Mitsubishi FB161820KT Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 478

- Size: 39.4MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- FB161820KT Forklift

- 1. GENERAL INFORMATION

- 1.1. GENERAL INFORMATION

- 1.1.1. Vehicle Exterior

- 1.1.2. Serial Number Locations

- 1.1.3. Chassis and Mast Model Identification

- 1.1.4. Dimensions

- 1.1.5. Technical Data

- 2. BRAKE SYSTEM

- 2.1. BRAKE SYSTEM

- 2.1.1. Specifications

- 2.1.2. Structure and Functions

- 2.1.2.1. Caliper Assembly

- 2.1.2.2. Brake Pedal Assembly

- 2.1.2.3. Master Cylinder

- 2.1.2.4. Parking Brake Lever

- 2.1.3. Procedures and Suggestions for Disassembly and Reassembly

- 2.1.3.1. Master Cylinder

- 2.1.4. Inspection and Adjustment

- 2.1.4.1. Pad Clearance Adjustment

- 2.1.4.2. Brake Pedal Adjustment

- 2.1.4.3. Brake Switch Installation

- 2.1.4.4. Brake Fluid Line Bleeding

- 2.1.4.5. Parking Brake Adjustment

- 2.1.5. Troubleshooting

- 2.1.6. Service Data

- 3. HYDRAULIC SYSTEM

- 3.1. HYDRAULIC SYSTEM

- 3.1.1. Specifications

- 3.1.2. Structure and Functions

- 3.1.2.1. Hydraulic Line

- 3.1.2.2. Control Valve

- 3.1.2.3. Lift and Tilt Cylinders

- 3.1.2.4. Flow Regulator Valve

- 3.1.2.5. Down Safety Valve

- 3.1.3. Gear Pump

- 3.1.3.1. Procedures and Suggestions for Removal and Installation

- 3.1.4. Control Valve

- 3.1.4.1. Procedures and Suggestions for Removal and Installation

- 3.1.4.2. Procedures and Suggestions for Disassembly and Reassembly

- 3.1.5. Lift Cylinders

- 3.1.5.1. Procedures and Suggestions for Removal and Installation

- 3.1.5.2. Procedures and Suggestions for Disassembly and Reassembly

- 3.1.6. Tilt Cylinders

- 3.1.6.1. Procedures and Suggestions for Removal and Installation

- 3.1.6.2. Procedures and Suggestions for Disassembly and Reassembly

- 3.1.7. Flow Regulator Valve

- 3.1.7.1. Procedures and Suggestions for Disassembly and Reassembly

- 3.1.8. Suction Strainer and Return Filter

- 3.1.8.1. Procedures and Suggestions for Removal and Installation

- 3.1.9. Inspection and Adjustment

- 3.1.9.1. Hydraulic Tank

- 3.1.9.2. Control Valve

- 3.1.9.3. Lift Cylinders and Tilt Cylinders

- 3.1.9.4. Adjustment Values of Microswitches

- 3.1.9.5. Procedures for Adjusting Microswitches

- 3.1.10. Hydraulic Circuit Diagram

- 3.1.11. Hydraulic Circuits

- 3.1.12. Troubleshooting

- 3.1.13. Service Data

- 4. MAST AND FORKS

- 4.1. MAST AND FORKS

- 4.1.1. Mast Systems

- 4.1.1.1. Mast Type Code Stamping Position

- 4.1.1.2. Explanation of Mast Type Code

- 4.1.1.3. Mast Types

- 4.1.2. Description

- 4.1.2.1. Dual-stage Panoramic Mast (Simplex Mast)

- 4.1.2.2. Dual-stage Full Free Panoramic Mast (Duplex Mast)

- 4.1.2.3. Triple-stage Full Free Panoramic Mast (Triplex Mast)

- 4.1.2.4. Operation of Dual-stage Full Free Panoramic Mast

- 4.1.2.5. Operation of Triple-stage Full Free Panoramic Mast

- 4.1.3. Removal and Installation

- 4.1.3.1. Mast and Lift Bracket Assembly

- 4.1.4. Disassembly and Reassembly

- 4.1.4.1. Dual-stage Panoramic Mast (Simplex Mast)

- 4.1.4.2. Dual-stage Full Free Panoramic Mast (Duplex Mast)

- 4.1.4.3. Triple-stage Full Free Panoramic Mast (Triplex Mast)

- 4.1.5. Inspection and Adjustment

- 4.1.5.1. Chain Tension Adjustment

- 4.1.5.2. Clearance Adjustment on Lift Bracket

- 4.1.5.3. Mast Clearance Adjustment

- 4.1.5.4. Main Roller Shim Replacement

- 4.1.5.5. Mast Strip Adjustment

- 4.1.5.6. Tilt Angle Adjustment

- 4.1.5.7. Lift Cylinder Stroke Adjustment

- 4.1.6. Troubleshooting

- 4.1.7. Service Data

- 4.1.8. Motor Installation Positions

- 4.1.9. Specifications

- 4.1.10. Structures

- 4.1.11. Tightening of High-power Cable Terminals

- 4.1.12. Inspection of Brushes for Wear and Brush Replacement

- 4.1.13. Procedures and Suggestions for Removal and Installation

- 4.1.14. Procedures and Suggestions for Disassembly and Reassembly

- 4.1.15. Troubleshooting

- 4.1.16. Service Data

- 4.1.17. Checks and Repairs

- 5. Options Supplement

- 5.1. FORWORD

- 5.2. AMBER STROBE KIT

- 5.3. BACK BUZZER KIT

- 5.4. HEAD LAMP KIT (48 V AND 36 V) (Not applicable to EU models)

- 5.5. REARVIEW MIRROR KIT (Not applicable to EU models)

- 5.6. ADDITIONAL-ON CONTROL VALVE KIT (For MC model)

- 5.7. FOOT-OPERATED DIRECTION CONTROL KIT (Not applicable to US EE model)

- 5.8. EE MODEL AND EE UNCOVERED BATTERY MODEL (US EE model)

- 6. OPTIONS

- 6.1. OPTIONS

- 6.1.1. Rearview Mirror Kit

- 6.1.2. Backup Buzzer Kit

- 6.1.3. Working Lamp Kit

- 6.1.4. Tire Kit (Solid)

- 6.1.5. Tire Kit (Nonmarking Cushion)

- 6.1.6. Foot Direction Control Kit

- 7. POWER TRAIN

- 7.1. POWER TRAIN

- 7.1.1. Procedures and Suggestions for Removal and Installation

- 7.1.1.1. Removal

- 7.1.1.2. Installation

- 7.1.2. Service Data

- 8. REAR AXLE

- 8.1. REAR AXLE

- 8.1.1. Structure and Functions

- 8.1.1.1. Rear Wheels

- 8.1.2. Procedures and Suggestions for Removal and Installation

- 8.1.2.1. Rear Wheels

- 8.1.2.2. Rear Axle

- 8.1.3. Procedures and Suggestions for Disassembly and Reassembly

- 8.1.3.1. Steering Axle

- 8.1.3.2. Rear Axle Assembly

- 8.1.4. Inspection and Adjustment

- 8.1.4.1. Making sure of Minimum Turning Radius

- 8.1.5. Service Data

- 9. SERVICE DATA

- 9.1. SERVICE DATA

- 9.1.1. Inspection Standards

- 9.1.2. Periodic Replacement of Parts

- 9.1.2.1. Critical Safety Parts

- 9.1.3. Lubricating Standards

- 9.1.3.1. Lubrication Chart

- 9.1.3.2. Lubricant Quantities

- 9.1.3.3. Recommended Lubricant

- 9.1.4. Main Component Weights

- 9.1.5. Tightening Torques for Standard Bolts and Nuts

- 9.1.6. Special Tool Table

- 10. STEERING SYSTEM

- 10.1. STEERING SYSTEM

- 10.1.1. Specifications

- 10.1.2. Structure and Functions

- 10.1.2.1. General

- 10.1.2.2. Steering Control Valve

- 10.1.3. Procedures and Suggestions for Removal and Installation

- 10.1.3.1. Steering Column Assembly

- 10.1.4. Steering Control Valve

- 10.1.4.1. Disassembly

- 10.1.4.2. Inspection

- 10.1.4.3. Reassembly

- 10.1.5. Hydraulic Circuit Diagram

- 10.1.6. Troubleshooting

- 10.1.7. Service Data

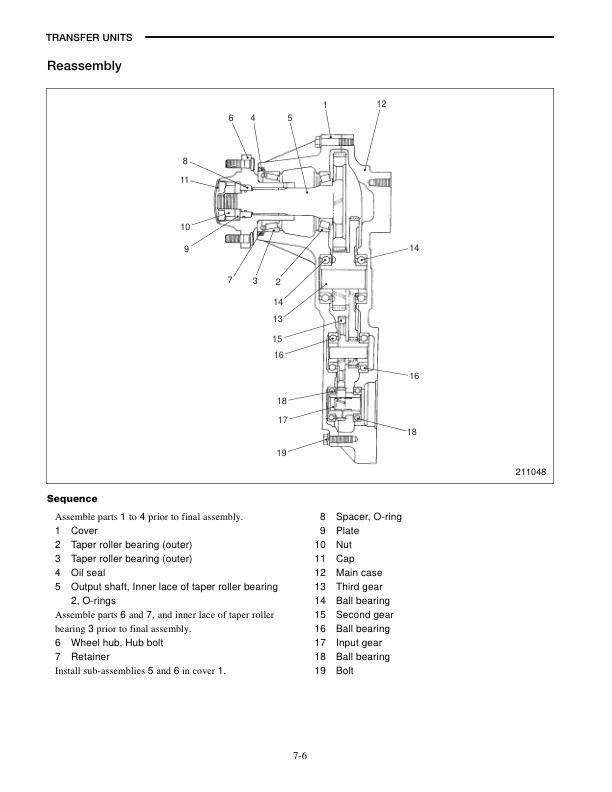

- 11. TRANSFER UNITS

- 11.1. TRANSFER UNITS

- 11.1.1. Specifications

- 11.1.2. Structure and Functions

- 11.1.3. Procedures and Suggestions for Disassembly and Reassembly

- 11.1.3.1. Disassembly

- 11.1.3.2. Inspection after Disassembly

- 11.1.3.3. Reassembly

- 11.1.4. Service Data

- 12. VEHICLE ELECTRICAL COMPONENTS

- 12.1. VEHICLE ELECTRICAL COMPONENTS

- 12.1.1. Console Box

- 12.1.1.1. Functions of Central Vehicle Monitor System

- 12.1.1.2. Electrical Components in Console Box

- 12.1.1.3. Disassembly and Reassembly

- 12.1.2. Direction Lever

- 12.1.3. Accelerator Control

- 12.1.4. Key Switch

- 12.1.5. Lighting Switch

- 12.1.6. Lamp Specification Chart

- 12.1.7. Troubleshooting of Lighting and Horn Systems

- 13. Chassis, Mast, Options

- 13.1. SERVICE MANUAL CHASSIS, MAST, AND OPTIONS

- 13.1.1. FOREWORD

- 13.1.2. HOW TO USE THIS MANUAL

- 13.1.3. GROUP INDEX

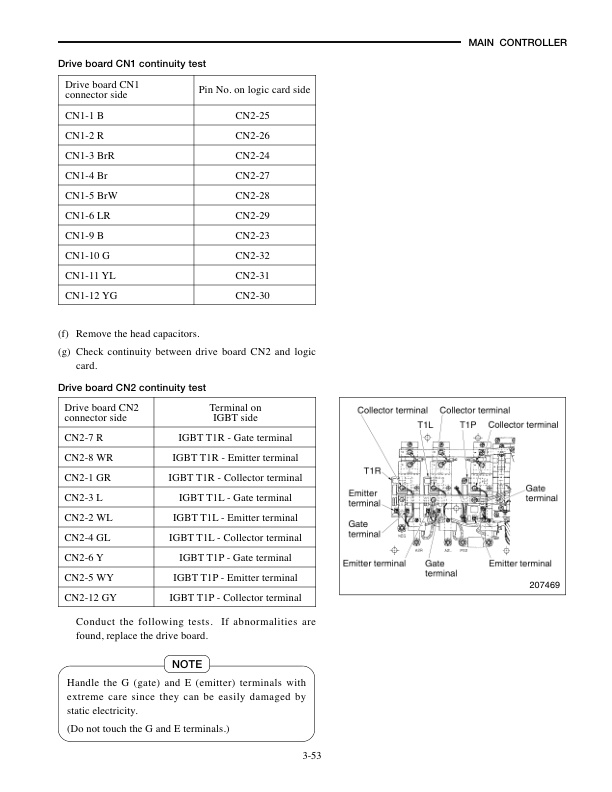

- 14. MAIN CONTROLLER

- 14.1. MAIN CONTROLLER

- 14.1.1. Outline

- 14.1.2. Controller Components (Part 1)

- 14.1.3. Controller Components (Part 2)

- 14.1.4. Logic Card Components

- 14.1.5. Controller Models

- 14.1.6. Operation Outline

- 14.1.7. Drive System

- 14.1.7.1. Neutral Position

- 14.1.7.2. Powering

- 14.1.7.3. Drive Motors Current Table (48 V type)

- 14.1.7.4. Drive Motors Current Table (36 V type)

- 14.1.7.5. Regeneration

- 14.1.7.6. Steering and Turns

- 14.1.7.7. Lever Regeneration Characteristic (48 V type)

- 14.1.7.8. Lever Regeneration Characteristic (36 V type and EE option type)

- 14.1.7.9. Auto Regeneration Characteristic (48 V type)

- 14.1.7.10. Auto Regeneration Characteristic (36 V type and EE option type)

- 14.1.7.11. Steering Characteristic (1.6 ton type)

- 14.1.7.12. Steering Characteristic (1.8 ton type)

- 14.1.7.13. Steering Characteristic (2.0 ton type)

- 14.1.8. Hydraulic System

- 14.1.8.1. Chopper Model

- 14.1.8.2. Contactor Model

- 14.1.9. Fail-safe System

- 14.1.9.1. Output Power Control at Low Battery Voltage

- 14.1.9.2. Overheat

- 14.1.9.3. Brush Wear

- 14.1.9.4. Maximum Vehicle Speed Control (SUO 7)

- 14.1.9.5. Output Power Control During Braking

- 14.1.9.6. Chat Timer (SUO 24)

- 14.1.9.7. Seat Switch Timer (SUO 25)

- 14.1.10. Malfunction Detection (Run Time Diagnosis)

- 14.1.11. Malfunction Data Record (History Folder)

- 14.1.11.1. Data Storage

- 14.1.11.2. Review of Stored Data

- 14.1.12. Setting

- 14.1.12.1. Printed Circuit Board Settings

- 14.1.12.2. Adjustment of Remaining Battery Level

- 14.1.12.3. Setup Options

- 14.1.13. Self-diagnosis

- 14.1.14. Other Functions

- 14.1.15. Display Unit

- 14.1.15.1. BDI (Battery Discharge Indicator)

- 14.1.15.2. Hourmeters and Time Display

- 14.1.15.3. Vehicle Speed and Error Code Display

- 14.1.15.4. Action Lights (LEDs)

- 14.1.16. Inspection and Adjustment

- 14.1.16.1. Inspection and Adjustment Tools

- 14.1.16.2. Removal and Installation of Logic Card

- 14.1.16.3. Tightening of High-tension Cable Terminals

- 14.1.16.4. Component Testing

- 14.1.17. Service Data

- 14.1.18. Tightening Torque

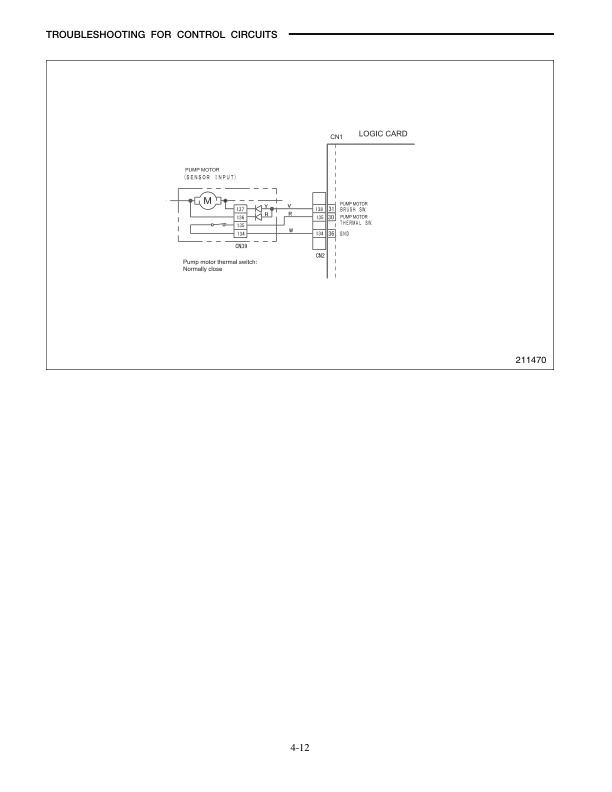

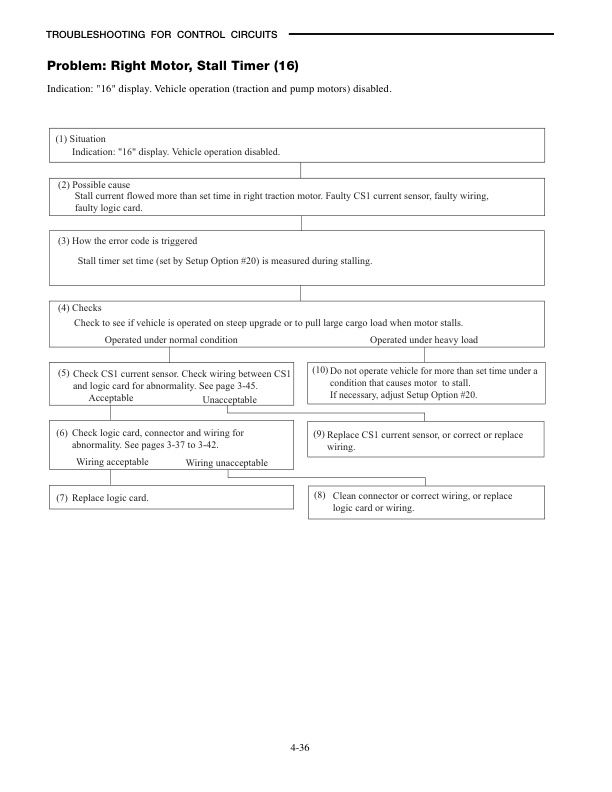

- 15. TROUBLESHOOTING FOR CONTROL CIRCUITS

- 15.1. TROUBLESHOOTING FOR CONTROL CIRCUITS

- 15.1.1. General Information

- 15.1.2. Alarm List

- 15.1.3. E0 Right Motor,Overheating

- 15.1.4. E1 Left Motor,Overheating

- 15.1.5. E2 Pump Motor,Overheating

- 15.1.6. E3 Controller,Overheating

- 15.1.7. E4 Right Motor,Worn Brushes

- 15.1.8. E5 Left Motor,Worn Brushes

- 15.1.9. E6 Pump Motor,Worn Brushes

- 15.1.10. Brake Oil,Low Level

- 15.1.11. Right Motor,Faulty Armature Circuit

- 15.1.12. Right Motor,Transistor Wire Breakage

- 15.1.13. Right Motor,Shorted Transistor

- 15.1.14. Right Motor,Faulty Transistor Drive

- 15.1.15. Right Motor,Faulty Current Sensor

- 15.1.16. Right Motor,Armature Over-current

- 15.1.17. Right Motor,Stall Timer

- 15.1.18. Right Motor,Faulty Field Circuit

- 15.1.19. Right Motor,Faulty Field Drive

- 15.1.20. Right Motor,Field Over-current

- 15.1.21. Left Motor,Faulty Armature Circuit

- 15.1.22. Left Motor,Transistor Wire Breakage

- 15.1.23. Left Motor,Shorted Transistor

- 15.1.24. Left Motor,Faulty Transistor Drive

- 15.1.25. Left Motor,Faulty Current Sensor

- 15.1.26. Left Motor,Armature Over-current

- 15.1.27. Left Motor,Stall Timer

- 15.1.28. Left Motor,Faulty Field Circuit

- 15.1.29. Left Motor,Faulty Field Drive

- 15.1.30. Left Motor,Field Over-current

- 15.1.31. Pump Motor,Faulty Circuit

- 15.1.32. Pump Motor,Transistor Wire Breakage

- 15.1.33. Pump Motor,Shorted Transistor

- 15.1.34. Pump Motor,Faulty Transistor Drive

- 15.1.35. Pump Motor,Faulty Current Sensor

- 15.1.36. Pump Motor,Armature Over-current

- 15.1.37. Line Contactor,Abnormality

- 15.1.38. Regeneration Contactor,Abnormality

- 15.1.39. Pump Contactor,Abnormality

- 15.1.40. Regeneration Diode,Abnormality

- 15.1.41. Right Armature Diode,Abnormality

- 15.1.42. Left Armature Diode,Abnormality

- 15.1.43. Pump Armature Diode,Abnormality

- 15.1.44. Right Motor,Wire Breakage

- 15.1.45. Left Motor,Wire Breakage

- 15.1.46. Pump Motor,Wire Breakage

- 15.1.47. Steering Sensor,Abnormality

- 15.1.48. Accelerator,Abnormality

- 15.1.49. Right Vehicle Speed Sensor,Abnormality

- 15.1.50. Left Vehicle Speed Sensor,Abnormality

- 15.1.51. E Direction Lever and Accelerator,Faulty Setting

- 15.1.52. (E)Seat Switch,Faulty Setting

- 15.1.53. H1 Lift Lever,Faulty Setting

- 15.1.54. H2 Tilt Lever,Faulty Setting

- 15.1.55. H3 Attachment 1 Lever,Faulty Setting

- 15.1.56. H4 Attachment 2 Lever,Faulty Setting

- 15.1.57. Data Communication,Abnormality

- 15.1.58. EEPROM,Abnormality

- 15.1.59. Logic Card,Faulty Initial Setting

- 15.1.60. Controller,Abnormality

- 15.1.61. Battery Voltage,Excessively Low (For 48-V Vehicles Only)

- 15.1.62. Battery Voltage,Excessively High (For 36-V Vehicles Only)

Rate this product

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Troubleshooting Service Manual 99799-56104

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

$50.00