Description

Table of Content – Groundsmaster 4500-D, 4700-D (Model 30857, 30858)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- 3 – Kubota Diesel Engine

- Specifications

- General Information

- Stopping the Engine

- Service and Repairs

- Air Filter System

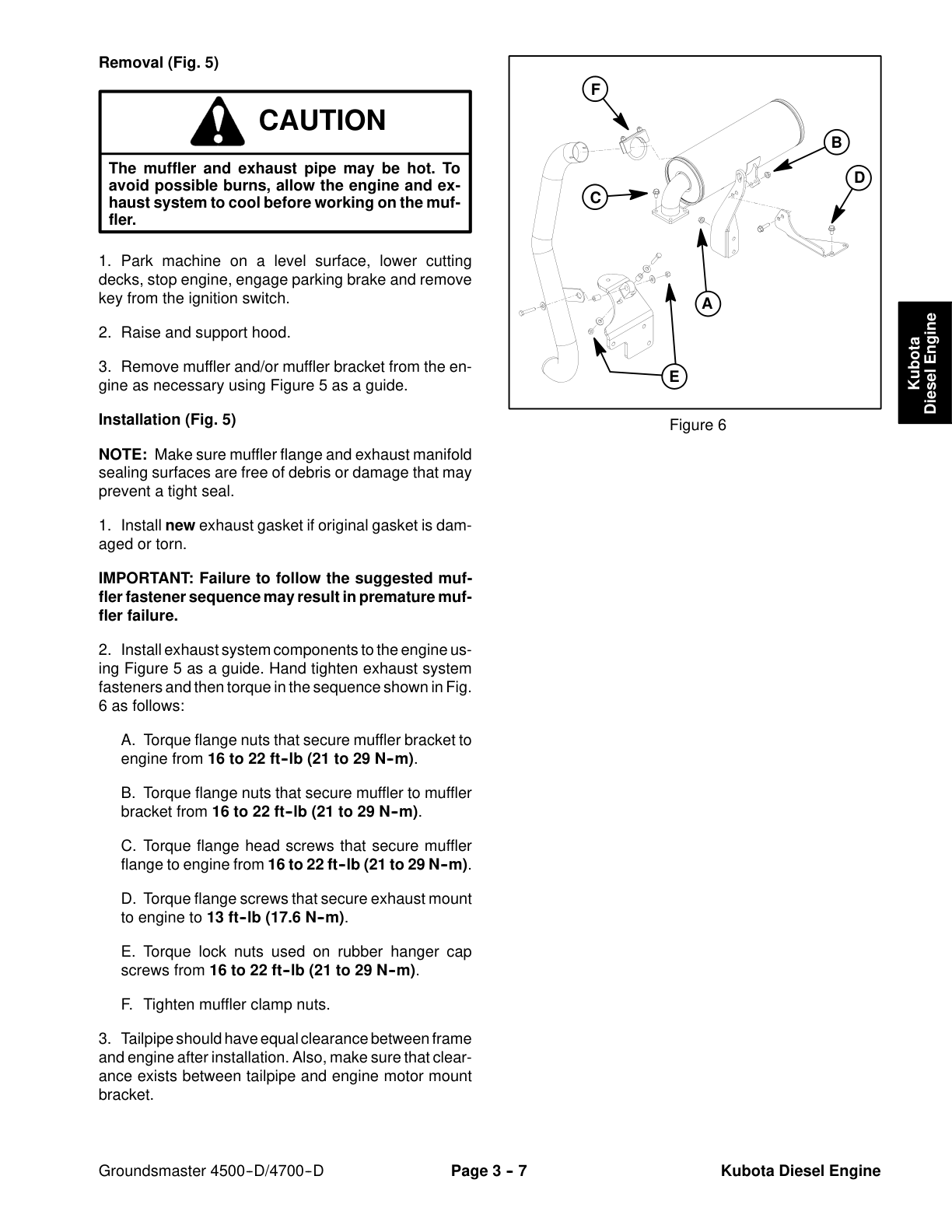

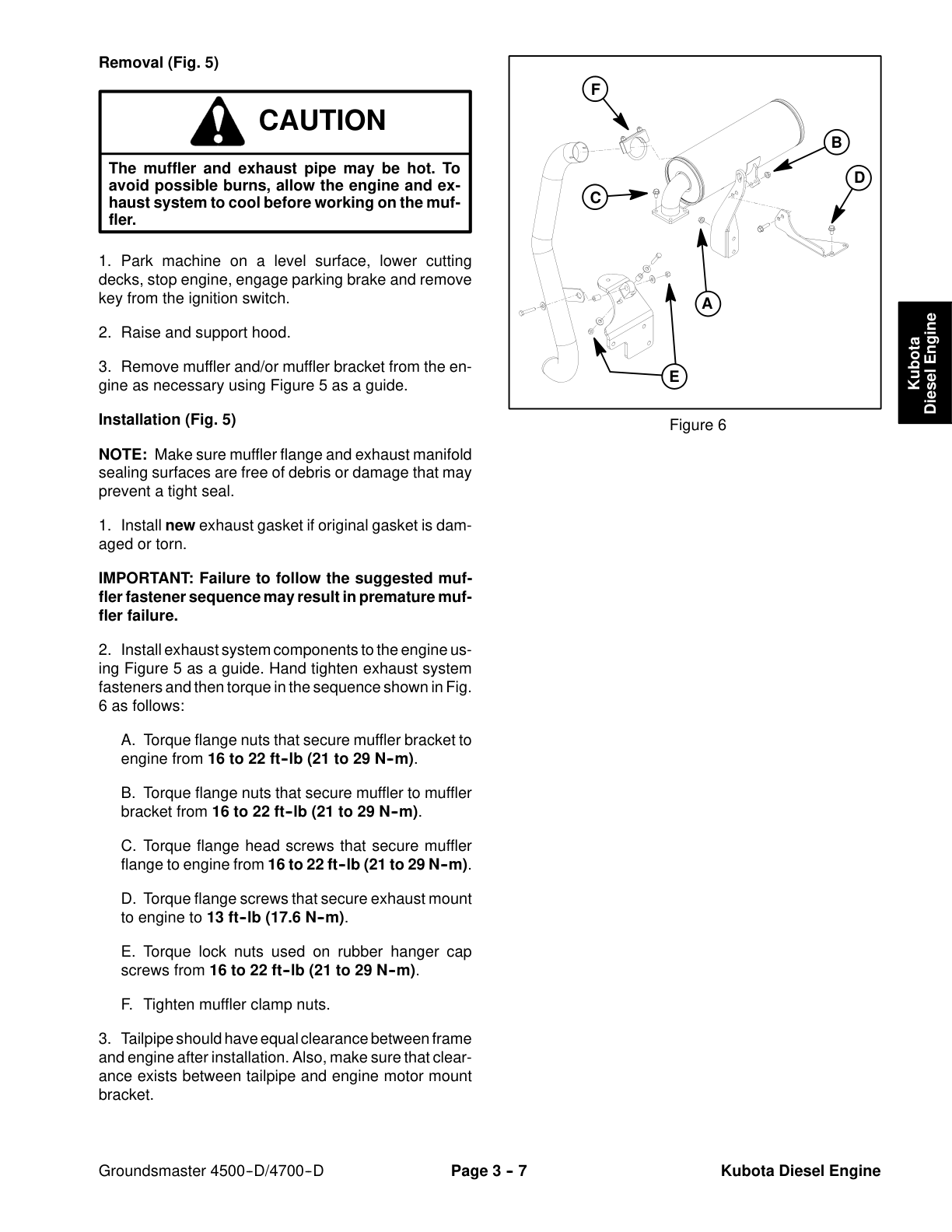

- Exhaust System

- Fuel System

- Radiator

- Engine

- Pump Adapter Plate

- Kubota Diesel Engine Workshop Manual

- 4 – Hydraulic System

- Specifications

- General Information

- Operator’s Manual

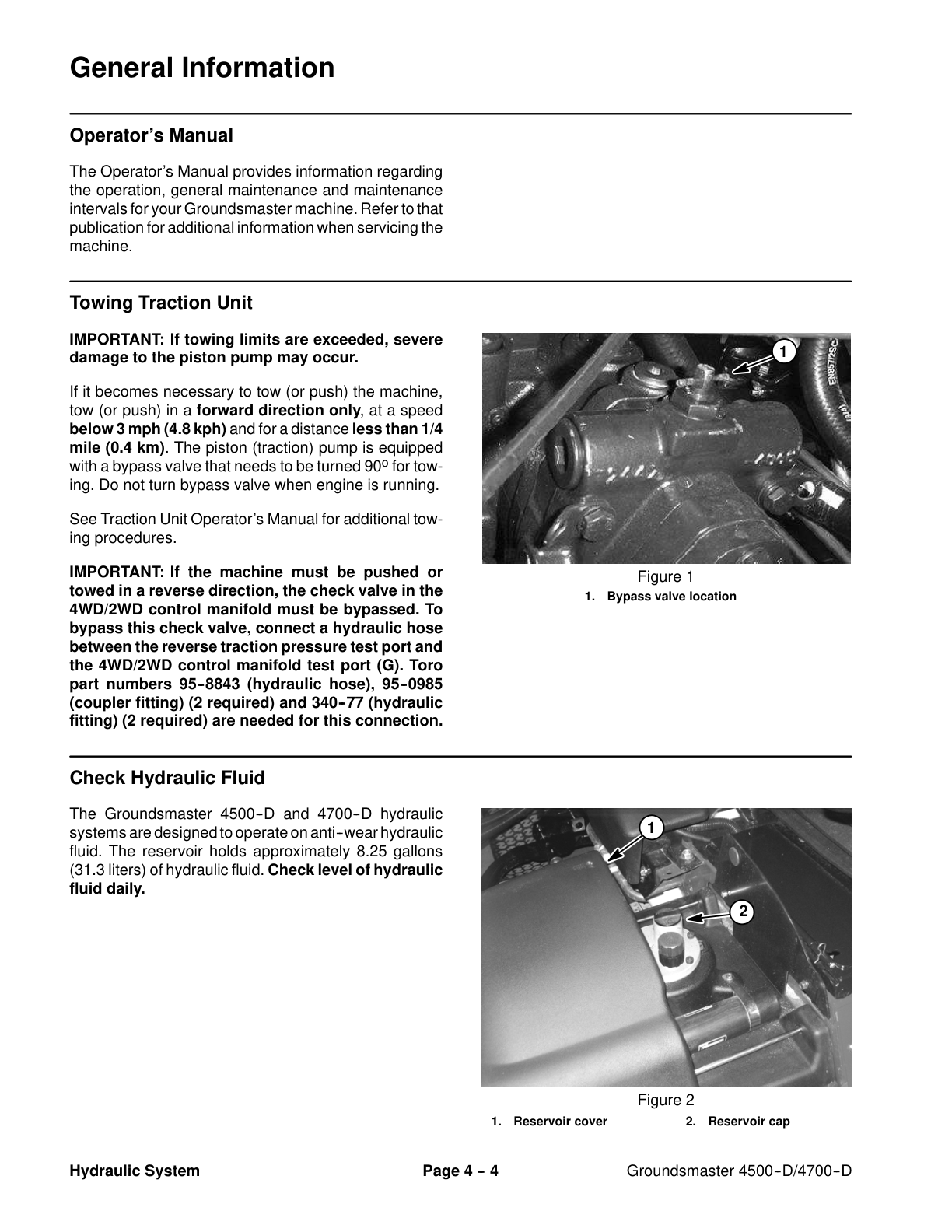

- Towing Traction Unit

- Check Hydraulic Fluid

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O–Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O–Ring Fitting into Component Port)

- Hydraulic Schematics

- GM4500

- GM4700

- Hydraulic Flow Diagrams

- Traction Circuit: Low Speed

- Traction Circuit: High Speed

- Lower Cutting Decks: GM4500

- Lower Cutting Decks: GM4700

- Raise Cutting Decks: GM4500

- Raise Cutting Decks: GM4700

- Mow Circuit

- Cutting Deck Blade Braking

- Steering Circuit

- Engine Cooling Fan Circuit

- Special Tools

- Hydraulic Pressure Test Kit

- Hydraulic Tester (Pressure and Flow)

- Hydraulic Test Fitting Kit

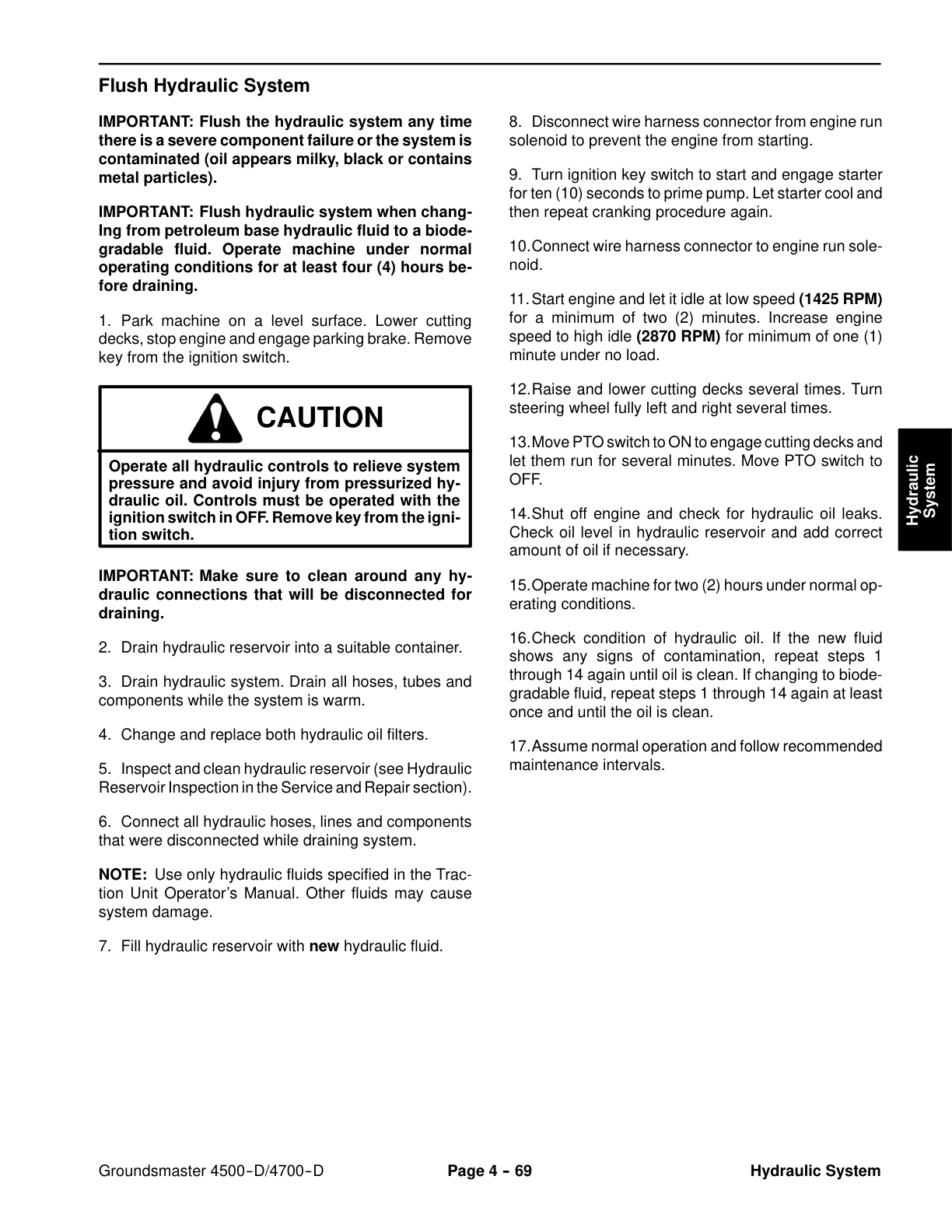

- Measuring Container

- O–ring Kit

- High Pressure Hydraulic Oil Filter

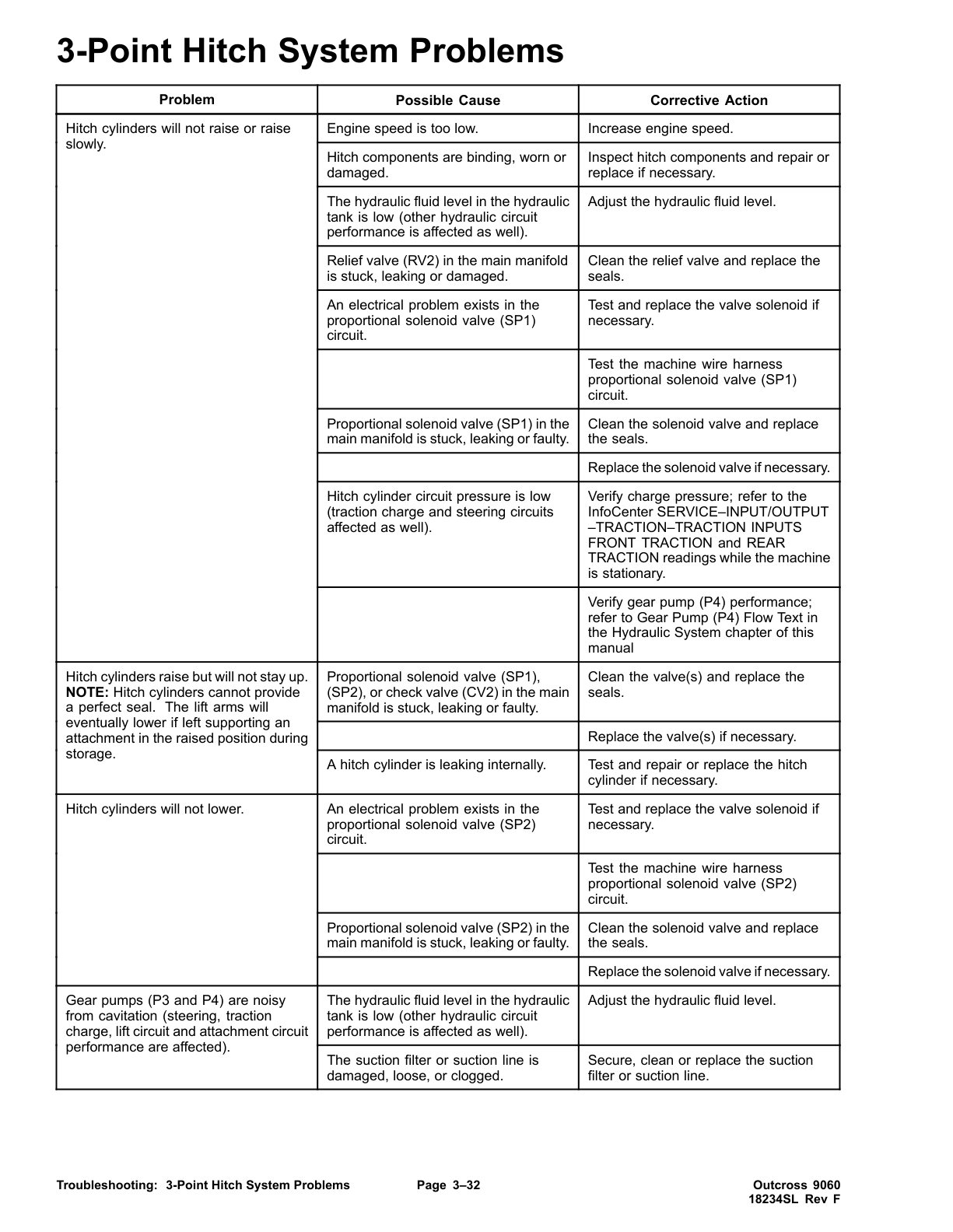

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- PTO Problems

- Steering Circuit Problems

- Lift, Lower Circuit Problems

- Engine Cooling Fan Circuit Problems

- Testing

- Traction Circuit Charge Pressure (Using Pressure Gauge)

- Traction Circuit Relief Pressure (Using Pressure Gauge)

- Rear Traction Circuit Relief (RV) Pressure (Using Pressure Gauge)

- Traction Circuit Reducing Valve (PR) Pressure (Using Pressure Gauge)

- Cutting Deck Circuit Pressure (Using Pressure Gauge)

- Cutting Deck Circuit Relief Pressure (Using Tester with Pressure Gauges and Flow Meter)

- Cutting Deck Motor Case Drain Leakage (Using Tester with Pressure Gauges and Flow

- Gear Pump P1 and P2 Flow (Cutting Deck Circuits) (Using Tester with Pressure Gauges

- Steering Circuit Relief Pressure (Using Pressure Gauge)

- Lift, Lower Circuit Relief Pressure (Using Pressure Gauge)

- Gear Pump P3 Flow (Steering and Lift, Lower Circuits) (Using Tester with Pressure

- Cooling Fan Circuit (Using Pressure Gauge and Phototac)

- Gear Pump P4 Flow (Cooling Fan Circuit) (Using Tester with Pressure Gauges and Flow

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Flush Hydraulic System

- Charge Hydraulic System

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- 4WD, 2WD and Filtration, Charge Control Manifolds

- 4WD, 2WD Control Manifold Service

- Filtration, Charge Control Manifold Service

- Rear Axle Motor

- Front Wheel Motors

- Rear Axle and Front Wheel Motor Service

- Cutting Deck Motor

- Cutting Deck Motor Service

- Deck Control Manifold

- Deck Control Manifold Service (GM 4500–D)

- Deck Control Manifold Service (GM 4700–D)

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Engine Cooling Fan Motor

- Engine Cooling Fan Motor Service

- Fan Control Manifold

- Fan Control Manifold Service

- Lift Control Manifold

- Lift Control Manifold Service (GM 4500–D)

- Lift Control Manifold Service (GM 4700–D)

- Lift Circuit Junction Manifold

- Lift Cylinders: Decks #1, #4 and #5

- Lift Cylinders: Decks #2 and #3

- Lift Cylinders: Decks #6 and #7 (GM 4700–D)

- Lift Cylinder Service

- Hydraulic Reservoir

- Hydraulic Oil Cooler

- Eaton Piston Pump Repair Information

- Eaton Piston Motor Repair Information

- Danfoss Steering Unit Service Repair Manual

- 5 – Electrical System

- General Information

- Operator’s Manual

- Toro Electronic Controllers (TEC)

- CAN–bus Communications (Groundsmaster 4700–D

- Electrical Drawings

- Special Tools

- Multimeter

- Skin–Over Grease

- Battery Hydrometer

- Diagnostic Display

- Troubleshooting

- Diagnostic Display

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Electrical System Quick Checks

- Check Operation of Interlock Switches

- Glow Plug System Test

- Charging System Test

- Battery Test (Open Circuit Test)

- Component Testing

- Ignition Switch

- Fuses

- Indicator Lights

- PTO Switch

- Cutting Deck Lift Switches

- Hi–Low Speed and Headlight Switches

- Engine Cooling Fan Switch

- Seat Switch

- Parking Brake Switch

- Cutting Deck Position Switch

- Hour Meter

- Temperature Gauge

- Glow and Main Power Relays

- Start Relay

- Hydraulic Solenoid Valve Coils

- Engine Coolant and Hydraulic Oil Temperature Senders

- Fuel Pump

- Temperature Sender

- Traction Neutral Switch

- Service and Repairs

- Battery Storage

- Battery Care

- Battery Service

- Hydraulic Solenoid Valve Coil

- 6 – Axles, Planetaries and Brakes

- Table of Contents

- Specifications

- General Information

- Operator’s Manual

- Adjustments

- Planetary Drive Endplay (OPH-2 series planetary drives)

- Service and Repairs

- Brake Assembly

- Brake Inspection and Repair

- Planetary Drive Assembly

- OPH-2 Series Planetary Drive Service

- VA02 Series Planetary Drive Service

- Rear Axle Assembly

- Rear Axle Service

- Bevel Gear Case and Axle Case

- Differential Shafts

- Axle Shafts

- Input Shaft, Pinion Gear

- Differential Gear

- Pinion Gear to Ring Gear Engagement

- 7 – Chassis

- General Information

- Operator’s Manual

- Cutting Deck Identification

- Service and Repairs

- Steering Column

- Console Arm

- Lift Arms for Cutting Decks #1, #4 and #5

- Lift Arms for Cutting Decks #2 and #3

- Lift Arms for Cutting Decks #6 and #7 (Groundsmaster 4700–D)

- Operator Seat

- Operator Seat Service

- Operator Seat Suspension

- Hood

- 8 – Cutting Decks

- Specifications

- General Information

- Operator’s Manual

- Troubleshooting

- Factors That Can Affect Quality of Cut

- Special Tools

- Rear Roller Bearing and Seal Installation Tools

- Spindle Plug

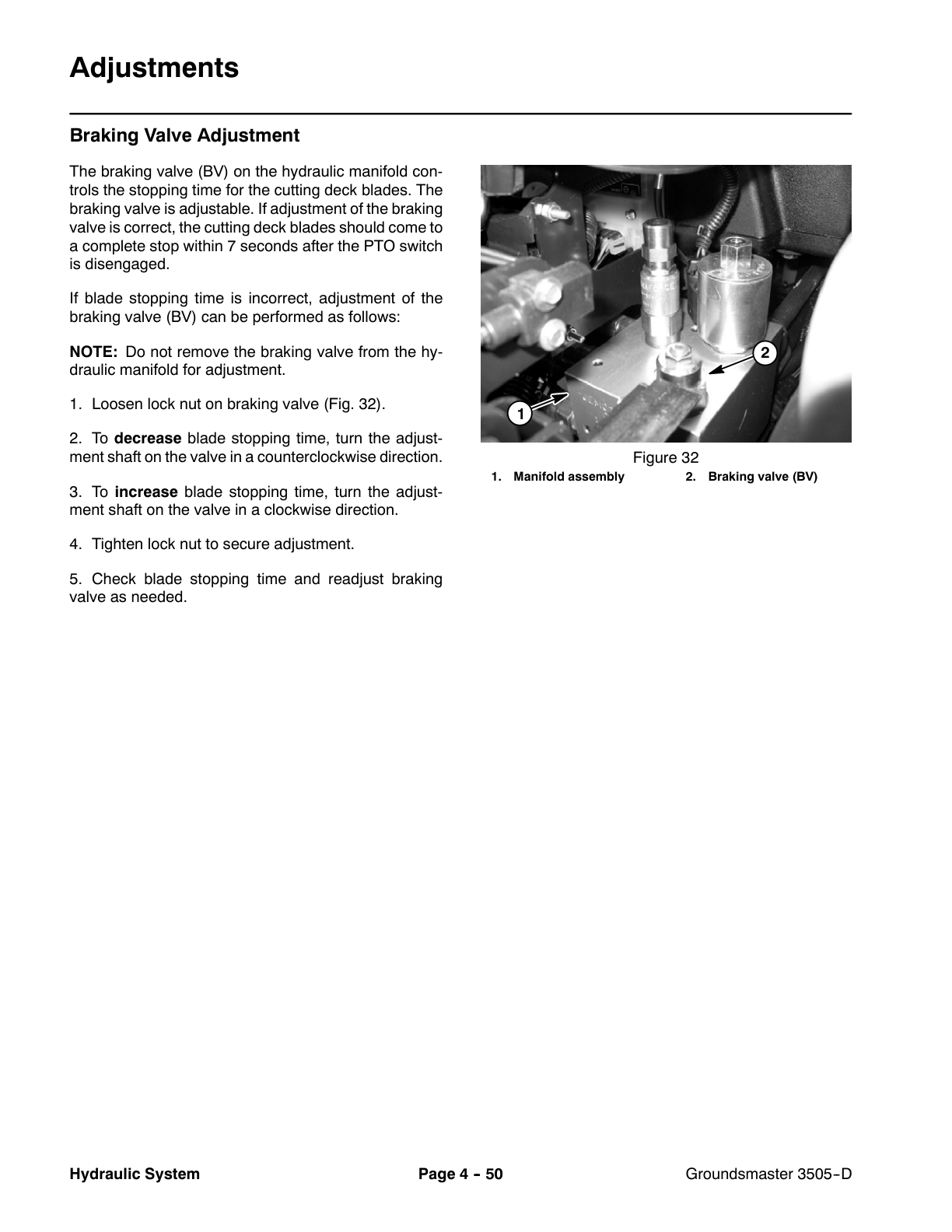

- Adjustments

- Blade Stopping Time

- Service and Repairs

- Blade Spindle Assembly

- Blade Spindle Service

- Rear Roller

- Rear Roller Service

- Front Roller Service

- Cutting Deck Carrier Frame

- 9 – Foldout Drawings

- Hydraulic Schematics (2)

- Electrical Schematics (3)

- Main Wire Harness

- Main Wire Diagram

- Seat and Console Wire Harness

- Seat and Console Wire Diagram

- Power Center Wire Harness

- Power Center Wire Diagram

- Deck 6 and 7 Wire Harness

- Deck 6 and 7 Wire Diagram

Rate this product

You may also like