Caterpillar NR12-14N3(L)(C), NR16-20N3, NR16-25N3H(X), NRM20-25N3, NTD13-15N3 Service Manual SM21GBRE1AC3

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM21GBRE1AC3

- Number of Pages: 474

- Size: 15.6MB

- Format: PDF

-

Model List:

- NR12-14N3(L)(C), NR16-20N3, NR16-25N3H(X), NRM20-25N3, NTD13-15N3

- 1. sm21gbre1ac3-1

- 1.1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1.1. Introduction

- 1.1.1.1. General

- 1.1.1.2. The trucks

- 1.1.1.3. Genuine Parts

- 1.1.1.4. Authorised service personnel

- 1.1.1.5. Symbol key

- 1.1.2. Safety

- 1.1.2.1. General

- 1.1.2.2. Safety instructions

- 1.1.2.3. Truck modification

- 1.1.2.4. Lifting the truck

- 1.1.2.5. Towing/moving non-powered NRM20-25N3

- 1.1.2.6. Welding on truck

- 1.1.3. Environmental considerations

- 1.1.3.1. We respect the environment

- 1.1.4. Preparations

- 1.1.4.1. Service

- 1.1.4.2. Troubleshooting

- 1.1.5. Truck data

- 1.1.5.1. Machine plates

- 1.1.5.2. Type designation

- 1.1.5.3. Truck types

- 1.1.6. Component specification

- 1.1.6.1. Drive motor

- 1.1.6.2. Electric brake

- 1.1.6.3. Gearbox

- 1.1.6.4. Hydraulic unit

- 1.1.6.5. Control system for traction and pump motors

- 1.1.6.6. Steering servo motor

- 1.1.6.7. Controller system for steering

- 1.1.7. Recommended consumable materials

- 1.1.7.1. Oil and grease types

- 1.1.8. Standards and abbreviations

- 1.1.8.1. General

- 1.1.8.2. Screw types and tensile grades

- 1.1.8.3. Tightening torques for screws and nuts

- 1.1.8.4. Tightening torque for hydraulic couplings

- 1.1.8.5. Tightening torque for banjo screws with rubber-steel washer

- 1.1.8.6. Tightening torque, conversion table

- 1.1.9. Code explanations

- 1.1.9.1. Colour codes for wiring diagrams

- 1.1.9.2. Designations for electrical components in electrical diagram

- 1.1.9.3. Standard abbreviations and units

- 1.1.9.4. Acronyms and abbreviations

- 1.2. SPECIAL TOOLS

- 1.2.1. List of tools

- 1.3. SERVICE

- 1.3.1. Service inspection

- 1.3.1.1. Daily/Weekly inspection

- 1.3.1.2. General

- 1.3.1.3. First service (200 hours)

- 1.3.1.4. Service intervals

- 1.3.1.5. Verification of safety functions

- 1.3.1.6. Check list

- 1.3.2. Lubrication

- 1.3.2.1. Symbol key lubrication chart

- 1.3.2.2. Lubrication chart NR12-14N3(L)(C) / NR16-20N3 / NR16-25N3H(X)

- 1.3.2.3. Lubrication chart NRM20-25N3

- 1.3.2.4. Lubrication chart NTD13-15N3

- 1.3.2.5. Tri-lateral head maintenance schedule

- 1.3.2.6. Cab lubrication schematic diagram (option)

- 1.4. CHASSIS

- 1.4.1. Design and function

- 1.4.1.1. Chassis frame

- 1.4.1.2. Machine housing

- 1.4.1.3. Overhead guard

- 1.4.1.4. Battery locking

- 1.4.1.5. Armrest and steering wheel

- 1.4.1.6. Foot plate

- 1.4.1.7. Covers and panels

- 1.4.1.8. Tightening torque for chassis plates

- 1.4.2. Repair and maintenance instructions

- 1.4.2.1. Panels

- 1.4.2.2. Load wheels

- 1.4.2.3. Machine housing

- 1.4.2.4. Adjusting the stabilising lugs (NR16-25N3H(X))

- 1.4.2.5. Driver seat

- 1.4.2.6. Overhead guard

- 1.4.2.7. Batteries

- 1.4.2.8. Battery rollers

- 1.4.2.9. Adjustable armrest

- 1.4.2.10. Fitting the antistatic chain

- 1.5. DRIVE UNIT

- 1.5.1. Design and function

- 1.5.1.1. Drive motor

- 1.5.1.2. Gearbox

- 1.5.2. Repair and maintenance instructions

- 1.5.2.1. Before work is performed

- 1.5.2.2. Drive unit

- 1.5.2.3. Traction motor

- 1.5.2.4. Removal and installation of the traction motor

- 1.5.2.5. First service

- 1.5.2.6. Preventive maintenance

- 1.5.2.7. Reconditioning the traction motor

- 1.5.2.8. Gearbox

- 1.5.2.9. Drive wheel

- 1.5.3. Diagnostics and troubleshooting

- 1.5.3.1. Troubleshooting chart

- 1.6. MAST SYSTEM

- 1.6.1. Design and function

- 1.6.1.1. Mast system

- 1.6.1.2. Fork carriage

- 1.6.2. Repair and maintenance instructions

- 1.6.3. Lift cylinders

- 1.6.3.1. Adjustment of the cylinder attachments in the mast

- 1.6.4. Lift chains

- 1.6.4.1. Checking the lift chains

- 1.6.4.2. Adjusting the lift chains

- 1.6.4.3. Routine periodic maintenance

- 1.6.4.4. Mounting chains

- 1.6.5. Reach carriage

- 1.6.5.1. Removal and installation of the mast with carriage

- 1.6.5.2. Adjusting the reach carriage

- 1.6.6. Fork carriage

- 1.6.6.1. Removal and installation of the fork carriage

- 1.6.6.2. Adjusting the fork carriage

- 1.6.6.3. Inspection and adjustment of the rubber shock absorbers on the forklift, NTD13-15N3

- 1.6.6.4. Inspection of forged forks

- 1.6.7. Side shift unit of hanging type

- 1.6.7.1. Preventive maintenance

- 1.6.7.2. Check of cylinders

- 1.6.8. Integrated side shift unit (ISS)

- 1.6.8.1. Preventive maintenance

- 1.6.8.2. Removal and installation of the unit (ISS)

- 1.6.8.3. Removing the sliding pads

- 1.6.8.4. Dismantling the cylinder

- 1.6.9. Integral Fork positioner/sideshift, NR12-14N3(L)(C), NR16-20N3, NR16N3H, NR20N3H

- 1.6.9.1. General

- 1.6.9.2. Dismantling and fitting the forks

- 1.6.9.3. Replacing the bushings

- 1.6.9.4. Replacing the slide plate

- 1.6.9.5. Dismounting the hydraulic cylinder

- 1.6.9.6. Repacking the hydraulic cylinder

- 1.6.9.7. Cleaning the flow divider

- 1.6.10. Integral Fork positioner/sideshift, NR25N3H

- 1.6.10.1. General

- 1.6.10.2. Dismantling and fitting the forks

- 1.6.10.3. Replacing the bushings

- 1.6.10.4. Replacing the fork support rollers

- 1.6.10.5. Dismounting the hydraulic cylinder

- 1.6.10.6. Repacking the hydraulic cylinder

- 1.6.10.7. Cleaning the flow divider

- 1.6.11. Hydraulic fork spreading, NRM20-25N3

- 1.6.11.1. General

- 1.6.11.2. Lifting the unit.

- 1.6.11.3. Adjusting the fork angle, NRM20-25N3

- 1.6.11.4. Maintenance

- 1.6.12. Swivel forks unit (NTD13-15N3)

- 1.6.12.1. General

- 1.6.12.2. Safety instructions

- 1.6.12.3. Machine plate

- 1.6.12.4. Lifting the tri-lateral head

- 1.6.12.5. Installing the swivel forks unit

- 1.6.12.6. Removing the swivel forks unit

- 1.6.12.7. Maintenance

- 1.6.12.8. Trouble shooting

- 1.6.13. Diagnostics and trouble shooting

- 1.6.13.1. Troubleshooting chart (Triplex with free lift, Duplex)

- 1.6.13.2. Troubleshooting chart for the side shift unit of hanging type (Duplex)

- 1.6.13.3. Troubleshooting chart for the integrated side shift unit (ISS) (Triplex with free lift)

- 1.6.13.4. Troubleshooting chart for Integral Fork positioner/sideshift, (Triplex with free lift)

- 1.6.13.5. Fault-finding chart for fork spreaders (NRM20-25N3)

- 1.7. STEERING

- 1.7.1. Design and function

- 1.7.1.1. General

- 1.7.1.2. Steering

- 1.7.1.3. Steering servo motor controller

- 1.7.2. Repair and maintenance instructions

- 1.7.2.1. Steering wheel

- 1.7.2.2. Steering servo motor

- 1.7.2.3. Settings, adjustments and testing

- 1.7.2.4. Options

- 1.7.3. Diagnostics and troubleshooting

- 1.7.3.1. Troubleshooting chart

- 1.8. HYDRAULIC SYSTEM

- 1.8.1. Design and function

- 1.8.1.1. Description

- 1.8.1.2. Hose rupture valve

- 1.8.1.3. Electric proportional valve

- 1.8.1.4. Electric solenoid valve

- 1.8.1.5. MTC (Mast Tilt Control)

- 1.8.1.6. Hydraulic diagram

- 1.8.2. Maintenance and repair instructions

- 1.8.2.1. General rules

- 1.8.2.2. Installation

- 1.8.2.3. Connections

- 1.8.2.4. Dismantling and assembling hydraulic hoses

- 1.8.2.5. Pump motor

- 1.8.2.6. Hydraulic oil tank

- 1.8.2.7. MTC (Mast Tilt Control)

- 1.8.3. Control valve

- 1.8.3.1. Operation of the control valve

- 1.8.3.2. Control valve overview

- 1.8.3.3. Removal and installation of the control valve

- 1.8.3.4. Adjusting the working pressure

- 1.8.3.5. Inspection and adjustment of the lowering rate

- 1.8.3.6. Calibrating the hydraulic functions

- 1.8.3.7. S3 valve

- 1.8.3.8. Emergency lowering valve

- 1.8.3.9. Hose rupture valve

- 1.8.4. Control valve (NTD13-15N3)

- 1.8.4.1. Operation of the control valve

- 1.8.4.2. Control valve overview

- 1.8.4.3. Removal and installation of the control valve

- 1.8.4.4. Adjusting the working pressure

- 1.8.4.5. Inspection and adjustment of the lowering rate

- 1.8.5. Diagnostics and troubleshooting

- 1.8.5.1. Troubleshooting the hydraulic system

- 1.8.5.2. Troubleshooting chart

- 1.8.5.3. Troubleshooting the control valve

- 1.8.5.4. Troubleshooting, sensors S21 and S22

- 1.9. HYDRAULIC CYLINDERS

- 1.9.1. Design and function

- 1.9.1.1. Mast shift cylinder

- 1.9.1.2. Tilt cylinder

- 1.9.1.3. Free lift cylinder

- 1.9.1.4. Final stroke cylinder

- 1.9.2. Repair and maintenance instructions

- 1.9.2.1. General

- 1.9.2.2. Reach cylinder

- 1.9.2.3. Tilt cylinder

- 1.9.2.4. Free lift cylinder

- 1.9.2.5. Final stroke cylinder

- 1.9.2.6. Removal and installation of the gasket in the hydraulic cylinder

- 1.10. ELECTRICAL SYSTEM

- 1.10.1. Introduction

- 1.10.1.1. Description of components

- 1.10.2. Safety

- 1.10.2.1. Safety instructions

- 1.10.2.2. Electronic controllers

- 1.10.2.3. Safety checks

- 1.10.2.4. Steering servo system

- 1.10.2.5. Traction system

- 1.10.2.6. Hydraulic system

- 1.10.3. Design and function

- 1.10.3.1. Battery

- 1.10.3.2. Battery capacity measurement

- 1.10.3.3. Battery parameters

- 1.10.3.4. Truck computer ATC

- 1.10.4. Repair and maintenance instructions

- 1.10.4.1. Traction and pump regulation

- 1.10.4.2. Insulation resistance

- 1.10.4.3. Temperature measurement and management

- 1.10.4.4. System for detecting the carriage position

- 1.10.4.5. Electrical monitoring of battery locking

- 1.10.5. Diagnostics and troubleshooting

- 1.10.5.1. Troubleshooting of the hydraulic functions, channels 3, 4 and 5

- 1.10.5.2. Troubleshooting of the hydraulic functions, channels 1, 2 and 3

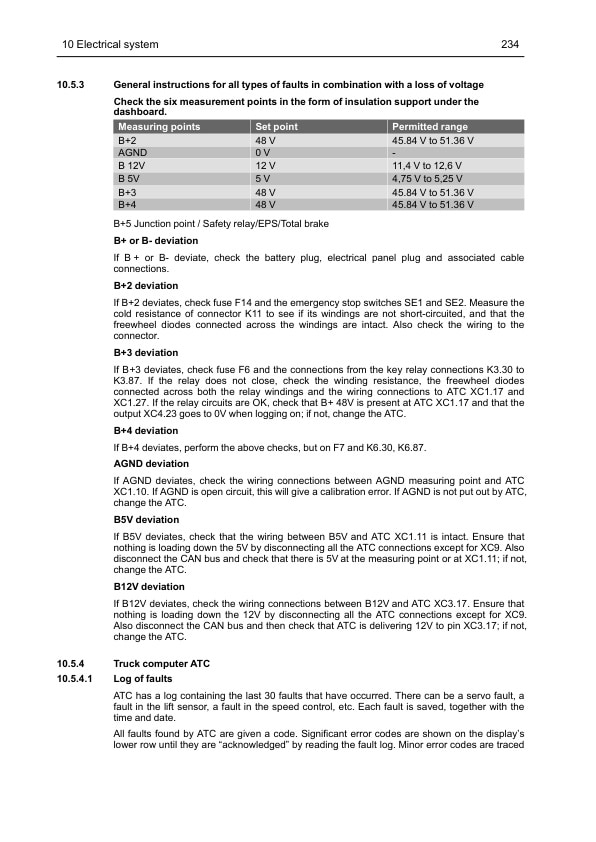

- 1.10.5.3. General instructions for all types of faults in combination with a loss of voltage

- 1.10.5.4. Truck computer ATC

- 1.10.5.5. ATC error codes

- 1.10.5.6. ATC, warnings

- 1.10.5.7. Troubleshooting – operational disturbances

- 1.10.5.8. Troubleshooting table – battery

- 1.10.5.9. Enclosure

- 1.11. SPEED CONTROL AND BRAKE SYSTEMS

- 1.11.1. Design and function

- 1.11.1.1. Electric brake

- 1.11.1.2. Speed and brake sensor

- 1.11.1.3. Hill hold

- 1.11.2. Repair and maintenance instructions

- 1.11.2.1. Electric brakes

- 1.11.2.2. Brake Pedal Assembly

- 1.11.2.3. Left-foot switch

- 1.11.2.4. Speed Controller

- 1.11.3. Diagnostics and troubleshooting

- 1.11.3.1. Brake troubleshooting

- 1.12. MISCELLANEOUS

- 1.12.1. Level selector and height indication

- 1.12.1.1. Pulse height preset

- 1.12.1.2. Level Assistance System, LAS

- 1.12.1.3. Height indication on the display

- 1.12.1.4. Settings for height system

- 1.12.1.5. Checking the fork offset

- 1.12.2. Example of use

- 1.12.2.1. Ex.1 Collecting a load

- 1.12.2.2. Ex.2 Just logged on

- 1.12.2.3. Ex.3 Placing the load

- 1.12.3. Stability Support System, S3-1

- 1.12.3.1. Identification

- 1.12.3.2. Functionality, S3-1

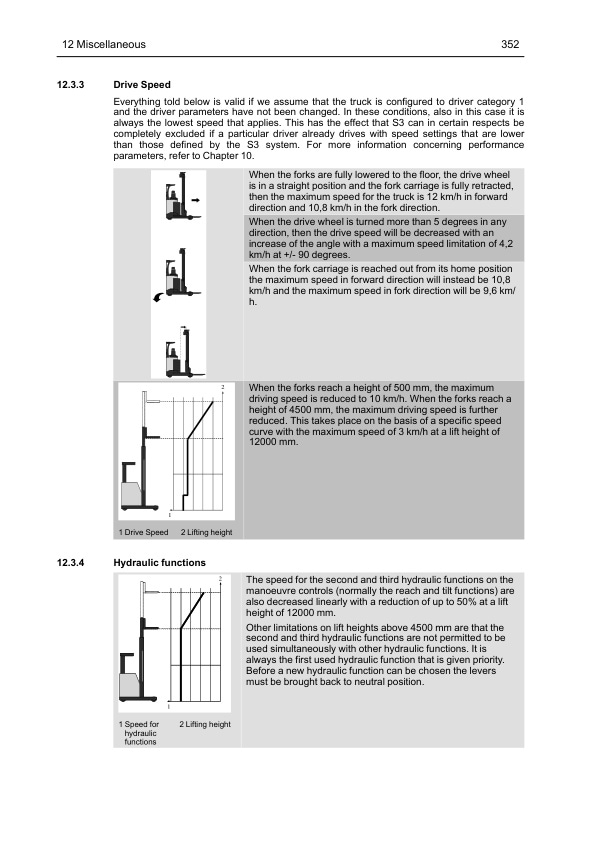

- 1.12.3.3. Drive Speed

- 1.12.3.4. Hydraulic functions

- 1.12.3.5. Technical description

- 1.12.4. Smart card

- 1.12.5. Weight system

- 1.12.5.1. Introduction

- 1.12.5.2. Accompanying hardware

- 1.12.5.3. S3-2 Speed and weight alternatives

- 1.12.5.4. Weight indication

- 1.12.5.5. Side effects, Weight system

- 1.12.5.6. Calibrating the Weight system

- 1.12.5.7. Diagnostics menu

- 1.12.6. Rail guided steering

- 1.12.6.1. General

- 1.12.6.2. Installation

- 1.12.6.3. Dismantling and fitting the rail guide wheel

- 1.12.6.4. Adjusting the sensor

- 1.12.6.5. Straight driving mode, audible and light signals

- 1.12.6.6. Speed limits

- 1.12.6.7. Adjusting max. speed

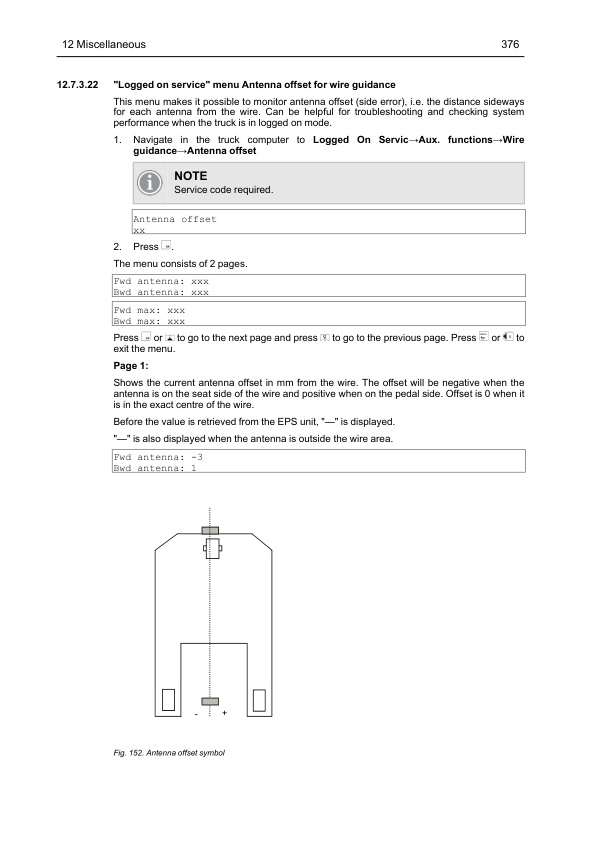

- 1.12.7. Wire guidance

- 1.12.7.1. Wire guidance antenna

- 1.12.7.2. Fitting/removing antennae for wire guidance

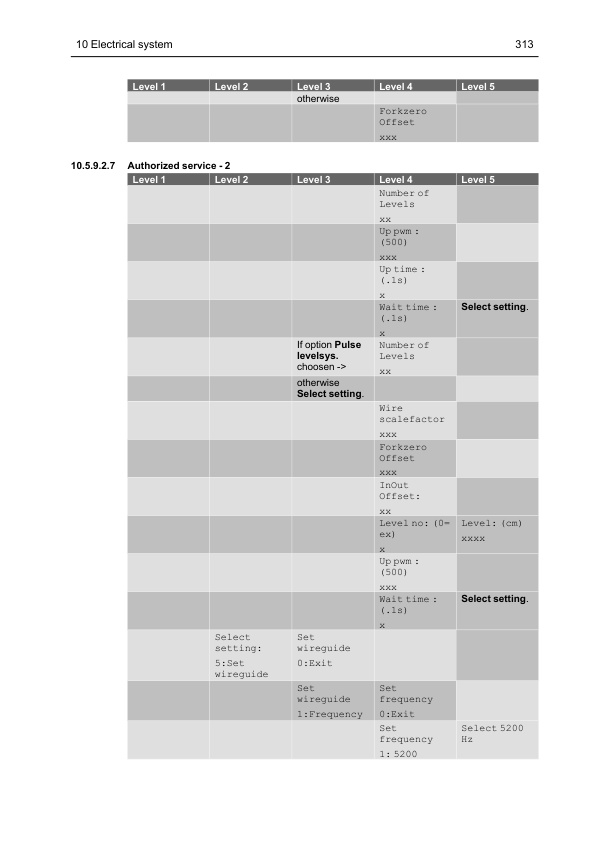

- 1.12.7.3. Setting the wire guidance.

- 1.12.7.4. Calibrating wire guidance.

- 1.12.7.5. Manual calibration of wire guidance.

- 1.12.7.6. Troubleshooting for wire guidance

- 1.12.8. End of Aisle magnetic system

- 1.12.8.1. Introduction to End of Aisle magnetic system

- 1.12.8.2. Installation of End of Aisle magnetic system

- 1.12.8.3. End of Aisle magnetic system settings

- 1.12.8.4. End of Aisle magnetic system troubleshooting

- 1.12.9. Collision sensor

- 1.12.10. Service indication

- 1.12.11. Trucks equipped with restart

- 1.12.12. Hand-controlled direction selector

- 1.12.13. Side shift and tilt centring

- 1.12.14. Speed reduction

- 1.12.15. Automatic logging off

- 1.12.16. Buzzer when the battery voltage is low

- 1.12.17. Straddle leg monitor (NRM20-25N3)

- 1.12.18. Load wheel covers

- 1.12.18.1. Installation of load wheel covers

- 1.12.19. Delivery mode

- 1.12.19.1. Activate delivery mode

- 1.12.19.2. Disable delivery mode

- 1.12.20. Options

- 1.12.20.1. General

- 1.12.20.2. Cold storage cab

- 1.12.20.3. Battery on motor-powered rollers

- 1.12.20.4. Levers

- 1.12.20.5. Electrically heated drivers seat (option)

- 2. sm21gbre1ac3-2

- 3. sm21gbre1ac3-3

- 4. sm21gbre1ac3-4

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8609

Caterpillar Service Manual PDF

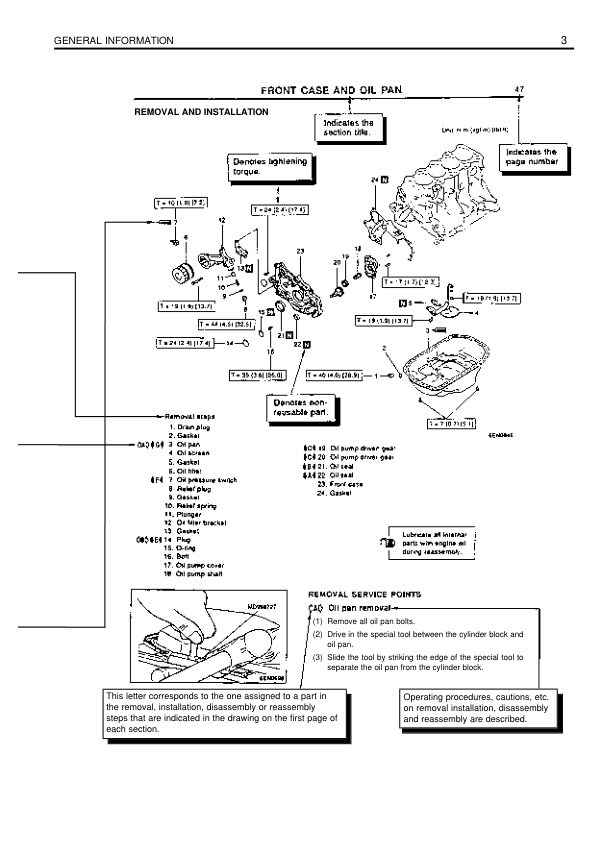

Caterpillar 4G63, 4G64 Gasoline Engine Service Manual 99729-84120

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Troubleshooting Service Manual 99799-67104

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-67103

Caterpillar Service Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Operation and Maintenance Manual Service Manual 99799-67105

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99719-84130

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-64103