Mitsubishi SBR12N2 to PBS30N2 Service Manual SM24GBST1AA3

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM24GBST1AA3

- Number of Pages: 378

- Size: 19.5MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- SBR12N2, SBR12N2I, SBR16N2, SBR16N2I, SBR16N2S, SBR20N2, SBR20N2I, SBR20N2S, SBR10N2TF, PBR20N2, PBR30N2, SBS16N2, SBS16N2I, SBS16N2S, SBS20N2, SBS20N2I, SBS20N2S, SBS10N2TF, PBS20N2, PBS30N2

- 1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1. Introduction

- 1.1.1. General

- 1.1.2. The trucks

- 1.1.3. Genuine Parts

- 1.1.4. Authorised service personnel

- 1.1.5. Symbol key

- 1.2. Safety

- 1.2.1. General

- 1.2.2. Safety instructions

- 1.2.3. Truck modification

- 1.2.4. Lifting the truck

- 1.2.5. Welding on truck

- 1.3. Environmental considerations

- 1.3.1. We respect the environment

- 1.4. Preparations

- 1.4.1. Service

- 1.4.2. Troubleshooting

- 1.5. Truck data

- 1.5.1. Machine plates

- 1.5.2. Safety and warning signs

- 1.5.3. Type designation

- 1.5.4. Truck types

- 1.5.5. Weight, stand-in stacker version

- 1.5.6. Weight, sit-on stacker version

- 1.5.7. Weight, low lifter

- 1.5.8. Dimensions, stand-in version

- 1.5.9. Dimensions, sit-on version

- 1.5.10. Miscellaneous

- 1.6. Component placement

- 1.7. Component specification

- 1.8. Recommended consumable materials

- 1.8.1. Oil and grease types

- 1.9. Code explanations

- 1.9.1. Colour codes for wiring diagrams

- 1.9.2. Designations for electrical components in electrical diagram

- 1.9.3. Standard abbreviations and units

- 1.9.4. Acronyms and abbreviations

- 2. SPECIAL TOOLS

- 2.1. List of tools

- 3. SERVICE

- 3.1. Service schedule / inspection

- 3.1.1. Introduction

- 3.1.2. Safety

- 3.1.3. Service schedule explanation

- 3.1.4. Inspection daily / monthly / PDI and commissioning

- 3.1.5. First service (200 hours)

- 3.1.6. Main service

- 3.1.7. Extra service inspections

- 3.1.8. Service inspection

- 3.1.9. Dye penetration inspection instruction

- 3.2. Service schedule

- 3.3. Lubrication

- 3.3.1. Recommended lubricants

- 3.3.2. Symbol key, lubrication chart

- 3.3.3. Lubrication chart

- 3.4. Specific instructions

- 3.4.1. Storage of machines and motors

- 3.4.2. Traction motor

- 3.4.3. Gearbox

- 3.4.4. Lift chains and forks

- 3.4.5. Operator protection

- 3.4.6. Hydraulic oil

- 3.5. Maintaining the battery (Lead Acid)

- 3.6. Battery servicing

- 4. CHASSIS

- 4.1. Design and function

- 4.1.1. Machine housing

- 4.1.2. Covers and panels

- 4.1.3. Wheels

- 4.2. Repair and maintenance instructions

- 4.2.1. Before work is performed

- 4.2.2. Remove and install panels and covers

- 4.2.3. Remove and install the overhead guard

- 4.2.4. Remove and install the floor plate, stand-in version

- 4.2.5. Remove and install the floor plate, sit-on version

- 4.2.6. Remove and install the driving seat, sit-on version

- 4.2.7. Wheels

- 5. DRIVE UNIT

- 5.1. Design and function

- 5.1.1. Description

- 5.1.2. Traction Motor

- 5.1.3. Gearbox

- 5.1.4. Drive wheel

- 5.2. Repair and maintenance instructions

- 5.2.1. Before work is performed

- 5.2.2. Servicing and maintenance

- 5.2.3. Traction motor

- 5.2.4. Gearbox

- 5.2.5. Drive wheel

- 5.3. Diagnostics and troubleshooting

- 5.3.1. Troubleshooting chart

- 6. MAST SYSTEM

- 6.1. Design and function

- 6.1.1. Mast systems, Stacker

- 6.1.2. Initial lift (option)

- 6.1.3. Fork carriage, stacker

- 6.1.4. Fork carriage, low lifter

- 6.1.5. Link system

- 6.2. Repair and maintenance instructions

- 6.2.1. Before work is performed

- 6.2.2. Leaning angle of truck, adjustment

- 6.2.3. Initial lift

- 6.2.4. Fork carriage, stacker

- 6.2.5. Fork carriage, low lifter

- 6.2.6. Inspection of welded fork carriages

- 6.2.7. Inspection of forged forks

- 6.2.8. Lift chains

- 6.2.9. Link system

- 6.2.10. Wheels

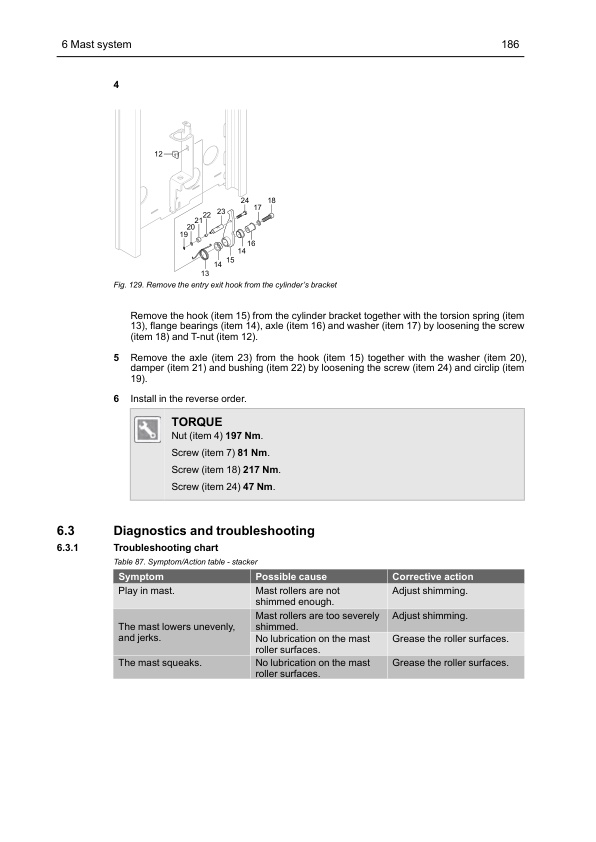

- 6.2.11. Closed pallet entry and exit (option for low lifter)

- 6.3. Diagnostics and troubleshooting

- 6.3.1. Troubleshooting chart

- 7. STEERING

- 7.1. Design and function

- 7.1.1. General

- 7.1.2. Feedback sensors

- 7.1.3. Communication between the servo components

- 7.2. Repair and maintenance instructions

- 7.2.1. Before work is performed

- 7.2.2. Remove and install the steering wheel sensor

- 7.2.3. Remove and install the servo motor

- 7.2.4. Remove and install the encoders, servo motor

- 7.2.5. Remove and install the zero position sensor

- 7.2.6. Remove and install the temperature sensor

- 7.2.7. Calibration of the steering angle

- 8. HYDRAULIC SYSTEM

- 8.1. Design and function

- 8.1.1. Description

- 8.1.2. Hose break valve

- 8.1.3. Lowering brake valve

- 8.1.4. Pilot operated check valve

- 8.1.5. Electric proportional valve

- 8.1.6. Hydraulic diagram

- 8.1.7. Hydraulic unit

- 8.1.8. Hydraulic unit valves

- 8.1.9. Hydraulic oil

- 8.2. Repair and maintenance instructions

- 8.2.1. Before work is performed

- 8.2.2. General instructions

- 8.2.3. Installation

- 8.2.4. Connections

- 8.2.5. Hydraulic hoses

- 8.2.6. Start-up

- 8.2.7. Hydraulic oil, changing/draining

- 8.2.8. Replace the air filter, stackers

- 8.2.9. Replace the air filter, low lifters

- 8.2.10. Oil filter element, replacement

- 8.2.11. Checking the hydraulic oil level

- 8.2.12. Hose break valve

- 8.2.13. Hydraulic control valves

- 8.2.14. Hydraulic Pump motor Standard

- 8.2.15. Hydraulic Pump motor Heavy duty

- 8.2.16. Hydraulic pump motor, low lifter

- 8.2.17. Installation instruction for pipe couplings

- 8.3. Diagnostics and troubleshooting

- 8.3.1. Symptom and Actions

- 9. CYLINDERS

- 9.1. Design and function

- 9.1.1. Description

- 9.2. Repair and maintenance instructions

- 9.2.1. Before work is performed

- 9.2.2. Bleeding of the hydraulic cylinders with an air bleed screw

- 9.2.3. Bleeding of the hydraulic cylinders without a bleed air screw

- 9.2.4. Lift cylinder, Triplex with free lift (DTFV)

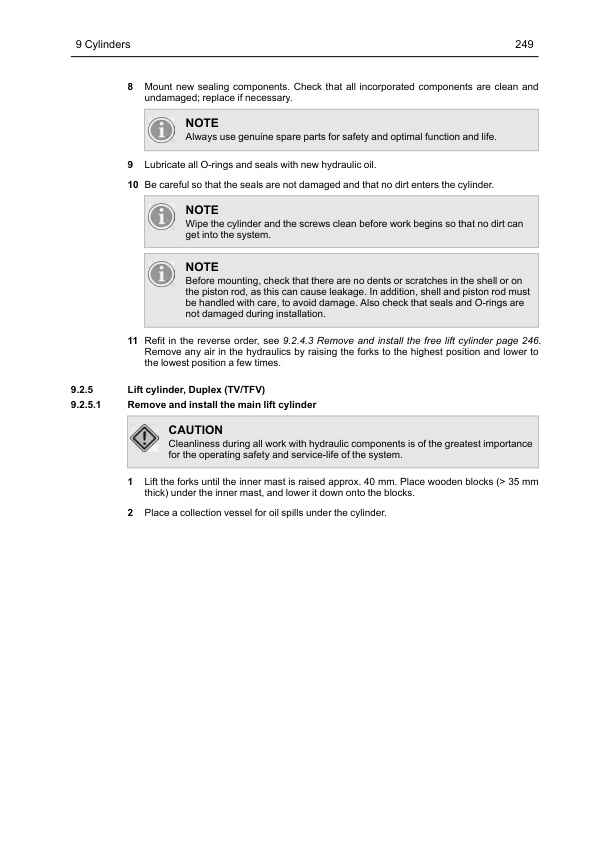

- 9.2.5. Lift cylinder, Duplex (TV/TFV)

- 9.2.6. Lift cylinder, Initial

- 9.2.7. Stabilizer cylinder, Triplex with free lift (DTFV)

- 9.2.8. Lift cylinder, Low lifter

- 10. ELECTRICAL SYSTEM

- 10.1. Introduction

- 10.1.1. Overview of components

- 10.1.2. CAN bus communication

- 10.2. Safety

- 10.2.1. Safety instructions

- 10.2.2. Electronic controllers

- 10.2.3. Sensors

- 10.3. Design and function

- 10.3.1. Battery capacity

- 10.3.2. VCM (Vehicle Control Module) (truck computer)

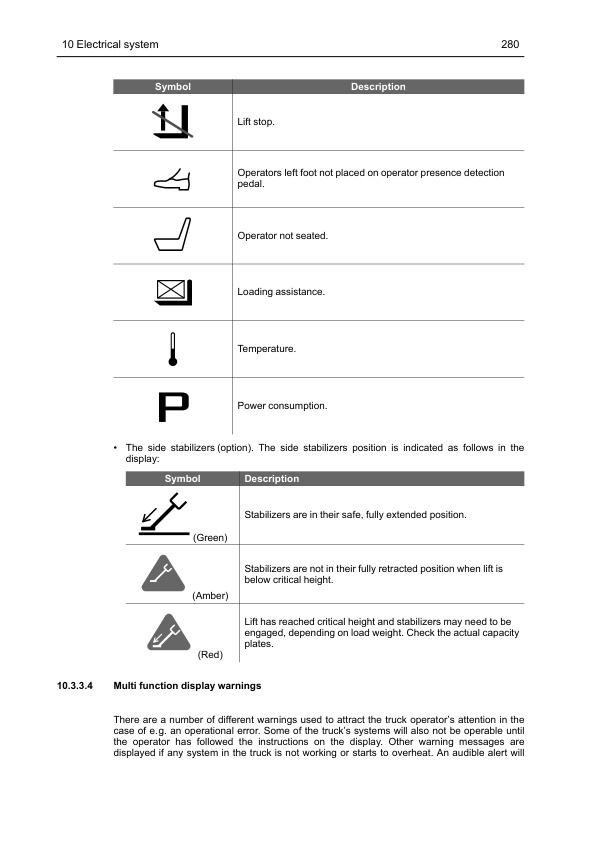

- 10.3.3. Display

- 10.3.4. CMC (Combi Motor Controller)

- 10.3.5. TMC (Traction Motor Controller)

- 10.3.6. PMC (Pump Motor Controller)

- 10.3.7. EPS (Electrical Power Steering) controller

- 10.3.8. Connector specifications

- 10.4. Repair and maintenance instructions

- 10.4.1. Before work is performed

- 10.4.2. Wiring diagram

- 10.4.3. Insulation resistance test

- 10.4.4. Remove and install the battery (Lead Acid)

- 10.4.5. Remove and install the battery (Lithium-ion)

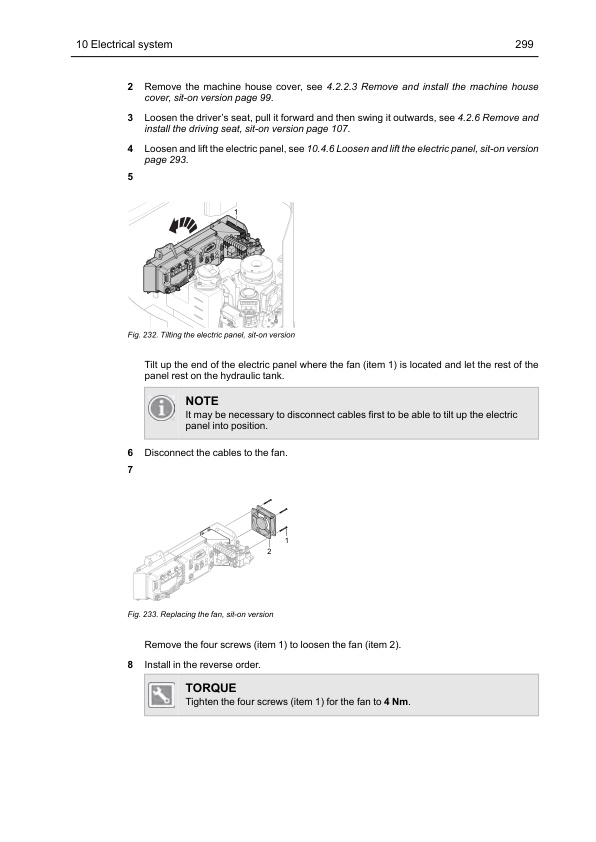

- 10.4.6. Loosen and lift the electric panel, sit-on version

- 10.4.7. Remove and install the CMC

- 10.4.8. Remove and install the TMC

- 10.4.9. Remove and install the PMC

- 10.4.10. Remove and install the EPS

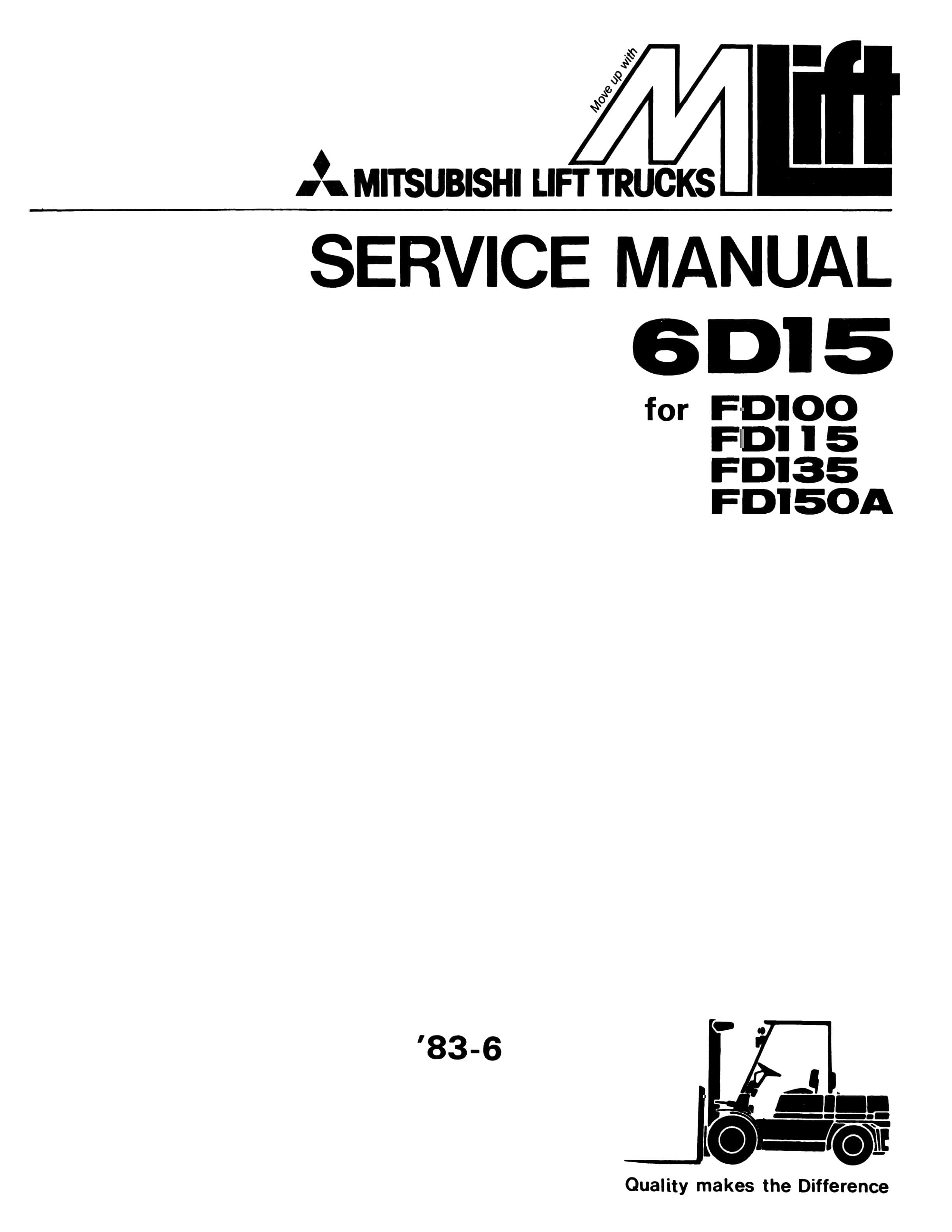

- 10.4.11. Remove and install the control units fan

- 10.4.12. Remove and install the compartment fan, sit-on version

- 10.4.13. Remove and install the VCM

- 10.4.14. Remove and install the relay

- 10.4.15. Remove and install the fuses

- 10.4.16. Remove and install the power fuse

- 10.4.17. Remove and install the EPS Power fuse

- 10.4.18. Remove and install the line contactor

- 10.4.19. Remove and install the emergency stop contactor

- 10.4.20. Remove and install the horn (standard) and buzzer (option)

- 10.4.21. Remove and install the emergency stop

- 10.4.22. Remove and install the standard display (HMI-10)

- 10.4.23. Remove and install the multi function display (HMI-20)

- 10.4.24. Remove and install the DC/DC converter, sit-on version

- 10.4.25. Remove and install the foot protection sensor (option) (S11) reflector, stand-in version

- 10.4.26. Remove and install the safety sensors

- 10.4.27. TruckTool

- 10.5. Diagnostics and troubleshooting

- 11. SPEED CONTROL AND BRAKE SYSTEMS

- 11.1. Design and function

- 11.1.1. Speed control

- 11.1.2. Electric brake

- 11.2. Repair and maintenance instructions

- 11.2.1. Before work is performed

- 11.2.2. Speed Controller

- 11.2.3. Electric brake

- 11.3. Diagnostics and troubleshooting

- 11.3.1. Troubleshoot the speed controller

- 11.3.2. Troubleshoot the brake

- 12. MISCELLANEOUS

- 12.1. Options

- 12.1.1. Additional equipment

- 12.1.2. Equipment bar installation

- 12.1.3. Side posts for overhead guard installation

- 12.1.4. Dashboard protection (only for stand-in version) and mini equipment bar installation

- 12.1.5. Finger guard installation

- 12.1.6. Writing surface installation

- 12.1.7. Rear view mirror installation

- 12.1.8. Work light (option)

- 12.1.9. Interior lights (option)

- 12.1.10. Warning light installation

- 12.1.11. Camera and monitor installation

- 12.1.12. Laser position guide (option)

- 12.1.13. Floor spot (option)

- 12.1.14. Radio (Option)

- 12.1.15. USB-power supply socket (option)

- 12.1.16. power supply socket (option)

- 12.1.17. Direction switch for 360 steering (option)

- 12.1.18. V DC / 12 V DC converter (option)

- 12.1.19. Load backrest (option)

- 12.1.20. Foldable seat (option)

- 12.1.21. Ergo Forks Trailing Control (EFTC) (option)

- 12.1.22. Closed Pallet Entry and Exit (option)

- 12.1.23. Remove and install the side stabilizers

- 12.1.24. Side stabilizer functionality test

- 12.1.25. Side stabilizer adjustment of clearance

- 12.1.26. Travel alarm (option)

Rate this product

You may also like

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-14110

$50.00

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

$50.00