Caterpillar NVT11, NVT12, NVT13, NVT14, NVT15, NVT15XL, NVT20 Service Manual SM23GBVNA1C1

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM23GBVNA1C1

- Number of Pages: 222

- Size: 19.0MB

- Format: PDF

-

Model List:

- NVT11, NVT12, NVT13, NVT14, NVT15, NVT15XL, NVT20

- 1. INTRODUCTION

- 1.1. Contact details

- 1.2. Scope of validity of this operation manual

- 1.2.1. Topicality of this operation manual and/or revisions

- 1.2.2. Scope of this documentation

- 1.3. Guarantee

- 1.3.1. Guarantee according to the General Conditions

- 1.3.2. Limitation of liability

- 1.4. Content of this operation manual

- 1.4.1. Enclosures to this operation manual

- 1.4.2. Subdivision and identification

- 1.5. Safety notes/rating plate

- 1.5.1. Safety decals/symbols on the machine

- 1.5.2. Rating plate and load capacity plate

- 1.5.3. Key to symbols

- 1.5.4. Formula letter symbols

- 1.6. Supplementary documentation

- 2. HEALTH AND SAFETY REGULATIONS, ENVIRONMENTAL PROTECTION

- 2.1. Laws, Decrees, Directives

- 2.2. Basic safety rules

- 2.2.1. Responsibility of the operating authority

- 2.2.2. Tasks and responsibilities of the operating personnel

- 2.2.3. Qualification of the operating personnel

- 2.3. Risks/ Residual dangers

- 2.3.1. Dangers during unloading

- 2.3.2. Dangers when preparing operation

- 2.3.3. Dangers during operation

- 2.3.4. Dangers during maintenance work

- 2.3.5. Dangers during repair work

- 2.3.6. Dangers due to change of the truck

- 2.4. Disposal and environmental protection

- 2.5. Safety devices on the industrial truck

- 3. TECHNICAL DATA

- 3.1. Order data

- 3.2. Changes to the vehicle

- 4. UNLOADING, IN-PLANT TRANSPORT

- 4.1. Safety notes

- 4.2. Use of lifting gear for in-plant transport

- 4.2.1. Transport and unloading of the truck

- 4.2.2. Packaging and preservation

- 4.2.3. Completeness of delivery

- 4.3. Treatment of transport damage

- 4.4. Temporary storage

- 4.5. Requirements for the floor in the narrow aisle

- 5. FUNCTIONS AND DESCRIPTION OF THE TRUCK

- 5.1. Use of the industrial truck

- 5.1.1. Intended conditions of use

- 5.1.2. Non-intended conditions of use

- 5.1.3. Safety notes

- 5.2. Functions of the industrial truck

- 5.2.1. Travel function

- 5.2.2. Lift functions

- 5.2.3. Functional criteria

- 5.3. Description of the industrial truck

- 5.3.1. Safety devices on the truck, safety interlocks

- 5.3.2. Chassis and wheels

- 5.3.3. Operators cabin

- 5.3.4. Control panel with indicators and controls

- 5.3.5. Travel drive

- 5.3.6. Steering

- 5.3.7. Brakes

- 5.3.8. Lift unit

- 5.3.9. Attachment and load picking unit

- 5.4. Options or equipment

- 5.5. Guidance systems

- 5.5.1. Mechanical guidance

- 5.5.2. Wire guidance

- 5.6. Safety interlocks

- 5.6.1. Safety interlocks for speed reduction and/or height limitations outside narrow aisles

- 5.6.2. Safety interlocks for speed reduction and/or height limitations in narrow aisles with guidance systems

- 5.6.3. Safety interlocks according to truck position and travel movement in narrow aisles

- 5.7. Description of the control panel

- 5.7.1. Control panel with rotary switches or ball handle bar

- 5.7.2. Control panel with multi-function lever

- 5.7.3. Control panel with single levers

- 5.7.4. Explanations to the console switches, symbols

- 6. PREPARING THE TRUCK FOR OPERATION

- 6.1. Safety notes

- 6.1.1. Ambient conditions

- 6.1.2. Condition of travel routes

- 6.1.3. Packaging and preservation

- 6.2. Checks before initial use/after repairs

- 6.2.1. Safety devices

- 6.2.2. Absence of emissions

- 6.2.3. Chassis and wheels

- 6.2.4. Lift unit

- 6.2.5. Attachment

- 6.3. Daily sight checks when the truck is stopped/out of operation

- 6.3.1. Safety devices

- 6.3.2. Absence of emissions

- 6.3.3. Chassis

- 6.3.4. Drive System

- 6.3.5. Lift unit

- 6.3.6. Attachment/load picking unit

- 6.4. Daily inspections and performance checks on the truck ready for operation

- 6.4.1. Safety devices

- 6.4.2. Operators cabin

- 6.4.3. Controls

- 6.4.4. Battery status

- 6.4.5. Steering

- 6.4.6. Brakes

- 6.4.7. Hydraulic functions

- 6.5. Daily inspections of the safety interlocks

- 6.5.1. Components of safety interlocks on the truck

- 6.5.2. Components of safety inter-locks in the warehouse

- 6.6. Check list Pre-start sight/safety checks

- 6.6.1. Checks when the truck is turned OFF

- 6.6.2. Checks when the truck is turned ON

- 7. START-UP, OPERATING AND SHUTDOWN PROCEDURES

- 7.1. Safety notes

- 7.1.1. Safety devices

- 7.1.2. Instructions for the operating crew

- 7.2. Start-up

- 7.3. Operation

- 7.3.1. Operators seat and control panel

- 7.3.2. Emergency STOP push-button

- 7.3.3. Steering/Steering indicator

- 7.3.4. Brakes

- 7.4. Travel drive

- 7.4.1. Running in instructions

- 7.4.2. Travel outside narrow aisles

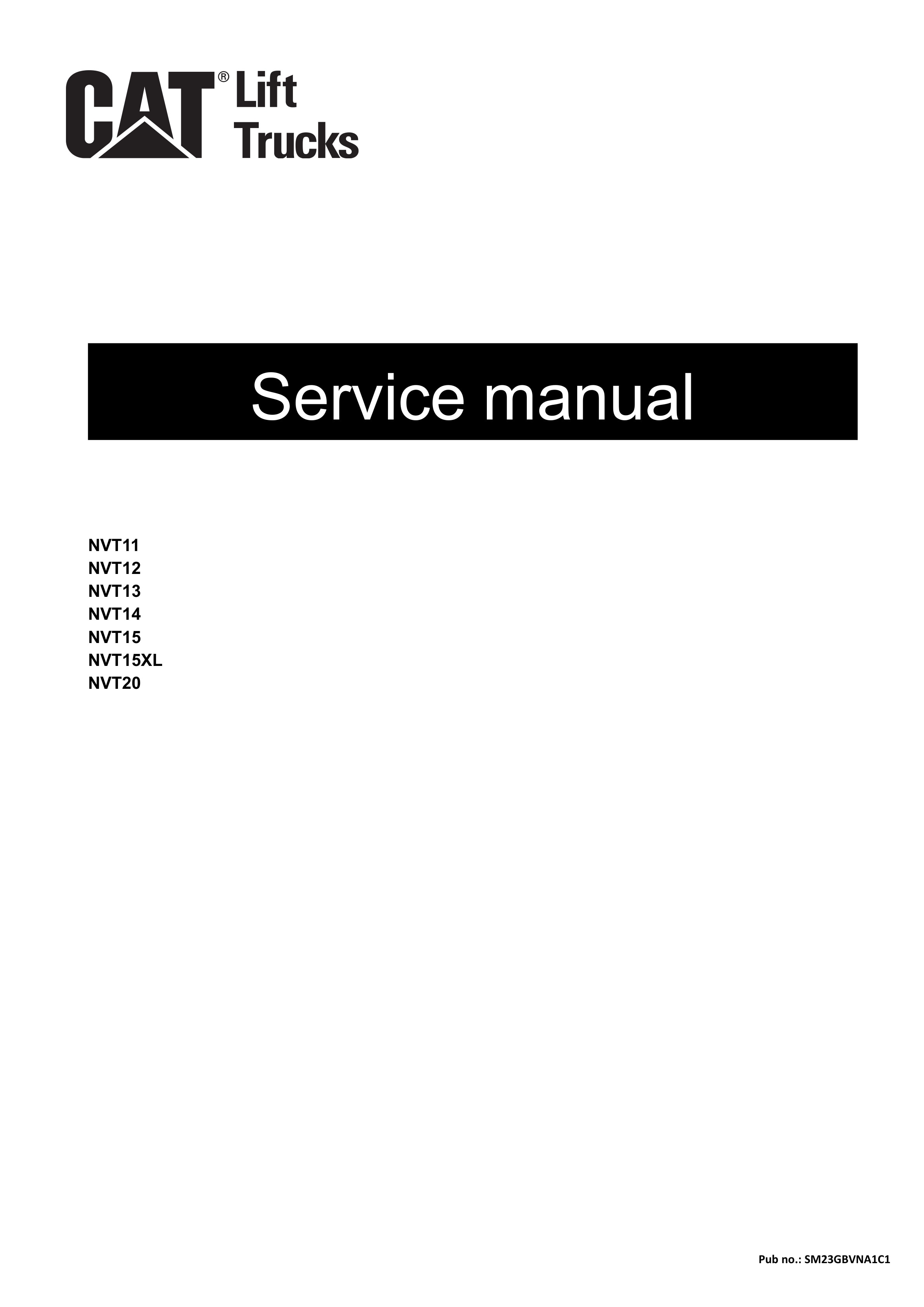

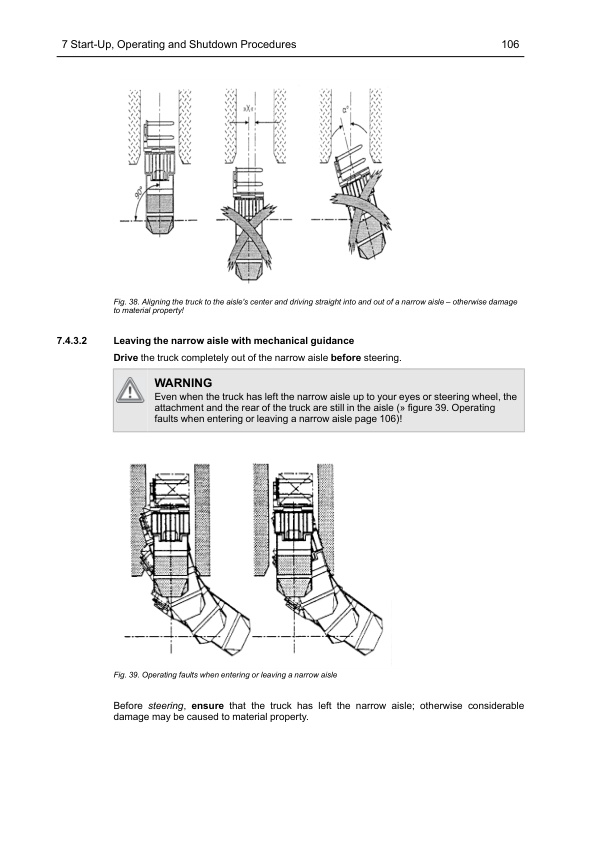

- 7.4.3. Guided travelling inside the narrow aisles

- 7.4.4. Towing the truck

- 7.5. Lifting and lowering

- 7.5.1. Lifting and lowering the operators cabin outside the narrow aisle

- 7.5.2. Lifting and lowering the operators cabin inside the narrow aisle

- 7.5.3. Operation of the attachment/load picking unit

- 7.6. Picking up load

- 7.6.1. Load capacity plate

- 7.6.2. Adjusting the fork spread

- 7.6.3. Picking up a load with the load picking unit

- 7.6.4. Depositing a load

- 7.7. Shutdown and preservation procedures

- 7.7.1. Stopping and parking the truck

- 7.7.2. Preservation for up to 3 months

- 7.7.3. Decommissioning

- 8. INSPECTION AND MAINTENANCE

- 8.1. Safey note

- 8.1.1. Instructing the maintenance personnel

- 8.1.2. Qualification of the maintenance personnel

- 8.1.3. Recurring safety inspections according FEM-4.004

- 8.2. Technical data on maintenance/repair work

- 8.2.1. Lubricants

- 8.2.2. Screw torques

- 8.2.3. Required Materials

- 8.3. Inspection, cleaning, care

- 8.3.1. Inspection

- 8.3.2. Cleaning and Care

- 8.4. General remarks on service and maintenance work

- 8.4.1. Wear or damage to components

- 8.4.2. Checking rubber and plastic parts

- 8.4.3. Screwed connections

- 8.5. Safety measures, preparatory work

- 8.5.1. Securing the lifted mast and/or attachment

- 8.5.2. Opening aggregate compartments

- 8.6. Maintenance work as required

- 8.6.1. Lubrication

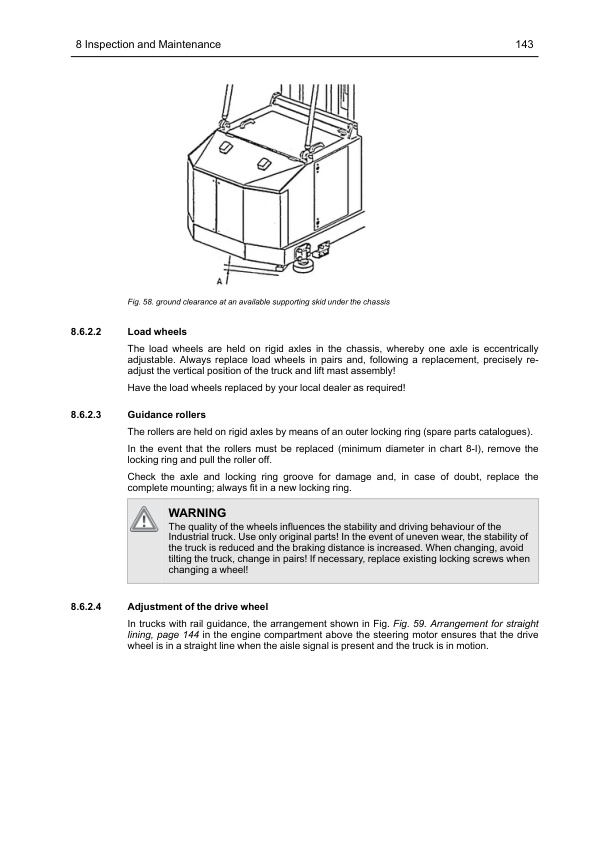

- 8.6.2. Changing wheels

- 8.6.3. Handling the battery

- 8.7. Inspections/maintenance list

- 8.8. Inspection and maintenance work during the first operating hours

- 8.8.1. After 8 operating hours

- 8.8.2. After 25 operating hours

- 8.8.3. After 50 operating hours

- 8.9. Inspection and maintenance DAILY or every 8-10 operating hours

- 8.9.1. Visual Control

- 8.9.2. Battery

- 8.9.3. Wire guidance

- 8.10. Inspection and maintenance work MONTHLY or every 80 operating hours

- 8.10.1. Chassis and wheels

- 8.10.2. Battery

- 8.10.3. Hydraulic system

- 8.10.4. Attachment

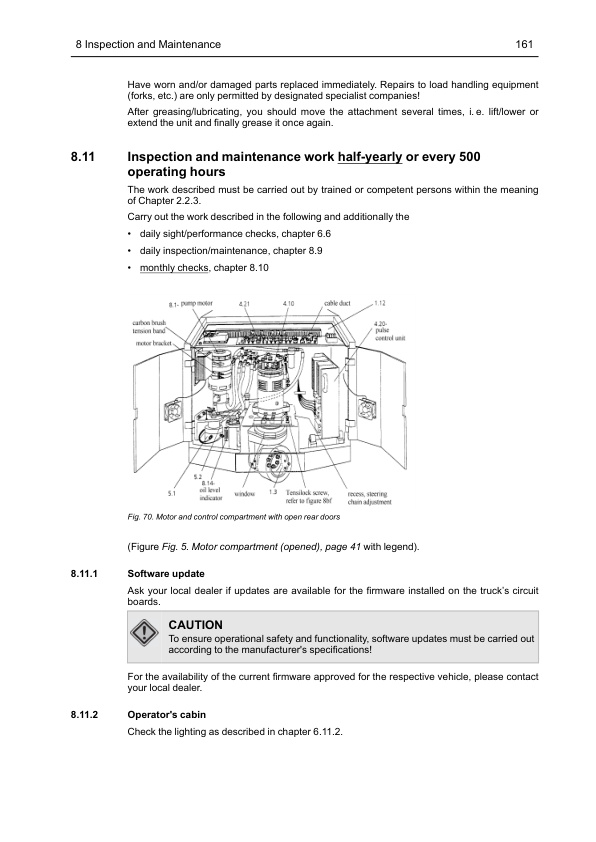

- 8.11. Inspection and maintenance work half-yearly or every 500 operating hours

- 8.11.1. Software update

- 8.11.2. Operators cabin

- 8.11.3. Emergency lowering device

- 8.11.4. Chassis and wheels

- 8.11.5. Engine Compartment

- 8.11.6. Battery

- 8.11.7. Electrical system

- 8.11.8. Steering

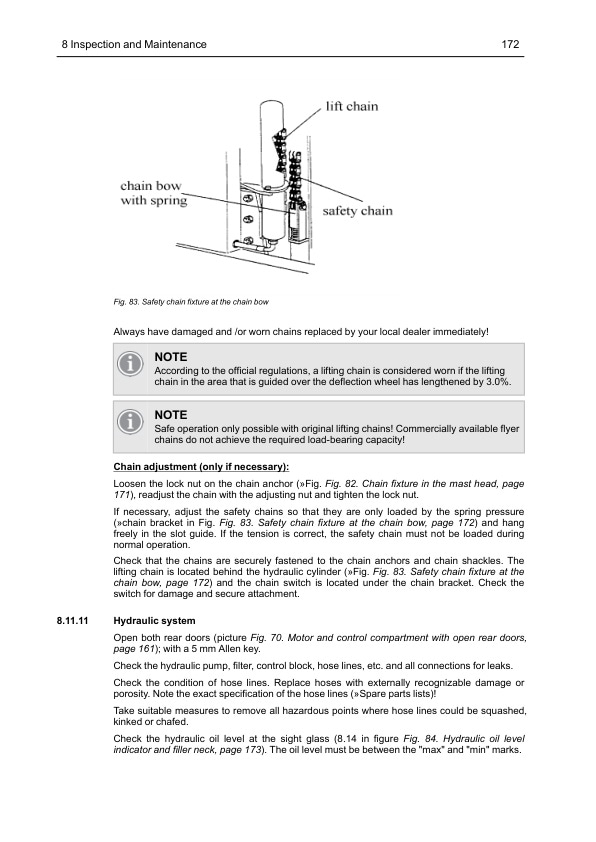

- 8.11.9. Lift unit

- 8.11.10. Hydraulic system

- 8.11.11. Attachment

- 8.11.12. Wire Guidance

- 8.12. Inspection and maintenance work YEARLY or every 1000 operating hours

- 8.12.1. Safety circuits

- 8.12.2. Battery

- 8.12.3. Drive unit

- 8.12.4. Hydraulic system

- 8.12.5. Attachment

- 8.13. Inspection and maintenance work EVERY 2 YEARS or every 2,000 operating hours

- 8.13.1. Drive unit

- 8.13.2. Electrical system

- 9. FUNCTIONAL DISORDERS, THEIR CAUSES AND RECTIFICATION

- 9.1. Causes for functional disorders

- 9.2. Trouble shooting

- 9.3. Customer service

- 9.4. Error messages on the display

- 9.5. Check list functional disorders

- 9.5.1. Truck does not start

- 9.5.2. Truck does not drive

- 9.5.3. Truck reduces travel speed autonomously

- 9.5.4. Truck stops during operation

- 9.5.5. Truck does not (re)start

- 9.5.6. Steering does not work

- 9.5.7. Lifting/Lowering does not work

- 9.5.8. Truck does not lower completely

- 9.5.9. Truck does not perform diagonal travelling

- 9.5.10. Unusual operating noise, unsteady operation

- 9.5.11. Functional disorders of the hydraulic system

- 10. APPENDIX TO THESE OPERATING INSTRUCTIONS

- 10.1. Applicable documents

- 10.2. List of abbreviations, definitions and terms

- 11. OPTIONS

- 11.1. Cold store operation

- 11.2. Position Assistance System

- 11.3. Simultaneous lifting of main and auxiliary lift

- 11.4. Emergency exit with makrolon screen

- 11.5. Height level positioning system with indicator for cabin lift

- 11.6. Hydraulic telescopic forks

- 11.7. Two hand operation for passenger

- 11.8. Emergency side shift device

- 11.9. Folding seat

- 11.10. Battery change with battery rollers

- 11.11. Battery change with winch

- 11.12. Adaptive Support Skid

- 11.13. Guidance at the lift mast

- 11.14. Load scale system on Multicheck

- 11.15. Full Automation

- 11.16. Remote Control Laser

- 11.17. Onboard Charger

Caterpillar Service Manual PDF

Caterpillar 1.4 Liter (4G33) to 3.0 Liter (6G72) LP Gas Supplement Service Manual SENB8531

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-67103

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Specifications Service Manual 99799-64101

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-64105

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Service Manual SCEEA-AT15F-200

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-64103

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Operation and Maintenance Manual Service Manual 99799-67105

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99719-84130

Caterpillar Service Manual PDF

Caterpillar 4G15, 4G63, 4G64, 6G72 Engine Service Manual 99719-34130

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-85100