Caterpillar EP10CB-35CB Lift Trucks Operation and Maintenance Manual OCFEM-M22C0-200

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OCFEM-M22C0-200

- Number of Pages: 230

- Size: 29.7MB

- Format: PDF

-

Model List:

- EP10CB, EP15CB, EP18CB, EP20CB, EP25CB, EP20LCB, EP25LCB, EP30CB, EP35CB

- 1. INTRODUCTION

- 2. CONTENTS

- 3. READ FIRST

- 3.1. Read first

- 3.2. For the manager

- 3.2.1. Qualification for operating

- 3.2.1.1. Handling a new truck

- 3.2.1.2. Warranty and after-sales service

- 3.2.1.3. About inspection

- 3.2.1.4. Enforce periodic replacement of regular replacement parts

- 3.2.1.5. Genuine parts

- 3.3. Regarding the operation manual

- 3.3.1. How to read this manual

- 3.3.1.1. Special considerations in this manual

- 3.3.1.2. Description of posted truck

- 3.3.1.3. Attachment

- 4. FOR SAFE AND COMFORTABLE OPERATION

- 4.1. Before starting to use

- 4.1.1. Perform pre-operation inspection (Daily inspection)

- 4.2. For managers (Operator should read also)

- 4.2.1. Appointment of operator

- 4.2.1.1. Plan, Working place

- 4.2.1.2. Main use / non-use

- 4.2.1.3. About the truck

- 4.2.1.4. About load to handle

- 4.2.1.5. About inspection

- 4.2.1.6. Transportation of truck by trailer

- 4.2.1.7. Fixing method when transferring trucks

- 4.3. Precautions when traveling

- 4.4. Precautions for load handling

- 4.5. Stop, Parking

- 4.6. Precautions for inspection

- 4.7. To prevent truck fires

- 4.8. In case of emergency

- 4.8.1. In case the brakes do not work

- 4.8.2. When the forks stops going down

- 4.8.3. In case of emergency

- 4.9. To prevent tipping over

- 4.9.1. Characteristics of a truck (Center of gravity, stability)

- 4.9.1.1. Maintain truck balance

- 4.9.1.2. Determine the center of gravity of your load

- 4.9.1.3. Change in the center of gravity position (Understand the composite center of gravity position)

- 4.9.1.4. Center of gravity stability area (Center of gravity triangle)

- 4.9.1.5. Maximum loading capacity

- 4.9.1.6. Factors affecting the stability of trucks

- 4.10. Danger / Warning / Caution and instruction labels

- 4.10.1. Danger / Warning / Caution labels

- 4.10.1.1. Do not jump off the truck when tipping over (①)

- 4.10.1.2. Caught by mast moving (②)

- 4.10.1.3. Be careful with pinch fingers (③)

- 4.10.1.4. Handling of the battery (④)

- 4.10.1.5. No entry (⑤)

- 4.10.1.6. Precautions for use (⑥)

- 4.10.1.7. Precautions when charging (⑦)

- 4.10.1.8. Beware of electric shock (⑧)

- 4.10.1.9. Precautions to prevent battery dropout (⑨)

- 4.10.1.10. For safety notice following warnings (⑩)

- 4.10.1.11. Headguard, backrest (⑪)

- 4.10.1.12. Parking brake (⑫)

- 4.10.1.13. Alarm must sound (⑬)

- 4.10.1.14. Replace seat (⑭)

- 4.10.1.15. Attention to matching rim (1.0 to 1.8 ton pneumatic tire only) (⑮)

- 4.10.1.16. Attention to battery side loading Option (⑯)

- 4.10.1.17. Attention of laser beam of laser pointer Option (Part 1) (⑰)

- 4.10.1.18. Attention of laser beam of laser pointer Option (Part 2) (⑱)

- 4.10.1.19. Attention to blue light Option (⑲)

- 4.10.1.20. Careful handling of clamp lockout Option (⑳)

- 4.10.2. Instruction label

- 4.10.2.1. Truck name plate (a)

- 4.10.2.2. Mast label (b)

- 4.10.2.3. Lubrication chart label (c)

- 4.10.2.4. OK mark (d)

- 4.10.2.5. Gas spring operation method (e)

- 4.10.2.6. Hoisting point (f)

- 4.10.2.7. Hydraulic oil filler (g)

- 4.10.2.8. Specification of hydraulic oil (h)

- 4.10.2.9. Connection status of the battery electrolyte level sensor (i)

- 4.10.2.10. Refill water (Automatic battery fluid supply) Option (j)

- 4.10.2.11. Operating method of optional single hydraulic lever (k)

- 4.10.2.12. Manual is missing (l)

- 4.11. Name plate, Serial number

- 4.11.1. Chassis serial number

- 4.11.1.1. Name plate

- 4.11.1.2. Mast label

- 5. HANDLING OF EACH DEVICE

- 5.1. Function

- 5.1.1. Safety function

- 5.1.1.1. Neutral safety control

- 5.1.1.2. OIS control (OISOperator Interlock System)

- 5.1.2. Support function

- 5.1.2.1. Parking brake warning

- 5.1.2.2. Pitching control

- 5.1.2.3. Accelerator-off regeneration

- 5.1.2.4. Auto power-off control

- 5.1.2.5. Laser pointer Option

- 5.1.2.6. Automatic tilt horizontal stop Option

- 5.1.2.7. S-Assist control Option

- 5.2. Meter panel screen

- 5.2.1. Meter panel screen

- 5.2.1.1. Simple table of contents for meter panel screen

- 5.2.2. Meter panel screen basic flow

- 5.2.3. Meter panel switch

- 5.2.4. Mode display

- 5.2.4.1. ECO mode

- 5.2.5. Normal screen

- 5.2.5.1. Name of parts on the normal screen

- 5.2.5.2. Battery discharge indicator (BDI)

- 5.2.5.3. Lift interrupt at over discharging (Lift lock by discharge level) Option

- 5.2.5.4. Turtle mode (Travel speed limit)

- 5.2.5.5. Main meter panel

- 5.2.5.6. Icon display

- 5.2.5.7. Laser pointer icon Option

- 5.2.5.8. Error code display and Abnormal code display

- 5.2.6. Operation results

- 5.2.6.1. Basic rules of operation result screen flow

- 5.2.6.2. Table of operation result screen

- 5.2.6.3. How to reset LAP

- 5.2.7. User settings

- 5.2.7.1. Basic rules for user setting screen flow

- 5.2.7.2. User setting screen list

- 5.2.7.3. How to change setting items (including date and time setting method)

- 5.2.7.4. C (Customize) mode setting confirmation flow details

- 5.2.7.5. Setting method of tare (load weight indicator) Option

- 5.2.8. Simple PIN code (password) entry Option

- 5.2.8.1. PIN code (password) input method

- 5.2.8.2. How to enter

- 5.2.9. Manager PIN code (password) entry

- 5.2.9.1. PIN code (password) input method

- 5.2.9.2. How to enter

- 5.2.10. Manager settings

- 5.2.10.1. Basic rules of manager setting screen flow

- 5.2.10.2. List of manager setting screen (Simplified version)

- 5.2.10.3. Custom feeling setting flow details

- 5.2.10.4. How to change setting items

- 5.2.11. Maintenance timer

- 5.2.11.1. Types of maintenance timer display

- 5.3. Name of each part

- 5.3.1. Name of each part (Appearance)

- 5.3.1.1. Name of each part (Around operators seat)

- 5.4. How to use the switch

- 5.4.1. Emergency switch

- 5.4.1.1. Key switch

- 5.4.1.2. Lighting switch

- 5.4.1.3. Turn signal lever

- 5.4.1.4. Horn switch

- 5.4.1.5. Rear assist grip with horn switch

- 5.4.1.6. Work light switch Option

- 5.5. Traveling device

- 5.5.1. Overhead guard

- 5.5.1.1. Getting on / off step assist grip

- 5.5.1.2. Seat belt (Retractable type)

- 5.5.1.3. Storage pocket, magazine box

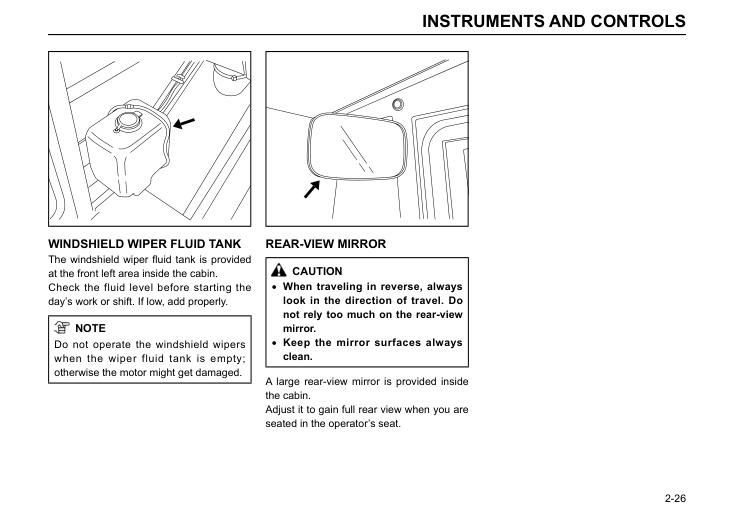

- 5.5.1.4. Back mirror (Rearview mirror)

- 5.5.1.5. Steering wheel

- 5.5.1.6. Tilt steering

- 5.5.1.7. Brake pedal

- 5.5.1.8. Double brake pedal Option

- 5.5.1.9. Parking brake lever

- 5.5.1.10. Directional lever

- 5.5.1.11. Accelerator pedal

- 5.6. Load handling equipment

- 5.6.1. Type of operating levers

- 5.6.1.1. Lift lever / Tilt lever

- 5.6.1.2. Attachment lever Option

- 5.6.1.3. Automatic tilt horizontal stop Option

- 5.6.1.4. Fingertip control Option armrest adjustment

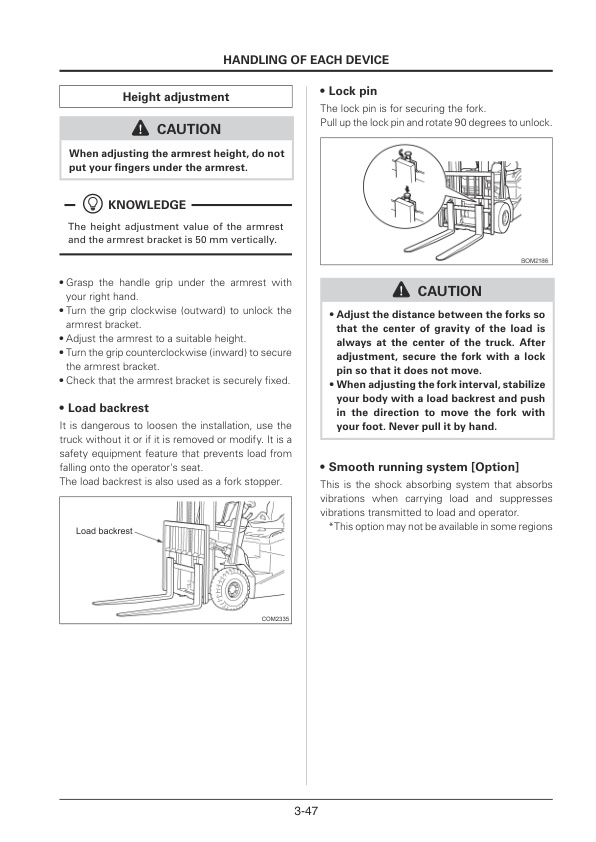

- 5.6.1.5. Load backrest

- 5.6.1.6. Lock pin

- 5.6.1.7. Smooth running system Option

- 5.6.2. Extension fork Option

- 5.6.2.1. For safe handling

- 5.6.2.2. Be prepared for safety

- 5.6.2.3. Handling of extension forks

- 5.6.2.4. Load handling

- 5.7. Other safety devices

- 5.7.1. Back buzzer

- 5.7.1.1. Travel forward chime Option

- 5.7.1.2. Two working lights Option

- 5.7.1.3. Back operation light Option

- 5.7.1.4. Revolving light Option

- 5.7.1.5. Rear LED line Option

- 5.7.1.6. LED blue spotlight Option

- 5.7.1.7. LED spotlight Option

- 5.8. Other optional equipment

- 5.8.1. Front window Option

- 5.8.1.1. Rear window Option

- 5.8.1.2. Plastic cabin Option

- 5.8.1.3. AOS (Advanced Operation System) Option

- 5.8.1.4. Fire extinguisher Option

- 6. OPERATION

- 6.1. Before turning the key switch to the ON position

- 6.1.1. Boarding and getting off

- 6.1.1.1. Seat adjustment

- 6.1.1.2. Adjusting the steering wheel

- 6.1.1.3. Adjustment of back mirror (Rear view mirror)

- 6.1.1.4. Turn the key switch to ON.

- 6.2. How to start

- 6.3. How to switch between forward and backward

- 6.3.1. Switching after stopping the truck by operating the brake

- 6.3.1.1. Switching by plugging operation while traveling

- 6.4. How to travel

- 6.5. How to turn

- 6.6. How to stop the truck

- 6.7. How to park the truck

- 6.7.1. Parking in cold weather

- 7. LOAD HANDLING

- 7.1. Before load handling

- 7.1.1. Fork spread adjustment

- 7.1.1.1. Secure loading

- 7.2. Unstacking operation

- 7.3. Stacking operation

- 7.4. Traveling with a load

- 8. BATTERY AND CHARGER

- 8.1. Handling the battery

- 8.1.1. Fire prohibited

- 8.1.1.1. Caution for running out of electrolyte

- 8.1.1.2. Be careful of ventilation

- 8.1.1.3. Be careful of over-discharge

- 8.1.1.4. Keep the battery dry and clean

- 8.1.1.5. Pay attention to static electricity

- 8.1.1.6. Beware of electric shock

- 8.2. Safety guidelines for lead-acid batteries for electric vehicles and lead-acid batteries for small electric vehicles

- 8.2.1. Safe handling

- 8.2.1.1. Daily inspection

- 8.2.1.2. Maintenance

- 8.2.1.3. Storage (Place)

- 8.2.1.4. Handling of electrolyte

- 8.2.1.5. Handling of an end-of-life battery and disposal of the used battery

- 8.2.1.6. What to do if something goes wrong

- 8.3. Notes for charging

- 8.3.1. Never let the battery run out of electrolyte

- 8.3.1.1. Use distilled or purified water

- 8.3.1.2. Do not overcharge

- 8.3.1.3. Beware of electric shock

- 8.3.1.4. Charge in a well-ventilated place

- 8.3.1.5. Check the specific gravity

- 8.3.1.6. Inspection of charger and power supply plugs

- 8.3.1.7. Insertion and removal of plug

- 8.3.1.8. Interruption of charge

- 8.3.1.9. Process before charging

- 8.3.1.10. Precautions after charging

- 8.4. Handling of the charger

- 8.4.1. Transformer tap adjustment

- 8.5. About the charger

- 8.6. Type of charge

- 8.6.1. Normal charge

- 8.6.1.1. Equal (Balancing) charge

- 8.6.1.2. Reserved charge (Built-in charger) Option

- 8.6.1.3. Supplementary charge

- 8.7. Name of each part

- 8.7.1. Automatic battery fluid supply Option

- 8.8. How to charge

- 8.8.1. Preparation to charge

- 8.8.2. How to charge (Built-in charger) Option

- 8.8.2.1. AUTO (Normal) charge

- 8.8.2.2. EQUAL charge

- 8.8.2.3. RESERVE charge Option

- 8.8.3. Reserved charge procedure

- 8.8.3.1. Basic rules for operation of the meter panel screen

- 8.8.3.2. Procedure of the reserved charge

- 8.8.4. Charging

- 8.8.5. After charge

- 8.8.6. Processing after charge

- 8.8.6.1. Supplementary charge

- 8.8.7. Charge for long term storage

- 8.9. Error code and abnormal code related to charge

- 8.9.1. List of error and abnormal code

- 8.10. Charge with the stationary charger

- 8.10.1. Names and functions of each part

- 8.10.1.1. Charger

- 8.10.2. How to handle the charger

- 8.10.2.1. How to install the charger

- 8.10.3. How to charge

- 8.10.3.1. Before to charge

- 8.10.3.2. Start to charge

- 8.10.3.3. Completion of charge

- 8.10.4. Inspection and treatment in case of abnormality

- 8.10.4.1. Periodic inspection

- 8.10.4.2. Treatment for abnormality

- 8.10.4.3. Precautions for disposal

- 9. PRE-OPERATION INSPECTION AND SIMPLE MAINTENANCE

- 9.1. What is a pre-operation inspection

- 9.2. Precautions for inspection

- 9.2.1. Preparation before inspection

- 9.2.1.1. After inspection

- 9.3. List of items for a pre-operation inspection

- 9.4. How to a perform Pre-operation inspection, adjustment, and replenishment

- 9.4.1. Abnormal parts on the previous day

- 9.4.1.1. Abnormal parts

- 9.4.2. Around the truck

- 9.4.2.1. Truck Posture

- 9.4.2.2. Oil (inspect leakage)

- 9.4.2.3. Lights (inspect dirt or damage)

- 9.4.2.4. Load backrest and Overhead guard (inspect damage or ill-fitting)

- 9.4.2.5. Tilt cylinder rod and lock nut (inspect looseness)

- 9.4.2.6. Tire and rim (inspect damage)

- 9.4.2.7. Wheel nut (inspect looseness)

- 9.4.2.8. Tires (inspect air pressure)

- 9.4.2.9. Brake fluid (inspect level)

- 9.4.2.10. Hydraulic oil (inspect level)

- 9.4.3. Open the battery cover

- 9.4.3.1. Opening and closing the battery cover

- 9.4.3.2. Electrolyte (inspect level)

- 9.4.4. In the operators seat

- 9.4.4.1. Seat position

- 9.4.4.2. Seat belt

- 9.4.4.3. Brake pedal (inspect working)

- 9.4.4.4. Parking brake lever (inspect working)

- 9.4.4.5. Horn (inspect sound)

- 9.4.4.6. Rearview mirror (inspect dirt or damage)

- 9.4.4.7. Lights (inspect working)

- 9.4.4.8. Brake light (inspect working)

- 9.4.4.9. Steering wheel (inspect play and wobble)

- 9.4.5. Turn the key switch to the ON position

- 9.4.5.1. Turn signals (inspect working)

- 9.4.5.2. Back up light and back buzzer (inspect working)

- 9.4.5.3. Meter panel screen (inspect working)

- 9.4.6. In slow operation (Traveling, load handling and steering)

- 9.4.6.1. Steering wheel (inspect working)

- 9.4.6.2. Brake (inspect working)

- 9.4.6.3. Motor (inspect noise and vibration)

- 9.4.6.4. Drive unit (inspect noise and vibration)

- 9.4.7. After stopping

- 9.4.7.1. Lift chain (inspect tension)

- 9.4.7.2. Forks (inspect fitting)

- 9.4.8. During operation(Load handling and steering)

- 9.4.8.1. Mast (inspect working)

- 9.4.8.2. Laser pointer (inspect working) Option

- 9.4.8.3. Automatic tilt horizontal stop (inspect working) Option

Caterpillar Operation Manual PDF

Caterpillar DP100NL-160SNL Lift Trucks Operation and Maintenance Manual OCFEG-J091K-211

Caterpillar Operation Manual PDF

Caterpillar 2C7000 – 2C8000-SWB Lift Trucks Operation and Maintenance Manual OCFAA-AC1F2-200

Caterpillar Operation Manual PDF

Caterpillar DP60NM, DP60NMS, DP70NM, DP70NMS Operation and Maintenance Manual 99700-27110

Caterpillar Operation Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Operation and Maintenance Manual 99710-8M110

Caterpillar Operation Manual PDF

Caterpillar 3.3 Liter (4.2032) Diesel Engine Disassembly and Assembly SENB8128

Caterpillar Operation Manual PDF

Caterpillar DP100NM1, DP120NM1, DP135NM1, DP150NM1 Operation and Maintenance Manual 99790-87100

Caterpillar Operation Manual PDF

Caterpillar 1404 Engine Specifications Systems Operation Testing and Adjusting SENB8080-05

Caterpillar Operation Manual PDF

Caterpillar DP100NL-160SNL Lift Trucks Operation and Maintenance Manual OCFEG-J091K-213

Caterpillar Operation Manual PDF

Caterpillar DP60N3-100N3 Lift Trucks Operation and Maintenance Manual OCFEE-J04C4-201

Caterpillar Operation Manual PDF

Caterpillar 2.5 Liter (XD3P) Diesel Engine Disassembly and Assembly SENB8271