Caterpillar NR14N2L to NR25N2X Operation and Maintenance Manual 621185 EN-E

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 621185

- Language: EN-E

- Number of Pages: 183

- Size: 21.4MB

- Format: PDF

-

Model List:

- NR14N2L, NR16N2L, NR14N2S, NR14N2HS, NR16N2S, NR16N2HS, NR16N2, NR16N2H, NR16N2C, NR16NHC, NR20N2H, NR20N2X, NR25N2X

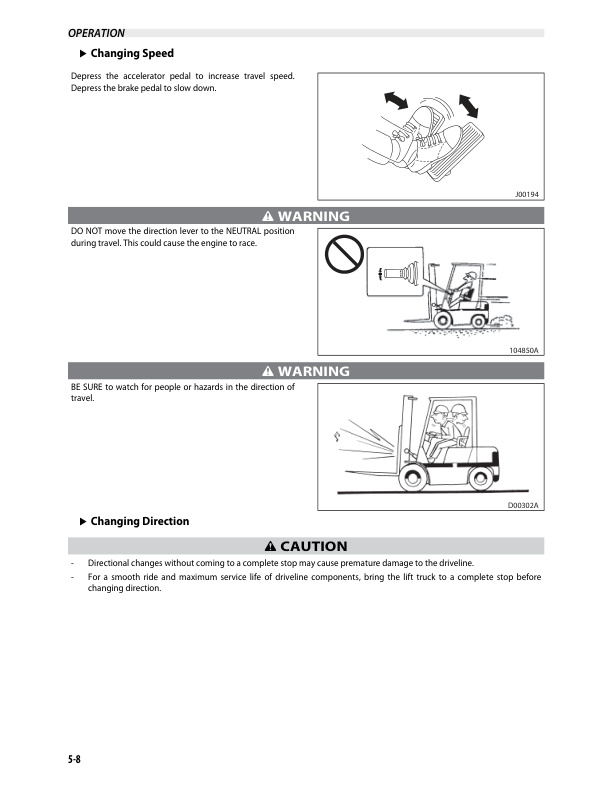

- 1. Contents

- 2. Foreword

- 3. How to read this manual

- 3.1. Safety-related signs

- 3.2. Symbols and abbreviations

- 3.2.1. Safety symbols

- 4. Safety instructions

- 4.1. Safety requirements for industrial trucks

- 4.2. Electromagnetic compatibility

- 4.3. Non-ionizing radiation

- 4.4. Noise

- 4.5. Vibration

- 4.6. Instructions for site supervision

- 4.7. Occupational safety

- 4.8. Requirements for the truck operator

- 4.9. Emergency procedures

- 4.10. Stability

- 4.10.1. Center of gravity

- 4.10.2. Capacity of the lift truck

- 4.11. Work at dangerous premises

- 4.12. Repairs and structural modifications

- 5. Operating environment

- 5.1. Surface requirements

- 5.2. Bearing capacity of the floor

- 5.3. Operating temperature

- 5.4. Wind forces

- 5.5. Lighting

- 5.6. Driveways

- 5.7. Free space

- 5.8. Ramps

- 5.9. Loading bridges

- 5.10. Elevators

- 6. General information

- 6.1. Truck

- 6.1.1. Intended use

- 6.1.2. Prohibited use

- 6.2. Identification plates on the truck

- 6.3. Overview of the truck

- 6.3.1. Overhead guard

- 6.3.2. Load backrest

- 6.3.3. Cabin (option)

- 6.3.4. Emergency exits (cabin truck only)

- 6.3.5. Operating devices

- 6.3.6. Control panel

- 6.3.7. Steering wheel

- 6.3.8. Armrest

- 6.3.9. Dual joystick armrest

- 6.3.10. Display panel

- 6.3.11. Truck operation modes

- 6.3.12. Truck display

- 6.3.12.1. Display control buttons

- 6.3.12.2. Main view of the truck display

- 6.3.12.3. Hierarchy of the truck display menus

- 6.3.13. Pedals

- 6.3.13.1. Accelerator pedal, operator pedal and brake pedal

- 6.3.13.2. Dual pedal and brake pedal

- 6.3.13.3. Pedal functionalities

- 6.3.14. Operators seat

- 6.3.15. Drive unit, hydraulic system and instrument panel

- 6.3.15.1. Instrument panel

- 6.3.15.2. Hydraulic system

- 6.3.15.3. Drive unit

- 6.3.16. Mast

- 7. Assembly and commissioning

- 8. Batteries

- 8.1. Lead-acid batteries

- 8.1.1. General information

- 8.1.2. Safety signs for lead-acid batteries

- 8.1.3. Requirements for the battery charging areas

- 8.1.4. Charge the battery

- 8.1.5. Measure the specific gravity of the battery water

- 8.1.6. Battery maintenance

- 8.1.6.1. How to clean batteries with a damp cleaning cloth

- 8.1.6.2. How to clean batteries with high-pressure cleaning equipment

- 8.1.6.3. Daily maintenance

- 8.1.6.4. Weekly maintenance

- 8.1.6.5. Monthly maintenance

- 8.1.6.6. Annual maintenance

- 8.1.7. Malfunctions

- 8.1.8. Acquire a new battery

- 8.1.9. Replace the battery

- 8.1.9.1. Quick battery replacement

- 8.1.10. Guide the battery connector cables

- 8.1.11. Storage

- 8.2. Lithium-ion batteries

- 8.2.1. General information

- 8.2.2. Safety signs

- 8.2.3. Requirements for the battery charging areas

- 8.2.4. Charge the battery

- 8.2.4.1. Recharging a lithium-ion battery

- 8.2.4.2. Before charging

- 8.2.4.3. After charging

- 8.2.4.4. Opportunity charging

- 8.2.4.5. Battery balancing

- 8.2.4.6. Malfunctions

- 8.2.5. Battery maintenance

- 8.2.5.1. Check the battery

- 8.2.5.2. How to clean the battery

- 8.2.6. Service and repair

- 8.2.7. Replace the battery

- 8.2.8. Acquire a new battery

- 8.2.9. Storage

- 9. Before operation

- 9.1. Daily maintenance before operation

- 9.2. Operator compartment adjustments

- 9.2.1. Adjust the armrest

- 9.2.2. Adjust the operators seat (MSG20)

- 9.2.2.1. Adjust the operators seat suspension according to the weight of the operator (MSG20)

- 9.2.2.2. Adjust the backrest (MSG20)

- 9.2.2.3. Adjust the seat distance (MSG20)

- 9.2.2.4. Clean the operators seat

- 9.2.3. Adjust the operators seat (MSG65/MSG75)

- 9.2.3.1. Adjust the operators seat suspension according to the weight of the operator (MSG65/MSG75)

- 9.2.3.2. Adjust the backrest (MSG65/MSG75)

- 9.2.3.3. Adjust the seat distance (MSG65/MSG75)

- 9.2.3.4. Adjust the lumbar support (MSG65/MSG75)

- 9.2.3.5. Clean the operators seat

- 9.2.4. Seat belt

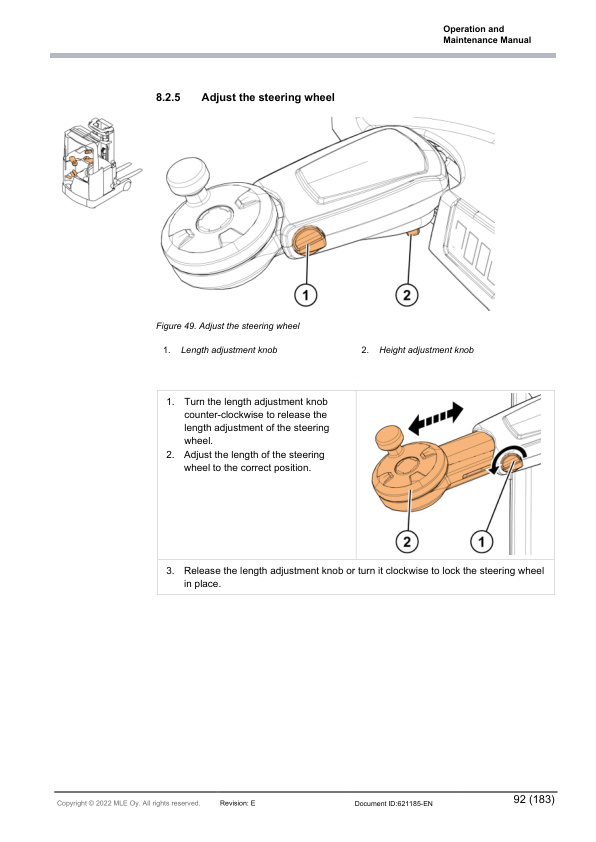

- 9.2.5. Adjust the steering wheel

- 9.2.6. Adjust the heater (cabin truck only)

- 9.2.7. Open the roof window (cabin truck only)

- 10. Operating instructions

- 10.1. How to operate the truck

- 10.1.1. How to enter and exit the operators compartment

- 10.1.2. Operating position

- 10.1.3. Operating direction

- 10.2. How to activate the truck

- 10.2.1. Activate the truck with a PIN code

- 10.2.2. Deactivate the truck

- 10.2.3. Program a new PIN code

- 10.3. Brakes

- 10.3.1. Service brake

- 10.3.2. Parking brake

- 10.4. Driving

- 10.4.1. General driving instructions

- 10.4.2. How to drive the truck

- 10.4.3. Speed

- 10.4.4. How to stop the truck

- 10.4.5. How to park the truck

- 10.5. General operating instructions

- 10.5.1. Traffic rules

- 10.5.2. How to avoid accidents

- 10.5.3. In case the truck turns over

- 10.6. How to handle loads

- 10.6.1. Lifting capacity

- 10.6.2. How to stack

- 10.6.3. How to unstack

- 10.6.4. Broken pallets

- 11. Maintenance

- 11.1. Safety instructions for maintenance

- 11.2. Scheduled maintenance

- 11.2.1. Daily maintenance

- 11.2.2. Weekly checks

- 11.2.3. Monthly maintenance

- 11.2.4. Annual (or 1,000 h) maintenance

- 11.2.5. Every second year (or 2,000 h) maintenance

- 11.3. Lubricant recommendation

- 11.3.1. Hydraulic oil

- 11.3.2. Transmission oil

- 11.3.3. Heavy duty grease for slewing bearing

- 11.3.4. Pump axle splines

- 11.3.5. Traction motor axle splines

- 11.3.6. Mast chains

- 11.3.7. Mast channels

- 11.4. Order spare parts

- 11.5. Maintenance operations

- 11.5.1. Truck covers

- 11.5.1.1. Remove the machinery cover

- 11.5.1.2. Remove the front bumper

- 11.5.1.3. Remove the floor plate

- 11.5.1.4. Open the machinery top cover

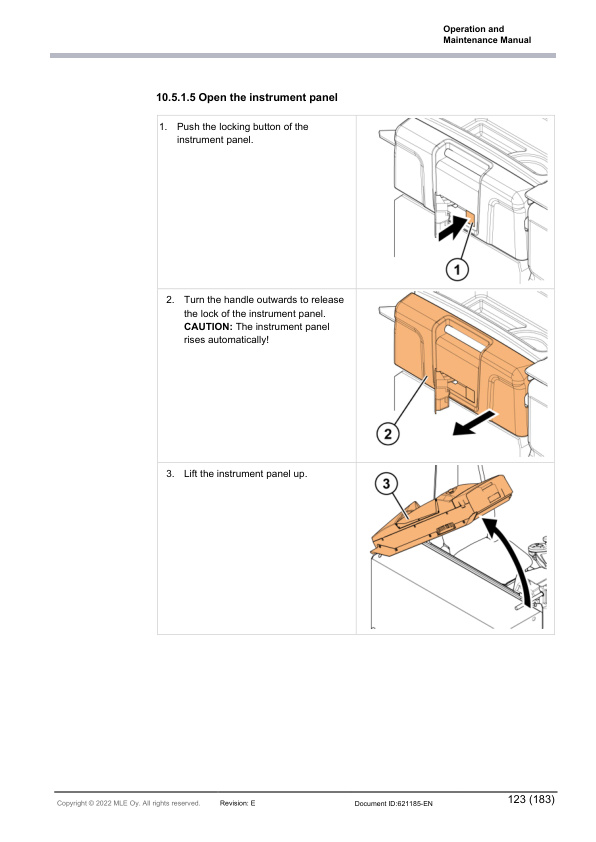

- 11.5.1.5. Open the instrument panel

- 11.5.1.6. Remove the instrument panel cover

- 11.5.1.7. Remove the control panel

- 11.5.1.8. Remove the cup holder

- 11.5.1.9. Remove the reach carriage cover

- 11.5.2. Cabin covers (cabin truck only)

- 11.5.2.1. Remove the instrument panel cover

- 11.5.2.2. Remove the ceiling cover

- 11.5.3. Location of the fuses in the instrument panel

- 11.6. Hazardous waste and disposal

- 11.7. Maintenance check list

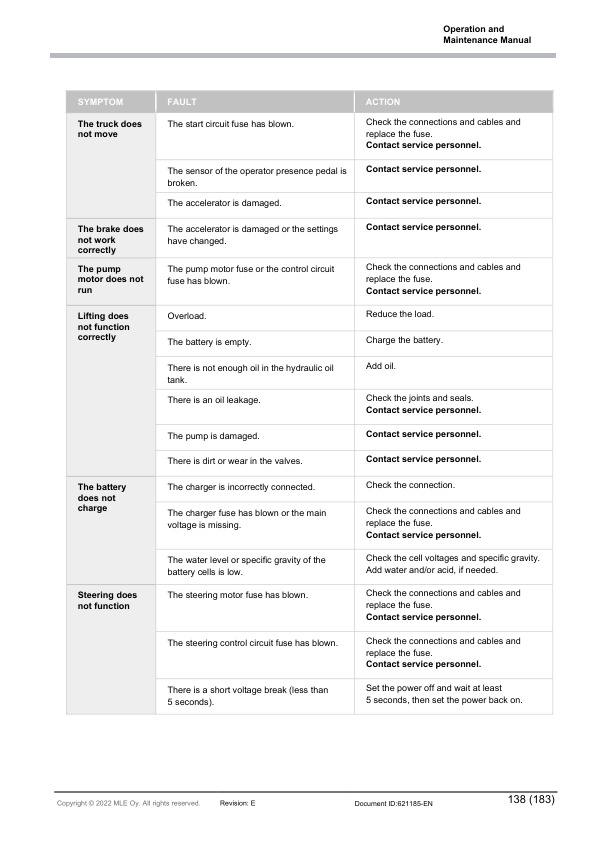

- 11.8. Troubleshooting

- 12. Transportation and storage

- 12.1. Lifting points

- 12.1.1. Jack points

- 12.1.2. Hoist points

- 12.2. How to tow the truck

- 12.2.1. Release the magnetic brake manually

- 12.3. Transportation

- 12.4. Storage

- 12.4.1. Return the truck to operation

- 12.5. Decommissioning

- 13. Options

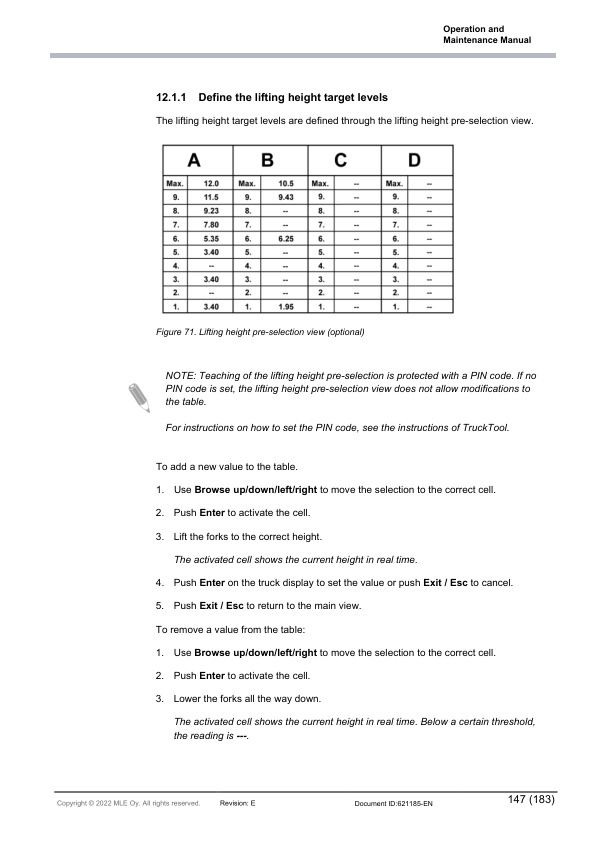

- 13.1. Lifting height pre-selection

- 13.1.1. Define the lifting height target levels

- 13.1.2. How to unstack with the lifting height pre-selection

- 13.1.3. How to stack with the lifting height pre-selection

- 13.2. Sideshift and tilt centering

- 13.2.1. Center the forks with the sideshift and tilt centering

- 13.3. Load weight indicator

- 13.4. Battery changing device for 2 batteries

- 13.4.1. Remove an empty battery with the battery changing device for two batteries

- 13.4.2. Install a charged battery with the battery changing device for two batteries

- 14. Technical specifications

- 14.1. Dimensions

- 14.2. Technical data

- 14.3. Mast heights

- 15. Declaration of Conformity

- 16. Index

- 17. APPENDIX A Stickers

Caterpillar Operation Manual PDF

Caterpillar DP160NE-230NE Lift Trucks Operation and Maintenance Manual OCFEG-J08B8-221

Caterpillar Operation Manual PDF

Caterpillar DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Operation and Maintenance Manual 99790-63100

Caterpillar Operation Manual PDF

Caterpillar 1404 Engine Disassembly and Assembly SENB8108-02

Caterpillar Operation Manual PDF

Caterpillar DP100NM1, DP120NM1, DP135NM1, DP150NM1 Operation and Maintenance Manual 99790-87100

Caterpillar Operation Manual PDF

Caterpillar DP60N3-100N3 Lift Trucks Operation and Maintenance Manual OCFEE-J04C4-201

Caterpillar Operation Manual PDF

Caterpillar DP100, DP115, DP135, DP150 Lift Trucks Operation and Maintenance Manual 99790-83110

Caterpillar Operation Manual PDF

Caterpillar DP100NZ, DP120NZ, DP135NZ, DP150NZ Operation and Maintenance Manual 99790-41000

Caterpillar Operation Manual PDF

Caterpillar DP100, DP115, DP135, DP150 Operation and Maintenance Manual 99790-33120

Caterpillar Operation Manual PDF

Caterpillar DP100NM1 to DP150NM1S Operation and Maintenance Manual OCFEG-JBT15-190

Caterpillar Operation Manual PDF

Caterpillar 3208, 3208T Vehicular Engines Disassembly and Assembly SENB8324