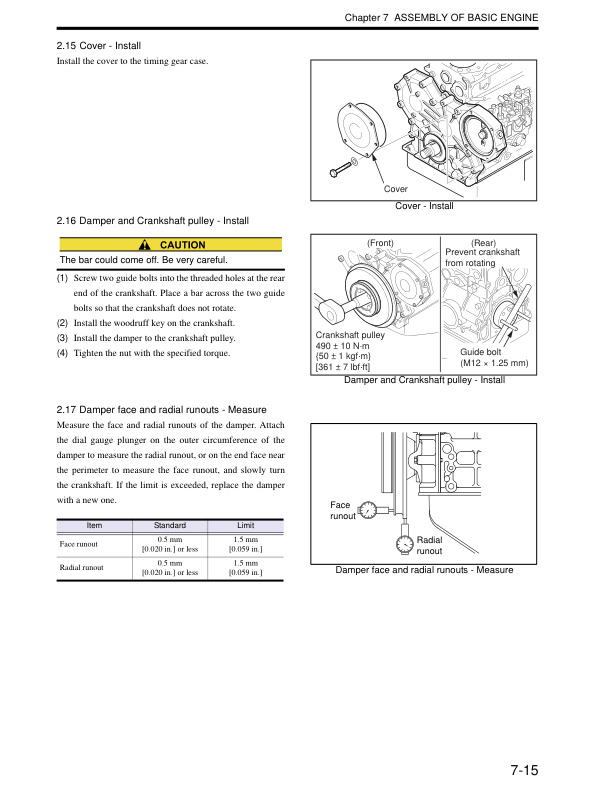

- 1.9.2.15. Cover – Install

- 1.9.2.16. Damper and Crankshaft pulley – Install

- 1.9.2.17. Damper face and radial runouts – Measure

- 1.9.3. Rear equipment – Assemble

- 1.9.3.1. Rear oil seal – Install

- 1.9.3.2. Rear plate – Install

- 1.9.3.3. Flywheel – Install

- 1.9.3.4. Flywheel face and radial runouts – Measure

- 1.9.4. Cylinder head and Valve mechanism – Assemble

- 1.9.4.1. Cylinder head – Assemble

- 1.9.4.2. Valve sinkage – Measure

- 1.9.4.3. Cylinder head gasket – Install

- 1.9.4.4. Cylinder head assembly – Install

- 1.9.4.5. Cylinder head bolt – Tighten

- 1.9.4.6. Push rod – Insert

- 1.9.4.7. Rocker shaft assembly – Install

- 1.9.4.8. Valve clearance – Inspect and Adjust

- 1.9.4.9. Rocker cover – Install

- 1.10. Chapter 8 FUEL SYSTEM

- 1.10.1. Fuel system – Remove

- 1.10.2. Fuel system – Disassemble, Inspect and Assemble

- 1.10.2.1. Fuel filter – Disassemble, Inspect and Assemble

- 1.10.2.2. Fuel filter – Assemble

- 1.10.2.3. Fuel injection nozzle – Disassemble and Inspect

- 1.10.2.4. Fuel injection nozzle – Inspect and Adjust

- 1.10.2.5. Fuel injection nozzle – Assemble

- 1.10.2.6. Gauze filter of distribute type fuel injection pump – Inspect and Clean

- 1.10.3. Fuel system – Install

- 1.11. Chapter 9 LUBRICATION SYSTEM

- 1.11.1. Lubrication system – Remove

- 1.11.2. Lubrication system – Disassemble, Inspect and Assemble

- 1.11.2.1. Oil pump – Disassemble and Inspect

- 1.11.2.2. Oil pump – Inspect

- 1.11.2.3. Oil pump – Assemble

- 1.11.2.4. Oil filter – Inspect

- 1.11.2.5. Relief valve – Inspect

- 1.11.3. Lubrication system – Install

- 1.12. Chapter 10 COOLING SYSTEM

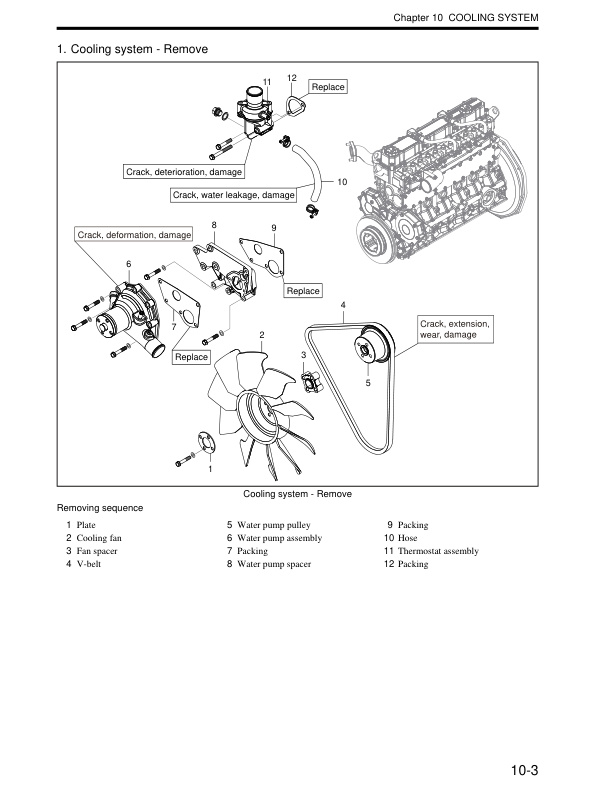

- 1.12.1. Cooling system – Remove

- 1.12.2. Cooling system – Disassemble, Inspect and Assemble

- 1.12.2.1. Thermostat – Disassemble and Inspect

- 1.12.2.2. Thermostat – Inspect

- 1.12.2.3. Water pump – Disassemble and Inspect

- 1.12.3. Cooling system – Install

- 1.13. Chapter 11 INLET AND EXHAUST SYSTEMS

- 1.13.1. Inlet and exhaust systems – Remove

- 1.13.2. Inlet and exhaust systems – Disassemble, Inspect and Assemble

- 1.13.2.1. Exhaust manifold distortion – Measure

- 1.13.3. Inlet and exhaust systems – Install

- 1.14. Chapter 12 ELECTRICAL SYSTEM

- 1.14.1. Electrical system – Remove and Inspect

- 1.14.1.1. Starter – Remove and Inspect

- 1.14.1.2. Inspection before removal of alternator

- 1.14.1.3. Alternator – Remove and Inspect

- 1.14.1.4. Magnetic valve (stop solenoid) – Remove and Inspect

- 1.14.1.5. Glow plug – Remove and Inspect

- 1.14.2. Electrical system – Disassemble, Inspect and Assemble

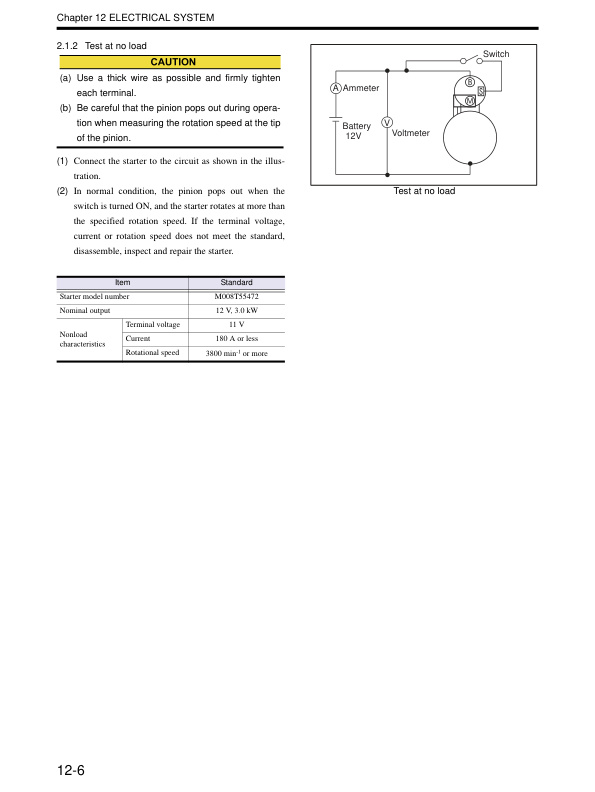

- 1.14.2.1. Inspection before disassembling starter

- 1.14.2.2. Starter – Disassemble and Inspect

- 1.14.2.3. Starter – Inspect and Repair

- 1.14.2.4. Starter – Assemble

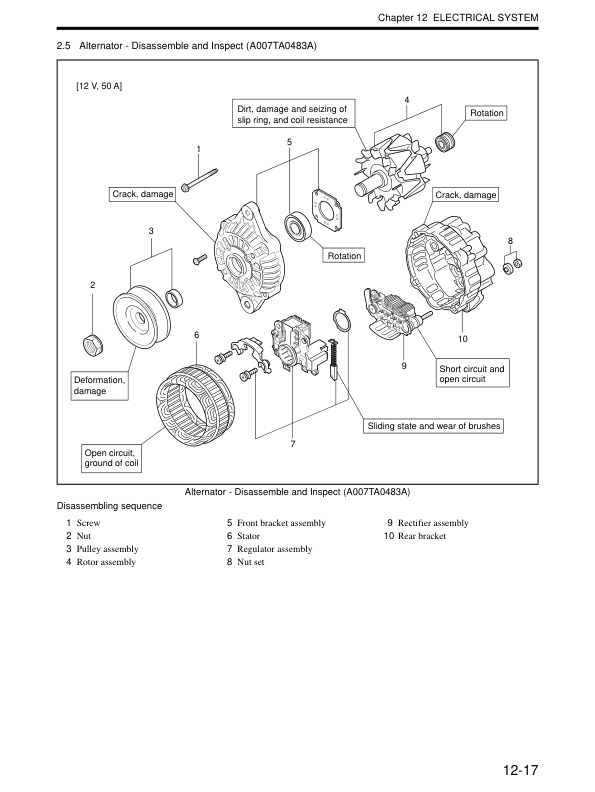

- 1.14.2.5. Alternator – Disassemble and Inspect (A007TA0483A)

- 1.14.2.6. Alternator – Inspect and Repair (A007TA0483A)

- 1.14.2.7. Alternator – Assemble (A007TA0483A)

- 1.14.2.8. Alternator – Disassemble and Inspect (A005TA5083A)

- 1.14.2.9. Alternator – Inspect and Repair (A005TA5083A)

- 1.14.2.10. Alternator – Assemble (A005TA5083A)

- 1.14.2.11. Alternator – Disassemble and Inspect (A002TA7871)

- 1.14.2.12. Alternator – Inspect and Repair (A002TA7871)

- 1.14.2.13. Alternator – Assemble (A002TA7871)

- 1.14.2.14. Glow plug – Inspect and Repair

- 1.14.2.15. Magnetic valve (stop solenoid) – Inspect and Repair

- 1.14.3. Electrical system – Install

- 1.14.3.1. Glow plug – Install

- 1.14.3.2. Magnetic valve (stop solenoid) – Install

- 1.14.3.3. Alternator – Install

- 1.14.3.4. Starter – Install

- 1.15. Chapter 13 ADJUSTMENT AND OPERATION

- 1.15.1. Engine – Adjust

- 1.15.1.1. Valve clearance – Inspect

- 1.15.1.2. Fuel system – Drain

- 1.15.1.3. Fuel system – Bleed air

- 1.15.1.4. V-belt tension – Inspect and Adjust

- 1.15.2. Break-in operation

- 1.15.2.1. Starting up

- 1.15.2.2. Break-in operation

- 1.15.3. Performance test

- 1.15.3.1. Engine equipment condition

- 1.15.3.2. Test items and purposes

- 1.15.3.3. Other inspections

- 1.15.3.4. Engine output adjustment

- 2. Vol 2

- 2.1. INTRODUCTION

- 2.1.1. How to use this manual

- 2.1.1.1. Methods of presentation

- 2.1.1.2. Terms used in this manual

- 2.1.1.3. Abbreviations

- 2.1.1.4. Units of measurement

- 2.1.2. Safety Cautions

- 2.1.2.1. Fire and explosion

- 2.1.2.2. Stay clear of all rotating and moving parts

- 2.1.2.3. Be careful of burns

- 2.1.2.4. Be careful of exhaust fume poisoning

- 2.1.2.5. Protect ears from noise

- 2.1.2.6. Be careful of falling down

- 2.1.2.7. Be careful of handling fuel, engine oil and LLC

- 2.1.2.8. Service battery

- 2.1.2.9. When abnormality occurs

- 2.1.2.10. Other cautions

- 2.1.2.11. About warning labels

- 2.1.2.12. Tips on disassembling and assembling

- 2.2. Chapter 1 GENERAL

- 2.2.1. External View

- 2.2.2. System flow diagrams

- 2.2.2.1. Outline of fuel system

- 2.2.2.2. Outline of lubrication system

- 2.2.2.3. Outline of cooling system

- 2.2.2.4. Outline of inlet and exhaust system

- 2.2.3. Engine serial number location

- 2.2.4. Main specifications

- 2.3. Chapter 2 SERVICE DATA

- 2.3.1. Maintenance service data

- 2.3.1.1. Engine general

- 2.3.1.2. Basic engine

- 2.3.1.3. Fuel system

- 2.3.1.4. Lubrication system

- 2.3.1.5. Cooling system

- 2.3.1.6. Inlet and exhaust system

- 2.3.1.7. Electrical system

- 2.3.2. Tightening torque table

- 2.3.2.1. Basic engine

- 2.3.2.2. Fuel system

- 2.3.2.3. Lubrication system

- 2.3.2.4. Cooling system

- 2.3.2.5. Inlet and exhaust system

- 2.3.2.6. Electrical system

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-74120

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102