Caterpillar S4Q2-5EFL(F) Diesel Engine Service Manual SCEEG-CT16F-231

$50.00

- Type Of Manual: Service Manual

- Manual ID: SCEEG-CT16F-231

- Number of Pages: 177

- Size: 5.8MB

- Format: PDF

-

Model List:

- S4Q2-5EFL(F) Diesel Engine

- 1. BINDING

- 2. INTRODUCTION

- 2.1. How to use this manual

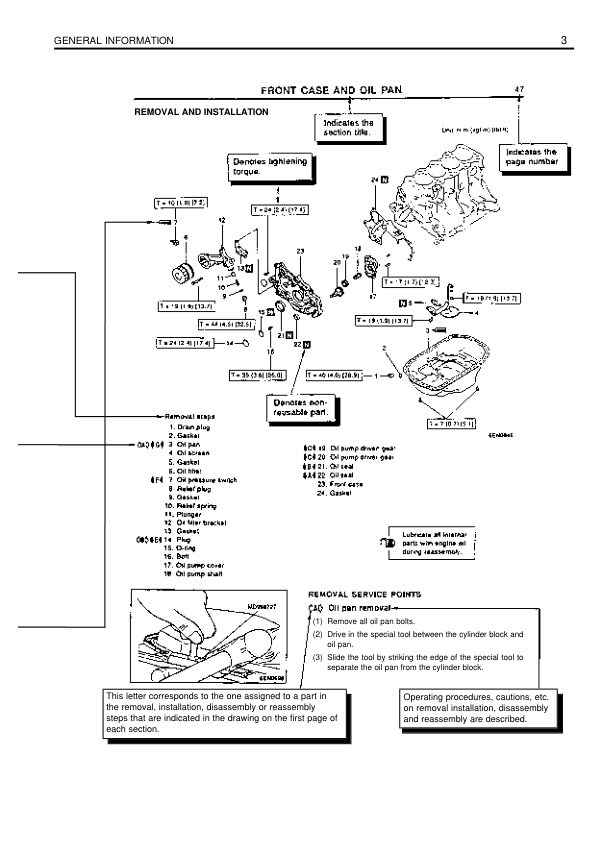

- 2.1.1. Methods of presentation

- 2.1.2. Terms used in this manual

- 2.1.3. Abbreviations

- 2.1.4. Units of measurement

- 2.2. Safety Cautions

- 2.2.1. Fire and explosion

- 2.2.2. Stay clear of all rotating and moving parts

- 2.2.3. Be careful of burns

- 2.2.4. Protect ears from noises

- 2.2.5. Be careful of falling down

- 2.2.6. Be careful of handling fuel, engine oil and LLC

- 2.2.7. Service battery

- 2.2.8. When abnormality occurs

- 2.2.9. Other cautions

- 2.2.10. About warning labels

- 3. GENERAL CONTENTS

- 4. GENERAL

- 4.1. External view

- 4.1.1. In-line fuel injection pump type

- 4.1.2. Distribution fuel injection pump type

- 4.2. System flow diagrams

- 4.2.1. Fuel system – flow diagram

- 4.2.2. Lubrication system – flow diagram

- 4.2.3. Cooling system – flow diagram

- 4.2.4. Inlet and exhaust system – flow diagram

- 4.3. Engine serial number location

- 4.4. Main specifications

- 4.5. Tips on disassembling and reassembling

- 4.5.1. Disassembling

- 4.5.2. Reassembling

- 5. SERVICE DATA

- 5.1. Maintenance service data

- 5.1.1. General

- 5.1.2. Basic engine

- 5.1.3. Fuel system

- 5.1.4. Lubrication system

- 5.1.5. Cooling system

- 5.1.6. Electrical system

- 5.2. Tightening torque table

- 5.2.1. Major bolt tightening torque

- 5.2.2. Standard bolt and nut tightening torque

- 6. SERVICE TOOLS

- 6.1. General tools

- 6.2. Special tool

- 7. DETERMINATION OF OVERHAUL

- 7.1. Determining overhaul timing

- 7.2. Testing compression pressure

- 8. DISASSEMBLY OF BASIC ENGINE

- 8.1. Disassembling and inspecting cylinder head and valve mechanism

- 8.1.1. Removing rocker shaft assembly

- 8.1.2. Disassembling rocker shaft assembly

- 8.1.3. Removing cylinder head assembly

- 8.1.4. Removing valve and valve spring

- 8.1.5. Removing valve stem seal

- 8.1.6. Cleaning cylinder head bottom surface

- 8.1.7. Measuring piston protrusion

- 8.2. Disassembling and inspecting flywheel

- 8.2.1. Removing flywheel

- 8.2.2. Removing oil seal case

- 8.2.3. Removing rear plate

- 8.3. Disassembling and inspecting timing gear, camshaft and oil pan

- 8.3.1. Removing crankshaft pulley

- 8.3.2. Removing timing gear case

- 8.3.3. Measuring timing gear backlash

- 8.3.4. Measuring idler gear end play

- 8.3.5. Removing idler gear

- 8.3.6. Measuring camshaft end play

- 8.3.7. Inverting crankcase

- 8.3.8. Removing oil pan and oil pan gasket

- 8.3.9. Removing oil pump

- 8.3.10. Removing camshaft

- 8.3.11. Removing front plate

- 8.4. Disassembling and inspecting piston, connecting rod, crankshaft and crankcase

- 8.4.1. Laying crankcase on its side

- 8.4.2. Measuring connecting rod end play

- 8.4.3. Removing connecting rod cap

- 8.4.4. Removing carbon deposits from the upper part of cylinder

- 8.4.5. Pulling out piston

- 8.4.6. Removing piston ring

- 8.4.7. Removing piston pin

- 8.4.8. Uprearing crankcase

- 8.4.9. Measuring crankshaft end play

- 8.4.10. Removing main bearing cap

- 8.4.11. Removing crankshaft

- 9. INSPECTION AND REPAIR OF BASIC ENGINE

- 9.1. Inspecting and repairing cylinder head and valve mechanism

- 9.1.1. Measuring distortion of the bottom surface of the cylinder head

- 9.1.2. Measuring clearance between rocker arm and rocker shaft

- 9.1.3. Measuring perpendicularity and free length of valve spring

- 9.1.4. Measuring push rod runout

- 9.1.5. Measuring valve stem outside diameter and valve guide inside diameter

- 9.1.6. Replacing valve guide

- 9.1.7. Inspecting valve face

- 9.1.8. Replacing valve seat

- 9.1.9. Refacing valve face

- 9.1.10. Refacing valve seat

- 9.1.11. Lapping valve and valve seat

- 9.1.12. Removing combustion jet

- 9.2. Inspecting and repairing flywheel

- 9.2.1. Inspecting ring gear

- 9.2.2. Replacing ring gear

- 9.3. Inspecting and repairing timing gear, camshaft and oil pan

- 9.3.1. Inspecting V-pulley

- 9.3.2. Inspecting oil seal contact surface

- 9.3.3. Measuring clearance between idler bushing and idler shaft

- 9.3.4. Replacing idler bushing

- 9.3.5. Replacing idler shaft

- 9.3.6. Measuring cam lift

- 9.3.7. Measuring camshaft journal diameter and journal bore diameter

- 9.3.8. Measuring camshaft runout

- 9.3.9. Removing camshaft gear

- 9.3.10. Installing camshaft gear and thrust plate

- 9.4. Inspecting and repairing piston, connecting rod, crankshaft and crankcase

- 9.4.1. Measuring piston outside diameter

- 9.4.2. Measuring piston ring groove

- 9.4.3. Measuring piston ring end gap

- 9.4.4. Measuring piston pin bore diameter and piston pin outside diameter

- 9.4.5. Measuring clearance between connecting rod bushing and piston pin

- 9.4.6. Replacing connecting rod bushing

- 9.4.7. Inspecting connecting rod bend and twist

- 9.4.8. Inspecting oil clearance of connecting rod bearing

- 9.4.9. Inspecting oil clearance of main bearing

- 9.4.10. Inspecting oil seal contact surface

- 9.4.11. Measuring crankshaft runout

- 9.4.12. Removing crankshaft gear

- 9.4.13. Installing crankshaft gear

- 9.4.14. Measuring cylinder inside diameter

- 9.4.15. Measuring crankcase top surface distortion

- 9.4.16. Inspecting tappet

- 9.4.17. Measuring clearance between tappet and tappet guide hole

- 9.4.18. Inspecting piston cooling nozzle

- 10. REASSEMBLY OF BASIC ENGINE

- 10.1. Reassembling piston, connecting rod, crankshaft and crankcase

- 10.1.1. Installing tappet

- 10.1.2. Installing main bearing

- 10.1.3. Installing crankshaft

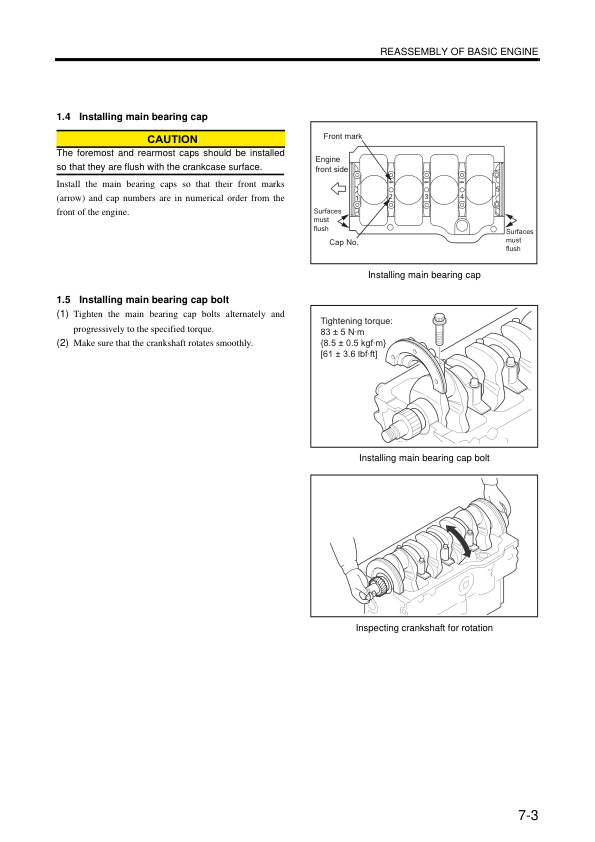

- 10.1.4. Installing main bearing cap

- 10.1.5. Installing main bearing cap bolt

- 10.1.6. Measuring crankshaft end play

- 10.1.7. Reassembling piston and connecting rod

- 10.1.8. Installing piston ring

- 10.1.9. Preparation for installing pistons

- 10.1.10. Installing connecting rod bolt and connecting rod bearing

- 10.1.11. Installing Pistons

- 10.1.12. Installing connecting rod cap

- 10.1.13. Uprearing crankcase

- 10.1.14. Inspecting crankshaft for rotation

- 10.2. Reassembling timing gear, camshaft and oil pan

- 10.2.1. Installing front plate

- 10.2.2. Installing camshaft

- 10.2.3. Installing oil pump

- 10.2.4. Installing oil pan

- 10.2.5. Inverting crankcase

- 10.2.6. Installing front idler gear

- 10.2.7. Inspecting and adjusting timing gear after installation

- 10.2.8. Installing oil seal

- 10.2.9. Installing timing gear case

- 10.2.10. Installing crankshaft pulley

- 10.3. Reassembling flywheel

- 10.3.1. Installing rear plate

- 10.3.2. Installing oil seal case

- 10.3.3. Installing flywheel

- 10.4. Reassembling cylinder head and valve mechanism

- 10.4.1. Installing valve stem seal

- 10.4.2. Installing valve and valve spring

- 10.4.3. Installing cylinder head gasket

- 10.4.4. Installing cylinder head assembly

- 10.4.5. Tightening cylinder head bolts

- 10.4.6. Reassembling rocker shaft assembly

- 10.4.7. Inserting push rod

- 10.4.8. Installing rocker shaft assembly

- 10.4.9. Adjusting valve clearance

- 11. FUEL SYSTEM

- 11.1. Removing fuel system

- 11.1.1. Removing fuel injection pump

- 11.2. Disassembling, inspecting and reassembling fuel system

- 11.2.1. Disassembling and inspecting fuel injection nozzle

- 11.3. Installing fuel system

- 12. LUBRICATION SYSTEM

- 12.1. Removing lubrication system

- 12.1.1. Removing and inspecting oil cooler and relief valve

- 12.1.2. Removing and inspecting oil pan, oil pump, oil pressure switch

- 12.2. Disassembling, inspecting and reassembling lubrication system

- 12.2.1. Disassembling and inspecting oil pump

- 12.2.2. Measuring clearance between outer rotor and inner rotor

- 12.2.3. Measuring end play of rotor and pump case

- 12.2.4. Measuring clearance between outor rotor and pump case

- 12.2.5. Reassembling oil pump

- 12.2.6. Inspecting relief valve

- 12.3. Installing lubrication system

- 12.3.1. Installing oil pan, oil pump and oil pressure switch

- 12.3.2. Installing oil cooler and relief valve

- 13. COOLING SYSTEM

- 13.1. Removing cooling system

- 13.2. Disassembling, inspecting and reassembling cooling system

- 13.2.1. Disassembling, inspecting and reassembling water pump

- 13.2.2. Disassembling, inspecting and reassembling thermostat

- 13.3. Installing cooling system

- 14. INLET AND EXHAUST SYSTEMS

- 14.1. Removing inlet and exhaust system

- 14.2. Inspecting inlet and exhaust system

- 14.2.1. Measuring exhaust manifold distortion

- 14.3. Installing inlet and exhaust system

- 15. ELECTRICAL SYSTEM

- 15.1. Removing electrical system

- 15.1.1. Removing starter

- 15.1.2. Inspection before removing alternator

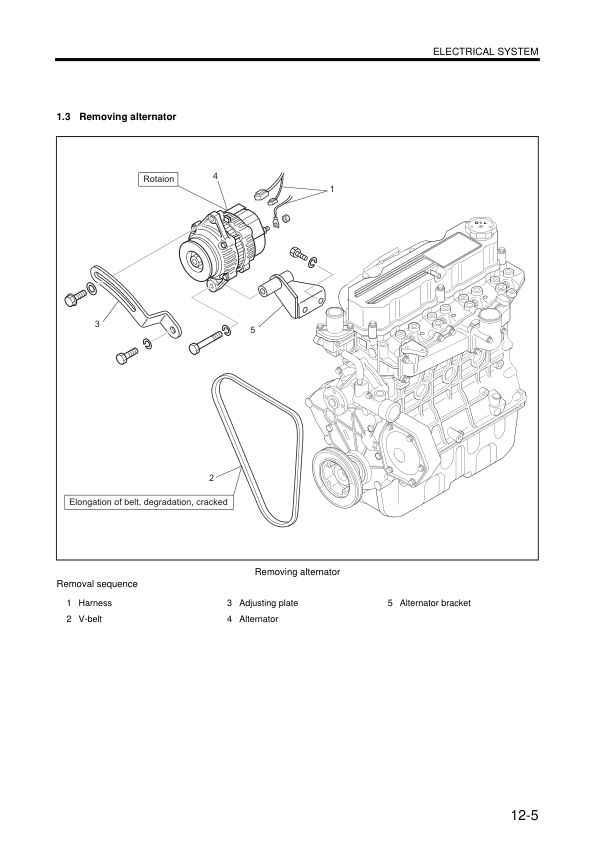

- 15.1.3. Removing alternator

- 15.1.4. Removing glow plug

- 15.2. Disassembling, inspecting and reassembling electrical system

- 15.2.1. Inspection before disassembling starter

- 15.2.2. Disassembling and inspecting starter

- 15.2.3. Inspecting and repairing starter

- 15.2.4. Reassembling starter

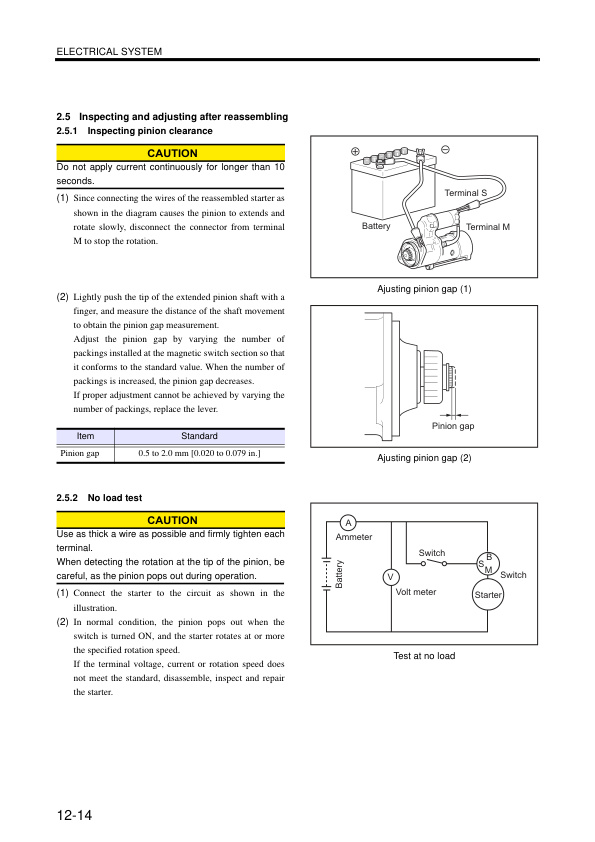

- 15.2.5. Inspecting and adjusting after reassembling

- 15.2.6. Disassembling, inspecting and reassembling alternator

- 15.3. Installing electrical system

- 15.3.1. Installing glow plug

- 15.3.2. Installing alternator

- 15.3.3. Installing starter

- 16. ADJUSTMENT AND OPERATION

- 16.1. Adjusting engine

- 16.1.1. Inspecting and adjusting valve clearance

- 16.1.2. Inspecting and adjusting fuel injection timing

- 16.1.3. Bleeding fuel injection pump

- 16.1.4. Inspecting V-belt

- 16.1.5. Inspecting and adjusting low idle speed and high idle speed

- 16.2. Break-in operation

- 16.2.1. Starting up

- 16.2.2. Inspecting engine condition after starting up

- 16.2.3. Break-in operation time

- 16.2.4. Inspection and adjustment after break-in operation

- 16.3. Performance test (JIS standard)

- 16.3.1. Engine equipment condition

- 16.3.2. Test items and purposes

- 16.3.3. Other inspections

- 16.3.4. Engine output adjustment

- 17. Engine inspection record sheet

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Service Manual SCEEA-AT15E-200

Caterpillar Service Manual PDF

Caterpillar 4G15, 4G63, 4G64, 6G72 Engine Service Manual 99719-34130

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Disassembly and Assembly Service Manual 99799-67102

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Fuel System Supplement Service Manual 99729-85110

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Gasoline Engine Service Manual 99729-84120

Caterpillar Service Manual PDF

Caterpillar 1.4 Liter (4G33) Gasoline Engine Service Manual SENB8525

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Troubleshooting Service Manual 99799-67104