Description

Table of Content – Outcross 9060

- Revision History

- Reader Comments

- Preface

- Service Procedure Icons

- Chapter 1 : Safety

- Safety Instructions

- Supervisor’s Responsibilities

- Before Operating the Machine

- Operating the Machine

- Maintenance and Service

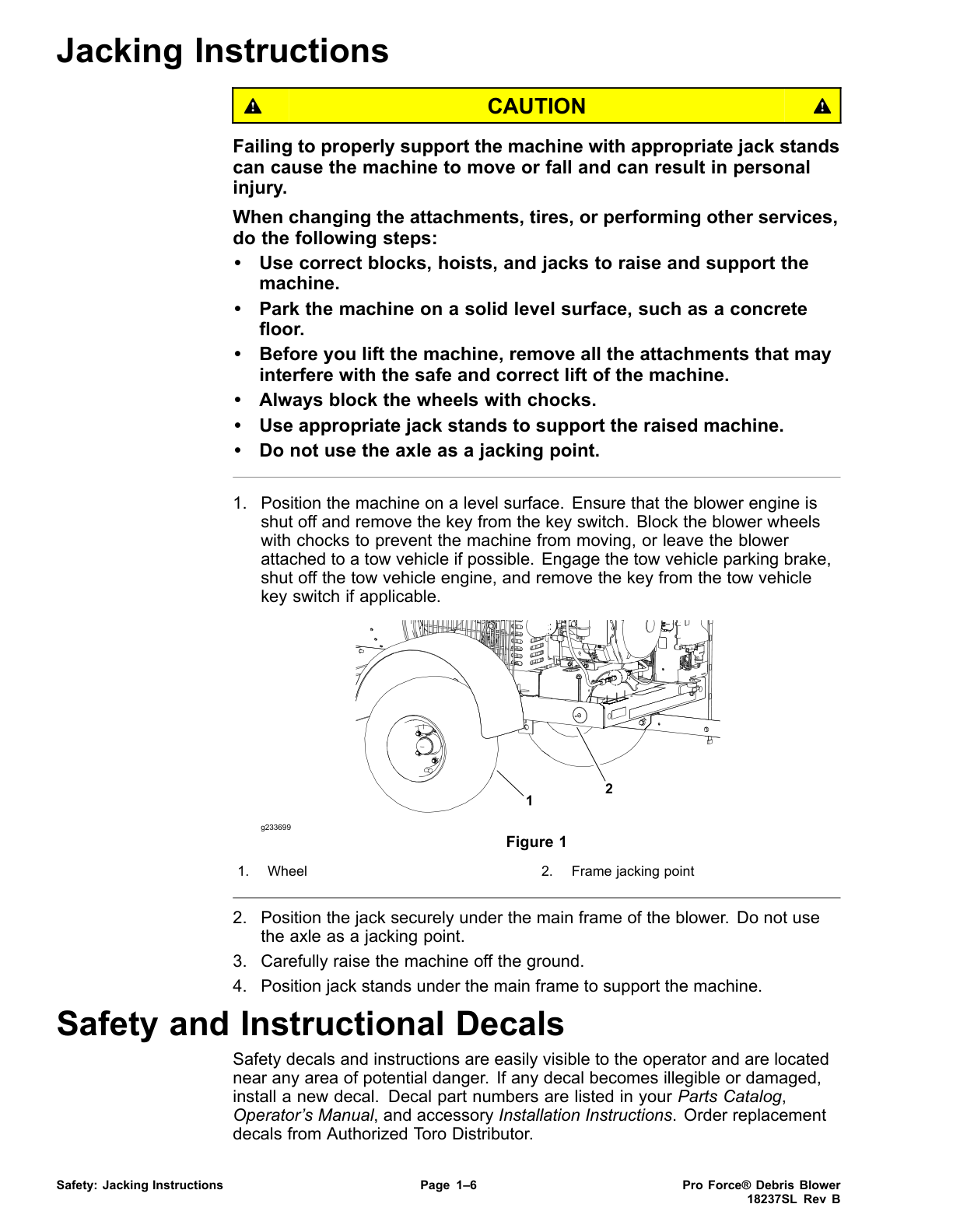

- Jacking Instructions

- Raising the Front of the Machine

- Raising the Rear of the Machine

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Overall Dimensions

- Traction Unit

- Engine

- Hydraulic System

- Traction and PTO Drive

- Chassis

- Torque Specifications

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Identifying the Fastener

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Troubleshooting

- GEARS – The Systematic Approach to Defining, Diagnosing and Solving Problems

- Gather Information

- Evaluate Potential Causes

- Assess Performance

- Repair

- Solution Confirmation

- Operator Advisories

- Machine and Engine Faults

- Using the InfoCenter display for Troubleshooting

- TRACTION (example):

- General Hydraulic System Problems

- Traction System Problems

- Steering System Problems

- PTO System Problems

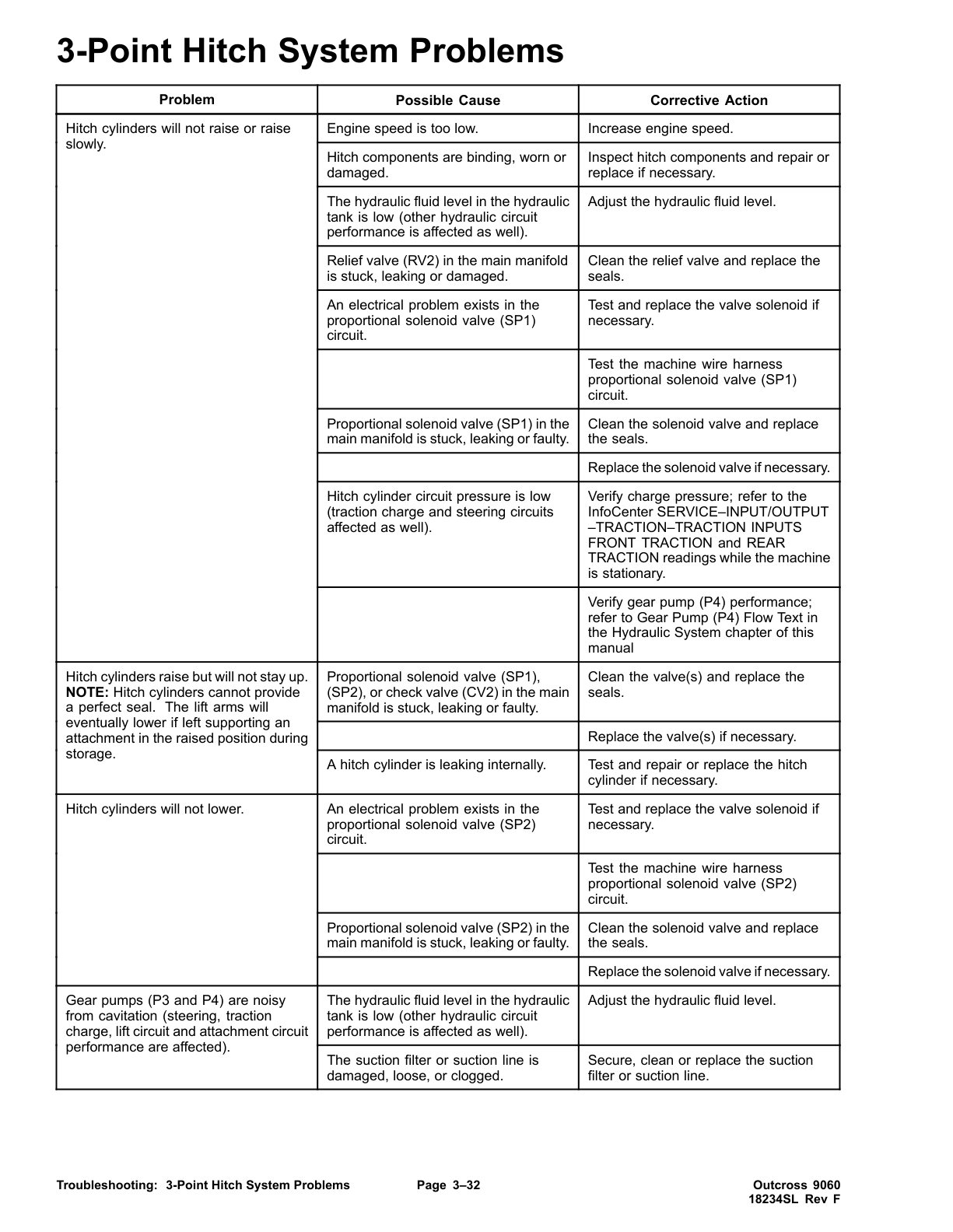

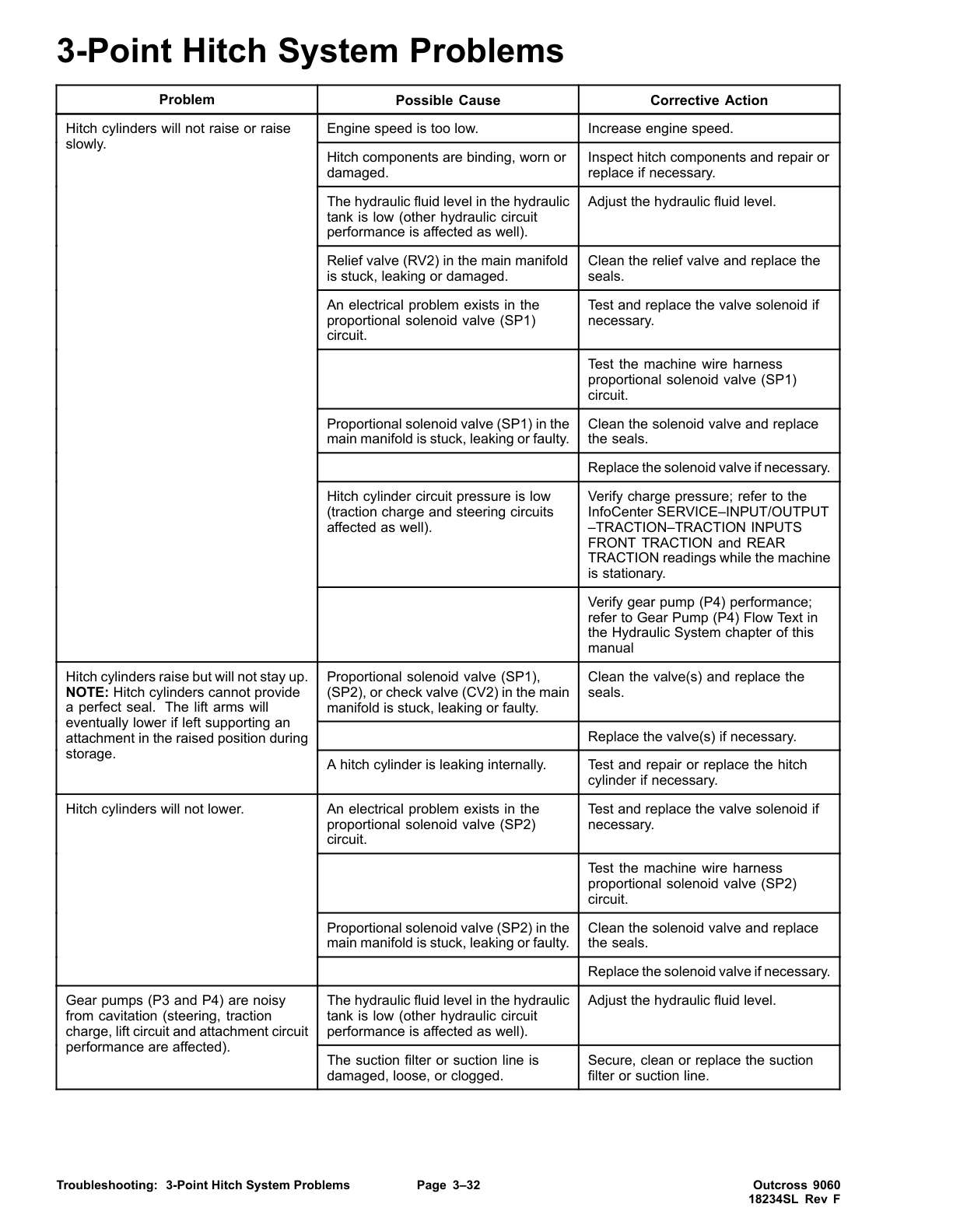

- 3-Point Hitch System Problems

- Attachment, Loader Problems

- Chapter 4 : Engine

- General Information

- Traction Unit Operator’s Manual

- Yanmar Service and Troubleshooting Manuals

- Shutting Off the Engine

- Engine Electronic Control Unit (ECU)

- Yanmar Engine

- Diesel Particulate Filter

- Service and Repairs

- Air Cleaner System

- Exhaust System

- Radiator

- Fuel System

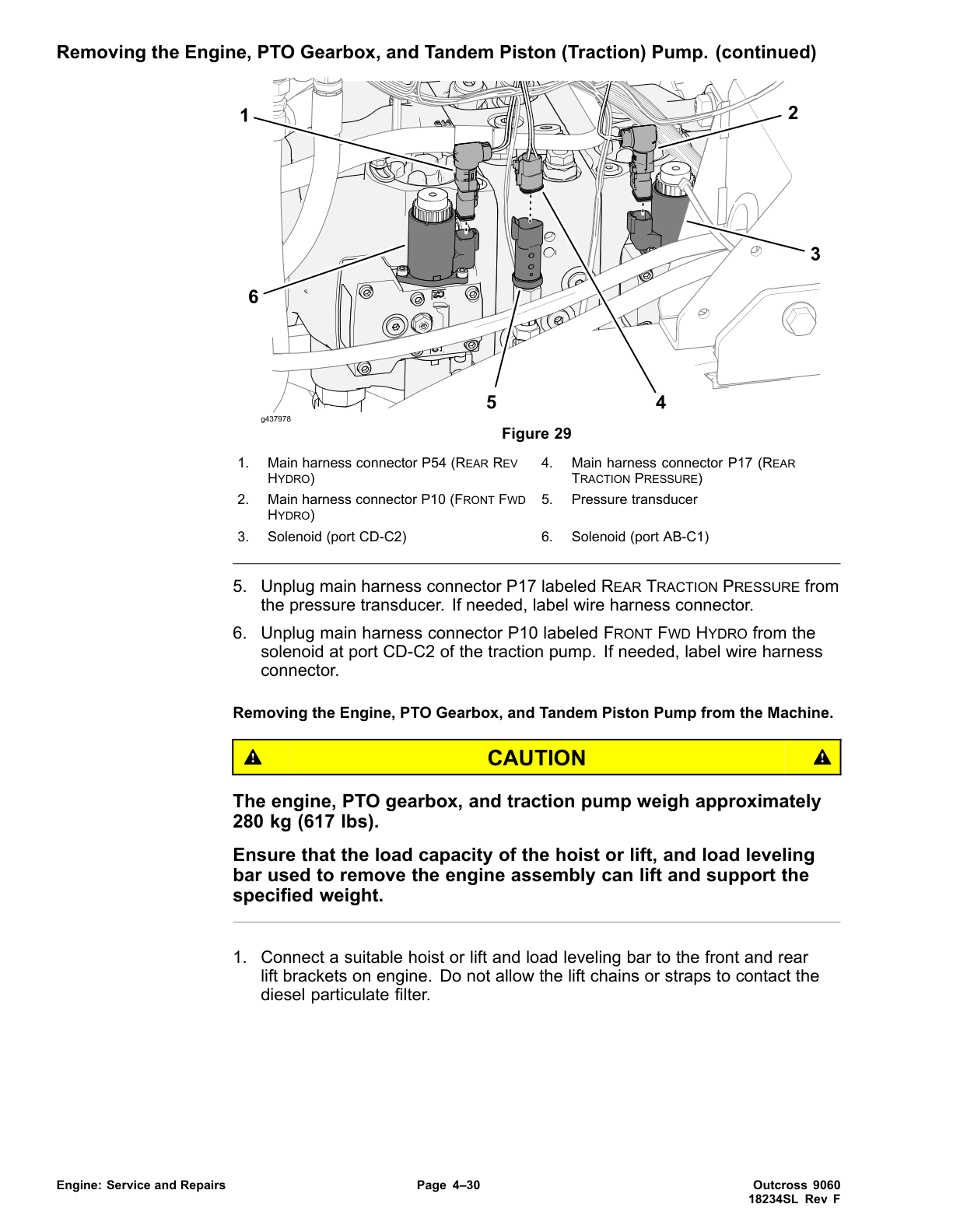

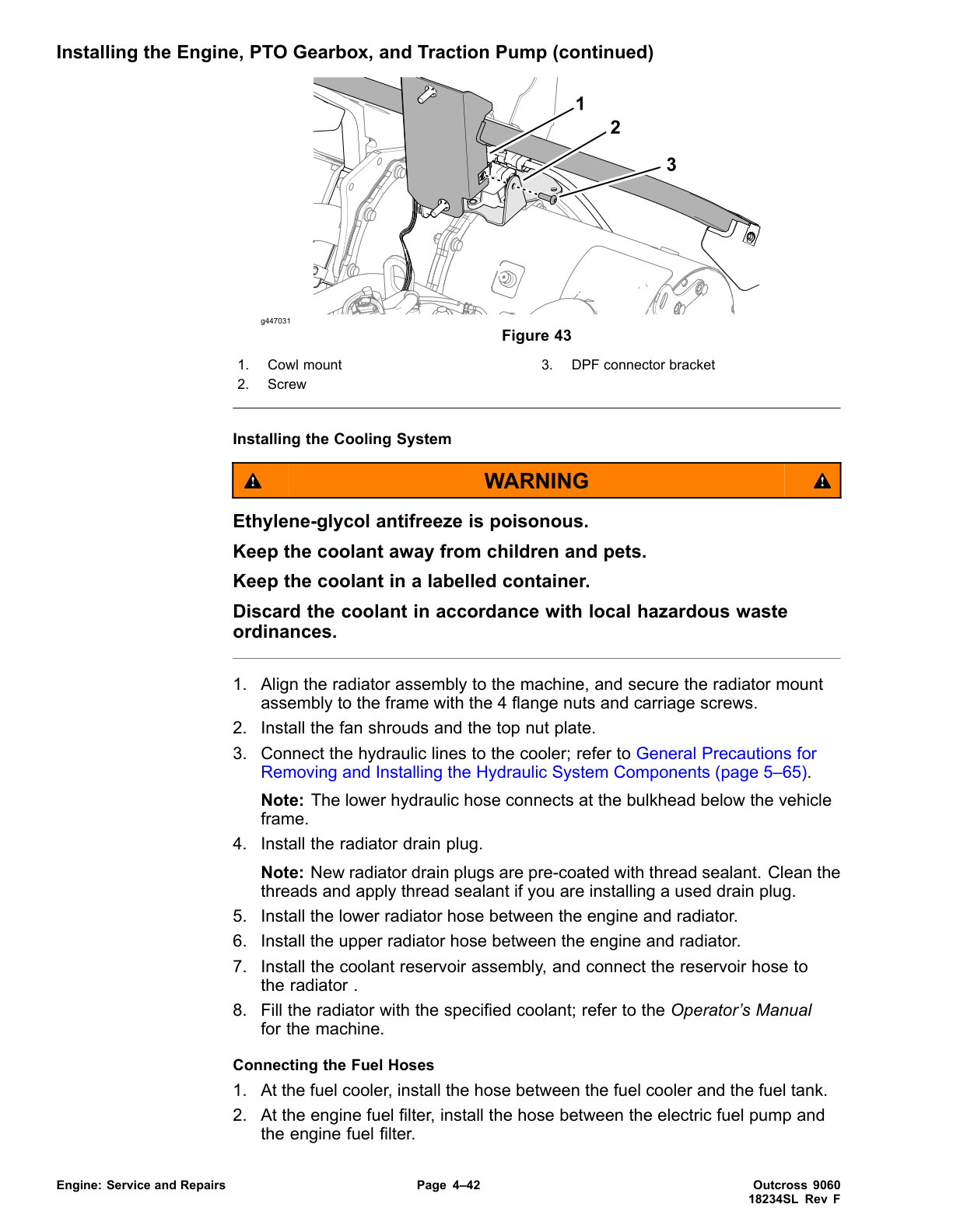

- Engine

- Flywheel Housing and Drive Coupler

- Chapter 5 : Hydraulic System

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Relieving Pressure from the Hydraulic System

- Towing the Traction Unit

- Traction Circuit (Closed-Loop) Component Failure

- Hydraulic Hoses

- Installing O-rings

- Installing Hydraulic Hoses and Tubes (O-Ring Face Seal)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fittings)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit

- Steering Circuit

- Hitch Cylinder Circuit

- Brake Circuit

- Differential Lock Circuit

- PTO Clutch Circuit

- Attachment Circuit

- Front Loader Circuit

- Selector Control Valve (SCV) Circuit (optional)

- Testing the Hydraulic System

- Hydraulic Test Selection

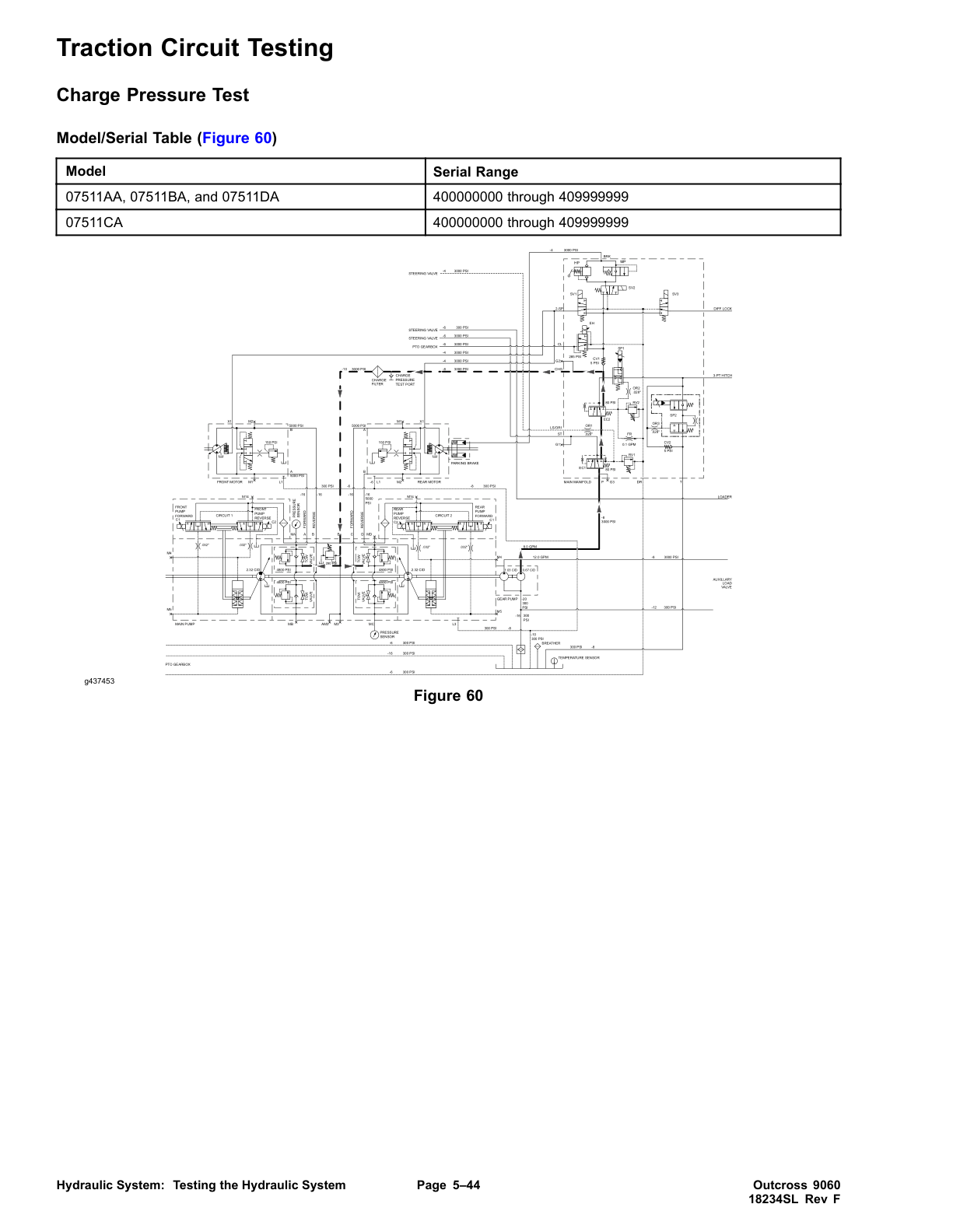

- Traction Circuit Testing

- Steering, Hitch Cylinder Circuit Testing – Steering Relief Valve (RV1) Pressure Test

- Steering, Hitch Cylinder Circuit Testing – Hitch Cylinder Relief Valve (RV2) Pressure Test

- Steering, Hitch Cylinder Circuit Testing – Gear Pump (P4) Flow

- Attachment, Loader Circuit Testing – Relief Valve Pressure Test

- Attachment, Loader Circuit Testing – Gear Pump (P3) Flow Test

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Checking the Hydraulic Lines and Hoses

- Flushing the Hydraulic System

- Filtering the Closed-Loop Traction Circuit

- Priming the Hydraulic Pumps

- Charging the Hydraulic System

- Hydraulic Tank

- Hydraulic Fluid Cooler

- Tandem Piston (Traction) Pump (P1) and (P2)

- Tandem Piston (Traction) Pump (P1) and (P2) Service

- Gear Pump (P3) and (P4)

- Gear Pump (P3) and (P4) Service

- Axle Motors

- Axle Motor Service

- Axle Differential Locks

- Hydraulic Brake Assembly

- Hydraulic Brake Service

- Main Hydraulic Manifold

- Main Manifold Service

- Cartridge Valve Service

- Steering Control Valve

- Steering Control Valve Service

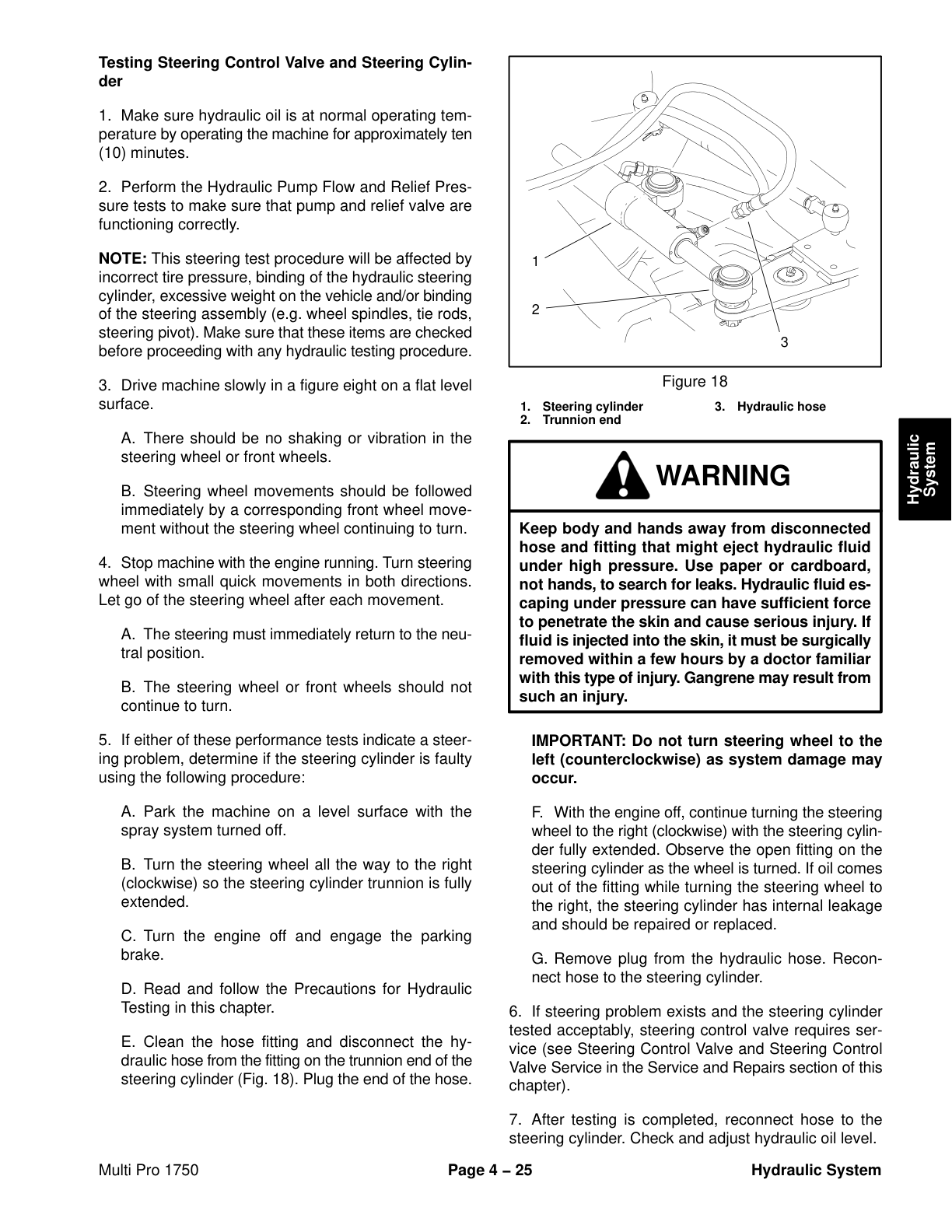

- Steering Cylinders

- Steering Cylinder Service

- 3-Point Hitch Cylinders

- 3-Point Hitch Cylinder Service

- PTO Clutch

- Auxiliary Load Valve

- Auxiliary Load Valve Service

- Front Loader Control Valve

- Front Loader Control Valve Service

- Selector Control Valve Manifolds (optional)

- Selector Control Valve Manifold (optional) Service

- Chapter 6 : Electrical System

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Yanmar Engine Electrical Components

- InfoCenter Display

- Primary Controller (T1: TEC)

- Status Display Controller (T2: TDM)

- Engine Electronic Control Unit (ECU)

- InchMode Controller (T3: TEC) (optional)

- CAN bus Communications

- Electrical Drawings

- Electrical System Quick Checks

- Testing the Charging System

- Checking the Operation of the Interlock Switches

- Electrical Component Testing

- Fuses

- Fusible Link Harness

- CAN bus

- Primary Controller (T1: TEC)

- Status Display Controller (T2: TDM)

- InchMode Controller (T3: TEC) (optional)

- Key Switch

- Mode Selector

- Parking Brake Switch

- Power Take Off (PTO) Enable Switch

- Economy (ECO) Mode Switch

- Hydraulic Auxiliary (AUX) Switch

- Seat Switch

- Paddle (3-Point Hitch) and Transmission Lever Switches

- Headlight, Work Light Switch

- Cruise Control Off, On, Set Switch

- Cruise Control Speed Increase, Decrease Switch

- Air Conditioning On, Off Switch

- Heater, Air Conditioning Blower Speed Switch

- InchMode Enable Switch (optional)

- InchMode Raise, Lower and Forward, Reverse Switches (optional)

- Loader Selector Control Valve (SCV) Switch (optional)

- Traction Pedal Assembly

- Decelerator Pedal Position Sensor

- Decelerator Pedal Neutral Switch

- 3-Point Hitch Position Sensor

- Hydraulic Fluid Temperature Sender

- Speed Sensors

- Traction Pressure Sensors

- Fuel Pump

- Fuel Level Sender

- Warning Buzzer

- Relays with 4 Terminals

- Relays with 5 Terminals

- Diode Assemblies

- Resistor Assembly

- CAN bus Terminator Resistors

- Hydraulic Solenoid Valve Coils

- Tandem Traction (Piston) Pump Control Solenoid Coils

- Service and Repairs

- Caring for the Battery

- Storing the Battery

- Servicing the Battery

- Chapter 7 : Traction and PTO Drive

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Adjustments

- Adjusting the Tie Rod Length

- Adjusting Axle Stop Bolts

- Service and Repairs

- Tie Rods

- Front Axle

- Front Axle

- Rear Axle

- Rear Axle

- Front and Rear Axle Service

- Front PTO Gearbox

- PTO Clutch Service

- Rear PTO Gearbox

- PTO Driveshaft

- Chapter 8 : Chassis

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Service and Repairs

- Front Screen

- Hood

- Operator Platform or Cab

- Steering Wheel, Instrument Panels and Dash Cover

- Operator’s Console

- Seats

- Standard Utility Box

- Front Loader Attachment

- Chapter 9 : Operator Cab

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Electrical Components, Schematics and Wire Harness Drawings

- Air Conditioning System

- Cab Heater System

- Adjustments

- Adjusting the Compressor Belt Tension

- Adjusting the Doors

- Service and Repairs

- Heating and Air Conditioning Components

- General Precautions for Removing and Installing Air Conditioning System Components

- Air Conditioning Compressor

- Control Panel and Windshield Wiper Assembly

- Windshield

- Doors

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Hydraulic Schematic

- Hydraulic Schematic

- Electrical Schematic (part 1 of 3)

- Electrical Schematic (part 2 of 3)

- Electrical Schematic (part 3 of 3)

- Wire Harness Drawing – Frame

- Wire Harness Diagram – Frame

- Wire Harness Drawing – Platform

- Wire Harness Diagram – Platform

- Wire Harness Diagram – Platform (continued)

- Wire Harness Drawing – Engine

- Wire Harness Diagram – Engine

- Wire Harness – Headlights

- Wire Harness – Cab Rooftop

- Wire Harness – Cab Control Panel

- Wire Harness – Cab Heat, Air Conditioning

- Wire Harness – InchMode (optional)

- Wire Harness – Loader Selector Control Valve (SCV) Switch (optional)

- Wire Harness – Loader Selector Control Valve (SCV) Valve (optional)

- Wire Harness – Rear Selector Control Valve (SCV) Kit (optional)

- Wire Harness – Cab Work Light Kit (optional)

- Wire Harness – Domestic Road Light Kit (optional)

- Wire Harness – Turn Signal, Hazard Lights (optional)

- Wire Harness – International Road Light Kit (optional)

Rate this product

You may also like