Mitsubishi FD20A, F18A Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 603

- Size: 13.7MB

- Format: PDF

-

Model List:

- FD20A, F18A

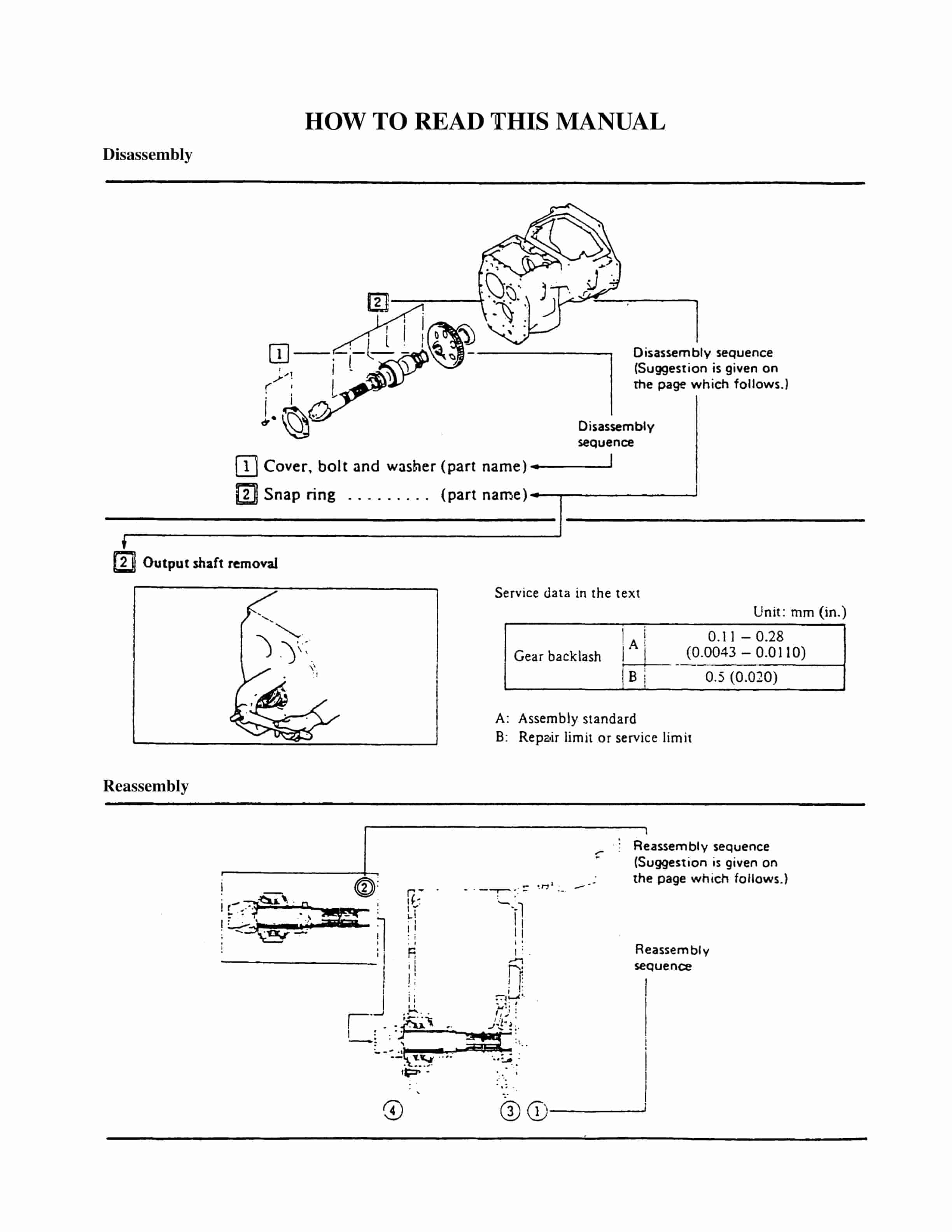

- 1. HOW TO READ THIS MANUAL

- 1.1. Introduction

- 2. GENERAL INFORMATION

- 2.1. External view

- 2.2. Truck models covered

- 2.3. Nameplate and serial number locations

- 2.4. Dimensions

- 2.5. Technical data

- 3. BRAKE SYSTEM

- 3.1. Description

- 3.1.1. Automatic adjusting device

- 3.1.2. Brake pedal and associated parts

- 3.1.3. Parking brake lever mechanism

- 3.2. Disassembly and Reassembly

- 3.2.1. Master cylinder

- 3.2.2. Wheel brakes

- 3.2.3. Wheel cylinders

- 3.2.4. Inspection and adjustment

- 4. CLUTCHES

- 4.1. Description

- 4.1.1. Types of drive

- 4.1.2. Dry-type clutch

- 4.1.3. Wet-type clutch

- 4.1.4. Clutch assister (for wet-type clutch pedal)

- 4.2. Disassembly and reassembly

- 4.2.1. Dry-type clutch

- 4.2.2. Wet-type clutch

- 4.2.3. Pressure plate assembly disassembly and reassembly

- 4.2.4. Clutch assister disassembly and reassembly

- 4.3. Inspection and adjustment

- 4.3.1. Clutch assister adjustment

- 4.3.2. Relationship between wet-type clutch pedal play and operating force

- 4.3.3. Clutch pedal adjustment

- 5. COOLING SYSTEM

- 5.1. Description

- 5.2. Removal and installation

- 5.3. Inspection and adjustment

- 6. ELECTRICAL EQUIPMENT

- 6.1. Description

- 6.1.1. Console box

- 6.1.2. Printed circuit

- 6.2. Disassembly and reassembly

- 6.3. Care of the battery

- 6.4. Major electrical components

- 6.5. Lamp bulb specifications

- 7. HYDRAULC

- 7.1. Description

- 7.1.1. Hydraulic tank

- 7.1.2. Hydraulic pump

- 7.1.3. Control valve

- 7.1.4. Lift and tilt cylinders

- 7.1.5. Flow regulator valve

- 7.1.6. Down safety valve

- 7.2. Removal and installation

- 7.2.1. Hydraulic pump

- 7.2.2. Control valve

- 7.2.3. Lift cylinders

- 7.2.4. Tilt cylinders

- 7.3. Disassembly and reassembly

- 7.3.1. Hydraulic pump

- 7.3.2. Control valve

- 7.3.3. Lift cylinders

- 7.3.4. Tilt cylinders

- 7.3.5. Flow regulator valve

- 7.3.6. Down safety valve

- 7.4. Inspection and adjustment

- 7.4.1. Hydraulic tank

- 7.4.2. Hydraulic pump

- 7.4.3. Control valve

- 7.4.4. Lift and tilt cylinders

- 7.4.5. Testing

- 8. INSPECTION GUIDE

- 8.1. Inspection guide

- 9. MANUAL TRANSMISSION

- 9.1. Description

- 9.1.1. Synchronizer construction and operation

- 9.2. Removal and installation

- 9.3. Disassembly and reassembly

- 9.3.1. Disassembly

- 9.3.2. Reassembly

- 10. MAST AND FORKS

- 10.1. Description

- 10.2. Removal and installation

- 10.3. Disassembly and reassembly

- 10.4. Inspection and adjustment

- 10.4.1. Chain tension adjustment

- 10.4.2. Lateral clearance between outer and inner masts

- 10.4.3. Mast strip adjustment

- 10.4.4. Lateral clearance on lift bracket

- 10.4.5. Mast adjustment chart

- 11. POWER TRAIN

- 11.1. Removal and installation

- 11.1.1. Removal and engine, transmission (or torque converter), reduction gear and differential as an assembly

- 11.2. Removal of engine proper

- 12. POWERSHIFT TRANSMISSION

- 12.1. Description

- 12.1.1. Hydraulic circuit diagram

- 12.1.2. Control

- 12.2. Removal and installation

- 12.3. Disassembly and reassembly

- 12.3.1. Torque converter

- 12.3.2. Transmission

- 12.3.3. Control valve

- 12.4. Inspection and adjustment

- 12.4.1. Oil pressure measurement

- 12.4.2. Clutch valve testing

- 12.4.3. Stall speed measurement

- 12.4.4. m (33-ft) starting acceleration test

- 12.4.5. Inching pedal adjustment

- 13. REAR AXLE

- 13.1. Description

- 13.2. Removal and installation

- 13.2.1. Rear tires

- 13.2.2. Rear axle

- 13.3. Disassembly and reassembly

- 13.3.1. Disassembly

- 13.3.2. Reassembly

- 13.4. Inspection and adjustment

- 13.4.1. Toe-in adjustment

- 13.4.2. Minimum turning radius adjustment

- 14. REDUCTION DIFFERENTIAL AND FRONT AXLE

- 14.1. Description

- 14.2. Removal and installation

- 14.2.1. Front tires

- 14.3. Disassembly and reassembly

- 14.3.1. Front axle

- 14.3.2. Reduction gear and differential

- 14.4. Inspection and adjustment

- 14.4.1. Side bearing preload adjustment

- 14.4.2. Reduction gear backlash adjustment

- 14.4.3. Face runout measurement

- 14.4.4. Tooth contact adjustment

- 15. STEERING SYSTEM

- 15.1. Description

- 15.1.1. Flow divider operation

- 15.2. Removal and installation

- 15.2.1. Steering gear and power cylinder

- 15.3. Disassembly and reassembly

- 15.3.1. Steering gear

- 15.3.2. Power cylinder

- 15.3.3. Flow divider

- 15.4. Inspection and adjustment

- 15.4.1. Steering wheel free play

- 15.4.2. Steering effort

- 15.4.3. Hydraulic pressure measurement and adjustment

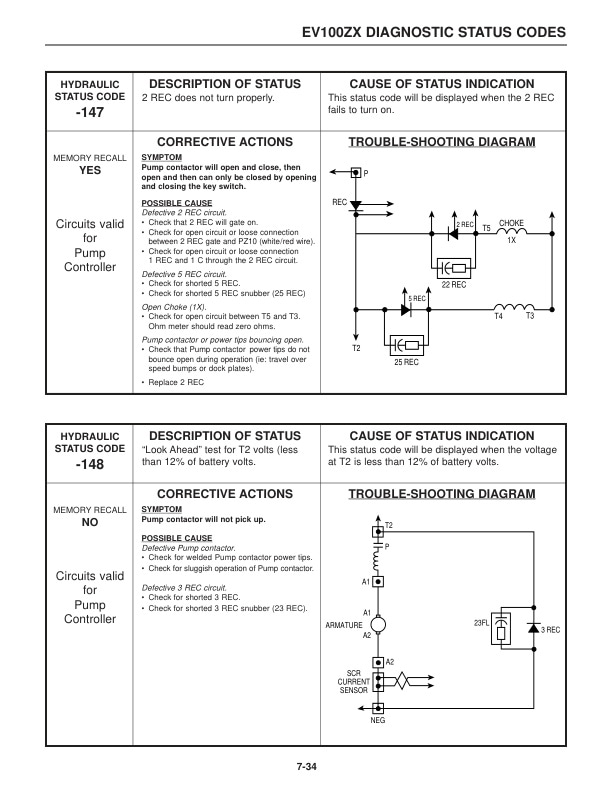

- 16. TROUBLESHOOTING

- 16.1. Electrical equipment

- 16.2. Clutches

- 16.3. Manual transmission

- 16.4. Powershift transmission

- 16.5. Reduction differential and front axle

- 16.6. Rear axle

- 16.7. Brake system

- 16.8. Steering system

- 16.9. Hydraulic system

- 16.10. Mast and forks

- 17. SERVICE MANUAL

- 17.1. GENERAL

- 17.1.1. Distinctive features of DPK injection pump

- 17.1.2. Features representing departures from the DPA injection pump

- 17.2. SPECIFICATIONS (for 4DQ5, S4E and S4E2 engines)

- 17.3. DESCRIPTION

- 17.3.1. Component parts of the DPK pump

- 17.3.2. Fule flow in the DPK pump

- 17.3.3. Transfer pump

- 17.3.4. Regulator valve

- 17.3.5. Metering valve

- 17.3.6. Fuel pressurization and distribution

- 17.3.7. Governor mechanism

- 17.3.8. Adjustment of maximum injection quantity

- 17.3.9. Increase of injection quantity for engine starting

- 17.3.10. Torque control

- 17.3.11. Automatic timing advancer

- 17.3.12. Shutoff solenoid valve

- 17.3.13. Cold advance mechanism

- 17.3.14. Fuel filter

- 17.4. INSPECTION AND ADJUSTMENT

- 17.4.1. Dismounting the DPK pump for inspection

- 17.4.2. Remounting the DPK pump

- 17.4.3. Matching the DPK pump to the engine for injection timing

- 17.4.4. Priming the fuel circuit

- 17.4.5. Adjusting the DPK pump for idling and maximum speeds

- 17.4.6. Torque Control adjustment

- 17.5. TROUBLESHOOTING GUIDE

- 17.5.1. SYMPTON Engine is hard to start or will not start.

- 17.5.2. SYMPTON Loss of power/poor fuel economy.

- 17.5.3. SYMPTON Excessive exhaust smoke.

- 17.5.4. SYMPTON The engine will not settle at the set speed limits (on idling speed and max. speed).

- 17.5.5. SYMPTON The engine runs erratically or misfires.

- 17.5.6. SYMPTON The engine knocks.

- 17.5.7. SYMPTON The engine lacks power gradually and stalls, all by itself.

- 17.5.8. SYMPTON The engine stalls easily.

- 17.5.9. SYMPTON The engine gives white exhaust smoke at the time of cold starting.

- 17.5.10. SYMPTON The engine gives white exhaust smoke even after it has been warmed up.

- 17.5.11. SYMPTON The engine knocks after it has been warmed up and, when loaded, runs noisy.

- 17.5.12. SYMPTON The engine will not stop running promptly.

- 17.6. DISASSEMBLY AND REASSEMBLY (For reference only)

- 17.6.1. Disassembly

- 17.6.2. Reassembly

- 17.7. COMPONENT PARTS

- 17.8. LUCAS SERVICE NETWORK

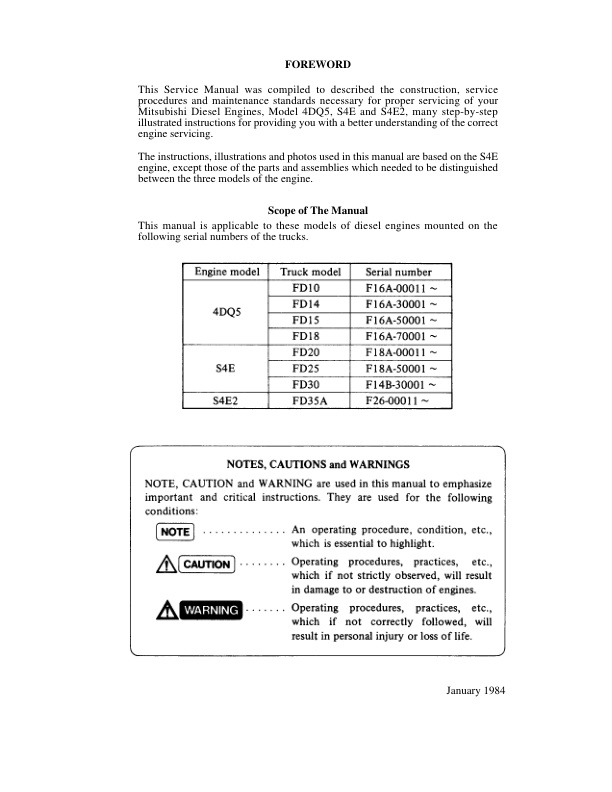

- 18. FOREWARD

- 19. FOREWORD

- 19.1. Foreward

- 19.2. List of Abbreviations

- 20. GENERAL INFORMATION

- 20.1. Exterior Views

- 20.2. Nomenclature and Sectional Views

- 20.3. Major Data and Specifications

- 20.4. Performance Curves

- 20.5. Engine Serial Number Location

- 20.6. Tips on Disassembly and Reassembly

- 21. COOLING SYSTEM

- 21.1. Description

- 21.2. Removal

- 21.3. Water Pump Disassembly

- 21.4. Inspection and Repair

- 21.5. Water Pump Reassembly

- 21.6. Installation

- 22. CRANKCASE AND MAJOR RUNNING PARTS

- 22.1. Description

- 22.2. Disassembly

- 22.3. Inspection and Repair

- 22.4. Reassembly

- 23. CYLINDER HEAD AND VALVE MECHANISM

- 23.1. Description

- 23.2. Removal

- 23.3. Disassembly

- 23.4. Inspection and Repair

- 23.5. Reassembly

- 23.6. Installation

- 24. CYLINDER SLEEVES, PISTONS AND CONNECTING RODS

- 24.1. Description

- 24.2. Removal

- 24.3. Disassembly

- 24.4. Inspection and Repair

- 24.5. Reassembly

- 24.6. Installation

- 25. ELECTRICAL SYSTEM

- 25.1. Description

- 25.2. Starter

- 25.3. Alternator

- 25.4. Glow Plugs

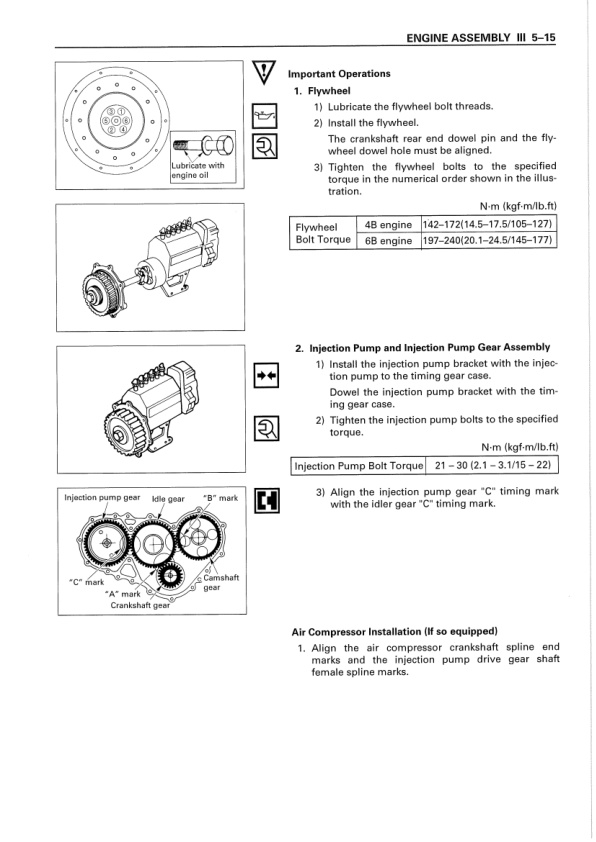

- 26. FLYWHEEL AND TIMING GEARS

- 26.1. Description

- 26.2. Removal

- 26.3. Inspection and Repair

- 26.4. Installation

- 27. FUEL SYSTEM

- 27.1. Description

- 27.2. Fuel Filter

- 27.2.1. Description

- 27.2.2. Removal and Installation

- 27.2.3. Disassembly and Reassembly

- 27.2.4. Inspection

- 27.3. Fuel Injection Pump (DPA)

- 27.3.1. Description

- 27.3.2. Removal and Installation

- 27.3.3. Idiling and Maximum speed Adjustments

- 27.4. Fuel Injection Nozzels

- 27.4.1. Description

- 27.4.2. Removal and Installation

- 27.4.3. Disassembly and Reassembly

- 27.4.4. Inspection

- 27.4.5. Testing and Adjustment

- 28. LUBRICATION SYSTEM

- 28.1. Description

- 28.2. Removal

- 28.3. Disassembly

- 28.4. Inspection and Repair

- 28.5. Reassembly

- 28.6. Installation

- 29. OVERHAUL INSTRUCTIONS

- 29.1. When to Overhaul the Engine

- 29.2. Testing the Compression Pressure

- 29.3. Bench Test

- 29.4. Performance Tests

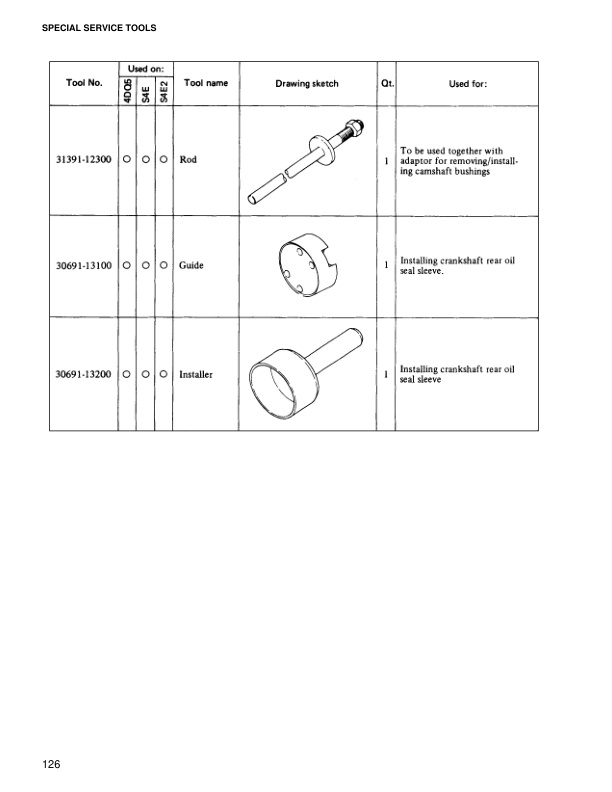

- 30. SPECIAL SERVICE TOOLS

- 30.1. Special Service Tools

- 31. BALE CLAMPS

- 31.1. ATTACHMENTS, TRUCKS AND MASTS COVERED

- 31.2. SPECIFICATIONS (1)-DIMENSIONS AND PERFORMANCE

- 31.3. SPECIFICATIONS (2)- RATED CAPACITIES

- 31.4. DESCRIPTION

- 31.5. REMOVAL AND INSTALLATION

- 31.6. DISASSEMBLY AND REASSEMBLY

- 31.7. INSPECTION AND ADJUSTMENT

- 31.8. TROUBLESHOOTING

- 31.9. SERVICE DATA

- 32. LOAD STABILIZERS

- 32.1. SPECIFICATIONS

- 32.2. DESCRIPTION

- 32.3. REMOVAL AND INSTALLATION

- 32.4. DISASSEMBLY AND REASSEMBLY

- 32.5. INSPECTION AND ADJUSTMENT

- 32.6. TROUBLESHOOTING

- 32.7. SERVICE DATA

- 33. MAST PIPINGS

- 33.1. Description

- 33.1.1. Type and features

- 33.1.2. Mast-and-piping combinations

- 33.2. Construction

- 33.2.1. Inner pulley type

- 33.2.2. Side pulley type

- 33.2.3. Center pulley type

- 33.2.4. Hose reel type

- 33.2.5. Hose reel

- 33.2.6. Junction block

- 33.3. Removal and installation

- 33.3.1. Inner pulley type (dual-stage panoramic mast with 3-element piping for pneumatic-tire models)

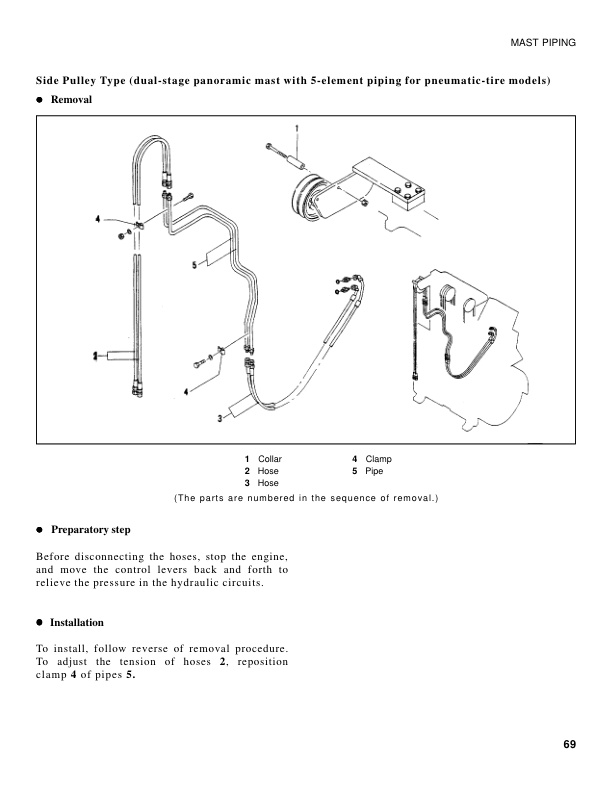

- 33.3.2. Side pulley type (dual-stage panoramic mast with 5-element piping for pneumatic-tire models)

- 33.3.3. Center pulley type (dual-stage, full free panoramic mast with 3-element piping for pneumatic-tire models)

- 33.3.4. Center pulley type (triple-stage, full free panoramic mast with 3-element piping for pneumatic-tire models

- 33.3.5. Hose reel type (dual-stage/triple-stage, full free panoramic mast with 4-element piping (right side) or 5-element piping (both s

- 33.3.6. General precautions for removal and installation

- 33.4. Disassembly and reassembly

- 33.4.1. Hose reel

- 33.4.2. Juntion block

- 33.5. Troubleshooting

- 33.6. Service data

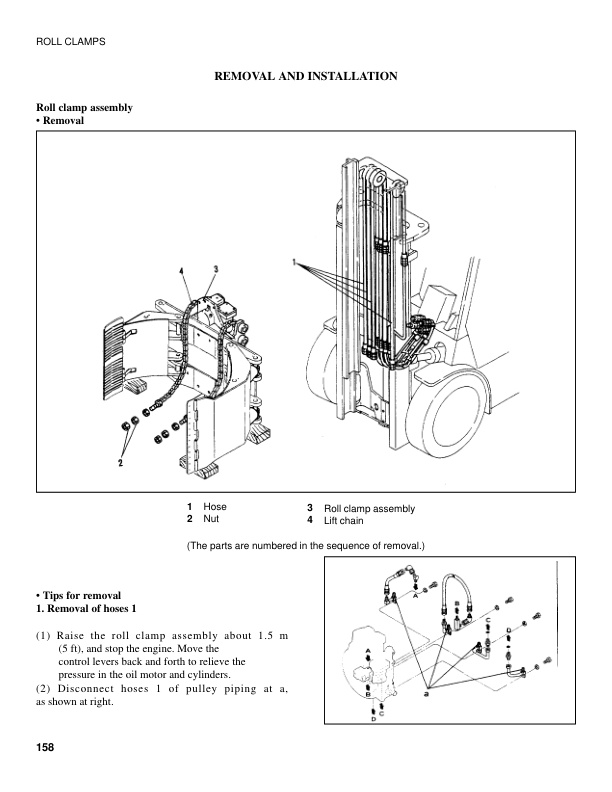

- 34. ROLL CLAMPS

- 34.1. ATTACHMENTS, TRUCKS AND MASTS COVERED

- 34.2. SPECIFICATIONS (1)-DIMENSIONS AND PERFORMANCE

- 34.3. SPECIFICATIONS (2) – RATED CAPACITIES

- 34.4. DESCRIPTION

- 34.5. REMOVAL AND INSTALLATION

- 34.6. DISASSEMBLY AND REASSEMBLY

- 34.7. INSPECTION AND ADJUSTMENT

- 34.8. TROUBLESHOOTING

- 34.9. SERVICE DATA

- 35. ROTATING FORKS

- 35.1. Attachments, trucks and masts covered

- 35.2. Specifications (1) – Dimensions and performance

- 35.3. Specifications (2) – Rated capacities

- 35.4. Description

- 35.5. Removal and installation

- 35.6. Disassembly and reassembly

- 35.7. Inspection and adjustment

- 35.8. Troubleshooting

- 35.9. Service data

- 36. SIDE-SHIFTERS

- 36.1. PNEUMATIC-TIRE MODELS

- 36.2. Attachments, trucks and mast covered

- 36.3. Applicable masts

- 36.4. Specifications (1) – Dimensions and performance

- 36.5. Specifications (2) – Rated capacities

- 36.6. Description

- 36.7. Removal and installation

- 36.8. Disassembly and reassembly

- 36.9. Inpection and adjustment

- 36.10. Troubleshooting

- 36.11. Service data

- 36.12. CUSHION-TIRE MODELS

- 36.13. Attachments, trucks and masts covered

- 36.14. Applicable masts

- 36.15. Specifications – Dimensions and performance

- 36.16. Description

- 36.17. Service data

- 37. SPECIAL MASTS

- 37.1. Trucks and masts covered

- 37.2. Description

- 37.2.1. Dual-stage full free panoramic mast

- 37.2.2. Triple-stage full free panoramic mast

- 37.2.3. Hook device

- 37.2.4. Lift cylinders

- 37.2.5. Flow reulator valve

- 37.2.6. Down safety valves

- 37.3. Removal and installation

- 37.3.1. Mast assembly

- 37.3.2. Lift cylinders

- 37.4. Disassembly and reassembly

- 37.4.1. Dual-stage full free panoramic mast

- 37.4.2. Triple-stage full free panoramic mast

- 37.4.3. Lift cylinders

- 37.4.4. Flow regulator valve

- 37.4.5. Down safety valves

- 37.5. Inspection and adjustment

- 37.5.1. Lift chains, chain wheels and chain wheel supports

- 37.5.2. Lift chain tension adjustment

- 37.5.3. Lift bracket stopper position inspection

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

Mitsubishi Service Manual PDF

Mitsubishi 5M15D, 5M20D, 5M25D, 5M30D, 5M35D Mast Supplement Service Manual 99739-151T0

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100