Mitsubishi FB14N2T, FB16(C)N2(T), FB18(C)N2(T), FB20N2(T) Service Manual 664201 EN A

$50.00

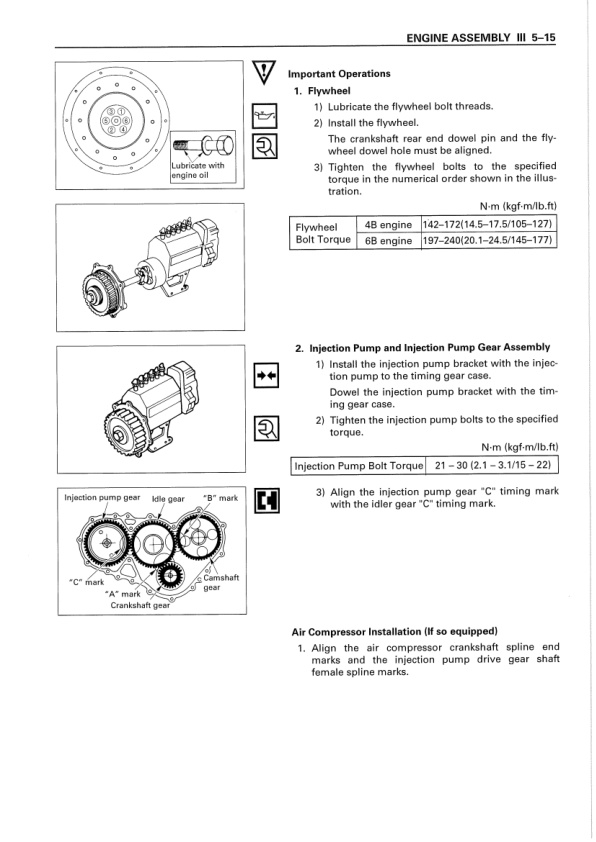

- Type Of Manual: Service Manual

- Manual ID: 664201

- Language: EN A

- Number of Pages: 568

- Size: 17.1MB

- Format: PDF

-

Model List:

- FB14N2T, FB16(C)N2(T), FB18(C)N2(T), FB20N2(T)

- 1. Table of contents

- 2. Foreword

- 3. How to read this manual

- 3.1. Safety-related signs

- 3.2. Safety symbols

- 3.3. Units

- 3.4. Interactive links

- 4. Safety instructions

- 4.1. General safety instructions

- 4.2. Safety requirements for industrial trucks

- 4.3. Repairs and structural modifications

- 4.4. Seat belt

- 4.5. Wheels

- 4.6. LOCKOUT and TAGOUT

- 4.7. Service area safety

- 4.8. Personal safety

- 4.9. Work safety

- 4.10. Operating temperature

- 5. General information

- 5.1. Truck models covered by this manual

- 5.2. Identification plates and decals

- 5.3. Special tools

- 5.4. Operating position

- 5.5. Operating direction

- 5.6. Transportation

- 5.6.1. Lifting the truck

- 5.6.2. Towing connection

- 5.6.3. Towing the truck

- 5.6.4. Brake release

- 5.7. Assembly and commissioning

- 5.8. Order spare parts

- 6. Main components

- 6.1. Truck covers

- 6.2. Overhead guard

- 6.3. Cabin

- 6.3.1. Manual holder

- 6.3.2. Emergency exits (cabin truck)

- 6.4. Operators seat

- 6.5. Operating devices

- 6.5.1. Steering wheel

- 6.5.2. Mini steering wheel

- 6.5.3. Armrest

- 6.5.4. Manual levers

- 6.5.5. Side control panel

- 6.6. Display panel

- 6.6.1. Emergency stop button

- 6.6.2. Key switch

- 6.6.3. Display control buttons

- 6.6.4. Truck display

- 6.7. Pedals

- 6.7.1. Accelerator pedal

- 6.7.2. Brake pedal

- 6.7.3. Electronic friction lock pedal (option)

- 6.7.4. Dual pedal

- 6.7.5. Pedal functionalities

- 6.8. Electric system

- 6.8.1. Electrical operation

- 6.8.2. Controllers

- 6.8.3. Vehicle master controller

- 6.8.4. Traction controller

- 6.8.5. Pump controller

- 6.8.6. Sensors and switches

- 6.8.7. Option panel

- 6.8.8. Fuses

- 6.8.9. Relays and contactors

- 6.8.10. DC/DC converter

- 6.8.11. Armrest connector

- 6.8.12. Display connector

- 6.9. Hydraulic operation

- 6.9.1. Hydraulic operation overview

- 6.9.2. Hydraulic operation lifting/lowering

- 6.9.3. Hydraulic symbols

- 6.9.4. Hydraulic valve unit with fingertip controls

- 6.9.5. Hydraulic valve unit with manual levers

- 6.9.6. Hydraulic supply system

- 6.9.7. Hydraulic flow distribution with additional hydraulic functions

- 6.10. Drive axle

- 6.11. Brakes

- 6.11.1. Service brake

- 6.11.2. Parking brake

- 6.12. Rear axle

- 6.13. Steering unit

- 6.14. Load handling

- 6.14.1. Lifting carriage

- 6.14.2. Integrated sideshift carriage

- 6.14.3. Integrated fork positioner with sideshift

- 6.14.4. Load backrest

- 6.15. Mast

- 6.15.1. Simplex mast

- 6.15.2. Duplex mast

- 6.15.3. Triplex mast

- 6.15.4. Mast chains

- 6.15.5. Main rollers

- 6.15.6. Mast cylinders

- 6.15.7. Automated performance reduction based on lift height

- 6.16. Wheels

- 6.16.1. Solid rubber wheels

- 6.16.2. Pneumatic wheels

- 7. Maintenance

- 7.1. Maintenance intervals

- 7.2. Truck covers

- 7.2.1. Remove the cover of the hydraulic valve block

- 7.2.2. Remove the pedal plate

- 7.2.3. Open the battery door

- 7.2.4. Open the battery cover

- 7.2.5. Remove the back cover

- 7.2.6. Remove the steering wheel cover

- 7.2.7. Remove the control panel

- 7.2.8. Remove the side control panel

- 7.2.9. Remove the step cover

- 7.2.10. Remove the side plate

- 7.2.11. Remove the right side cover

- 7.2.12. Open the roof cover (cabin trucks)

- 7.2.13. Remove the rear spoiler cover

- 7.3. Cabin

- 7.3.1. Windshield washer tank

- 7.3.2. Cabin seals

- 7.4. Drive unit

- 7.4.1. Fastening of the drive axle

- 7.4.2. Leakage check of the drive axle

- 7.4.3. Lubricate the drive axle

- 7.4.4. Test the parking brake

- 7.4.5. Test the regenerative brake

- 7.4.6. Electromechanical parking brake maintenance

- 7.5. Hydraulics

- 7.5.1. Hydraulic system maintenance

- 7.5.2. Leakage check of the hydraulic system

- 7.5.3. Replace the hydraulic oil return filter

- 7.5.4. Replace the air breather filter

- 7.5.5. Cleaning of the hydraulic oil suction filter

- 7.5.6. Oil level

- 7.5.7. Operation of the hydraulics

- 7.5.8. Relief valves

- 7.5.9. Hydraulic oil change

- 7.5.10. Hoses and cylinders

- 7.5.11. Lubricate the pump axle splines

- 7.5.12. Clean the oil tank

- 7.6. Mast

- 7.6.1. Mounting of the mast

- 7.6.2. Wear level of the mast rollers and contact surfaces

- 7.6.3. Chain tension

- 7.6.4. Chain lubrication

- 7.6.5. Chain wear measurement

- 7.6.6. Check the chain anchors and locking pins

- 7.6.7. Check the cylinders and piston rods

- 7.6.8. Lifting and lowering speed

- 7.6.9. Lubrication of the mast channel surfaces

- 7.6.10. Lifting test

- 7.6.11. Examine the welding in the mast for cracks

- 7.6.12. Mounting of any attachments and load-carrying components

- 7.6.13. Examine the welding of the cylinders and masts for cracking

- 7.6.14. Examine the rollers, pins and welds for cracking and damage

- 7.6.15. Apply grease to the lubrication points of the tilt cylinder

- 7.6.16. Additional mast attachments

- 7.7. Lifting carriage

- 7.7.1. Examine the welding in lifting carriage for cracks

- 7.7.2. Examine the load backrest for cracks

- 7.7.3. Fork inspection

- 7.7.4. Maintenance of the integrated sideshift carriage

- 7.7.5. Maintenance of the integrated fork positioner with sideshift

- 7.8. Rear axle

- 7.8.1. Lubricate the rear axle (3-wheel models)

- 7.8.2. Lubricate the rear axle (4-wheel models)

- 7.8.3. Examine the operating condition of the bearings, check for looseness of the bearings

- 7.8.4. Examine the welds for cracks

- 7.8.5. Examine the mounting of the rear axle

- 7.8.6. Examine the condition of the rubber spring

- 7.9. Wheels

- 7.9.1. Damage and wear in the wheels

- 7.9.2. Before you replace the wheels

- 7.9.3. Front wheels

- 7.9.4. Rear wheels

- 7.10. Electrics

- 7.10.1. Test the functionality of sensors

- 7.10.2. Steering wheel functions

- 7.10.3. Horn

- 7.10.4. Electrical connections tightening torques

- 7.10.5. Cables and wiring

- 7.10.6. Examine and clear the alarm history

- 7.10.7. Insulation resistance test

- 7.10.8. Discharge the controllers

- 7.10.9. Emergency stop button functionality check

- 7.10.10. Key switch functionality check

- 7.11. Safety

- 7.11.1. Inspect the seat belt

- 7.12. General

- 7.12.1. How to clean the truck

- 7.12.2. Lubrication

- 7.12.3. Examine the welding in the truck frame for cracking

- 7.12.4. Examine the truck frame and the lifting carriage

- 7.12.5. Examine the overhead guard for deformation, cracking and damage

- 7.12.6. Examine the gas springs

- 7.12.7. Examine the condition and position of the identification plates

- 7.12.8. Examine the covers

- 7.12.9. Safety functions

- 7.12.10. Examine the fastening of the steering wheel

- 8. Battery maintenance

- 8.1. Lead-acid batteries

- 8.1.1. Safety with lead-acid batteries

- 8.1.2. General information

- 8.1.3. Requirements for battery charging areas

- 8.1.4. Charge the battery

- 8.1.5. Battery maintenance

- 8.1.6. Malfunctions

- 8.1.7. Acquire a new battery

- 8.1.8. Storage

- 8.2. Lithium-ion batteries

- 8.2.1. General information

- 8.2.2. Safety signs

- 8.2.3. Requirements for battery charging areas

- 8.2.4. Charge the battery

- 8.2.5. Battery maintenance

- 8.2.6. Acquire a new battery

- 8.2.7. Storage

- 8.3. Replace the battery

- 8.3.1. General safety instructions

- 8.3.2. Replace the battery with a lifting device

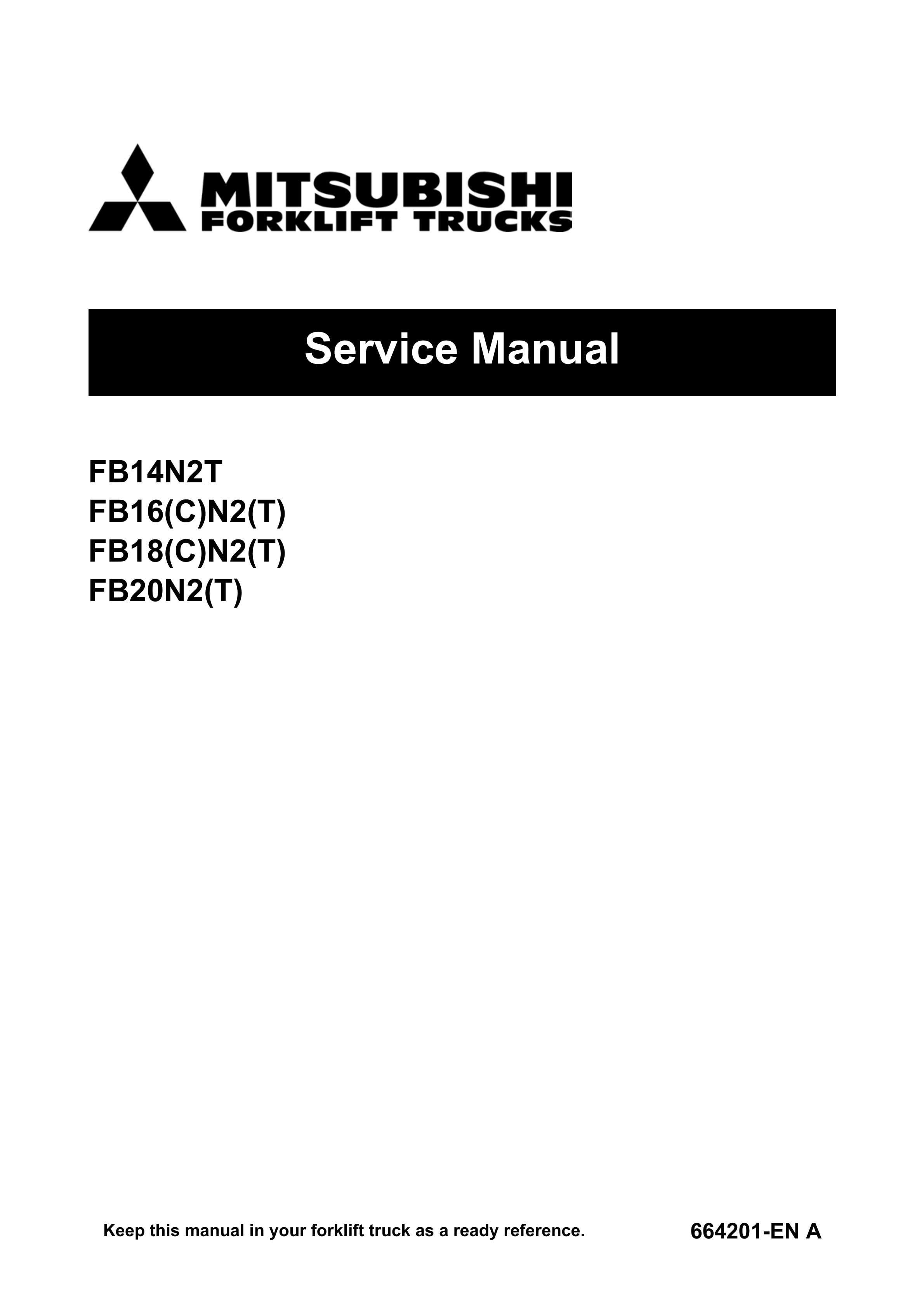

- 8.3.3. Remove the battery with the battery sideway exchange tools

- 8.3.4. Install a battery with the battery sideway exchange tools

- 9. Repair

- 9.1. Repair drive unit

- 9.1.1. Drive axle lifting and handling

- 9.1.2. Remove the drive axle

- 9.1.3. Disassemble the drive axle

- 9.1.4. Assemble the drive axle

- 9.1.5. Install the electromechanical parking brake

- 9.1.6. Install the drive axle

- 9.1.7. Test the drive axle

- 9.2. Repair rear axle

- 9.2.1. Rear axle lifting and handling

- 9.2.2. Rear axle (3-wheel models)

- 9.2.3. Remove and install the rear axle (4-wheel models)

- 9.3. Repair hydraulic system

- 9.3.1. Remove the pump motor

- 9.3.2. Disassemble the steering unit

- 9.3.3. Set the lifting pressure

- 9.3.4. Disassemble the coils

- 9.3.5. Disassemble the M1, M2 and M9 valves

- 9.3.6. Remove the clamp release valve

- 9.4. Repair mast

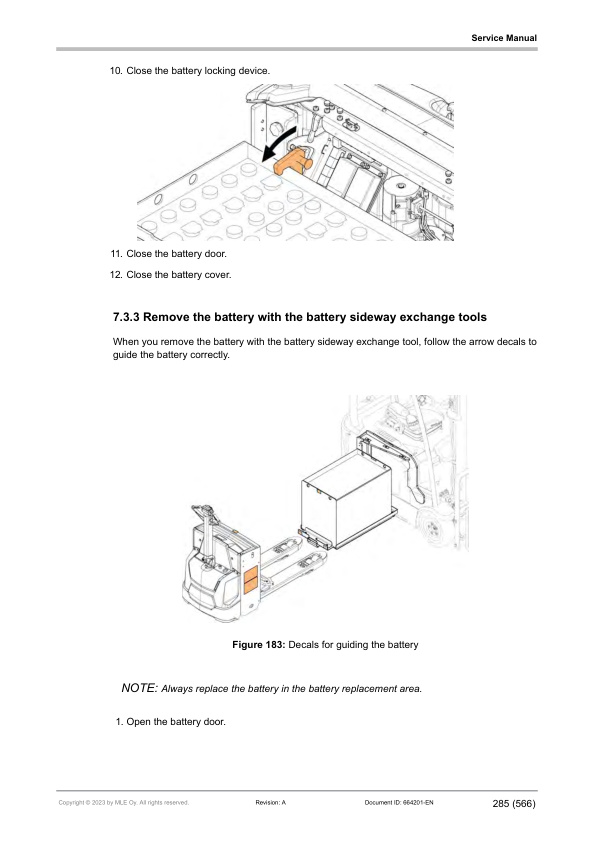

- 9.4.1. Remove the mast

- 9.4.2. Disassemble the mast

- 9.4.3. Repair mast chains

- 9.4.4. Repair free lift cylinder

- 9.4.5. Repair side cylinders

- 9.4.6. Repair tilt cylinders

- 9.4.7. Replace the main rollers of the mast

- 9.5. Repair lifting carriage

- 9.5.1. Remove the lifting carriage

- 9.5.2. Adjust the rollers of the lifting carriage

- 9.5.3. Replace the guidance rollers of the lifting carriage

- 9.5.4. Replace the main rollers of the lifting carriage

- 9.5.5. Replace the load backrest

- 9.5.6. Repair integrated sideshift carriage

- 9.5.7. Repair integrated fork positioner with sideshift

- 9.5.8. Repair hook-on sideshift carriage

- 9.6. Repair pedals

- 9.6.1. Remove the accelerator pedal

- 9.6.2. Remove the brake pedal

- 9.6.3. Remove the electronic friction lock pedal

- 9.6.4. Remove the dual pedal plate

- 9.6.5. Remove the dual pedal

- 9.6.6. Adjust the dual pedal

- 9.6.7. Adjust the direction sensor of the dual pedal

- 9.6.8. Adjust the dual pedal angle sensor

- 9.7. Repair steering wheel

- 9.7.1. Remove the steering wheel unit

- 9.7.2. Remove the steering wheel gas spring

- 9.7.3. Remove the lever unit

- 9.7.4. Remove the levers

- 9.8. Repair mini steering wheel

- 9.8.1. Disassemble the mini steering wheel

- 9.8.2. Disassemble the mini steering wheel holder

- 9.9. Repair armrest

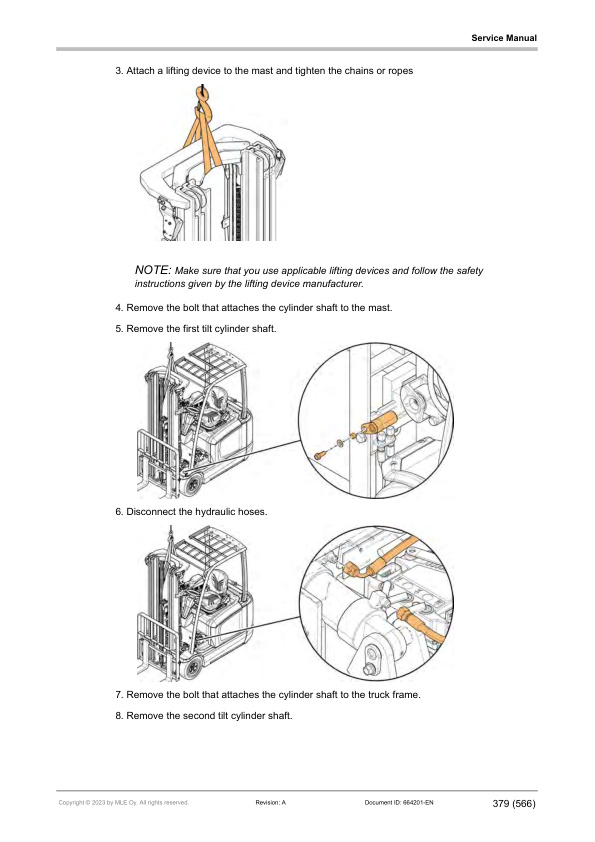

- 9.9.1. Remove the armrest

- 9.9.2. Remove the armrest base plate

- 9.9.3. Replace the armrest padding

- 9.9.4. Fingertip control armrest

- 9.9.5. Ergologic armrest

- 9.9.6. Dual joystick armrest

- 9.9.7. Calibrate the armrest

- 9.10. Repair operators seat

- 9.10.1. Remove the operators seat from the truck

- 9.10.2. Replace the seat switch

- 9.10.3. MSG65

- 9.11. Repair electric system

- 9.11.1. Remove the electric panel

- 9.11.2. Replace the horn

- 9.12. Repair sensors and switches

- 9.12.1. Replace the rotation sensor

- 9.12.2. Replace the battery door sensor

- 9.12.3. Replace the rear axle sensor

- 9.12.4. Replace the tilt angle sensor

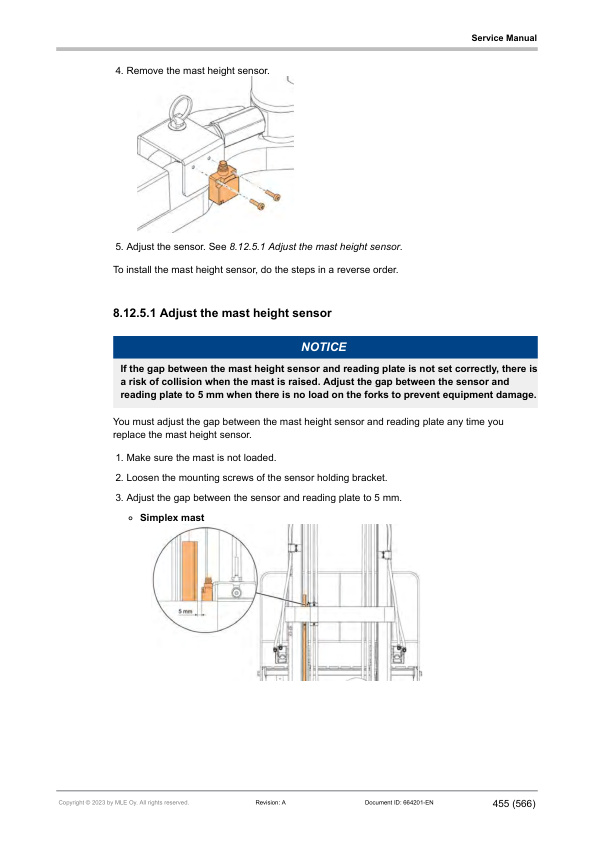

- 9.12.5. Replace the mast height sensor

- 9.12.6. Replace the sensors of the hydraulic valve unit with manual levers

- 9.12.7. Replace the manual lever switches

- 9.12.8. Replace the steering wheel sensor

- 9.12.9. Replace the mini steering wheel sensors

- 9.12.10. Replace the pressure sensor

- 9.12.11. Replace the horn switch

- 9.12.12. Replace the side control panel switches

- 9.12.13. Replace the autolight sensor

- 9.13. Repair cabin

- 9.13.1. Operator door

- 9.13.2. Side door

- 9.13.3. Rear window

- 9.13.4. Manual holder

- 9.13.5. Windshield washer (cabin truck)

- 9.13.6. Sun guard

- 10. TruckTool Diagnostics

- 10.1. Overview

- 10.2. Location of the service socket

- 11. Parameter descriptions

- 12. Service data

- 12.1. Special tightening torques

- 12.2. Tightening torques for standard bolts and nuts

- 12.3. Oils and lubricants

- 12.3.1. Lubrication points

- 12.3.2. Rear axle

- 12.3.3. Mast chains

- 12.3.4. Mast channels

- 12.3.5. Pump axle splines

- 12.4. Troubleshooting

- 12.4.1. Troubleshooting case examples

- 12.4.2. Traction

- 12.4.3. Brakes

- 12.4.4. Hydraulics

- 12.4.5. Steering

- 12.4.6. Charging

- 13. Options

- 13.1. Options overview

- 13.2. Accessory rack

- 13.3. A4 paper holder

- 13.4. Computer holder

- 13.5. Scanner holder

- 13.6. Holder arm

- 13.7. Reverse drive handle with horn button

- 13.8. Smart backup alarm

- 13.9. Rear combination and tail lights kit

- 13.9.1. Turn signals

- 13.9.2. Brake lights

- 13.9.3. Front lights

- 13.10. Amber strobe

- 13.10.1. Install the amber strobe under the overhead guard

- 13.11. Autolight sensor

- 13.11.1. Install the autolight sensor

- 13.12. Blue point light

- 13.12.1. Blue point front light

- 13.12.2. Blue point rear light

- 13.12.3. Remove the blue point lights

- 13.13. Working lights

- 13.13.1. Install the working lights

- 13.14. Red stripe

- 13.14.1. Install the red stripe safety lights

- 13.15. USB connector

- 13.16. Plastic storage locker

- 13.16.1. Install the plastic storage locker

- 13.17. Load weight indicator and overload notification

- 13.18. Operators seat options and accessories

- 13.18.1. Seat armrest

- 13.18.2. Backrest extension (MSG65)

- 13.18.3. Swivel seat

- 13.19. Battery sideway exchange system

- 13.19.1. Requirements for power pallet trucks used to move batteries of counterbalance trucks

- 13.19.2. Battery sideway exchange tools

- 13.20. Wide view mirror

- 13.20.1. Install the wide view mirror

- 13.21. Rear view mirror

- 13.21.1. Install the rear view mirror

- 13.22. Side-view mirrors

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-56103

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Specifications Service Manual 99799-56101

Mitsubishi Service Manual PDF

Mitsubishi 5V15D, 5V20D, 5V25D, 5V30D, 5V35D Mast Supplement Service Manual 99739-151S0

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111