Caterpillar EB10CB-35CB, EB20-25LCB Mechanical Systems Service Manual SCKEM-J22C0-203

$50.00

- Type Of Manual: Service Manual

- Manual ID: SCKEM-J22C0-203

- Number of Pages: 146

- Size: 13.1MB

- Format: PDF

-

Model List:

- EB10CB, EB15CB, EB18CB, EB20CB, EB25CB, EB20LCB, EB25LCB, EB30CB, EB35CB

- 1. SCKEM-J22C0-203_00_COVER FOREWORD

- 1.1. FOREWORD

- 2. SCKEM-J22C0-203_05_REMOVAL INSTALLATION

- 2.1. REMOVAL INSTALLATION

- 2.1.1. SERVICE INFORMATION

- 2.1.2. SERVICE DATA

- 2.1.2.1. Tightening Torque

- 2.1.2.2. Adjustment Value

- 2.1.3. FORK

- 2.1.3.1. Removal

- 2.1.3.2. Installation

- 2.1.4. LIFT BRACKET

- 2.1.4.1. Removal

- 2.1.4.2. Installation

- 2.1.4.3. Adjustment

- 2.1.5. MAST

- 2.1.5.1. Removal

- 2.1.5.2. Installation

- 2.1.6. FLOOR

- 2.1.6.1. Removal

- 2.1.6.2. Installation

- 2.1.7. COVERS

- 2.1.7.1. Removal

- 2.1.7.2. Installation

- 2.1.8. BATTERY

- 2.1.8.1. Removal

- 2.1.8.2. Installation

- 2.1.9. SEAT

- 2.1.9.1. Removal

- 2.1.9.2. Installation

- 2.1.10. BATTERY COVER

- 2.1.10.1. Removal

- 2.1.10.2. Installation

- 2.1.11. OVERHEAD GUARD

- 2.1.11.1. Removal

- 2.1.11.2. Installation

- 2.1.12. TILT CYLINDER

- 2.1.12.1. Removal

- 2.1.12.2. Installation

- 2.1.13. HYDRAULIC PUMP

- 2.1.13.1. Removal

- 2.1.13.2. Installation

- 2.1.14. HYD MOTOR

- 2.1.14.1. Removal

- 2.1.14.2. Installation

- 2.1.15. TRV MOTOR

- 2.1.15.1. Removal

- 2.1.15.2. Installation

- 2.1.16. FRONT TIRE

- 2.1.16.1. Removal

- 2.1.16.2. Installation

- 2.1.17. FRONT AXLE

- 2.1.17.1. Removal

- 2.1.17.2. Installation

- 2.1.18. HYDRAULIC OIL TANK

- 2.1.18.1. Removal

- 2.1.18.2. Installation

- 2.1.19. COUNTERWEIGHT

- 2.1.19.1. Removal

- 2.1.19.2. Installation

- 2.1.20. REAR TIRE

- 2.1.20.1. Removal

- 2.1.20.2. Installation

- 2.1.21. REAR AXLE

- 2.1.21.1. Removal

- 2.1.21.2. Installation

- 2.1.22. CONTROLLERS

- 2.1.22.1. Removal

- 2.1.22.2. Installation

- 2.1.23. TRANSFORMER (OPTION BUILT-IN CHARGER)

- 2.1.23.1. Removal

- 2.1.23.2. Installation

- 2.1.24. PS PUMP

- 2.1.24.1. Removal

- 2.1.24.2. Installation

- 2.1.25. PS MOTOR

- 2.1.25.1. Removal

- 2.1.25.2. Installation

- 3. SCKEM-J22C0-203_07_BRAKE SYSTEM

- 3.1. BRAKE SYSTEM

- 3.1.1. SERVICE DATA

- 3.1.1.1. Adjusting Value

- 3.1.1.2. Tightening Torque

- 3.1.2. SERVICE INFORMATION

- 3.1.3. SERVICE BRAKE

- 3.1.3.1. Construction

- 3.1.3.2. Disassembly

- 3.1.3.3. Inspection

- 3.1.3.4. Installation

- 3.1.3.5. Adjustment

- 3.1.4. BRAKE PEDAL

- 3.1.4.1. Layout

- 3.1.4.2. Removal and Installation

- 3.1.4.3. Adjustment

- 3.1.4.4. Construction

- 3.1.4.5. Disassembly and Assembly

- 3.1.4.6. Adustment and Inspection

- 3.1.5. MASTER CYLINDER

- 3.1.5.1. Disassembly Drawing

- 3.1.5.2. Inspection

- 3.1.6. BRAKE PIPING

- 3.1.6.1. Layout

- 3.1.6.2. Inspection

- 3.1.6.3. Adjustment

- 3.1.7. PARKING BRAKE

- 3.1.7.1. Layout

- 3.1.7.2. Inspection

- 3.1.7.3. Adjustment

- 4. SCKEM-J22C0-203_10_HYDAULIC SYSTEM

- 4.1. HYDRAULIC SYSTEM

- 4.1.1. SERVICE DATA

- 4.1.1.1. Hydraulic Oil and Oil Level

- 4.1.1.2. Accumulator (Smooth Running System) Specification

- 4.1.1.3. Adjustment Value

- 4.1.1.4. Tightening Torque

- 4.1.2. SERVICE INFORMATION

- 4.1.3. HYDRAULIC CIRCUIT DIAGRAM

- 4.1.3.1. Standard Specification

- 4.1.3.2. Proportional Valve Specification

- 4.1.3.3. Smooth Running System and Automatic Tilt Horizontal Stop Specifications (Optional)

- 4.1.3.4. Attachment Specification

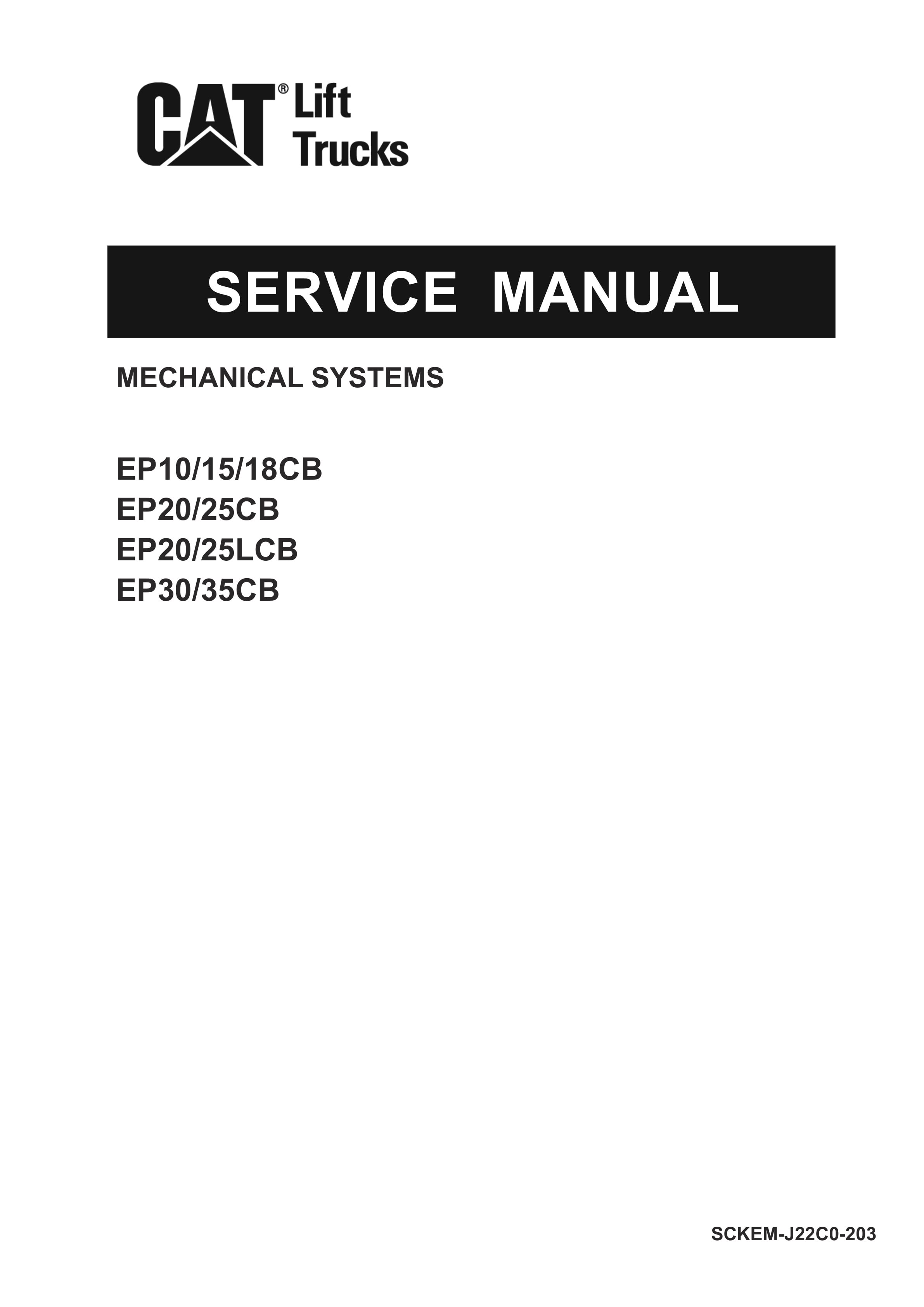

- 4.1.4. HYDRAULIC PIPING

- 4.1.4.1. Layout

- 4.1.4.2. Piping Components

- 4.1.4.3. Accumulator COMP.

- 4.1.4.4. Inspection

- 4.1.5. HYDRAULIC PUMP

- 4.1.5.1. External View

- 4.1.5.2. Service Information

- 4.1.6. CONTROL VALVE

- 4.1.6.1. External View

- 4.1.6.2. Construction

- 4.1.6.3. Removal and Reinstallation

- 4.1.6.4. Disassembly and Reassembly

- 4.1.7. HYD LEVER

- 4.1.7.1. Standard Lever

- 4.1.7.2. Single Hydraulic Lever (Optional)

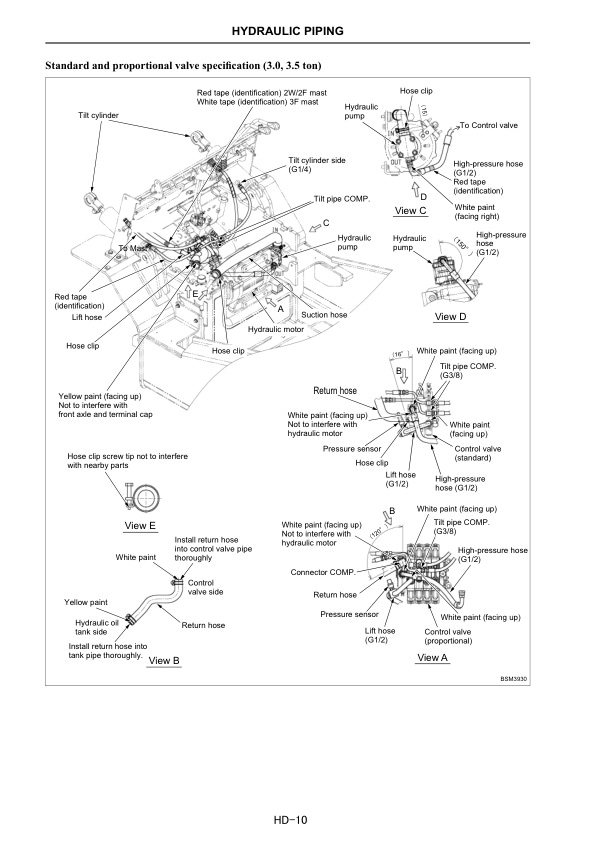

- 4.1.8. CYLINDERS

- 4.1.8.1. Tilt Cylinder

- 4.1.8.2. Lift Cylinder

- 4.1.8.3. Full-Free Cylinder (2F/3F Mast)

- 4.1.8.4. Bleeding

- 4.1.8.5. Down Safety Valve

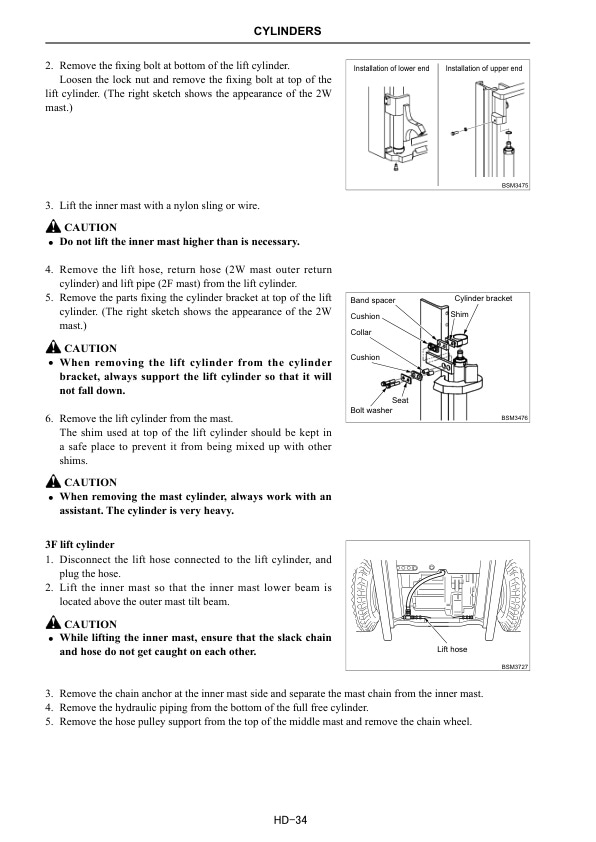

- 4.1.9. INSPECTION AND ADJUSTMENT

- 4.1.9.1. In Case of Emergency (Forks/Mast Cannot Be Lowered)

- 4.1.9.2. Hydraulic Pressure Inspection and Adjustment

- 4.1.9.3. Accumulator Inspection and Adjustment (Smooth Running System)

- 4.1.10. OPTIONAL EQUIPMENT

- 4.1.10.1. Layout

- 4.1.10.2. Relief Valve

- 5. SCKEM-J22C0-203_11_LOADING MECHANISM

- 5.1. LOADING MECHANISM

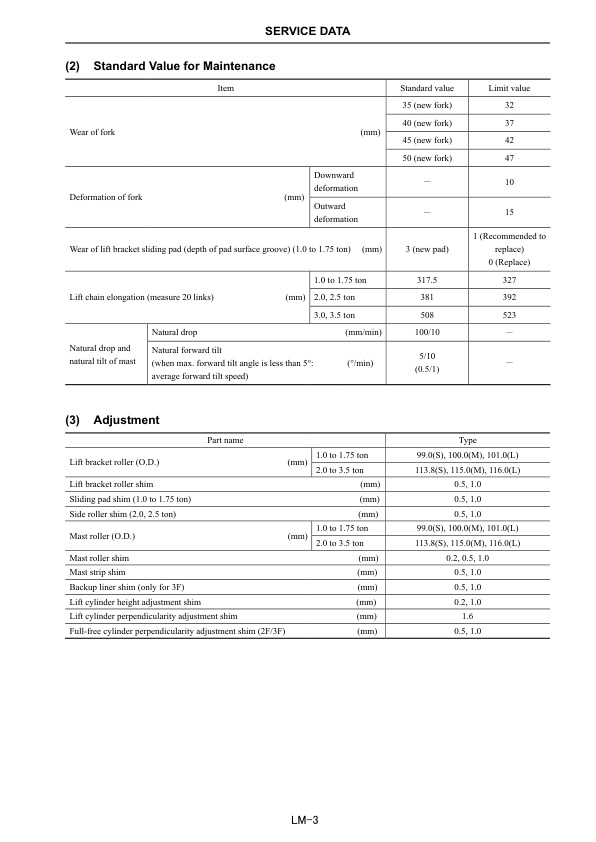

- 5.1.1. SERVICE DATA

- 5.1.1.1. Adjustment Value

- 5.1.1.2. Standard Value for Maintenance

- 5.1.1.3. Adjustment

- 5.1.1.4. Tightening Torque

- 5.1.2. FORK

- 5.1.2.1. Inspection

- 5.1.3. LIFT BRACKET

- 5.1.3.1. Disassembly

- 5.1.3.2. Inspection

- 5.1.3.3. Adjustment

- 5.1.3.4. Precautions When Assembling

- 5.1.4. MAST

- 5.1.4.1. Disassembly

- 5.1.4.2. Inspection

- 5.1.4.3. Assembly

- 5.1.4.4. Adjustment

- 5.1.4.5. Inspection of Natural Drop and Natural Tilt

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Operation and Maintenance Manual Service Manual 99799-67105

Caterpillar Service Manual PDF

Caterpillar 4G15, 4G63, 4G64, 6G72 Engine Service Manual 99719-34130

Caterpillar Service Manual PDF

Caterpillar 5V15D to 5V35D Mast Supplement Service Manual 99739-351S0

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-64103

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-67103

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99719-84130

Caterpillar Service Manual PDF