Caterpillar NR12N3L to NR20N3HX Service Manual SM24GBUN01C4

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM24GBUN01C4

- Number of Pages: 266

- Size: 9.8MB

- Format: PDF

-

Model List:

- NR12N3L, NR14N3L, NR14N3C, NR16N3, NR20N3, NR16N3H, NR20N3H, NR25N3H, NR20N3HX

- 1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1. Introduction

- 1.1.1. General

- 1.1.2. The trucks

- 1.1.3. Genuine Parts

- 1.1.4. Authorised service personnel

- 1.1.5. Symbol key

- 1.2. Safety

- 1.2.1. General

- 1.2.2. Safety instructions

- 1.2.3. Truck modification

- 1.2.4. Lifting the truck

- 1.2.5. Welding on truck

- 1.3. Environmental considerations

- 1.3.1. We respect the environment

- 1.4. Preparations

- 1.4.1. Service

- 1.4.2. Troubleshooting

- 1.5. Truck data

- 1.5.1. Machine plates

- 1.5.2. Safety and warning signs

- 1.5.3. Explanation of symbols

- 1.5.4. Type designation

- 1.5.5. Truck types

- 1.5.6. Dimensions

- 1.6. Component specification

- 1.6.1. Drive motor

- 1.6.2. Electric brake

- 1.6.3. Gearbox

- 1.6.4. Hydraulic unit

- 1.6.5. Control system for traction and pump motors

- 1.6.6. Steering servo motor

- 1.6.7. Controller system for steering

- 1.7. Recommended consumable materials

- 1.7.1. Oil and grease types

- 1.8. Code explanations

- 1.8.1. Colour codes for wiring diagrams

- 1.8.2. Designations for electrical components in electrical diagram

- 1.8.3. Standard abbreviations and units

- 1.8.4. Acronyms and abbreviations

- 2. SPECIAL TOOLS

- 2.1. List of tools

- 3. SERVICE

- 3.1. Pre-delivery Inspection (PDI)

- 3.2. Service schedule / inspection

- 3.2.1. Introduction

- 3.2.2. Safety

- 3.2.3. Service schedule explanation

- 3.2.4. Inspection daily / monthly / PDI and commissioning

- 3.2.5. First service (200 hours)

- 3.2.6. Main service

- 3.2.7. Extra service inspections

- 3.2.8. Service inspection

- 3.2.9. Dye penetration inspection instruction

- 3.3. Service schedule

- 3.4. Lubrication

- 3.4.1. Recommended lubricants

- 3.4.2. Symbol key lubrication chart

- 3.4.3. Lubrication chart – narrow reach truck, reach truck

- 3.4.4. Cab lubrication schematic diagram (option)

- 4. CHASSIS

- 4.1. Design and function

- 4.1.1. Chassis frame

- 4.1.2. Machine housing

- 4.1.3. Overhead guard

- 4.1.4. Battery locking

- 4.1.5. Armrest and steering wheel

- 4.1.6. Foot plate

- 4.1.7. Covers and panels

- 4.1.8. Tightening torque for chassis plates

- 4.2. Repair and maintenance instructions

- 4.2.1. Panels

- 4.2.2. Load wheels

- 4.2.3. Machine housing

- 4.2.4. Adjusting the stabilising lugs – NR16-25N3H(X)

- 4.2.5. Driver seat

- 4.2.6. Overhead guard

- 4.2.7. Batteries

- 4.2.8. Battery rollers

- 4.2.9. Adjustable armrest

- 4.2.10. Fitting the antistatic chain

- 5. DRIVE UNIT

- 5.1. Design and function

- 5.1.1. Drive motor

- 5.1.2. Gearbox

- 5.2. Repair and maintenance instructions

- 5.2.1. Before work is performed

- 5.2.2. Drive unit

- 5.2.3. Traction motor

- 5.2.4. Removal and installation of the traction motor

- 5.2.5. First service

- 5.2.6. Preventive maintenance

- 5.2.7. Reconditioning the traction motor

- 5.2.8. Gearbox

- 5.2.9. Drive wheel

- 5.3. Diagnostics and troubleshooting

- 5.3.1. Troubleshooting chart

- 6. MAST SYSTEM

- 6.1. Design and function

- 6.1.1. Mast system

- 6.1.2. Fork carriage

- 6.2. Repair and maintenance instructions

- 6.2.1. Lift chains

- 6.2.2. Reach carriage

- 6.2.3. Fork carriage

- 6.2.4. Side shift unit of hanging type

- 6.2.5. Integrated side shift unit (ISS)

- 6.2.6. Integral Fork positioner/sideshift, NR12-14N3(L)(C), NR16-20N3, NR16N3H, NR20N3H

- 6.2.7. Integral Fork positioner/sideshift (NR25N3H)

- 6.3. Diagnostics and troubleshooting

- 6.3.1. Troubleshooting chart, triplex with free lift (DTFV) and duplex (T)

- 6.3.2. Troubleshooting chart for the integrated side shift unit (ISS), triplex with free lift (DTFV)

- 6.3.3. Troubleshooting chart for the integral fork positioner/sideshift, triplex with free lift (DTFV)

- 7. STEERING

- 7.1. Design and function

- 7.1.1. General

- 7.1.2. Feedback sensors

- 7.1.3. Communication between the servo components

- 7.2. Repair and maintenance instructions

- 7.2.1. Steering wheel

- 7.2.2. Steering servo motor

- 7.2.3. Settings, adjustments and testing

- 7.2.4. Remove and install the zero position sensor

- 7.2.5. Options

- 7.3. Diagnostics and troubleshooting

- 7.3.1. Troubleshooting with TruckTool

- 8. HYDRAULIC SYSTEM

- 8.1. Design and function

- 8.1.1. Description

- 8.1.2. Hose rupture valve

- 8.1.3. Electric proportional valve

- 8.1.4. Electric solenoid valve

- 8.1.5. MTC (Mast Tilt Control)

- 8.1.6. Hydraulic diagram

- 8.2. Repair and maintenance instructions

- 8.2.1. Before work is performed

- 8.2.2. General instructions

- 8.2.3. Installation

- 8.2.4. Connections

- 8.2.5. Dismantling and assembling hydraulic hoses

- 8.2.6. Pump motor

- 8.2.7. Hydraulic oil tank

- 8.2.8. MTC (Mast Tilt Control)

- 8.3. Control valve

- 8.3.1. Operation of the control valve

- 8.3.2. Control valve overview

- 8.3.3. Removal and installation of the control valve

- 8.3.4. Adjusting the working pressure

- 8.3.5. Inspection and adjustment of the lowering rate

- 8.3.6. Calibrating the hydraulic functions

- 8.3.7. S3 valve

- 8.3.8. Emergency lowering valve

- 8.3.9. Hose rupture valve

- 8.4. Diagnostics and troubleshooting

- 8.4.1. Troubleshooting the hydraulic system

- 8.4.2. Troubleshooting chart

- 8.4.3. Troubleshooting the control valve

- 9. HYDRAULIC CYLINDERS

- 9.1. Design and function

- 9.1.1. Reach cylinder

- 9.1.2. Tilt cylinder

- 9.1.3. Free lift cylinder

- 9.1.4. Final stroke cylinder

- 9.2. Repair and maintenance instructions

- 9.2.1. General

- 9.2.2. Reach cylinder

- 9.2.3. Tilt cylinder

- 9.2.4. Free lift cylinder

- 9.2.5. Final stroke cylinder

- 9.2.6. Removal and installation of the gasket in the hydraulic cylinder

- 10. ELECTRICAL SYSTEM

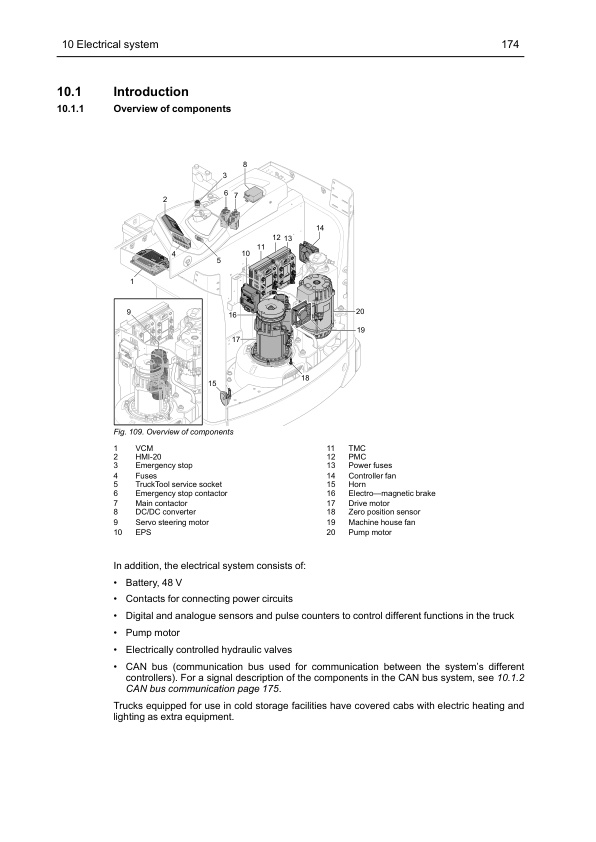

- 10.1. Introduction

- 10.1.1. Overview of components

- 10.1.2. CAN bus communication

- 10.2. Safety

- 10.2.1. Safety instructions

- 10.2.2. Electronic controllers

- 10.2.3. Traction system

- 10.2.4. Hydraulic system

- 10.2.5. Sensors

- 10.2.6. Maximum drive speed and drive stop

- 10.3. Design and function

- 10.3.1. Battery

- 10.3.2. Battery capacity measurement (lead-acid)

- 10.3.3. Battery parameters

- 10.3.4. Display

- 10.3.5. VCM (Vehicle Control Module) (truck computer)

- 10.3.6. TMC (Traction Motor Controller)

- 10.3.7. PMC (Pump Motor Controller)

- 10.3.8. EPS (Electrical Power Steering) controller

- 10.3.9. Connector specifications

- 10.4. Repair and maintenance instructions

- 10.4.1. Wiring diagram

- 10.4.2. Preventive maintenance

- 10.4.3. Remove and install the multi function display (HMI-20)

- 10.4.4. Remove and install the horn

- 10.4.5. Remove and install the emergency stop

- 10.4.6. Remove and install the direction selector button (option)

- 10.4.7. Remove and install the DC/DC converter (option)

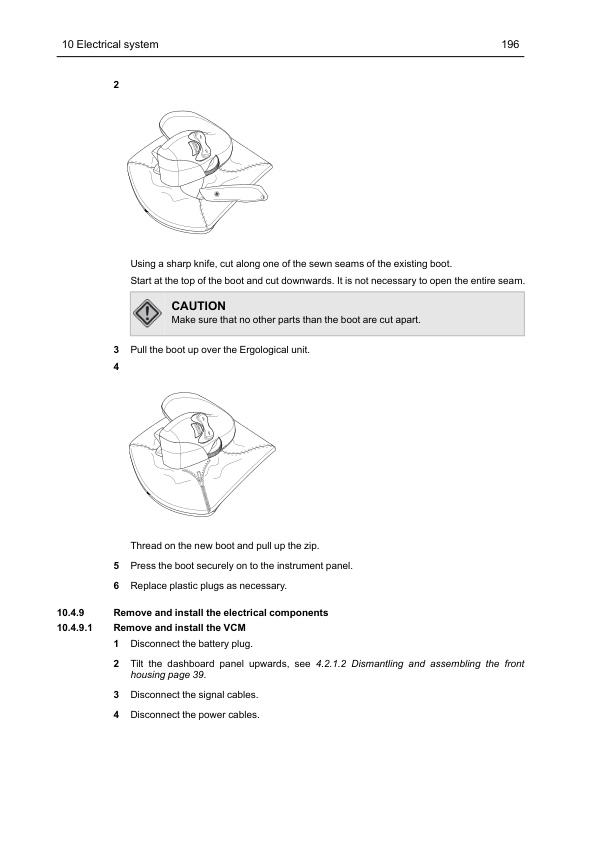

- 10.4.8. Ergologic unit

- 10.4.9. Remove and install the electrical components

- 10.4.10. Traction and pump regulation

- 10.4.11. Insulation resistance

- 10.4.12. Temperature measurement and management

- 10.4.13. System for detecting the reach carriage position

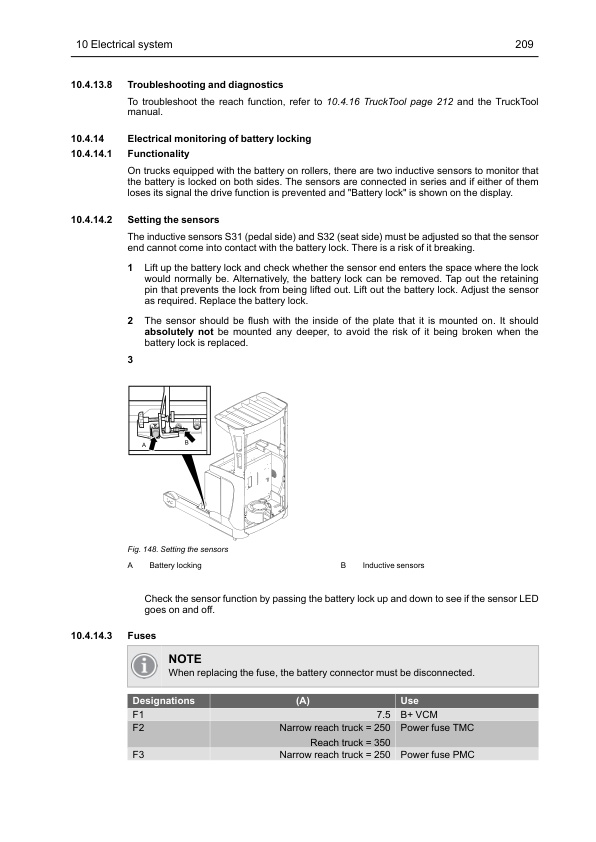

- 10.4.14. Electrical monitoring of battery locking

- 10.4.15. Maintaining and changing the battery (Lead Acid)

- 10.4.16. TruckTool

- 10.5. Diagnostics and troubleshooting

- 10.5.1. General instructions for all types of faults in combination with a loss of voltage

- 10.5.2. Troubleshooting – operational disturbances

- 10.5.3. Troubleshooting table – battery

- 11. SPEED CONTROL AND BRAKE SYSTEMS

- 11.1. Design and function

- 11.1.1. Electric brake

- 11.1.2. Speed and brake sensor

- 11.2. Repair and maintenance instructions

- 11.2.1. Electric brakes

- 11.2.2. Brake Pedal Assembly

- 11.2.3. Left-foot switch

- 11.2.4. Speed Controller

- 11.3. Diagnostics and troubleshooting

- 12. MISCELLANEOUS

- 12.1. Options

- 12.1.1. General

- 12.1.2. Service indication

- 12.1.3. Trucks equipped with restart

- 12.1.4. Side shift and tilt centring

- 12.1.5. Speed reduction

- 12.1.6. Automatic logging off

- 12.1.7. Buzzer when the battery voltage is low

- 12.1.8. Hand-controlled direction selector

- 12.1.9. Cold storage cab

- 12.1.10. Battery on motor-powered rollers

- 12.1.11. Electrically heated drivers seat (option)

- 12.2. Level selector and height indication

- 12.2.1. Pulse height preset

- 12.2.2. Level Assistance System, LAS

- 12.2.3. Height indication on the display

- 12.2.4. Checking the fork offset

- 12.3. Stability Support System, S3-1

- 12.3.1. Identification

- 12.3.2. Functionality, S3-1

- 12.3.3. Drive Speed

- 12.3.4. Hydraulic functions

- 12.3.5. Technical description

- 12.4. Weight system

- 12.4.1. Introduction

- 12.4.2. Enable options

- 12.4.3. Accompanying hardware

- 12.4.4. Premises and requirements

- 12.4.5. Calibration of the weight system

- 12.4.6. Weight indication

- 12.5. Load wheel covers

- 12.5.1. Installation of load wheel covers

- 12.6. Delivery mode

- 12.6.1. Driving in delivery mode and platform mode

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8609

Caterpillar Service Manual PDF

Caterpillar 2EC15-30 Chassis and Mast Service Manual 99759-80100

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64 Fuel System Supplement Service Manual 99729-85110

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Specifications Service Manual 99799-64101

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Disassembly and Assembly Service Manual 99799-67102

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Troubleshooting Service Manual 99799-64104

Caterpillar Service Manual PDF