Caterpillar GP15-35PT-PTD-PTL-PTE, DP15-35PT-D Lift Trucks Operation and Maintenance Manual OCFEG-MT13H-231

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OCFEG-MT13H-231

- Number of Pages: 308

- Size: 19.0MB

- Format: PDF

-

Model List:

- GP15PT, GP15PTD, GP15PTL, GP15PTE, GP18PT, GP18PTD, GP18PTL, GP18PTE, GP20CPT, GP20CPTD, GP20CPTL, GP20CPTE, GP20PT, GP20PTD, GP20PTL, GP20PTE, GP20PTH, GP20PTHDH, GP20PTHL, GP20PTHE, GP25PT, GP25PTD, GP25PTL, GP25PTE, GP25PTH, GP25PTHDH, GP25PTHL, GP25PTHE, GP30PT, GP30PTD, GP30PTL, GP30PTE, GP35PT, GP35PTD, GP35PTL, GP35PTE, DP15PT, DP15PTD, DP18PT, DP18PTD, DP20CPT, DP20CPTD, DP20PT, DP20PTD, DP25PT, DP25PTD, DP30PT, DP30PTD, DP35PT, DP35PTD

- 1. FOREWORD

- 2. CHANGE LOG

- 3. CHAPTER 1 IMPORTANT NOTIFICATION

- 3.1. General

- 3.1.1. How To Use This Manual

- 3.1.2. Models Covered in this Manual

- 3.1.3. LOCKOUT/TAGOUT

- 3.1.4. PRODUCT REGISTRATION

- 3.2. Warning Decals, Location

- 3.2.1. Warning Decals, Location

- 3.3. Description of Danger, Warning, and Caution Decals

- 3.3.1. Survive in Tip Over Decal

- 3.3.2. Parking Brake Decal

- 3.3.3. Fasten Seat Belt Decal

- 3.3.4. No Riders Warning Decal

- 3.3.5. Back-up Alarm Decal

- 3.3.6. Operation Warning Decal

- 3.3.7. Radiator Cap Warning Decal

- 3.3.8. No Access With Engine Running Decal

- 3.3.9. No One Under / On Forks and No One Between Mast and Lift Truck Decal

- 3.3.10. Load Backrest Extension Decal

- 3.3.11. Crush and Pinch Point Decal

- 3.3.12. Capacity Plate

- 3.3.13. Inspection / Lubrication Chart (For Latin America)

- 3.3.14. Gasoline / LPG Changeover Decal

- 3.3.15. Operator Restraint System Decal

- 3.3.16. Operate with OMM Decal

- 3.3.17. Deflate Air Before Loosening Nut Decal

- 3.3.18. No Contamination Permissible Decal

- 3.3.19. Hoist Point Decal (Mast)

- 3.3.20. Hoist Point Decal (Counterweight) (Except LPG)

- 3.3.21. Laser Light Decal (For Laser Fork Height Pointer, Option)

- 3.3.22. Clamp Release Decal (Double Action) (Option)

- 4. CHAPTER 2 SAFETY RULES

- 4.1. General

- 4.1.1. General

- 4.1.2. Authorized and Trained Operators Only

- 4.1.3. Lift Trucks Are NOT Intended to Use on Public Roads

- 4.1.4. Operator Responsibility

- 4.1.5. Know the Lift Truck and Attachments

- 4.1.6. Maintain Adequate Clearance, Crushing Hazard

- 4.1.7. Qualifications Required for Slinging Work

- 4.1.8. Have the Operators Receive Safety Education for Load Stacking Work

- 4.1.9. Education for New Lift Truck

- 4.1.10. Refresher Training for the Experieced Operators

- 4.1.11. Know All Signals and Traffic Rules

- 4.1.12. Developing Safe Work Plans

- 4.1.13. Operate the Lift Truck Safely Within the Rules and Regulations of Your Employer

- 4.1.14. Be Familiar with Traffic Zones and Operating Routes

- 4.1.15. Adhere to Speed Limits

- 4.1.16. Designate a Spotter for Blind Spots

- 4.1.17. Always Be Alert

- 4.1.18. Confirming Emergency Contact Methods

- 4.1.19. Dress Properly for the Job

- 4.1.20. DO NOT Operate the Lift Truck If You Are Pregnant or Have Suffered an Abdominal Disease or Injury

- 4.1.21. Daily Pre-start Inspection

- 4.1.22. Ensure the Lift Truck and Attachment Equipped Are Appropriate for the Job

- 4.1.23. Keep Out

- 4.1.24. Watch Out for Personnel

- 4.1.25. BEWARE of Personnel Working Near the Lift Truck Operation

- 4.1.26. Watch Out for Pedestrians at All Times

- 4.2. Fire Hazards

- 4.2.1. No Smoking While Refueling

- 4.2.2. No Smoking During Fueling and Battery Charging

- 4.2.3. Caution on Smoking in the Operator Compartment

- 4.2.4. Check for Any Source of Potential Fire Hazard

- 4.2.5. Check for Oil Leaks

- 4.2.6. Short Circuit Inspection

- 4.2.7. LP-Gases Are Flammable

- 4.2.8. Fire Evacuation Procedures

- 4.2.9. Exhaust Fumes Could Kill You

- 4.3. Inspection Maintenance

- 4.3.1. Inspect the Lift Truck Before Operation

- 4.3.2. Unauthorized Addition or Modification Is Prohibited

- 4.3.3. Qualified Technicians for Lift Truck Repair and Attachment Work

- 4.3.4. Authorized and Trained Operators Only

- 4.3.5. Turn OFF the Key Switch Before Servicing

- 4.3.6. Lower the Forks to the Ground Before Servicing

- 4.3.7. Take Fall Prevention Measures for the Forks and Mast When Checking or Maintenance with the Forks Raised

- 4.3.8. DO NOT Put Your Foot Under Forks

- 4.3.9. Caution on Jack-up Work

- 4.3.10. Caution Prior on Lift Truck Lifting Work

- 4.3.11. DO NOT Get Your Hand Caught in the Floor Plate and Engine Hood

- 4.3.12. Avoid Being Splashed by Scalding Hot Coolant

- 4.3.13. Perform the Engine Maintenance When the Engine Is Stopped and Has Cooled Down

- 4.3.14. Caution with Hot Oil Spraying at High Hydraulic Oil Temperatures

- 4.3.15. Inspecting Accumulators and Their Piping Can Be Hazardous

- 4.3.16. Check the Rotating Parts with the Engine Stopped

- 4.3.17. Proper Maintenance of Brake Fluid Is Critical to Brake Performance

- 4.3.18. Caution on Handling the Long-Life Coolant (LLC)

- 4.3.19. Keep the Operator Compartment Clean

- 4.3.20. Wipe Off Dirt, Oil and Grease Immediately

- 4.3.21. Dispose of Potentially Hazards Materials (e.g., Oils, Solvents, Engine Coolant, Batteries, etc.,) in Accordance with Applicable Laws and Regulations

- 4.3.22. DO NOT Remove the Overhead Guard

- 4.3.23. DO NOT OVERLY RELY ON OVERHEAD GUARDS

- 4.3.24. DO NOT Remove, or Disable, Safety Devices or Features (e.g., Overhead Guard, Load Backrest, Horn etc.)

- 4.3.25. Be Careful of Falling Off

- 4.3.26. DO NOT Substitute the Mast for a Ladder

- 4.3.27. DO NOT Start the Engine by Pushing or Pulling the Lift Truck

- 4.3.28. Caution When Adjusting the Air Pressure of the Tires (Rim and Compressor)

- 4.3.29. Caution on Handling Tire Mounting Nuts, Rims and Rim Mounting Bolts/Nuts

- 4.3.30. Precautions When Handling Controllers and Sensors

- 4.4. Pre-start/Before Getting on

- 4.4.1. Know Your Lift Truck Is Safe

- 4.4.2. Inspect the Lift Truck Before Operation

- 4.4.3. Make a Habit of Performing the Daily Pre-start Inspection

- 4.4.4. Performing and Recording the Periodic Check is Mandatory

- 4.4.5. Critical Safety Parts Must Be Replaced Periodically

- 4.4.6. DO NOT Operate a Damaged or Defective Lift Truck

- 4.4.7. DO NOT Operate an Unsafe Lift Truck

- 4.4.8. DO NOT Operate the Lift Truck Under the Influence of Drugs or Alcohol

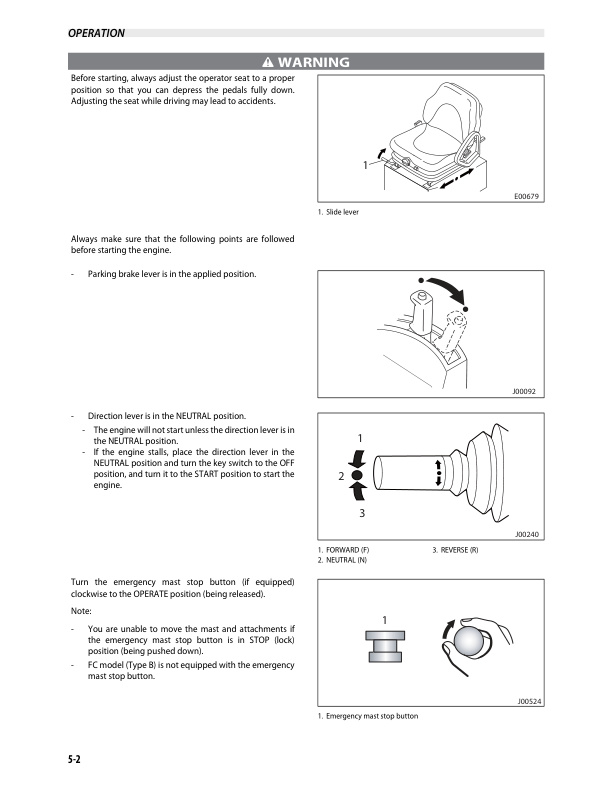

- 4.4.9. Position Levers Correctly for Starting

- 4.4.10. Sit in the Operator Seat When Starting the Engine and Operating the Operation Levers

- 4.5. Getting on – Before Driving

- 4.5.1. Face the Lift Truck During Ingress and Egress (Getting On and Off)

- 4.5.2. Three-point Contact

- 4.5.3. Adjust the Operator Seat Before Operating the Lift Truck

- 4.5.4. When Operating the Lift Truck, BE SURE to Fasten the Seat Belt

- 4.5.5. THE BACK-UP ALARM MUST ACTIVATE WHEN TRAVELING IN REVERSE

- 4.5.6. If There Is Any Abnormality with the Rear-view Mirrors, Back-up Alarm, Lights, and Horn, Have Them Repaired Immediately.

- 4.5.7. DO NOT Allow Any Riders

- 4.5.8. DO NOT Allow Anyone to Ride on Counterweight and Carry Any Passenger

- 4.5.9. Caution When Starting the Lift Truck

- 4.5.10. Make Sure Your Lift Truck Is in a Safe Operating Condition

- 4.5.11. Make Sure That No One Is Around the Lift Truck Before Starting

- 4.5.12. ALWAYS Be Aware of People Near Your Lift Truck

- 4.6. Know Your Working Area

- 4.6.1. Operate Only in Approved Areas

- 4.6.2. Always Check Overhead Clearance

- 4.6.3. Ensure Necessary Brightness for Safe Operation

- 4.6.4. Always Be Aware of Floor and Ground Capacity

- 4.6.5. Surface and Capacity (for CushionTire Models)

- 4.6.6. Check Work Places for High Risk

- 4.6.7. Trailer and Railroad Car Safety

- 4.6.8. Dock Plates (Bridge Plates) Safety

- 4.6.9. Operating in Elevators Safely

- 4.7. Driving/Traveling

- 4.7.1. Stay Under the Overhead Guard and Within the Confines of the Lift Truck

- 4.7.2. DO NOT Hold on to the Overhead Guard

- 4.7.3. DO NOT Jump Out of the Lift Truck in the Event of Tip Over

- 4.7.4. In Case of Tip over

- 4.7.5. Obey All Traffic Regulations and Warning Signs, Including Authorized Plant Speed Limits

- 4.7.6. DO NOT Overtake Another Lift Truck

- 4.7.7. Slow Down on Wet and Slippery Surfaces

- 4.7.8. Slow Down Where Vision Is Obstructed

- 4.7.9. DO NOT Indulge in Stunt Driving or Horseplay

- 4.7.10. Be Careful When Turning with a Load

- 4.7.11. DO NOT Speed When Making Turns

- 4.7.12. Always Look in the Direction of Travel

- 4.7.13. No Distracted Driving

- 4.7.14. Drive with Awareness of Surroundings

- 4.7.15. Travel in REVERSE If Forward Visibility Is Blocked

- 4.7.16. Be Careful of Drive End Swing

- 4.7.17. Allow for Tail Swing Distance

- 4.7.18. DO NOT Run Over Objects

- 4.7.19. Travel Safely on Grades with a Loaded Lift Truck

- 4.7.20. Travel Safely on Grades with an Empty Lift Truck

- 4.7.21. Be Particularly Careful When Driving Up or Down Asteep Slope

- 4.7.22. Slow Down at the Top of Upgrades

- 4.7.23. Starting the Lift Truck on an Upgrade Carefully

- 4.7.24. ALWAYS Descend a Grade Carefully

- 4.7.25. Adjust the Operation of the Lift Truck So That You Can Descend Safely

- 4.7.26. DO NOT Turn on Grades or Ramps

- 4.7.27. DO NOT Operate the Lift Truck with a Load Under Windy Conditions

- 4.7.28. DO NOT Operate the Parking Brake Lever During Travel

- 4.8. Load Handling

- 4.8.1. STAY CLEAR OF CRUSH AND PINCH POINTS

- 4.8.2. Check Fork Locking Pins for Engagement

- 4.8.3. Ensure Equal Tension in Both the Left and Right Lift Chains

- 4.8.4. Be Careful of Changes in Capacity

- 4.8.5. Always Stay Within the Capacity

- 4.8.6. DO NOT Lift Personnel Except on a Securely Attached, Specially Designed Work Platform

- 4.8.7. Precautions During Load Handling

- 4.8.8. DO NOT Allow Anyone to Hold Loads

- 4.8.9. DO NOT Allow Unloading from Raised Loads

- 4.8.10. Use the Proper Attachment

- 4.8.11. Side Shift Operation

- 4.8.12. Fork Positioner Operation

- 4.8.13. DO NOT Raise or Lower a Load While Side Shifting

- 4.8.14. DO NOT Use Damaged Pallets

- 4.8.15. DO NOT Speed When Approaching Loads

- 4.8.16. Operate the Direction Lever Smoothly

- 4.8.17. Avoid Off-center Loading

- 4.8.18. Be Careful of Forks That Extend Beyond the Load

- 4.8.19. Handle Only Stable and Safely Arranged Loads

- 4.8.20. Ensure the Load Isnt Too High

- 4.8.21. Falling Object Hazard

- 4.8.22. Ensure Stable Stacking of Loads

- 4.8.23. DO NOT Abuse Forks

- 4.8.24. DO NOT Use the Lift Truck Improperly

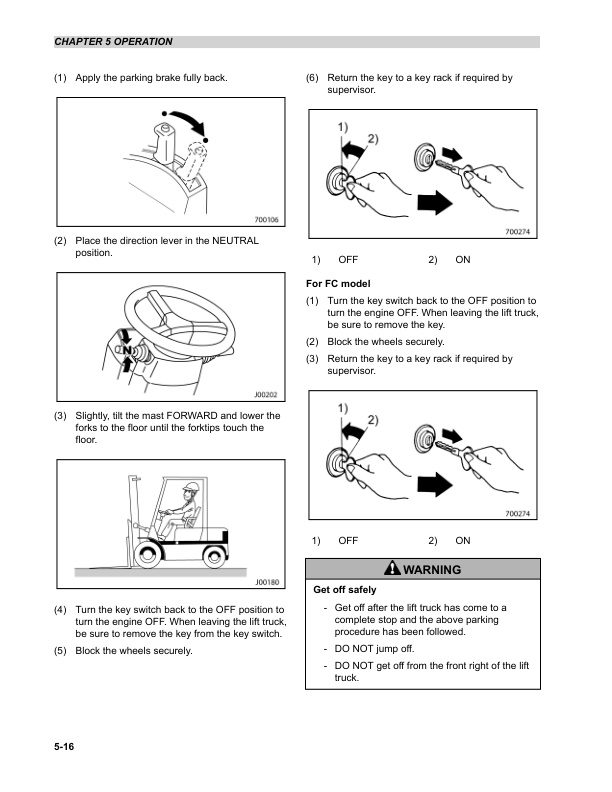

- 4.9. Stopping/Parking

- 4.9.1. Park in Authorized Areas Only

- 4.9.2. Park Disabled Lift Truck Safely

- 4.9.3. DO NOT Park on a Grade.

- 4.9.4. SET THE PARKING BRAKE PROPERLY

- 4.9.5. When You Leave or Park the Lift Truck

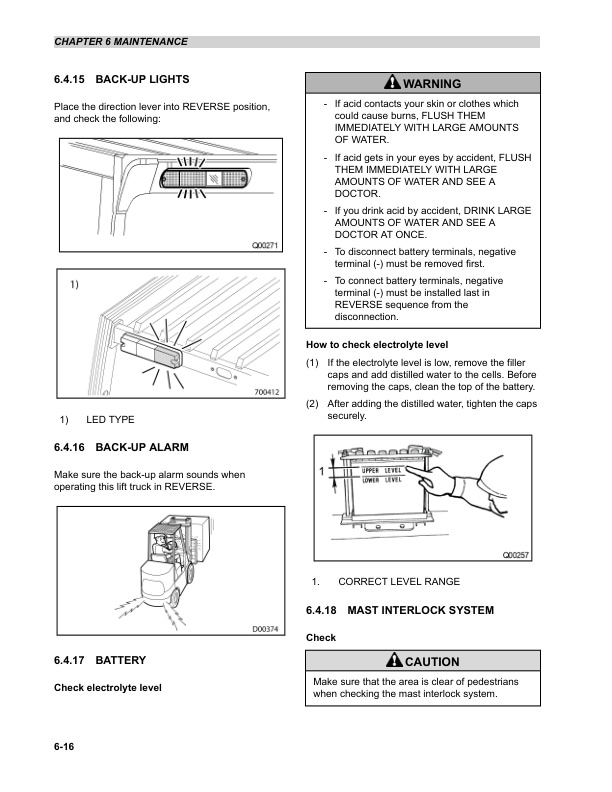

- 4.10. Handling of Battery Charger

- 4.10.1. Wear Protective Gear When Handling of Battery

- 4.10.2. Flush the Contact Area with Large Amounts of Water Immediately When Come Into Contact with Battery Electrolytes

- 4.10.3. Flammables and Fire Should Be Kept Away From the Battery

- 4.10.4. Keep Tools and Metal Parts Away From the Battery to Avoid Short Circuit

- 4.10.5. Caution When Handling of Battery Terminals

- 4.10.6. Caution When Using the Jumper Cables to Start

- 4.10.7. Caution When Handling of Charger

- 4.10.8. Caution During Battery Charging

- 4.10.9. DO NOT Short Circuit Both Battery Terminals to Check the Battery Charging Status

- 4.10.10. Caution on Static Electricity When Checking or Cleaning the Battery

- 4.10.11. Caution on Battery Voltage

- 4.10.12. Caution on Electrolyte Level

- 4.11. Handling of Fuel LPG Cylinder (Tank)

- 4.11.1. Fuel Handling

- 4.11.2. CAUTION ON HANDLING LPG CYLINDERS (TANKS)

- 4.12. Lift Truck Loading and Shipping (Transportation)

- 4.12.1. Lift Truck Loading and Shipping

- 4.13. Towing Your Lift Truck

- 4.13.1. DRAWBAR PIN

- 4.14. Lifting Your Lift Truck

- 4.14.1. LIFTING YOUR LIFT TRUCK

- 5. CHAPTER 3 HOW TO AVOID A TIP OVER

- 5.1. Know What Lift Truck Stability Is

- 5.1.1. Know What Lift Truck Stability Is

- 5.2. Center of Gravity (CG)

- 5.2.1. Center of Gravity (CG)

- 5.3. Stability and Center of Gravity

- 5.3.1. Stability and Center of Gravity

- 5.4. Lift Truck Stability Base

- 5.4.1. Lift Truck Stability Base

- 5.5. Capacity (Weight and Load Center)

- 5.5.1. Capacity (Weight and Load Center)

- 5.6. Capacity Plate

- 5.6.1. Capacity Plate – Overview

- 5.6.2. For Example

- 5.6.3. Nominal Capacity Height Indicator

- 5.7. Dos and Donts to Avoid Tip Over

- 5.7.1. Dos and Donts to Avoid Tip Over

- 5.8. How to Survive in a Tip Over

- 5.8.1. How to Survive in a Tip Over

- 6. CHAPTER 4 KNOW YOUR LIFT TRUCK

- 6.1. Serial Number and Capacity Plate

- 6.1.1. Serial Number and Capacity Plate

- 6.2. Electrical Components

- 6.2.1. Electrical Components

- 6.3. Model View

- 6.3.1. Model View – Overview

- 6.3.2. MC Model

- 6.3.3. FC Model

- 6.4. Driving Switches and Controls

- 6.4.1. Driving Switches and Controls – Overview

- 6.4.2. Key Switch

- 6.4.3. Direction Lever (Powershift)

- 6.4.4. Inching Pedal (Powershift)

- 6.4.5. Turn Signal / Light Switch

- 6.4.6. Steering Column Tilt Lever

- 6.5. Meter Panel

- 6.5.1. Meter Panel Parts Description

- 6.5.2. Button

- 6.5.3. LCD Screen Display Switching

- 6.5.4. LCD Screen

- 6.5.5. Warning Icons and Indicators

- 6.5.6. Basic Operation

- 6.5.7. When Diagnostic Code Is Shown on Display

- 6.5.8. Warning Symbols

- 6.5.9. Optional Features

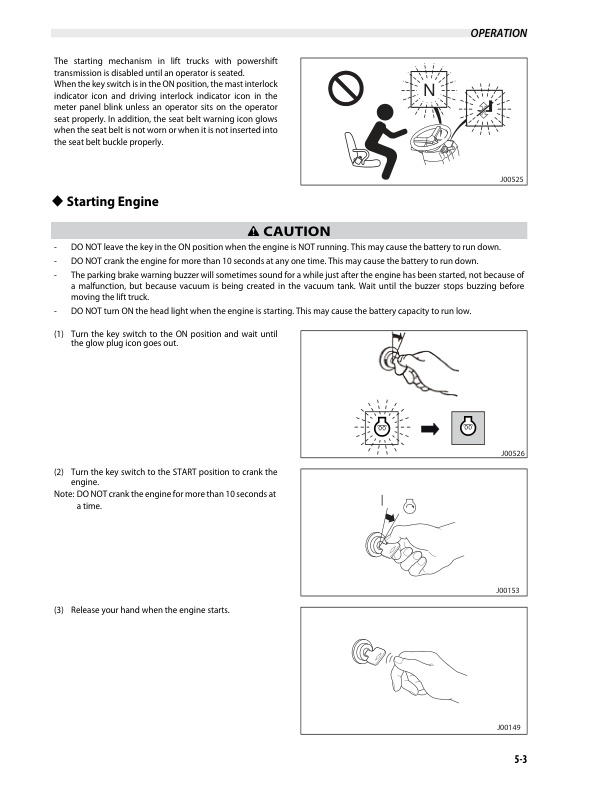

- 6.6. Presence Detection System

- 6.6.1. Presence Detection System (PDS) – Overview

- 6.6.2. Mast Interlock System

- 6.6.3. Mast Interlock System Functions

- 6.6.4. Driving Interlock System (Powershift Models)

- 6.6.5. Driving Interlock System Functions

- 6.6.6. Neutral System

- 6.6.7. Neutral System Functions

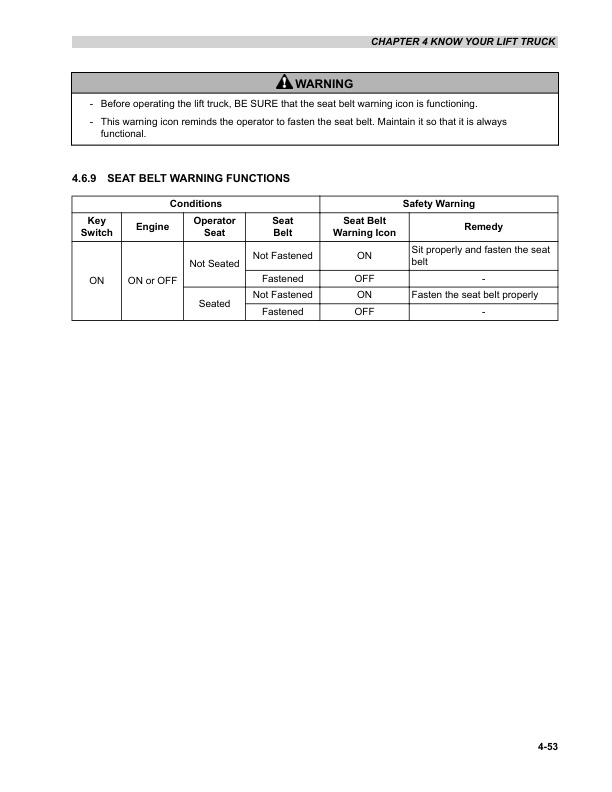

- 6.6.8. Seat Belt Warning Icon

- 6.6.9. Seat Belt Warning Functions

- 6.6.10. Parking Brake Warning Icon and Alarm

- 6.6.11. Parking Brake Warning Functions

- 6.6.12. Seatbelt Interlock (Standard for Australia Specification and Option for Other Destinations)

- 6.6.13. Seat Belt Interlock System Functions

Caterpillar Operation Manual PDF

Caterpillar DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Operation and Maintenance Manual 99790-42010

Caterpillar Operation Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Operation and Maintenance Manual 99710-8M110

Caterpillar Operation Manual PDF

Caterpillar DP100NL-160SNL Lift Trucks Operation and Maintenance Manual OCFEG-J091K-213

Caterpillar Operation Manual PDF

Caterpillar DP100NL-160SNL Lift Trucks Operation and Maintenance Manual OCFEG-J091K-211

Caterpillar Operation Manual PDF

Caterpillar 1404 Engine Disassembly and Assembly SENB8108-02

Caterpillar Operation Manual PDF

Caterpillar 4.236 Gasoline Engine Specifications Systems Operation Testing and Adjusting SENB8081-03

Caterpillar Operation Manual PDF

Caterpillar DP100NM1, DP120NM1, DP135NM1, DP150NM1 Operation and Maintenance Manual 99790-87100

Caterpillar Operation Manual PDF

Caterpillar DP60N3-100N3 Lift Trucks Operation and Maintenance Manual OCFEE-J04C4-201

Caterpillar Operation Manual PDF

Caterpillar DP100NM1 to DP150NM1S Operation and Maintenance Manual 99790-47120

Caterpillar Operation Manual PDF

Caterpillar DP100, DP115, DP135, DP150 Operation and Maintenance Manual 99790-83130