Mitsubishi OPBL10P Service Manual SM23GBEPL1A1

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM23GBEPL1A1

- Number of Pages: 158

- Size: 5.7MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

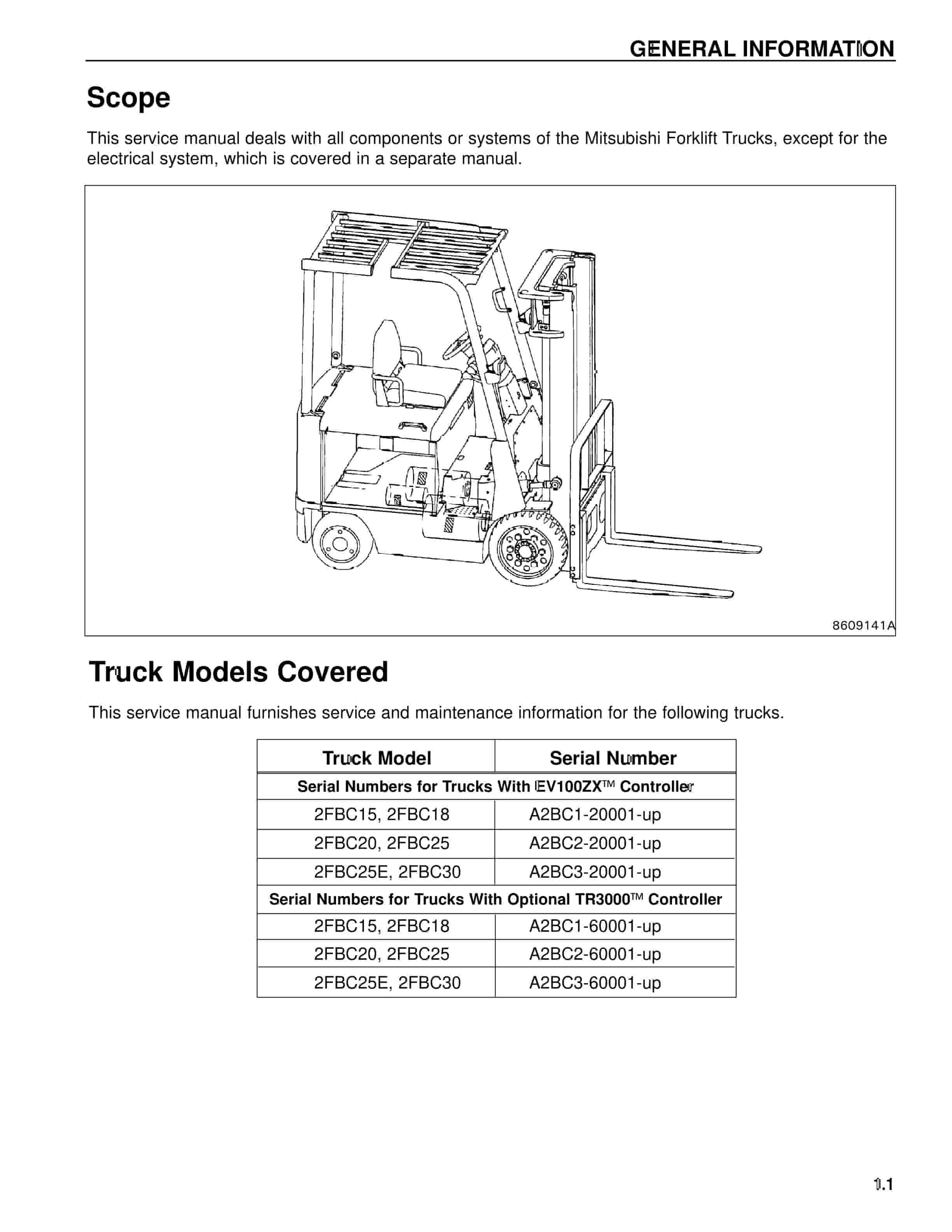

Model List:

- OPBL10P

- 1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1. Introduction

- 1.1.1. General

- 1.1.2. The trucks

- 1.1.3. Genuine Parts

- 1.1.4. Authorised service personnel

- 1.1.5. Symbol key

- 1.2. Safety

- 1.2.1. General

- 1.2.2. Safety instructions

- 1.2.3. Truck modification

- 1.2.4. Lifting the truck

- 1.2.5. Welding on truck

- 1.3. Environmental considerations

- 1.3.1. We respect the environment

- 1.4. Preparations

- 1.4.1. Service

- 1.4.2. Troubleshooting

- 1.5. Truck data

- 1.5.1. Machine plates

- 1.5.2. Safety and warning signs

- 1.5.3. Explanation of symbols

- 1.5.4. Type designation

- 1.5.5. Truck types

- 1.5.6. Dimensions and weights

- 1.6. Component placement

- 1.6.1. SLOP 24V

- 1.7. Component specification

- 1.7.1. Drive motor

- 1.7.2. Electric brake

- 1.7.3. Gearbox

- 1.7.4. Hydraulic unit

- 1.7.5. Control system for traction and pump motors

- 1.7.6. Steering servo motor

- 1.7.7. Controller system for steering

- 1.8. Recommended consumable materials

- 1.8.1. Oil and grease types

- 1.9. Code explanations

- 1.9.1. Colour codes for wiring diagrams

- 1.9.2. Designations for electrical components in electrical diagram

- 1.9.3. Standard abbreviations and units

- 1.9.4. Acronyms and abbreviations

- 2. SPECIAL TOOLS

- 2.1. List of tools

- 3. SERVICE

- 3.1. Service schedule / inspection

- 3.1.1. Introduction

- 3.1.2. Safety

- 3.1.3. Service schedule explanation

- 3.1.4. Inspection daily / monthly / PDI and commissioning

- 3.1.5. First service (200 hours)

- 3.1.6. Main service

- 3.1.7. Extra service inspections

- 3.1.8. Service inspection

- 3.1.9. Dye penetration inspection instruction

- 3.2. Service schedule

- 3.3. Lubrication

- 3.3.1. Recommended lubricants

- 3.3.2. Symbol key, lubrication chart

- 3.3.3. Lubrication chart

- 4. CHASSIS

- 4.1. Design and function

- 4.1.1. Machine housing

- 4.1.2. Overhead guard

- 4.1.3. Battery locking

- 4.1.4. Covers and panels

- 4.2. Repair and maintenance instructions

- 4.2.1. Before work is performed

- 4.2.2. Removal and installation of the overhead guard

- 4.2.3. Panels and housing

- 4.2.4. Removal and installation of the battery rollers

- 4.2.5. Remove and install the foot plate

- 4.2.6. Tilt the truck before changing wheels

- 4.2.7. Replacing the load wheels, SLOP 24V

- 5. DRIVE UNIT

- 5.1. Design and function

- 5.1.1. Description

- 5.1.2. Drive motor

- 5.1.3. Gearbox

- 5.1.4. Drive wheel

- 5.2. Repair and maintenance instructions

- 5.2.1. Before work is performed

- 5.2.2. Servicing and maintenance

- 5.3. Drive unit, SLOP 24V

- 5.3.1. Traction motor

- 5.3.2. Gearbox

- 5.3.3. Drive wheels

- 5.4. Diagnostics and troubleshooting

- 5.4.1. Troubleshooting

- 5.4.2. Troubleshooting chart

- 6. MAST SYSTEM

- 6.1. Design and function

- 6.1.1. Fixation of the mast

- 6.1.2. Operators platform

- 6.1.3. Mast switch in mast

- 6.2. Repair and maintenance instructions

- 6.2.1. Before work is performed

- 6.2.2. Operators platform

- 6.2.3. Fork carriage

- 6.2.4. Lift chains

- 6.2.5. Control of initial lift stroke

- 6.2.6. Inspection of forks

- 6.3. Diagnostics and troubleshooting

- 6.3.1. Troubleshooting

- 7. STEERING

- 7.1. Design and function

- 7.1.1. General

- 7.1.2. Feedback sensors

- 7.1.3. Communication between the servo components

- 7.2. Repair and maintenance instructions

- 7.2.1. Before work is performed

- 7.2.2. Steering wheel

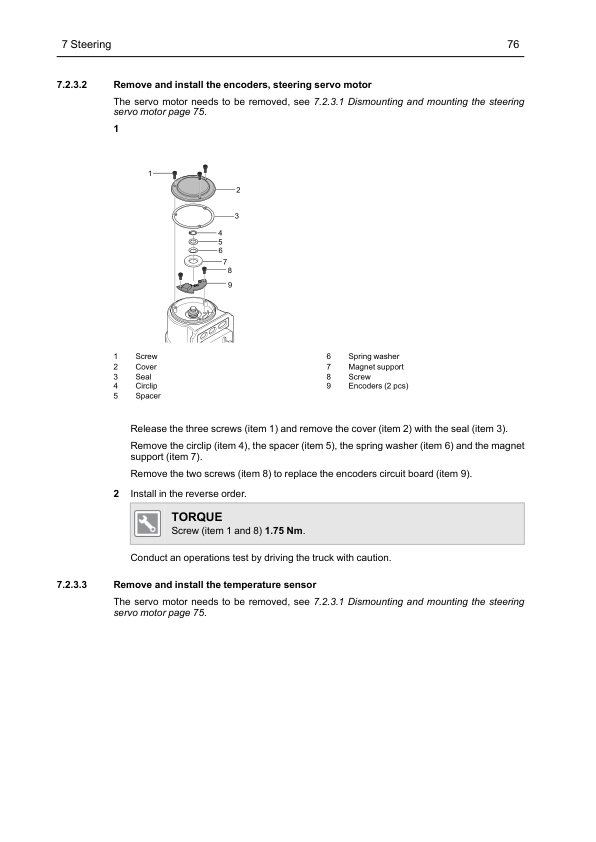

- 7.2.3. Steering servo motor

- 7.2.4. Remove and install the zero position sensor

- 7.2.5. Adjustments and tests

- 7.3. Diagnostics and troubleshooting

- 8. HYDRAULIC SYSTEM

- 8.1. Design and function

- 8.1.1. Description, SLOP 24V

- 8.1.2. Functions

- 8.1.3. Hydraulic diagram

- 8.1.4. Hydraulic unit, compact, SLOP 24V

- 8.1.5. Cylinders

- 8.1.6. Conduit components

- 8.1.7. Other components

- 8.1.8. Hydraulic oil

- 8.2. Repair and maintenance instructions

- 8.2.1. Before work is performed

- 8.2.2. General rules

- 8.2.3. Installation

- 8.2.4. Connections

- 8.2.5. Dismounting and mounting of hydraulic hoses

- 8.3. Hydraulic unit, compact, SLOP 24V

- 8.3.1. Dismounting and mounting

- 8.3.2. Start-up

- 8.3.3. Replacing the filter

- 8.3.4. Changing the oil

- 8.3.5. Checking the hydraulic oil level

- 8.3.6. Hydraulic motor

- 8.3.7. Pump, hydraulic unit

- 8.3.8. Hydraulic unit valves

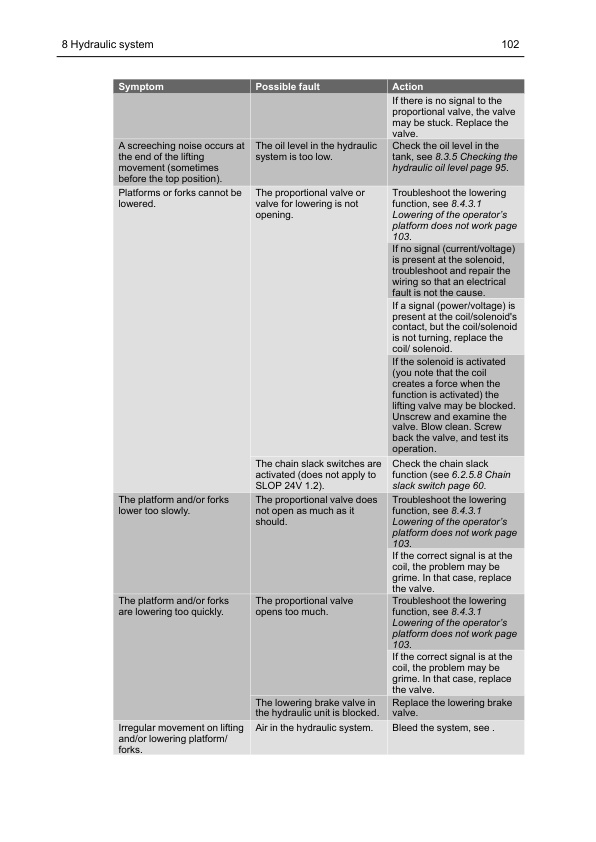

- 8.4. Diagnostics and troubleshooting

- 8.4.1. TruckTool

- 8.4.2. Troubleshooting

- 8.4.3. Troubleshooting, hydraulics functions, SLOP 24V

- 9. CYLINDERS

- 9.1. Design and function

- 9.1.1. Descriptions

- 9.1.2. Damping

- 9.1.3. Hose break valve

- 9.2. Repair and maintenance instructions

- 9.2.1. Before work is performed

- 9.2.2. Bleeding of the hydraulic cylinders without a bleed air screw

- 9.2.3. Bleeding of the hydraulic cylinders with an air bleed screw

- 9.2.4. Work with hose break valve/lowering brake valve in cylinders

- 9.2.5. Replace seals, lift cylinder

- 9.3. Cylinders, SLOP 24V

- 9.3.1. Dismounting and mounting, lift cylinder

- 9.3.2. Dismounting and mounting, initial cylinder (option)

- 10. ELECTRICAL SYSTEM

- 10.1. Introduction

- 10.1.1. Overview of components

- 10.1.2. CAN bus communication

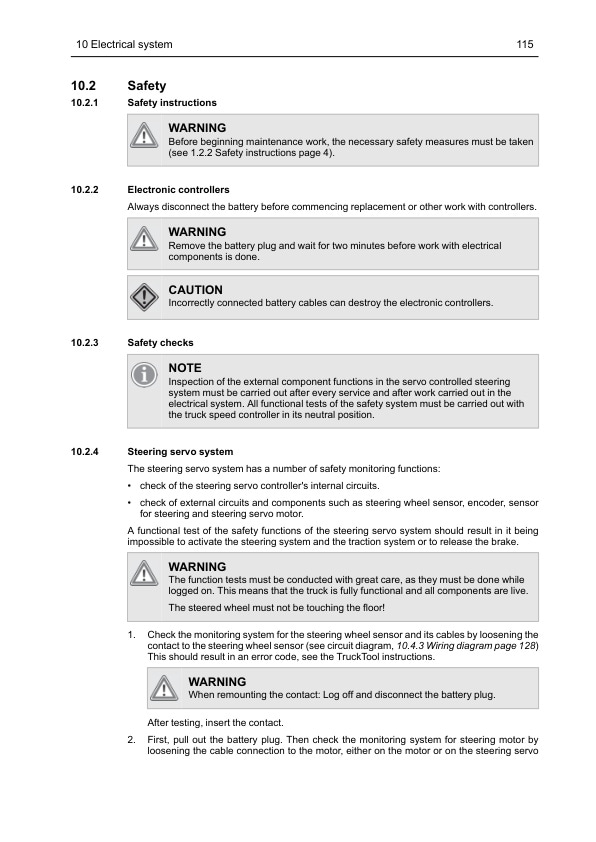

- 10.2. Safety

- 10.2.1. Safety instructions

- 10.2.2. Electronic controllers

- 10.2.3. Safety checks

- 10.2.4. Steering servo system

- 10.2.5. Hydraulic system

- 10.2.6. Traction speed system

- 10.2.7. Sensors

- 10.2.8. Safety controls, weight measurement system

- 10.2.9. Speed limits

- 10.3. Design and function

- 10.3.1. Battery replacement

- 10.3.2. Battery capacity

- 10.3.3. VCM (Vehicle Control Module) (truck computer)

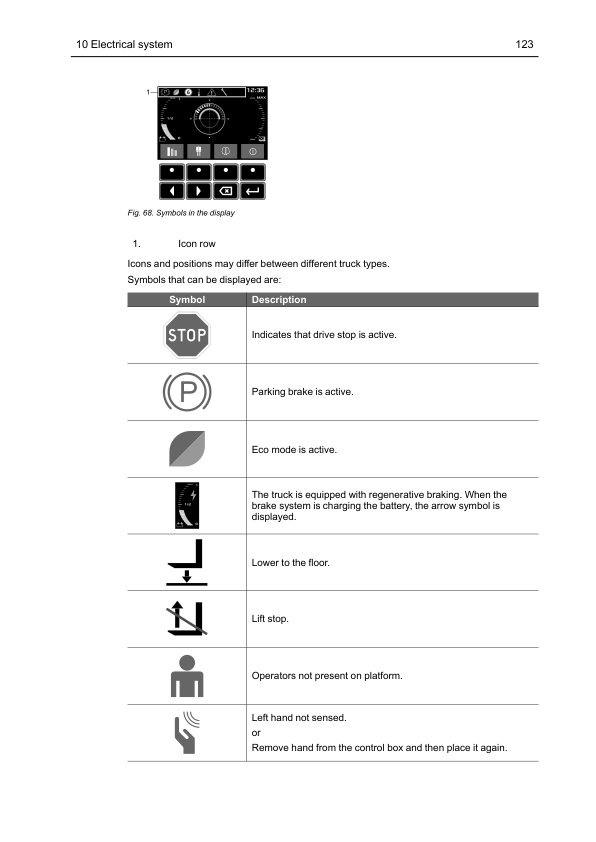

- 10.3.4. Display and icon panel

- 10.3.5. CMC (Combi Motor Controller)

- 10.3.6. EPS (Electrical Power Steering) controller

- 10.3.7. Hydraulic system

- 10.3.8. Brake system

- 10.3.9. Traction system

- 10.3.10. Connector specifications

- 10.4. Repair and maintenance instructions

- 10.4.1. Before work is performed

- 10.4.2. Connectors in cold store

- 10.4.3. Wiring diagram

- 10.4.4. Insulation test

- 10.4.5. Remove and install the VCM

- 10.4.6. Remove and install the multi function display (HMI-20)

- 10.4.7. Remove and install the safety sensors

- 10.4.8. TruckTool

- 10.5. Diagnostics and troubleshooting

- 11. SPEED CONTROL AND BRAKE SYSTEMS

- 11.1. Design and function

- 11.1.1. General

- 11.1.2. Speed and brake control

- 11.1.3. Electric brakes

- 11.1.4. Brake button

- 11.1.5. Motor brake

- 11.2. Repair and maintenance instructions

- 11.2.1. Before work is performed

- 11.2.2. Speed Controller

- 11.2.3. Brake button

- 11.2.4. Removal and installation of the left hand control

- 11.2.5. Electric brakes

- 11.3. Diagnostics and troubleshooting

- 11.3.1. Troubleshoot the speed controller

- 11.3.2. Troubleshoot the brake

- 12. MISCELLANEOUS

- 12.1. Stability support system, Cornering control

- 12.1.1. Speed restriction based on the steering angle

- 12.1.2. Dynamic cornering control

- 12.1.3. Settings DCC

- 12.2. Increased drive speed (option)

- 12.2.1. Design and function

- 12.2.2. Activation of Increased drive speed

- 12.2.3. Calibration of Weight system

- 12.3. Walk beside, option for SLOP 24V

- 12.3.1. Design and function

- 12.3.2. Activation Walk beside option

- 12.3.3. Setting the speed

- 12.4. Step warning

- 12.4.1. Design and function

- 12.4.2. Activation Step out warning option

- 12.5. PPS, Personnel Protection System

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Disassembly and Assembly Service Manual 99799-56102

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi FB16NT, FB18NT, FB20NT Chassis, Mast and Options Service Manual 99719-78100

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 1204E Diesel Engine Operation and Maintenance Manual Service Manual 99799-56105

$50.00