Description

Table of Content – Multi Pro 5800 (S.N below 316000000)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- Table Of Contents (Continued)

- 1 – Safety

- Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

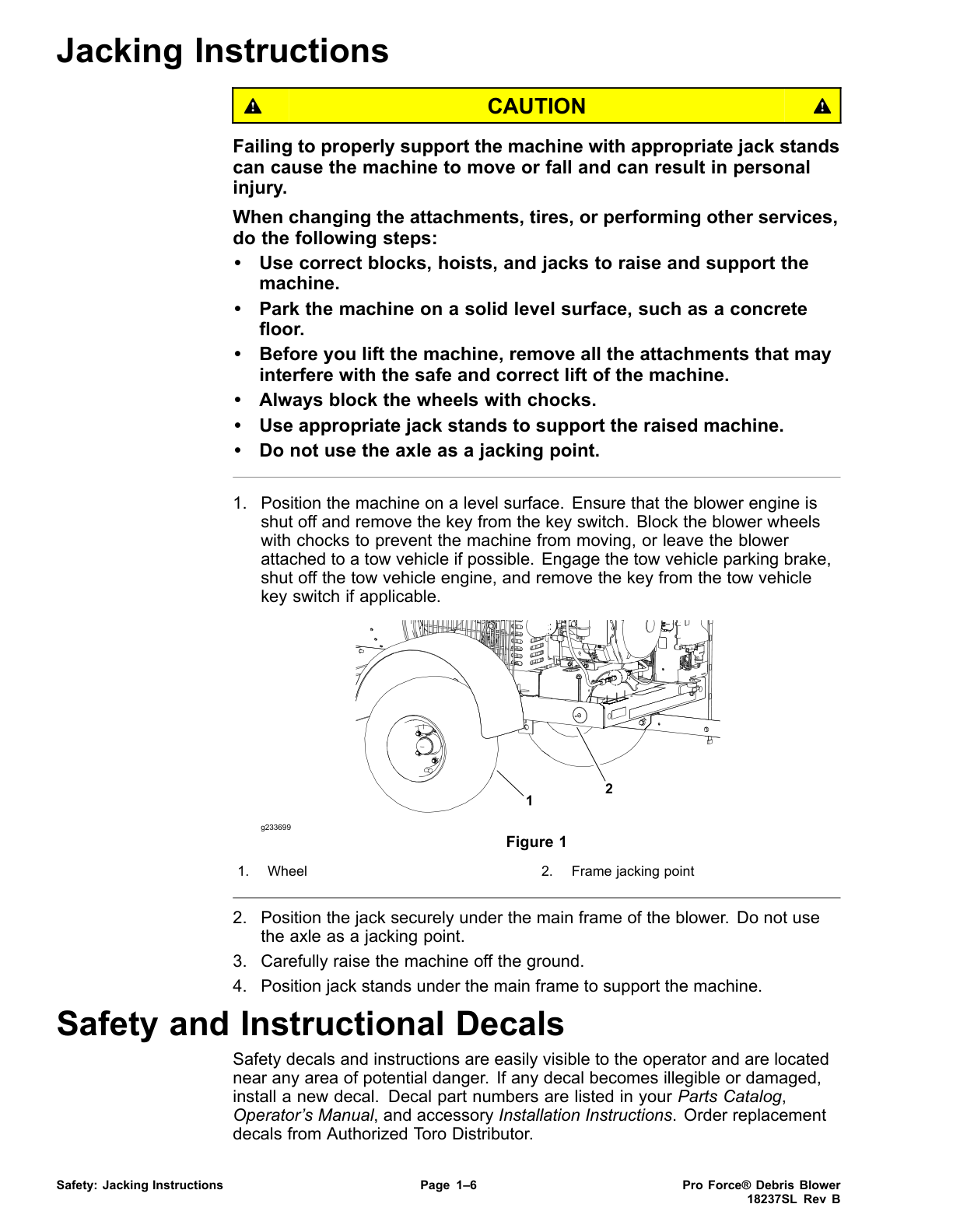

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Decimal and Millimeter Equivalents

- US to Metric Conversions

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series Fasteners)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- 3 – Kubota Diesel Engine

- General Information

- Operator’s Manual

- Specifications

- Adjustments

- Adjust Throttle Cable

- Service and Repairs

- Fuel System

- Air Cleaner

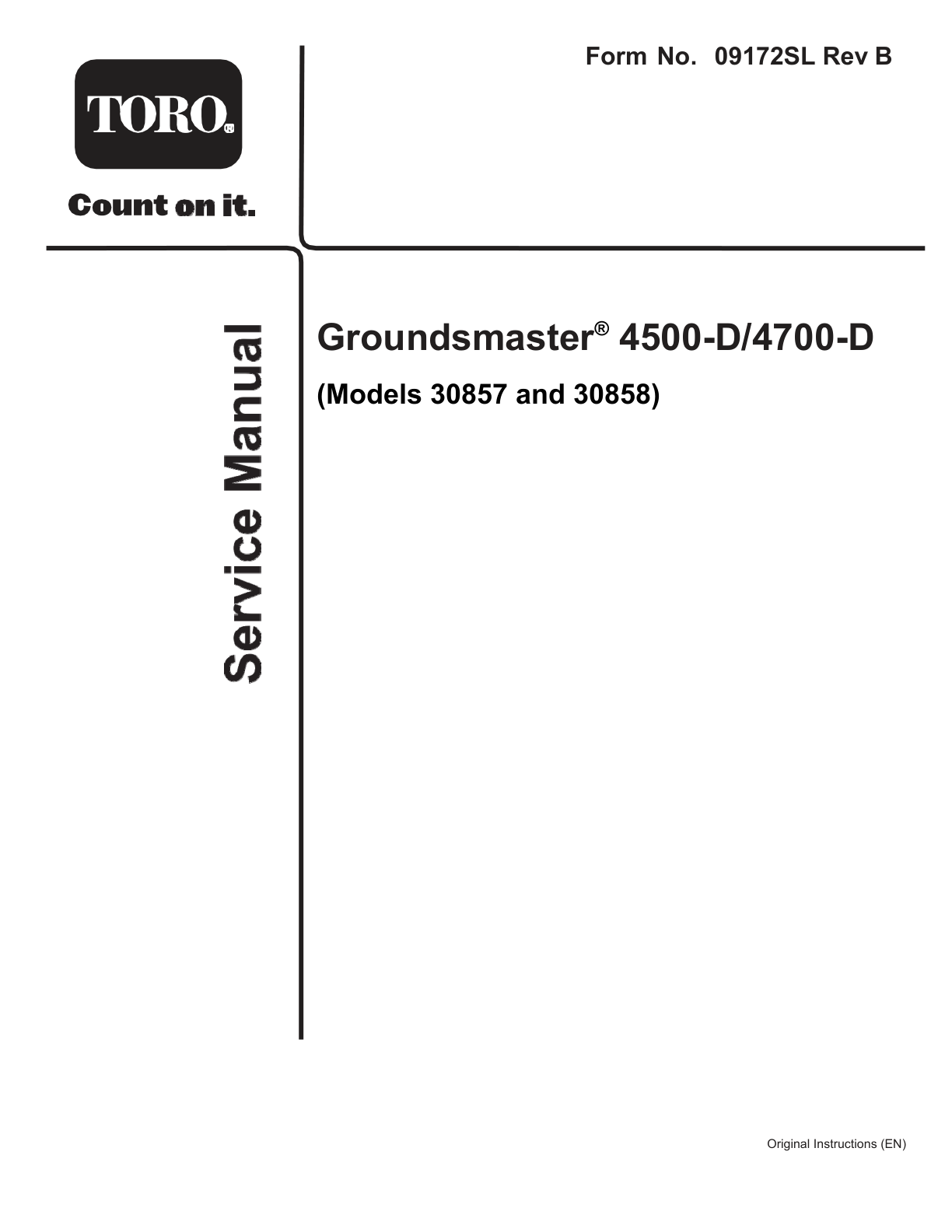

- Exhaust System

- Radiator

- Engine

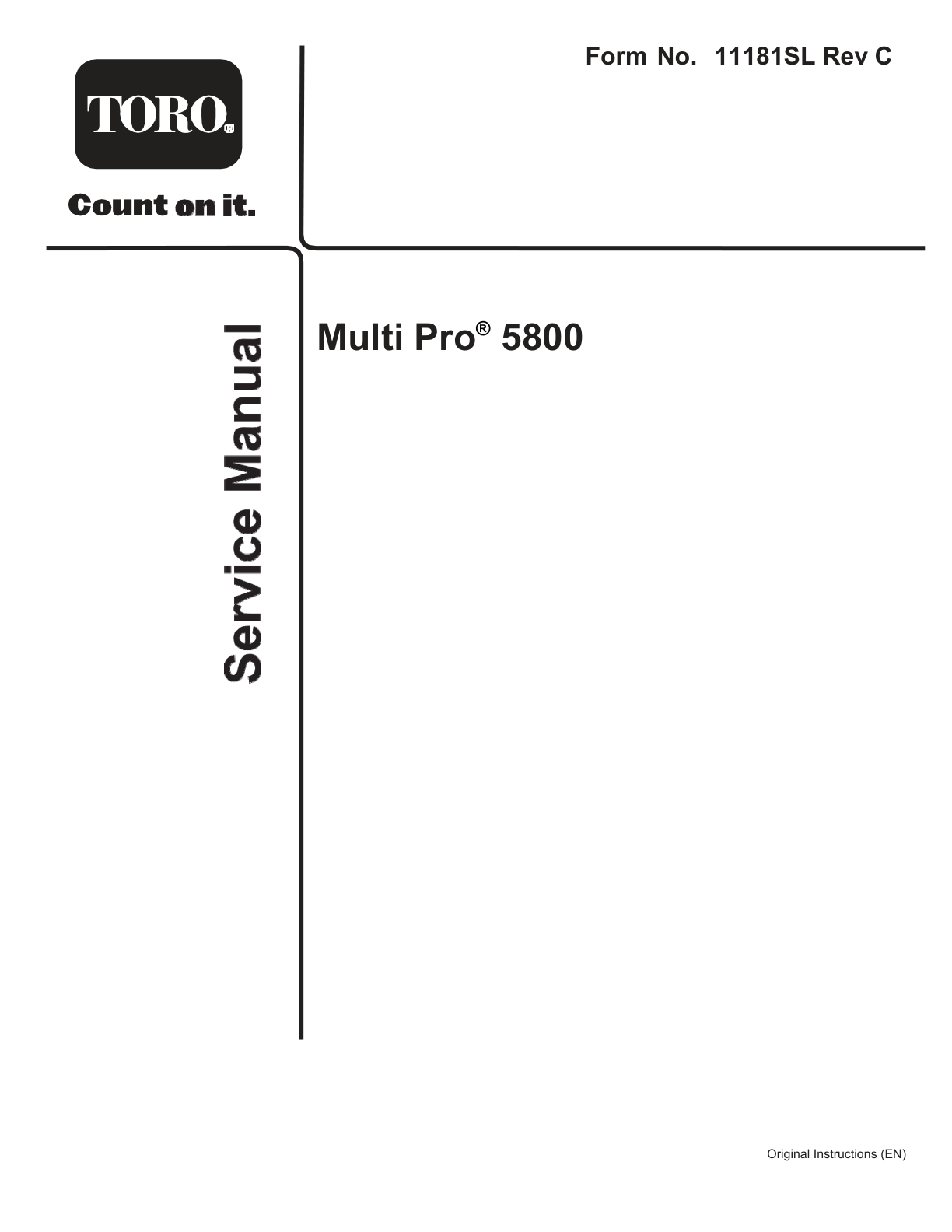

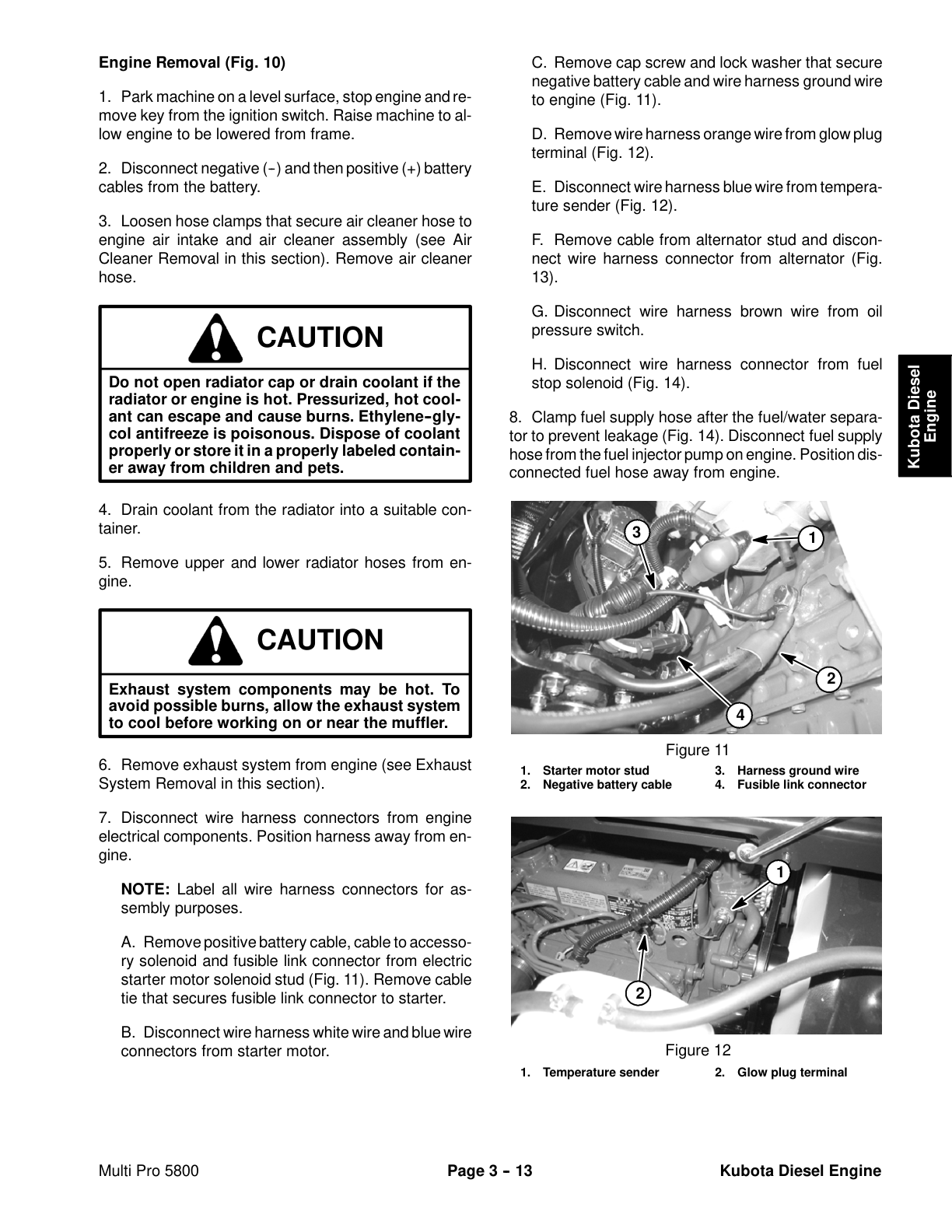

- Engine Removal

- Engine Installation

- Flywheel Coupler

- Kubota 05-E3B Series Workshop Manual

- 4 – Hydraulic System

- Specifications

- General Information

- Operator’s Manual

- Check Hydraulic Fluid

- Towing Sprayer

- Traction Circuit Component Failure

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O–Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O–Ring Fitting into Component Port)

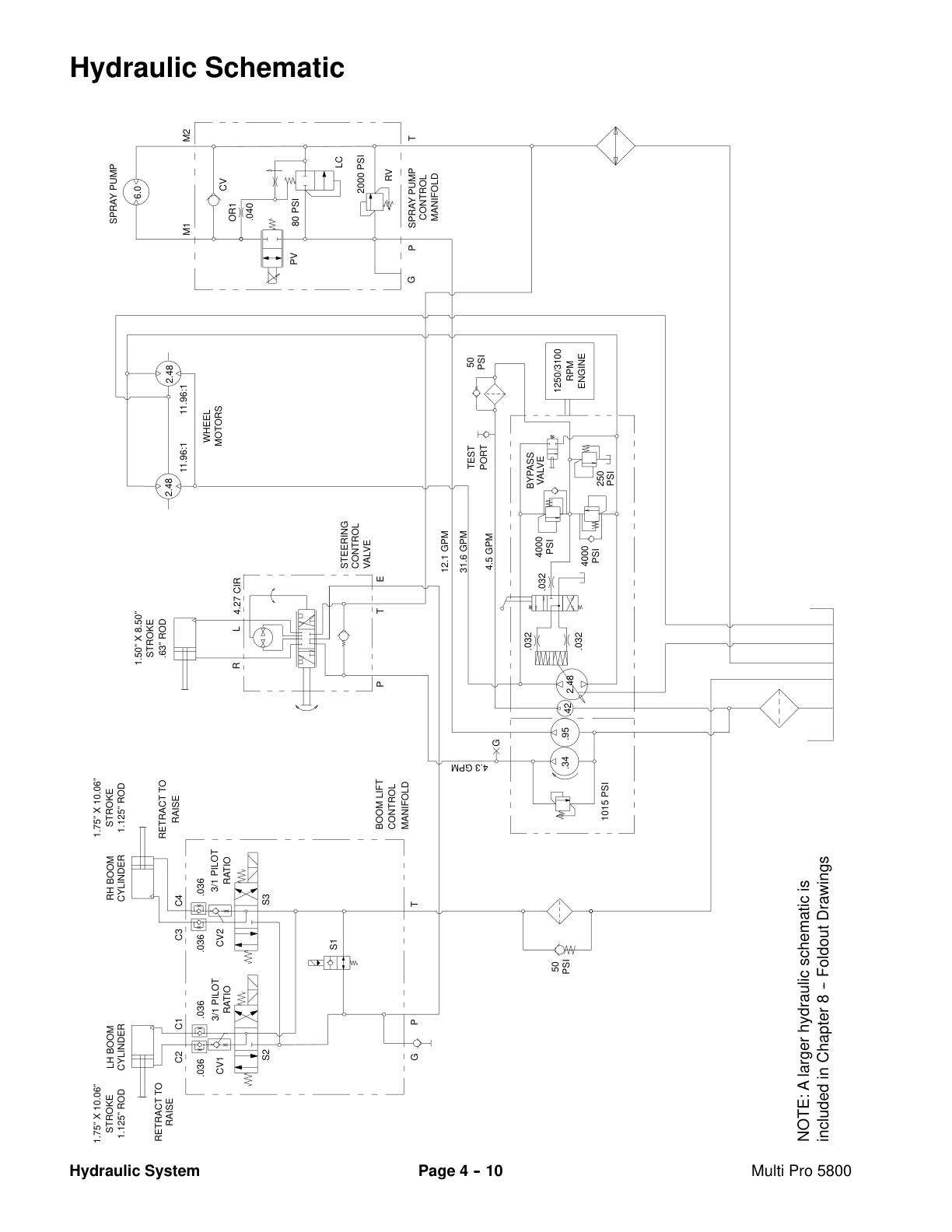

- Hydraulic Schematic

- Hydraulic Flow Circuits

- Traction Circuit

- Steering Circuit

- Spray Pump Drive Circuit

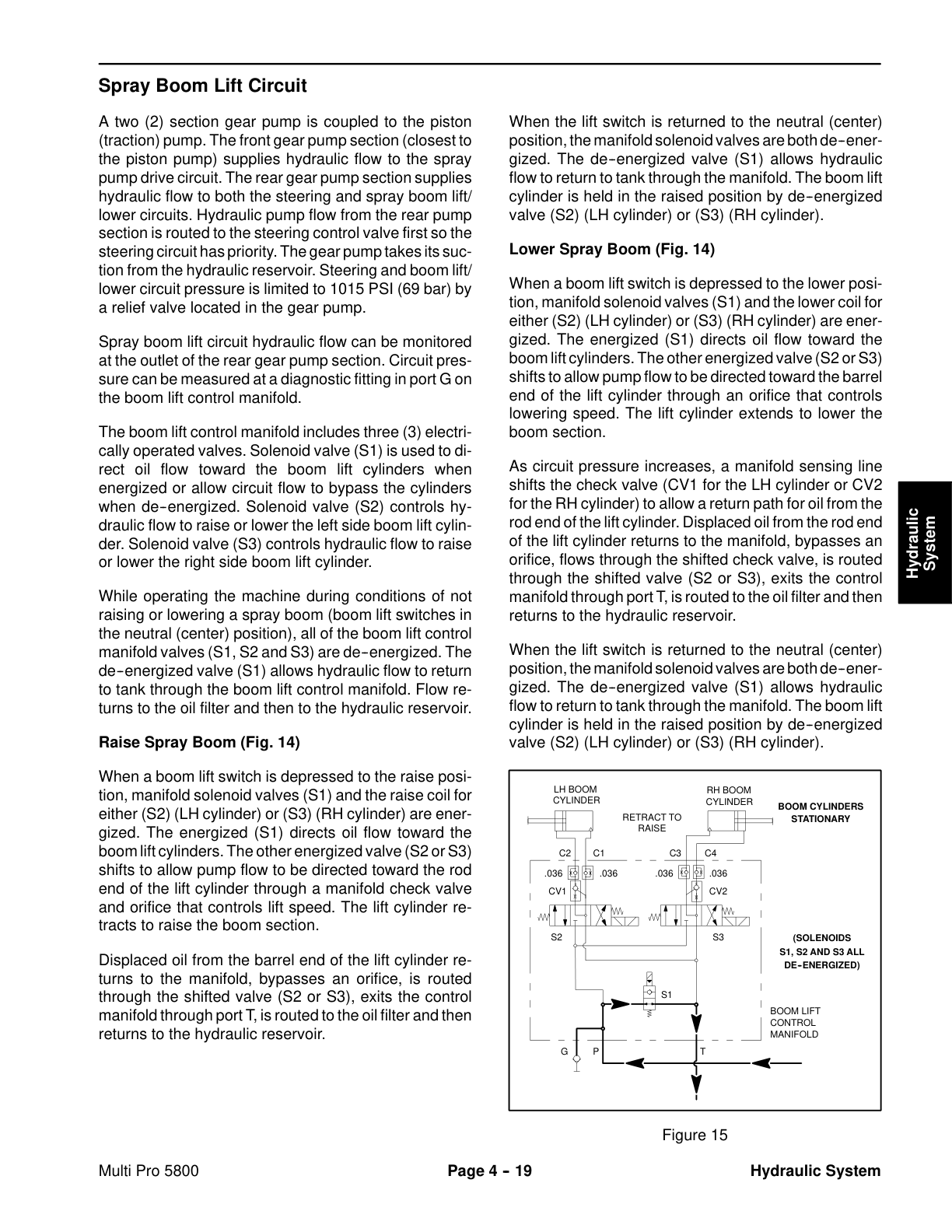

- Spray Boom Lift Circuit

- Special Tools

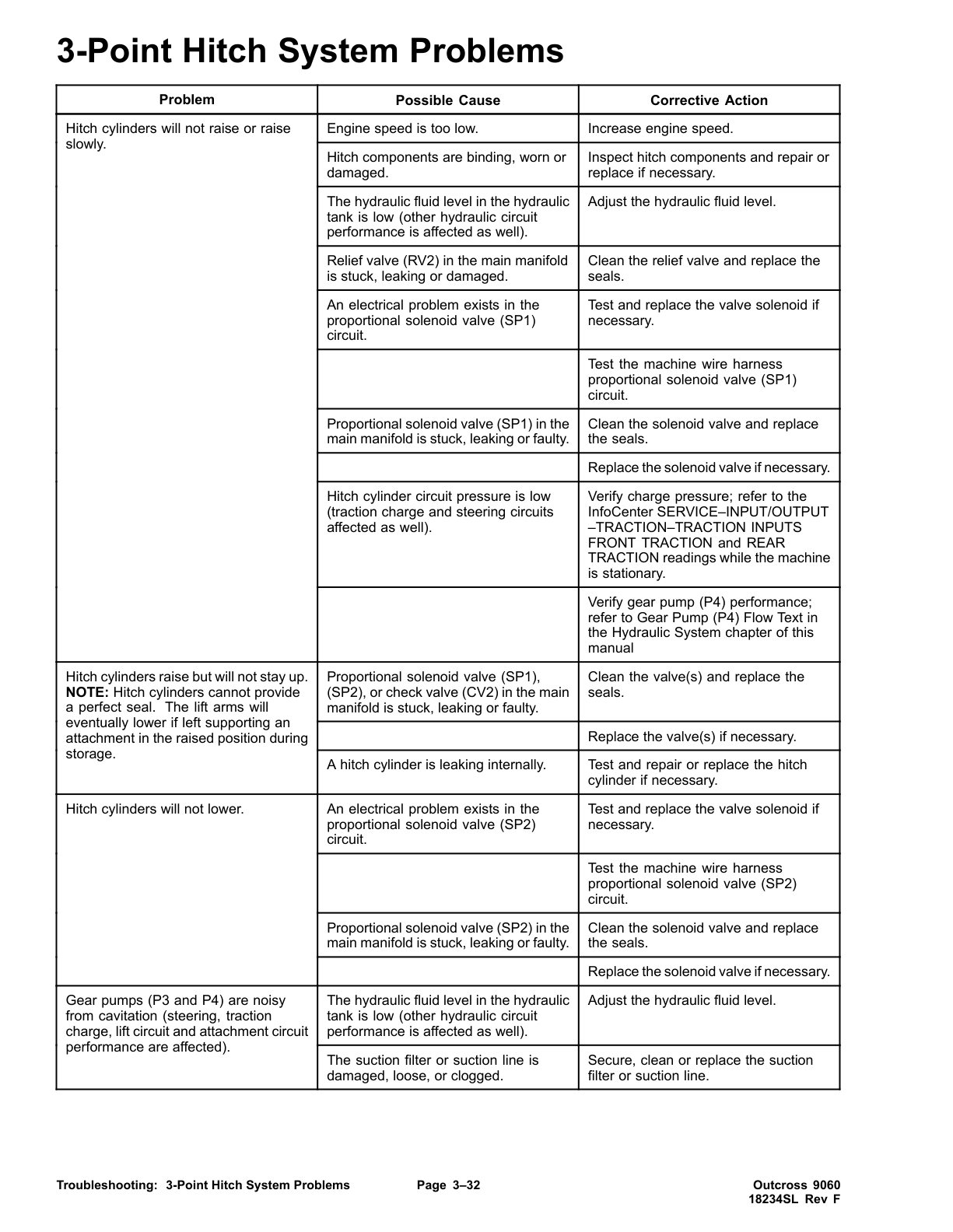

- Troubleshooting

- Testing

- Traction Circuit Charge Pressure Test

- Traction Circuit Relief Pressure Test

- Wheel Motor Efficiency

- Charge Pump Flow Test

- Piston (Traction) Pump Flow Test

- Steering, Boom Lift Circuits Relief Pressure Test

- Steering, Boom Lift Circuits Gear Pump Flow Test

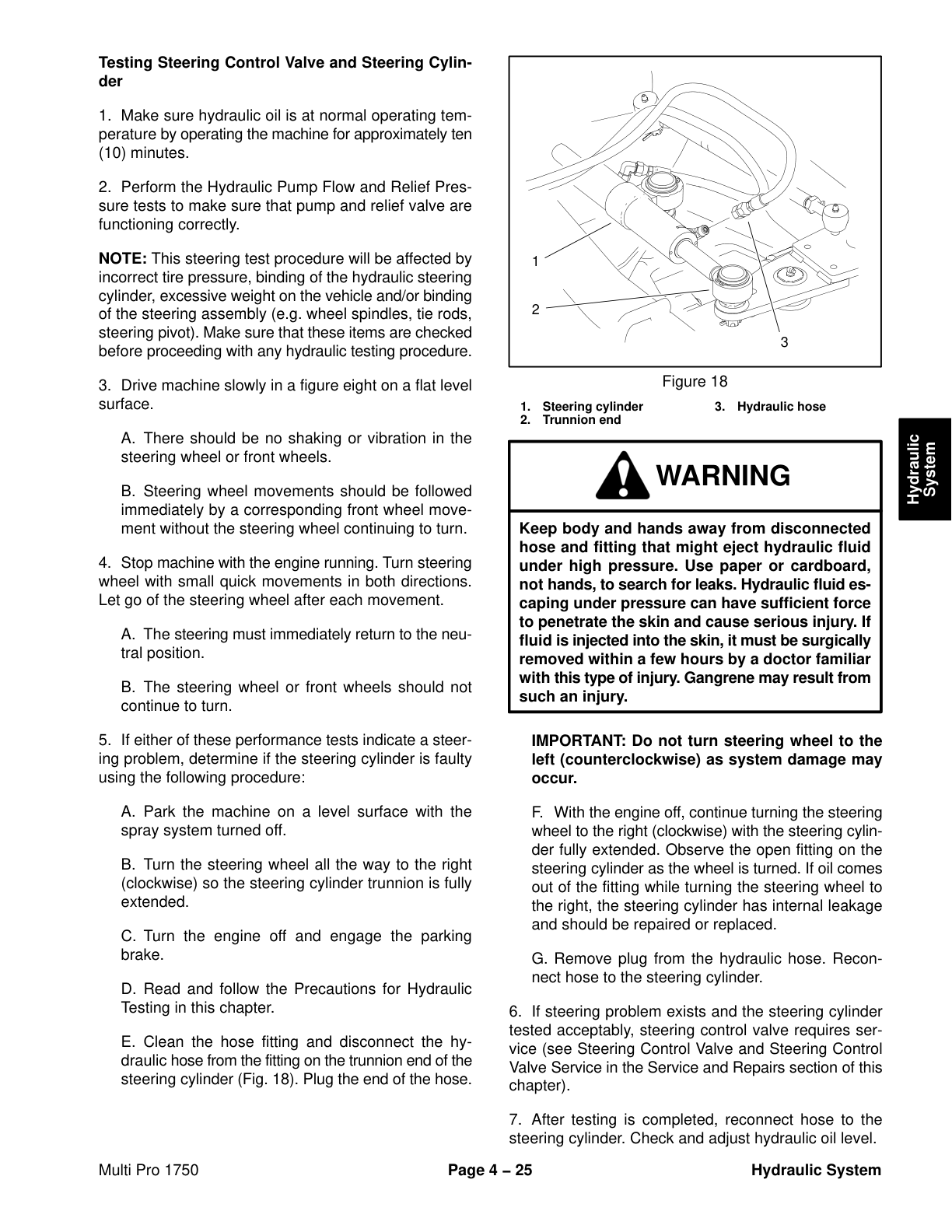

- Steering Cylinder Internal Leakage Test

- Boom Lift Cylinder Internal Leakage Test

- Spray Pump Circuit Gear Pump Flow Test

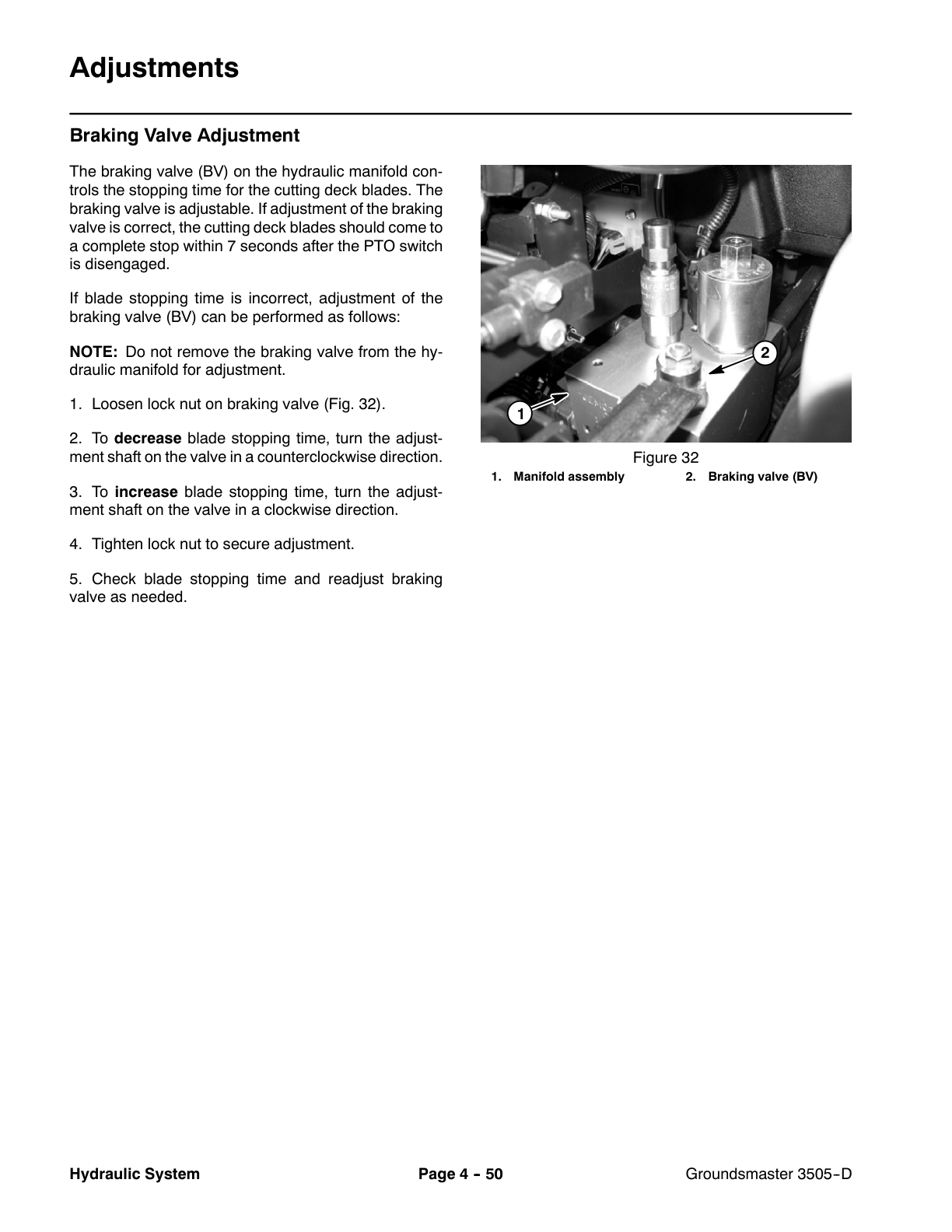

- Adjustments

- Adjust Traction Pedal for Neutral

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Flush Hydraulic System

- Filtering Closed–Loop Traction Circuit

- Charge Hydraulic System

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- Wheel Motors

- Wheel Motor Service

- Spray Pump Drive Motor

- Spray Pump Drive Motor Service

- Spray Pump Control Manifold

- Spray Pump Control Manifold Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Boom Lift Control Manifold

- Boom Lift Control Manifold Service

- Boom Lift Cylinder

- Boom Lift Cylinder Service

- Oil Cooler

- Hydraulic Reservoir

- Eaton Piston Pump Repair Information

- Eaton Piston Motor Repair Information

- Parker Torqlink Service Procedure

- Danfoss Steering Unit Service Repair Manual

- 5 – Electrical System

- General Information

- Electrical Drawings

- Operator’s Manual

- Special Tools

- Troubleshooting

- Starting Problems

- General Run Problems

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test

- Neutral Switch Operation

- Component Testing

- Ignition Switch

- Indicator Lights

- Hour Meter

- Headlight Switch

- Speed Lock Switch

- Pressure Rate Switch

- Boom Lift Switches

- Spray Pump, Agitation and Boom Control Switches

- Master Boom (Foot) Switch

- Speed Lock Coil

- Brake Pedal Switch

- Spray System Relays

- Main, Glow and Speed Lock Relays

- Traction Speed Sensor

- Hydraulic Valve Solenoid Coils

- Manual Interface Module

- Neutral Switch

- Fuel Stop Solenoid

- Glow Plug Controller

- Fuel Pump

- Temperature Sender

- Fusible Links

- Diode Assemblies

- Service and Repairs

- Headlights

- Traction Speed Sensor

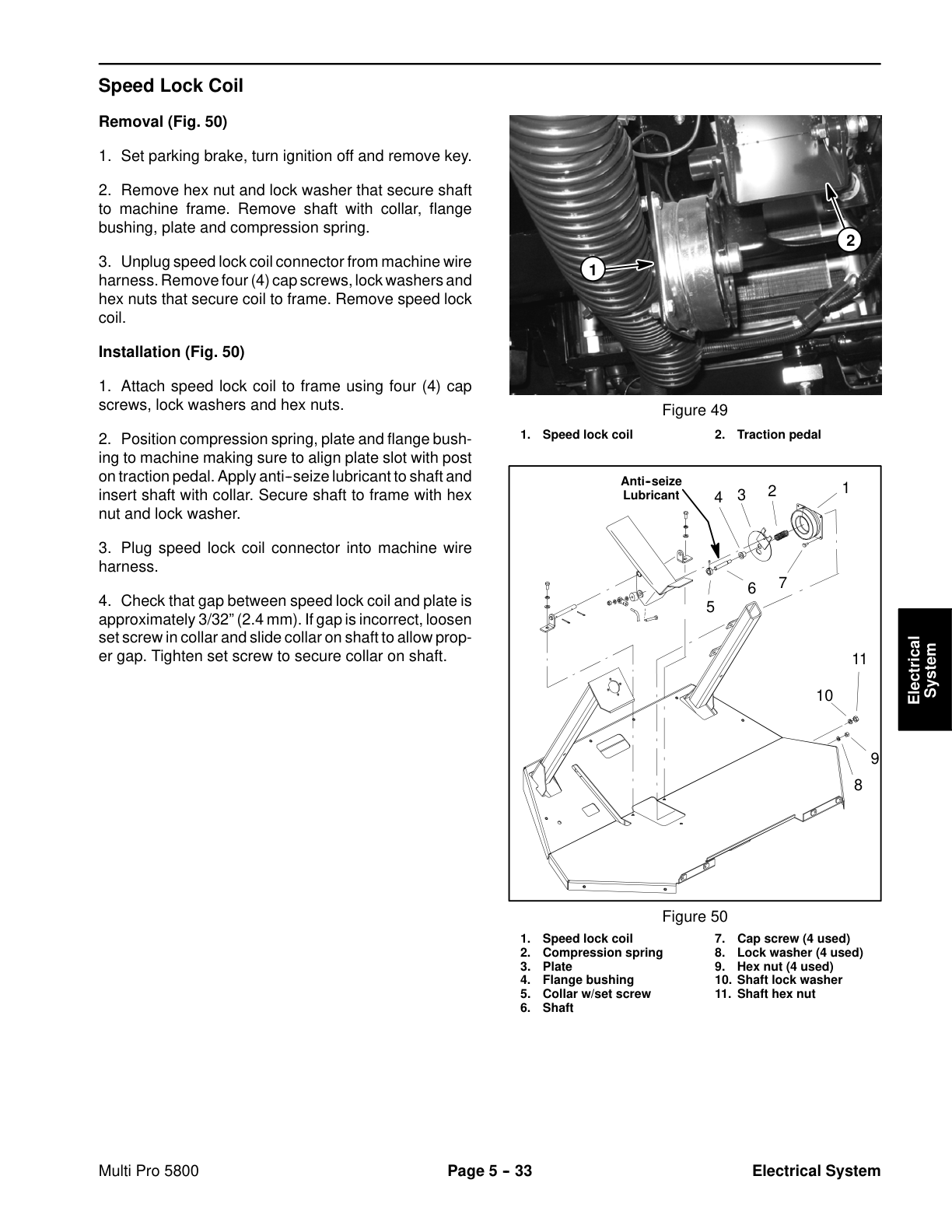

- Speed Lock Coil

- Battery Storage

- Battery Care

- Battery Service

- 6 – Spray System

- Specifications

- General Information

- Operator’s Manual

- Precautions Concerning Chemicals Used in Spray System

- Precautions for Removing or Adjusting Spray System Components

- Spray System Flow Diagram

- Spray System Operation

- Troubleshooting

- Service and Repairs

- Spray Pump

- Spray Pump Service

- Agitation Supply

- Pressure Relief Valve

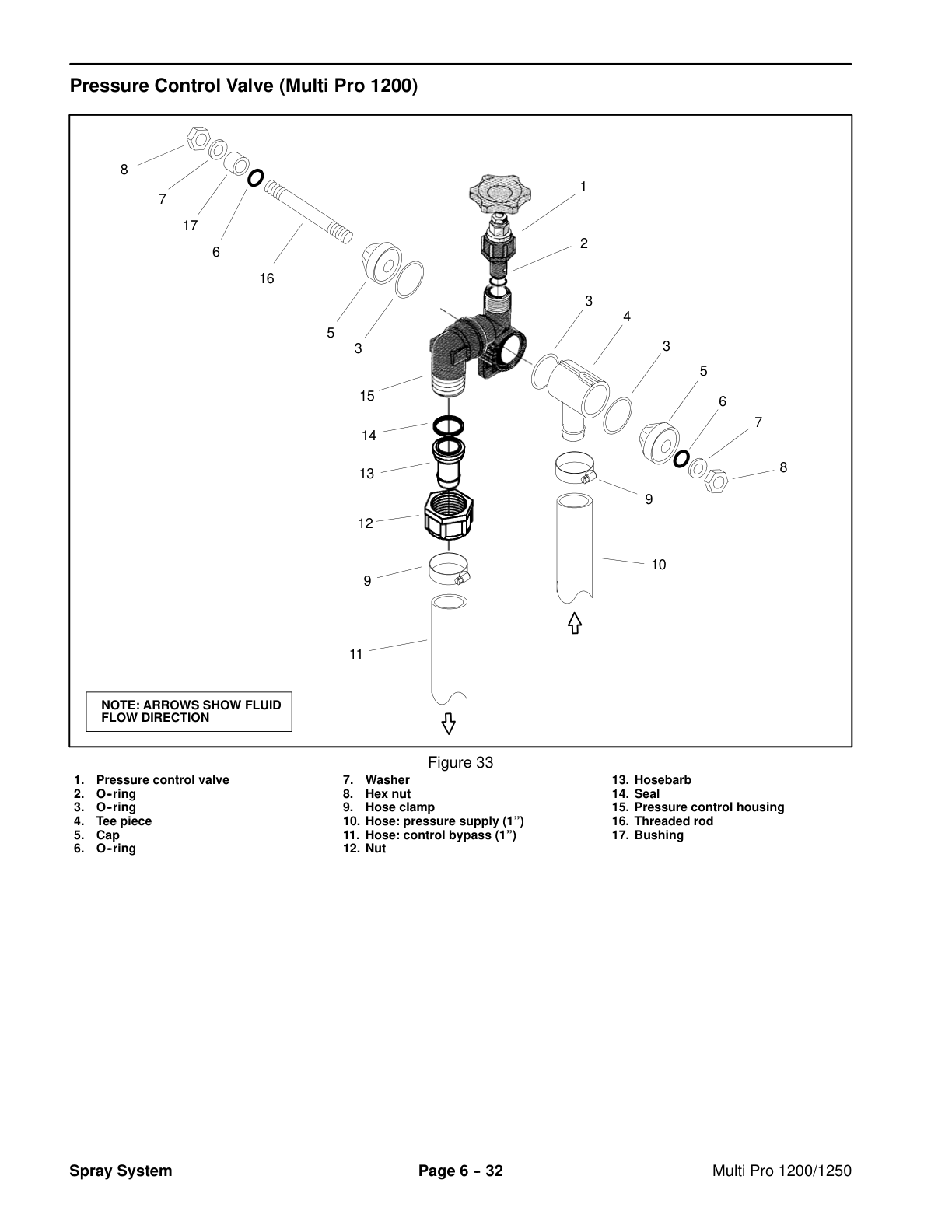

- Spray Control Assembly

- Boom Manifold Valve Assembly

- Agitation Valve Assembly

- Boom and Agitation Valve Motor Service

- Tank Suction

- Tank Drain Valve

- Turret Bodies

- Turret Body Service

- Boom Hinge

- Pro Control XP Spray System (Optional)

- 7 – Chassis

- Table of Contents

- Specifications

- General Information

- Operator’s Manual

- Adjustments

- Planetary Drive Assembly Endplay (OPH-2 series planetary drives)

- Service and Repairs

- Tie Rod Ends

- Front Wheels and Hubs

- Spindles

- Front Suspension

- Brake Assembly

- Brake Inspection and Repair

- Brake Cables

- Planetary Wheel Drive Assembly

- OPH-2 Series Planetary Drive Service

- VA02 Series Planetary Drive Service

- Console Assembly

- 7.1 – Ultra Sonic Boom System(Optional Kit)

- General Information

- Installation Instructions

- Precautions Concerning Chemicals Used in Spray System

- Precautions for Removing or Adjusting Spray System Components

- Special Tools

- Hydraulic Schematic

- Electrical Schematic

- Ultra Sonic Boom System Operation

- Sprayer Operation on Level Turf

- Downward Slope in Turf Encountered

- Rise in Turf Encountered

- Boom Level Changed by Operator

- Manual Boom Operation

- Troubleshooting

- Sonic Boom Light

- Ultra Sonic Boom Calibration

- Diagnostic Lamp

- Diagnostic Display

- Troubleshooting Chart

- Service and Repairs

- Sonic Boom Fuses

- Sonic Boom Switch

- Sonic Sensors

- Toro Electronic Controller (TEC)

- Boom Lift Control Manifold

- 8 – Foldout Drawings

- Hydraulic Schematic

- Vehicle Electrical Schematic

- Spray System Electrical Schematic

- Glow Plug Circuit

- Start Circuit

- Run Circuit

- Speed Lock Circuit

- Front Wire Harness Drawing

- Front Wire Harness Diagram

- Rear Wire Harness Drawing

- Rear Wire Harness Diagram

Rate this product

You may also like