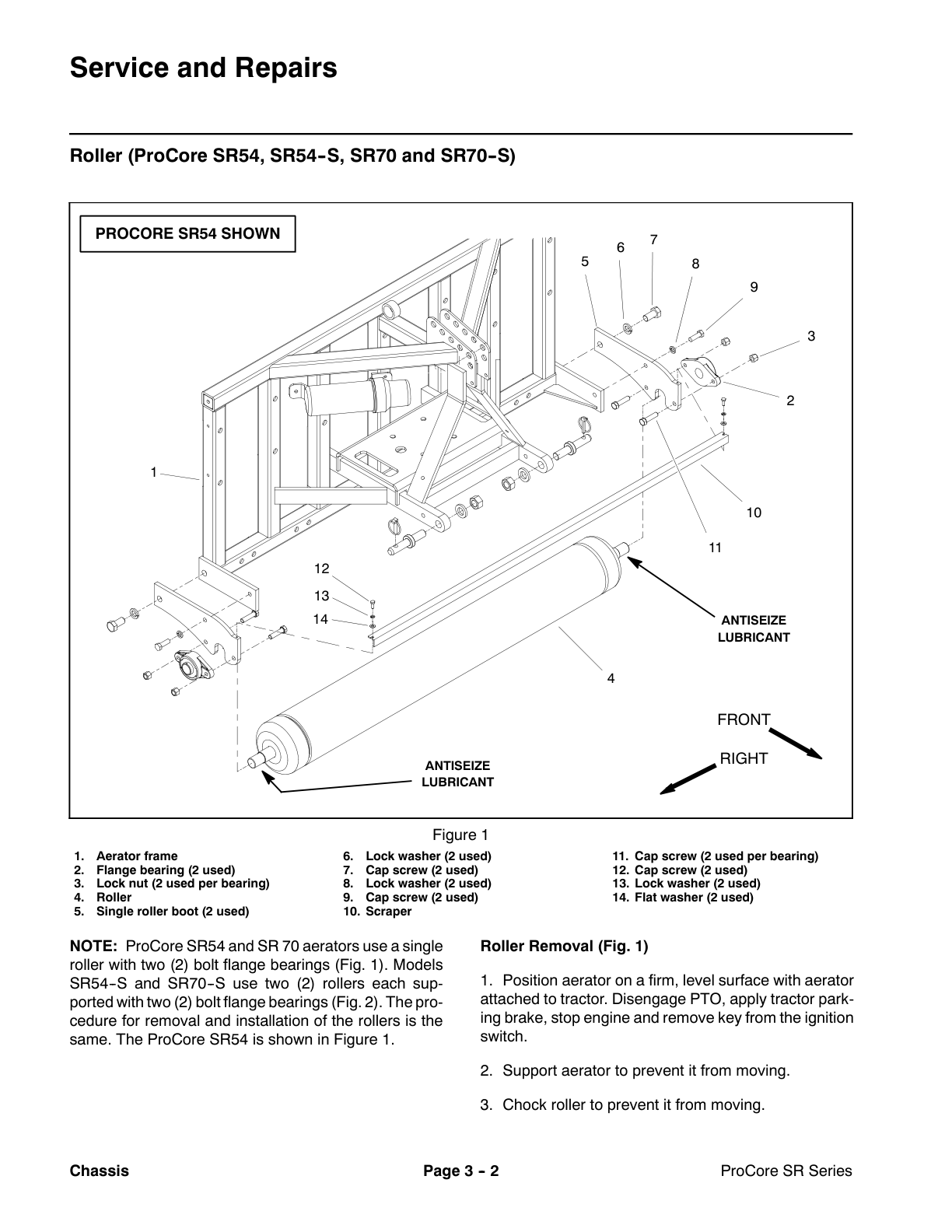

Description

Table of Content – Groundsmaster 7200, 7210 (with Kubota Engine)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- General Safety Instructions

- Supervisors Responsibilities

- Before Operating

- While Operating

- Maintenance and Service

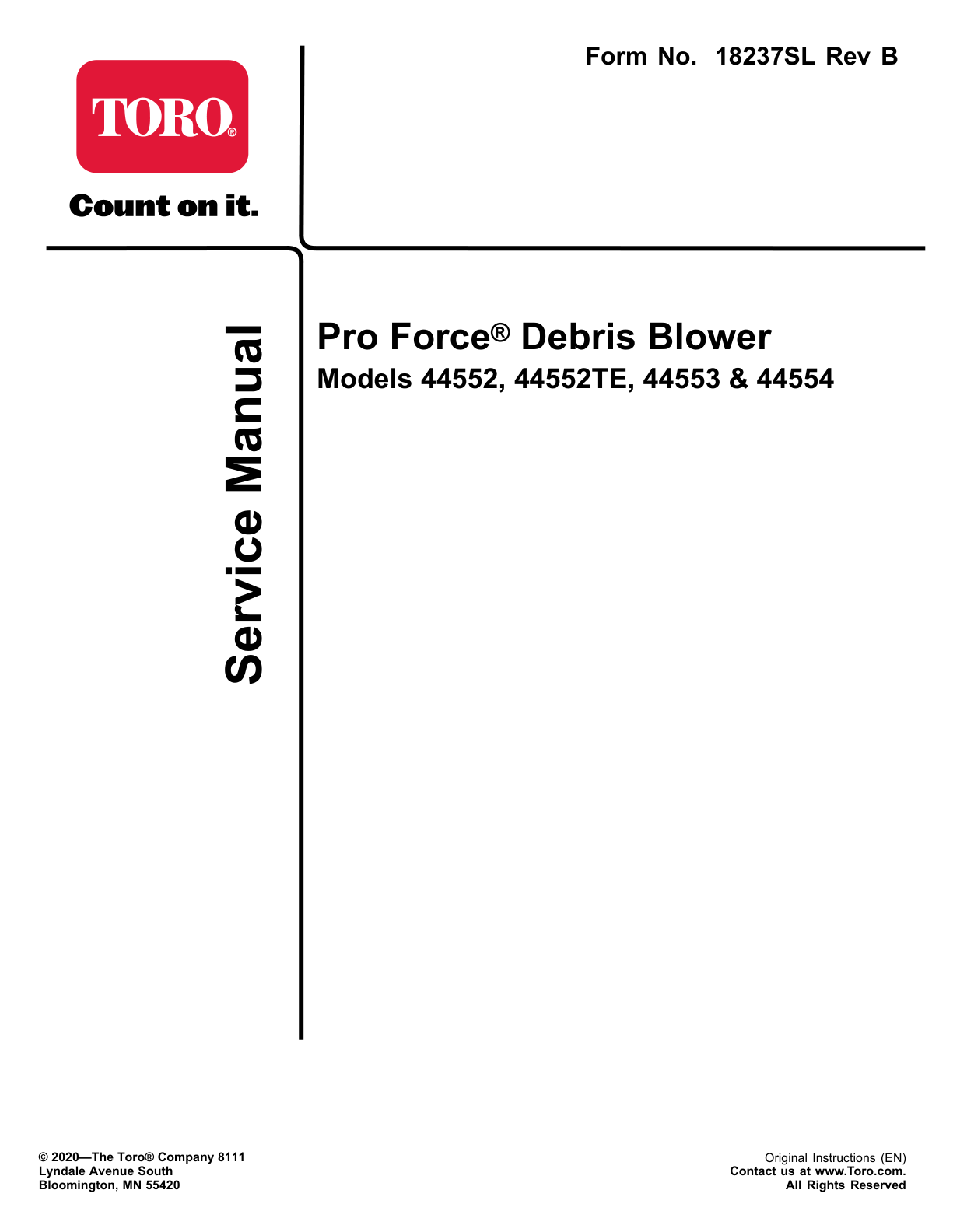

- Jacking Instructions

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- 3 – Kubota Diesel Engine

- Specifications: Groundsmaster 7200

- Specifications: Groundsmaster 7210

- General Information

- Operators Manual

- Stopping the Engine (Groundsmaster 7210)

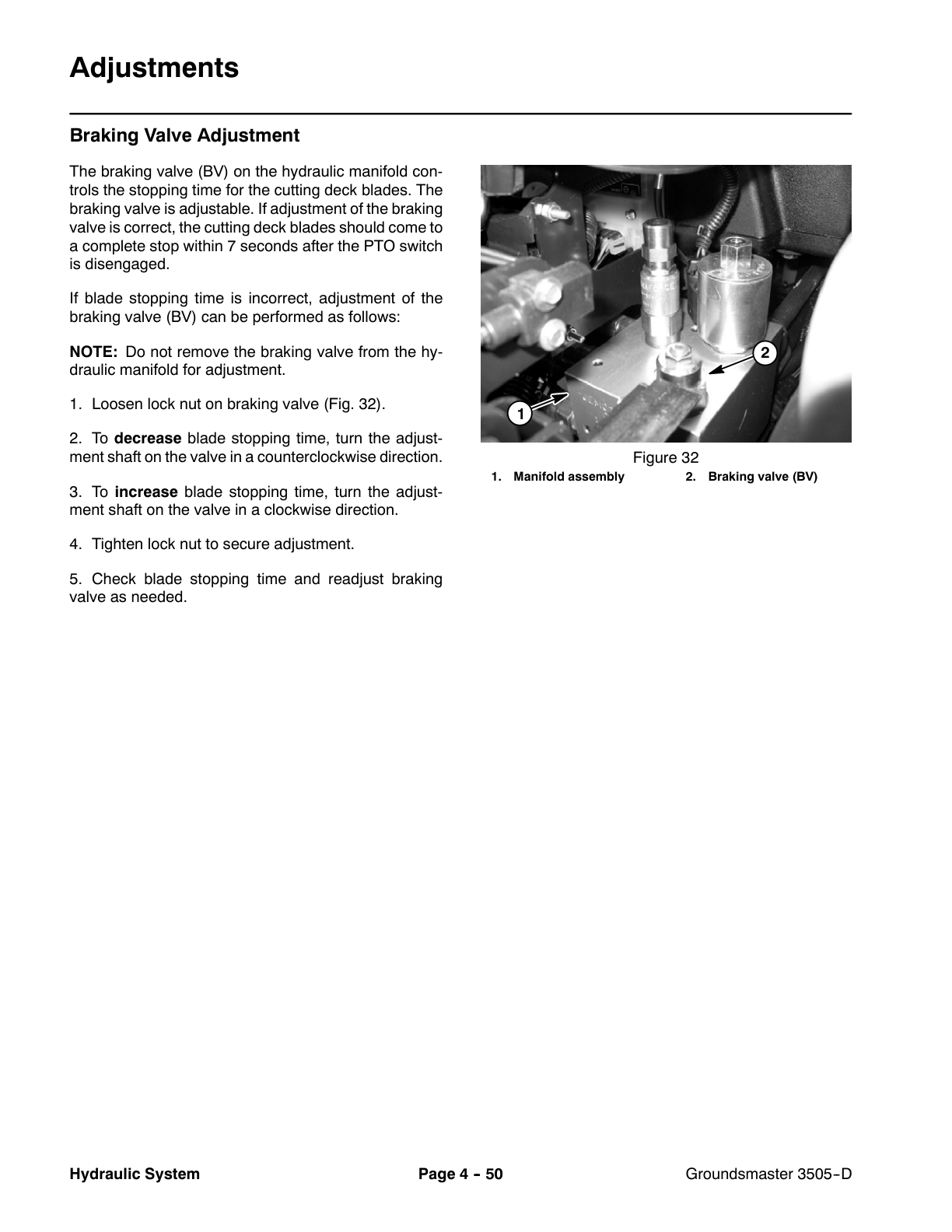

- Adjustments

- Adjust Throttle Control

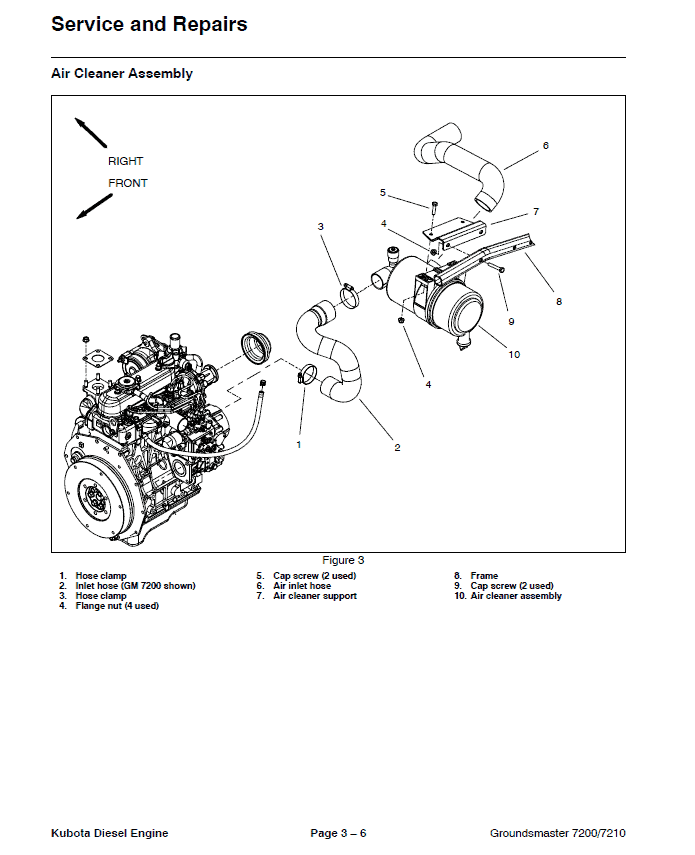

- Service and Repairs

- Air Cleaner Assembly

- Exhaust System

- Fuel System

- Radiator

- Engine

- Kubota 05 E2B Series Workshop Manual (S.N below 280000000)

- Kubota 05-E3B Series Workshop Manual (S.N 280000001 and up)

- Kubota 05-E4B Series Workshop Manual

- 4 – Hydraulic System

- Specifications

- General Information

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Operators Manual

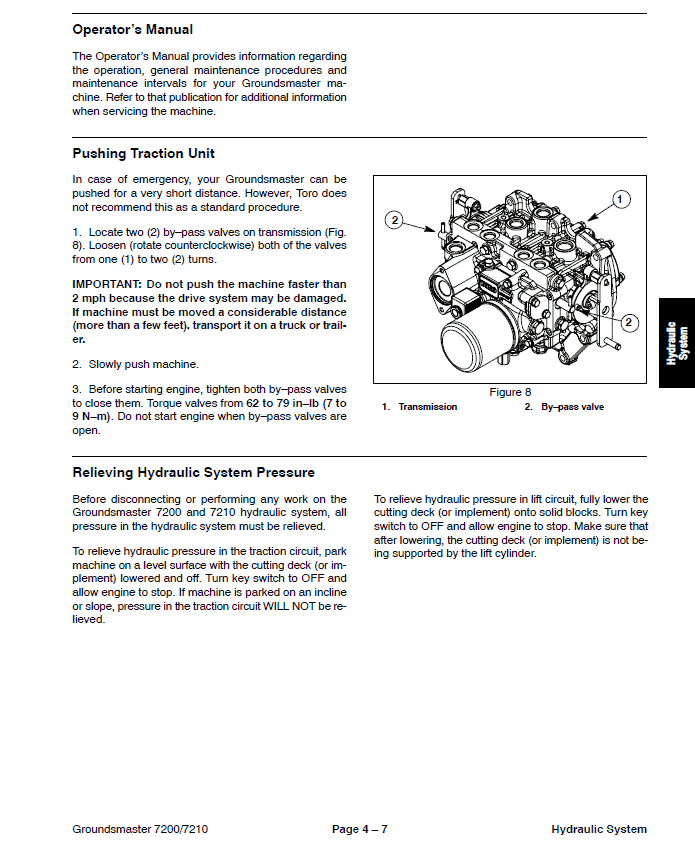

- Pushing Traction Unit

- Relieving Hydraulic System Pressure

- Traction Circuit (Closed Loop) Component Failure

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuits

- Lift Circuit (Raise)

- Lift Circuit (Lower)

- PTO Circuit

- Special Tools

- Hydraulic Pressure Test Kit

- 15GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Test Fitting Kit

- O-ring Kit

- High Flow Hydraulic Filter Kit

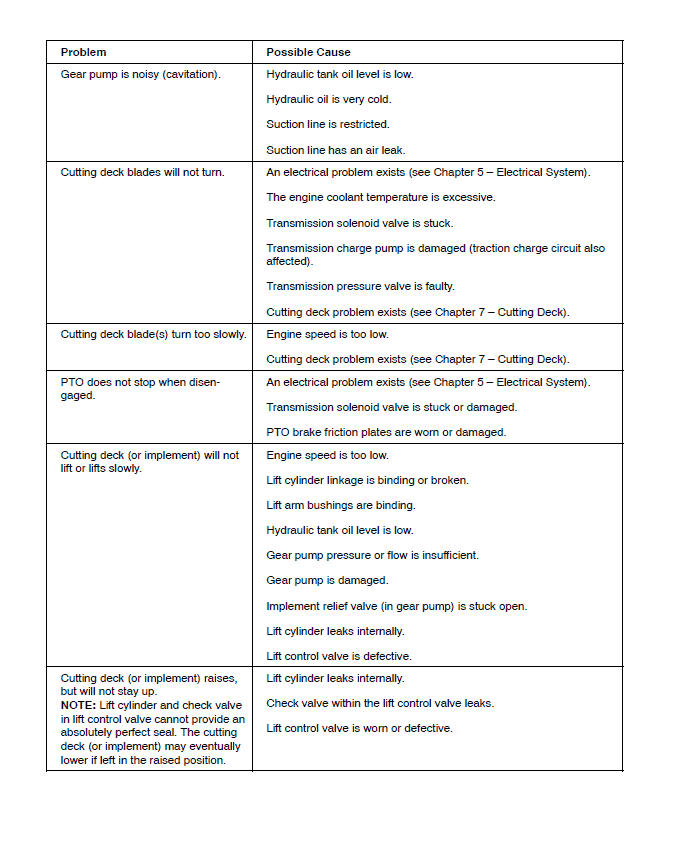

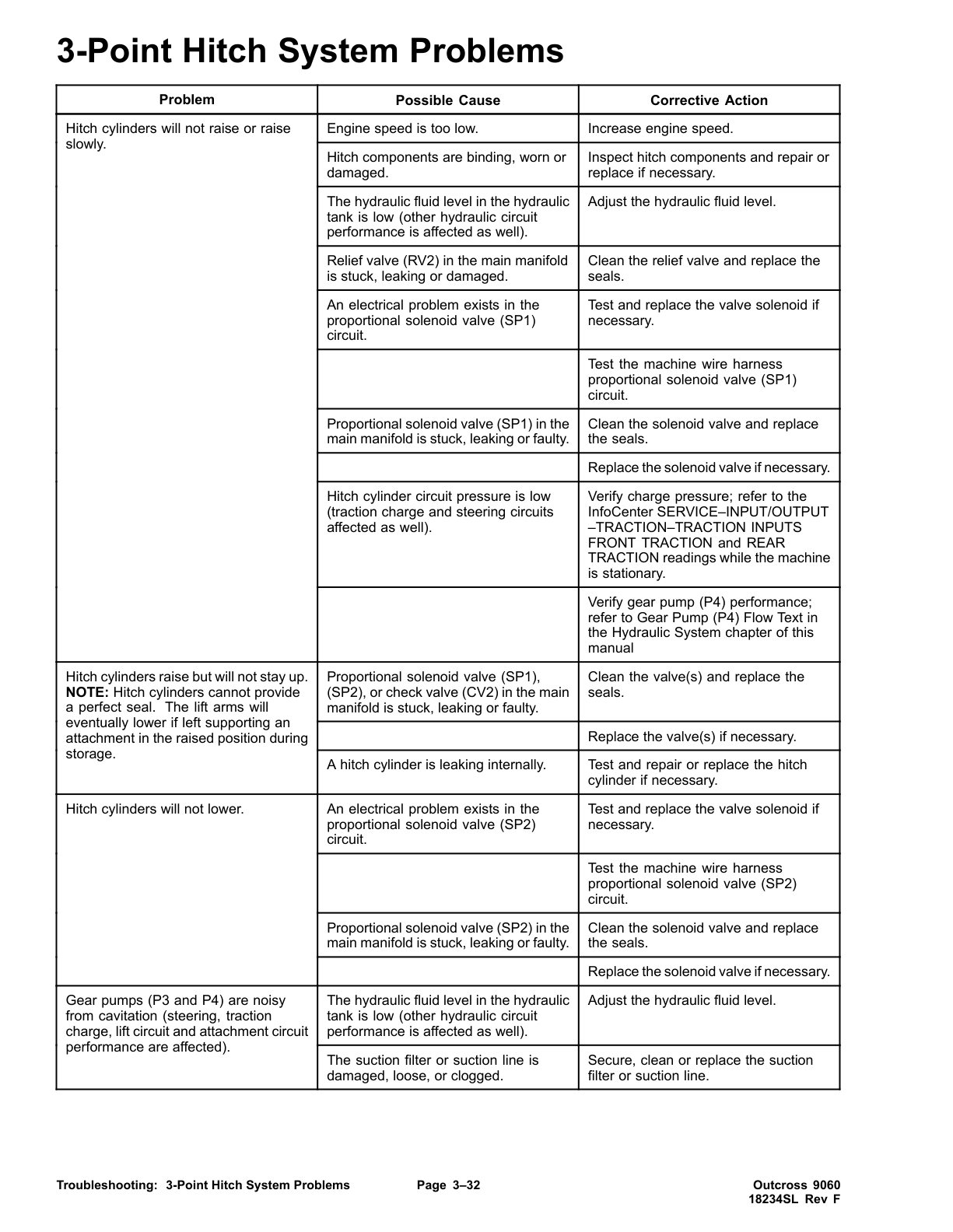

- Troubleshooting

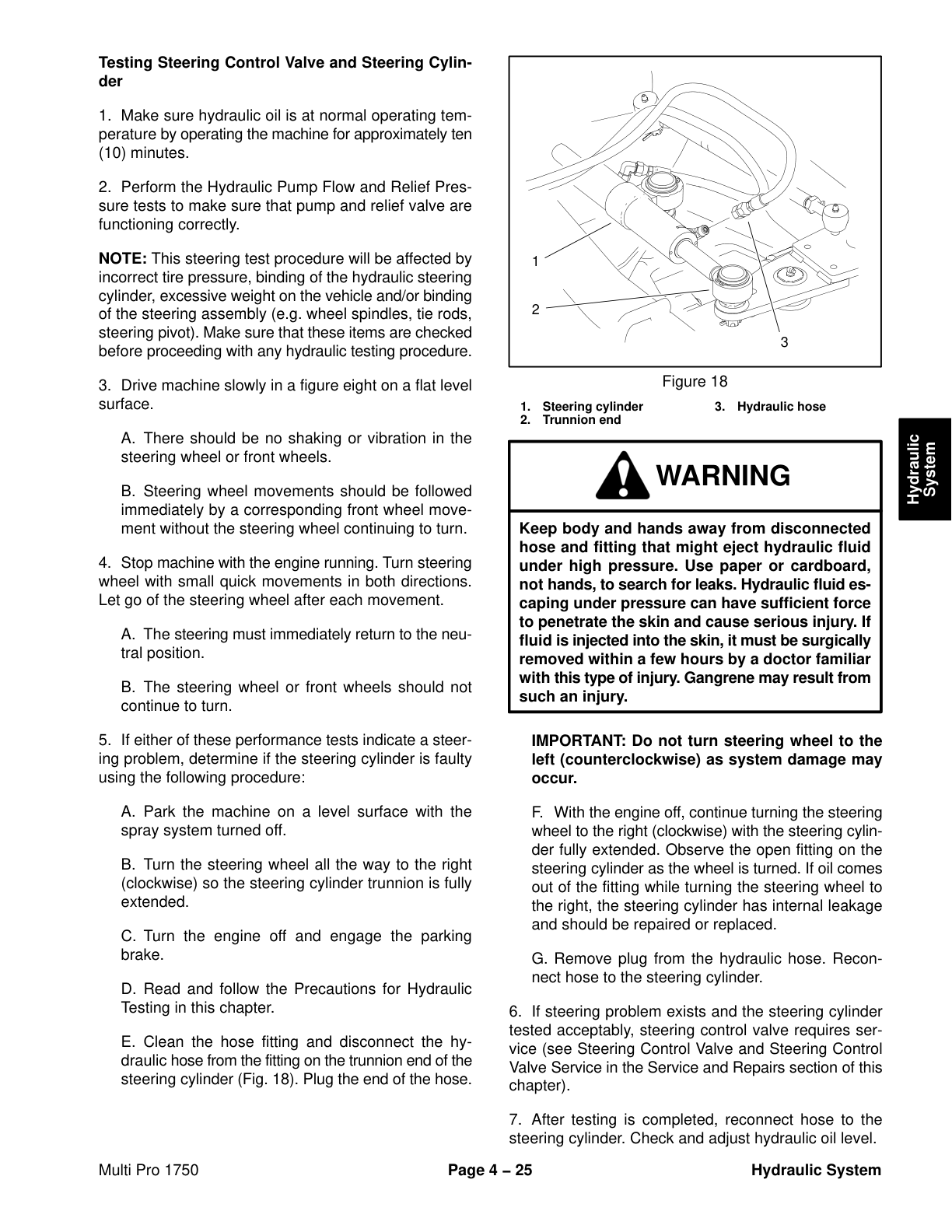

- Testing

- Traction System Operation Testing

- Charge Relief Valve Pressure Test (Using Pressure Gauge)

- Transmission Piston Pump Flow Test (Using Tester with Pressure Gauges and Flow Meter)

- Traction Relief Valve Pressure Test (Using Tester with Pressure Gauges and Flow Meter)

- Wheel Motor Efficiency Test (Using Tester with Pressure Gauges and Flow Meter)

- PTO Pressure Valve Test (Using Pressure Gauge)

- Implement Relief Pressure Test (Using Pressure Gauge)

- Gear Pump Flow Test (Using Tester with Pressure Gauges and Flow Meter)

- Lift Cylinder Internal Leakage Test

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Flush Hydraulic System

- Charge Hydraulic System

- Hydraulic Tank

- Wheel Motors

- Wheel Motor Service

- Transmission

- Transmission Service

- Gear Pump

- Gear Pump Service

- Manual Lift Control Valve (SN Below 313000000)

- Manual Lift Control Valve Service (SN Below 313000000)

- Lift Control Manifold (SN Above 313000000)

- Lift Control Manifold Service (SN Above 313000000)

- Polar TracTM Hydraulic Control Valve

- Polar TracTM Hydraulic Control Valve Service

- Lift Cylinder

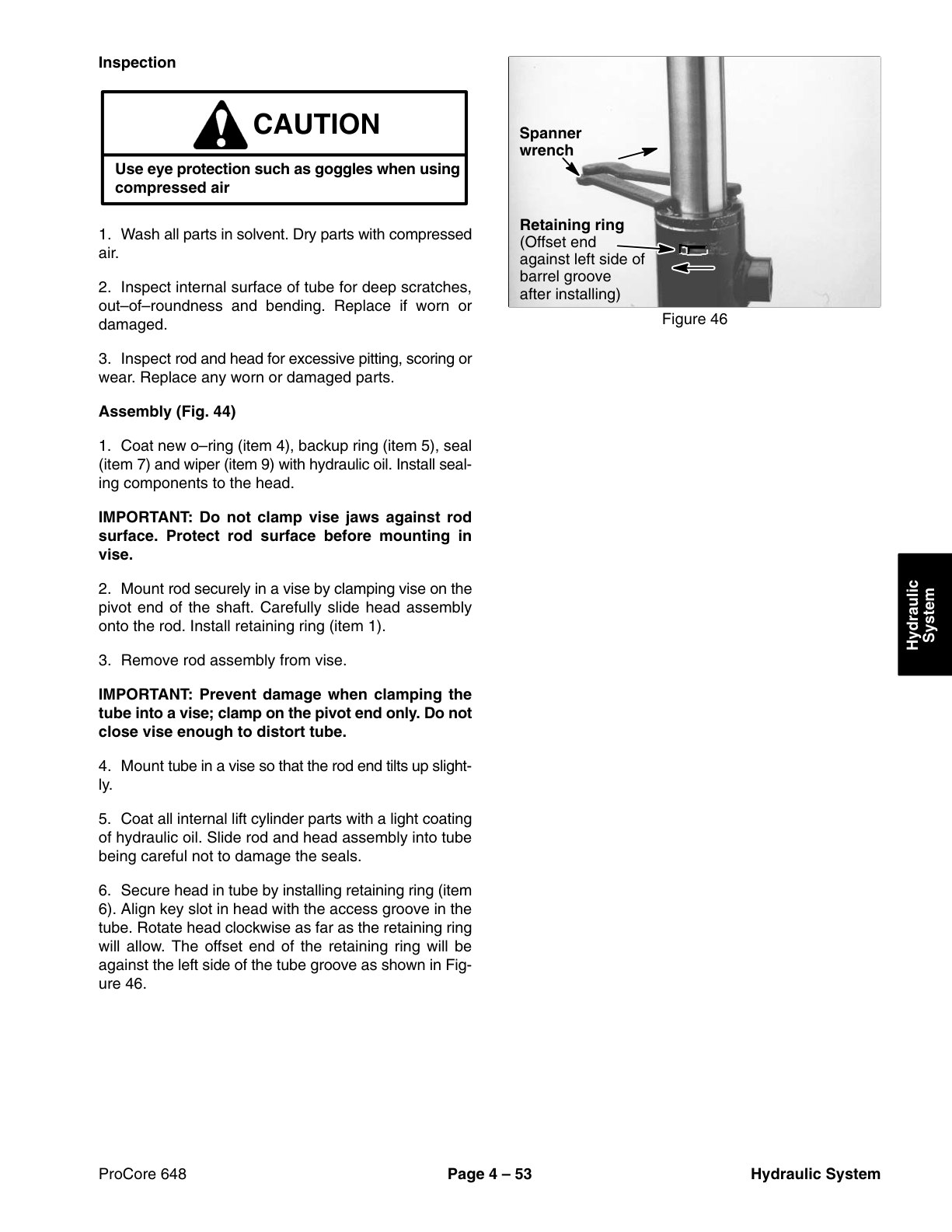

- Lift Cylinder Service

- Polar TracTM Lift Cylinder

- Polar TracTM Lift Cylinder Service

- Oil Cooler

- Parker Torqmotor Service Procedure

- 5 – Electrical System

- Electrical Schematics and Diagrams

- Special Tools

- Multimeter

- Battery Terminal Protector

- Dielectric Gel

- Battery Hydrometer

- Troubleshooting

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test

- Check Operation of Interlock Switches

- Component Testing

- Ignition Switch

- Indicator Lights

- Hour Meter

- PTO Switch

- Neutral Switches

- Seat Switch

- Parking Brake Switch (SN Below 310000000)

- Parking Brake Switch (SN Above 310000000)

- Standard Control Module

- Standard Control Module Logic Chart

- PTO Solenoid Valve Coil

- Lift Control Manifold Solenoid Valve Coils (SN Above 313000000)

- Fusible Link Harness

- Diode Assembly

- Glow Relay

- High Temperature Warning Switch

- High Temperature Shutdown Switch

- Dual Temperature Switch (Polar TracTM Machines)

- Deck Lift, Lower Switch (SN Above 313000000)

- Fuel Pump

- Fuel Stop Solenoid

- Glow Controller

- Service and Repairs

- PTO Solenoid Valve Coil

- Battery Storage

- Battery Care

- Battery Service

- 6 – Chassis

- Specifications

- General Information

- Operators Manual

- Service and Repairs

- Rear Wheels

- Polar TracTM Wheels

- Parking Brakes

- Parking Brake Service

- Parking Brake Assembly

- Front Castor Wheels

- Polar TracTM Wheel Hub Service

- PTO Drive Shaft

- PTO Drive Shaft Cross and Bearing Service

- Cutting Deck Lift Arms

- Operator Seat

- Operator Seat Service

- Hood

- 7 – Cutting Deck

- General Information

- Specifications

- Operators Manual

- Factors That Can Affect Cutting Performance

- Service and Repairs

- Blade Stopping Time

- Cutting Deck Removal and Installation

- Idler Assembly

- Blade Spindle

- Blade Spindle Service

- Gearbox

- Cutting Deck Pull Links

- 8 – Foldout Diagrams

- Electrical Drawing Designations

- Hydraulic Schematics

- Hydraulic Schematic (SN Below 313000000)

- Hydraulic Schematic (SN Below 313000000) with Rear Attach Lift Kit

- Hydraulic Schematic (SN Below 313000000) with Polar Trac Installed)

- Hydraulic Schematic (SN Below 313000000) with Polar Trac and Rear Attach Lift Kit

- Hydraulic Schematic (SN From 313000001 to 314999999)

- Hydraulic Schematic (SN Above 315000000)

- Electrical Schematics

- SN Below 313000000

- SN Below 313000000 (With Optional Kits Shown)

- SN 313000000 to 403440000 (With Optional Kits Shown)

- SN Above 403440001 (With Optional Kits Shown)

- Circuit Diagrams

- Glow Circuits

- Crank Circuits

- Run Circuits

- Run Circuits (PTO Engaged)

- Wire Harness

- SN Below 310000000

- SN From 310000001 to 312999999

- SN 313000001 to 403440000

- SN Above 403440001

Rate this product

You may also like