Caterpillar NRM20N2, NRM25N2 Service Manual SM24GBUFW1C4

$50.00

- Type Of Manual: Service Manual

- Manual ID: SM24GBUFW1C4

- Number of Pages: 254

- Size: 11.8MB

- Format: PDF

-

Model List:

- NRM20N2, NRM25N2

- 1. GENERAL INFORMATION AND TECHNICAL DATA

- 1.1. Introduction

- 1.1.1. General

- 1.1.2. The trucks

- 1.1.3. Genuine Parts

- 1.1.4. Authorised service personnel

- 1.1.5. Symbol key

- 1.2. Safety

- 1.2.1. General

- 1.2.2. Safety instructions

- 1.2.3. Truck modification

- 1.2.4. Lifting the truck

- 1.2.5. Towing/moving non-powered four-way reach truck

- 1.2.6. Welding on truck

- 1.3. Environmental considerations

- 1.3.1. We respect the environment

- 1.4. Preparations

- 1.4.1. Service

- 1.4.2. Troubleshooting

- 1.5. Truck data

- 1.5.1. Machine plates

- 1.5.2. Safety and warning signs

- 1.5.3. Explanation of symbols

- 1.5.4. Type designation

- 1.5.5. Truck types

- 1.5.6. Dimensions

- 1.6. Component specification

- 1.6.1. Drive motor

- 1.6.2. Electric brake

- 1.6.3. Gearbox

- 1.6.4. Hydraulic unit

- 1.6.5. Control system for traction and pump motors

- 1.6.6. Steering servo motor

- 1.6.7. Controller system for steering

- 1.7. Recommended consumable materials

- 1.7.1. Oil and grease types

- 1.8. Code explanations

- 1.8.1. Colour codes for wiring diagrams

- 1.8.2. Designations for electrical components in electrical diagram

- 1.8.3. Standard abbreviations and units

- 1.8.4. Acronyms and abbreviations

- 2. SPECIAL TOOLS

- 2.1. List of tools

- 3. SERVICE

- 3.1. Pre-delivery Inspection (PDI)

- 3.2. Service schedule / inspection

- 3.2.1. Introduction

- 3.2.2. Safety

- 3.2.3. Service schedule explanation

- 3.2.4. Inspection daily / monthly / PDI and commissioning

- 3.2.5. First service (200 hours)

- 3.2.6. Main service

- 3.2.7. Extra service inspections

- 3.2.8. Service inspection

- 3.2.9. Dye penetration inspection instruction

- 3.3. Service schedule

- 3.4. Lubrication

- 3.4.1. Recommended lubricants

- 3.4.2. Symbol key lubrication chart

- 3.4.3. Lubrication chart, four-way reach truck

- 3.4.4. Cab lubrication schematic diagram (option)

- 4. CHASSIS

- 4.1. Design and function

- 4.1.1. Chassis frame

- 4.1.2. Machine housing

- 4.1.3. Overhead guard

- 4.1.4. Battery locking

- 4.1.5. Armrest and steering wheel

- 4.1.6. Foot plate

- 4.1.7. Covers and panels

- 4.1.8. Tightening torque for chassis plates

- 4.2. Repair and maintenance instructions

- 4.2.1. Panels

- 4.2.2. Load wheels

- 4.2.3. Machine housing

- 4.2.4. Driver seat

- 4.2.5. Overhead guard

- 4.2.6. Batteries

- 4.2.7. Battery rollers

- 4.2.8. Adjustable armrest

- 4.2.9. Fitting the antistatic chain

- 5. DRIVE UNIT

- 5.1. Design and function

- 5.1.1. Drive motor

- 5.1.2. Gearbox

- 5.2. Repair and maintenance instructions

- 5.2.1. Before work is performed

- 5.2.2. Drive unit

- 5.2.3. Traction motor

- 5.2.4. Removal and installation of the traction motor

- 5.2.5. First service

- 5.2.6. Preventive maintenance

- 5.2.7. Reconditioning the traction motor

- 5.2.8. Gearbox

- 5.2.9. Drive wheel

- 5.3. Diagnostics and troubleshooting

- 5.3.1. Troubleshooting chart

- 6. MAST SYSTEM

- 6.1. Design and function

- 6.1.1. Mast system

- 6.1.2. Fork carriage

- 6.2. Repair and maintenance instructions

- 6.2.1. Lift chains

- 6.2.2. Reach carriage

- 6.2.3. Fork carriage

- 6.2.4. Hydraulic fork spreading, four-way reach truck

- 6.3. Diagnostics and troubleshooting

- 6.3.1. Troubleshooting chart, triplex with free lift (DTFV)

- 6.3.2. Fault-finding chart for fork spreaders, four-way reach truck

- 7. STEERING

- 7.1. Design and function

- 7.1.1. General

- 7.1.2. Feedback sensors

- 7.1.3. Communication between the servo components

- 7.2. Repair and maintenance instructions

- 7.2.1. Steering wheel

- 7.2.2. Steering servo motor

- 7.2.3. Settings, adjustments and testing

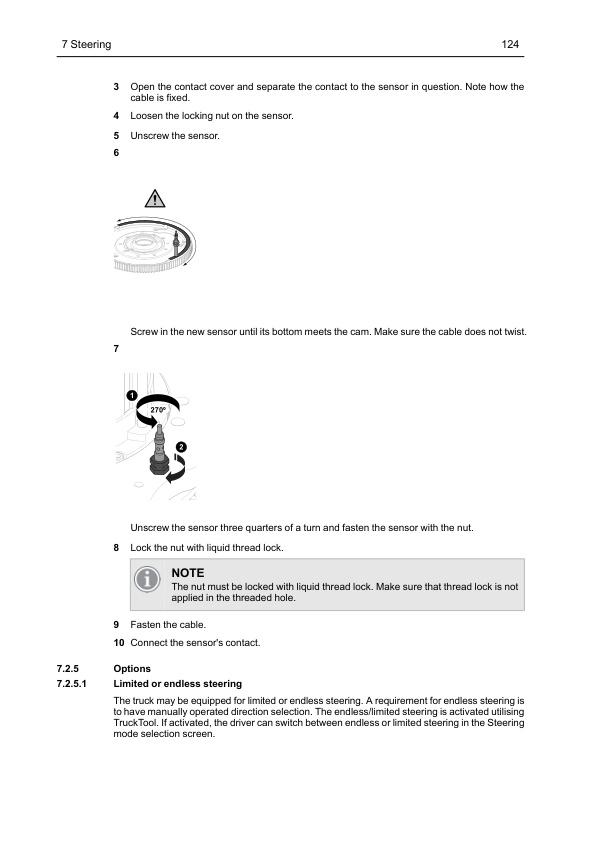

- 7.2.4. Remove and install the zero position sensor

- 7.2.5. Options

- 7.3. Diagnostics and troubleshooting

- 7.3.1. Troubleshooting with TruckTool

- 8. HYDRAULIC SYSTEM

- 8.1. Design and function

- 8.1.1. Description

- 8.1.2. Hose rupture valve

- 8.1.3. Electric proportional valve

- 8.1.4. Electric solenoid valve

- 8.1.5. MTC (Mast Tilt Control)

- 8.1.6. Hydraulic diagram

- 8.2. Repair and maintenance instructions

- 8.2.1. Before work is performed

- 8.2.2. General instructions

- 8.2.3. Installation

- 8.2.4. Connections

- 8.2.5. Dismantling and assembling hydraulic hoses

- 8.2.6. Pump motor

- 8.2.7. Hydraulic oil tank

- 8.2.8. MTC (Mast Tilt Control)

- 8.3. Control valve

- 8.3.1. Operation of the control valve

- 8.3.2. Control valve overview

- 8.3.3. Removal and installation of the control valve

- 8.3.4. Adjusting the working pressure

- 8.3.5. Inspection and adjustment of the lowering rate

- 8.3.6. Calibrating the hydraulic functions

- 8.3.7. S3 valve

- 8.3.8. Emergency lowering valve

- 8.3.9. Hose rupture valve

- 8.4. Diagnostics and troubleshooting

- 8.4.1. Troubleshooting the hydraulic system

- 8.4.2. Troubleshooting chart

- 8.4.3. Troubleshooting the control valve

- 9. HYDRAULIC CYLINDERS

- 9.1. Design and function

- 9.1.1. Reach cylinder

- 9.1.2. Tilt cylinder

- 9.1.3. Free lift cylinder

- 9.1.4. Final stroke cylinder

- 9.2. Repair and maintenance instructions

- 9.2.1. General

- 9.2.2. Reach cylinder

- 9.2.3. Tilt cylinder

- 9.2.4. Free lift cylinder

- 9.2.5. Final stroke cylinder

- 9.2.6. Removal and installation of the gasket in the hydraulic cylinder

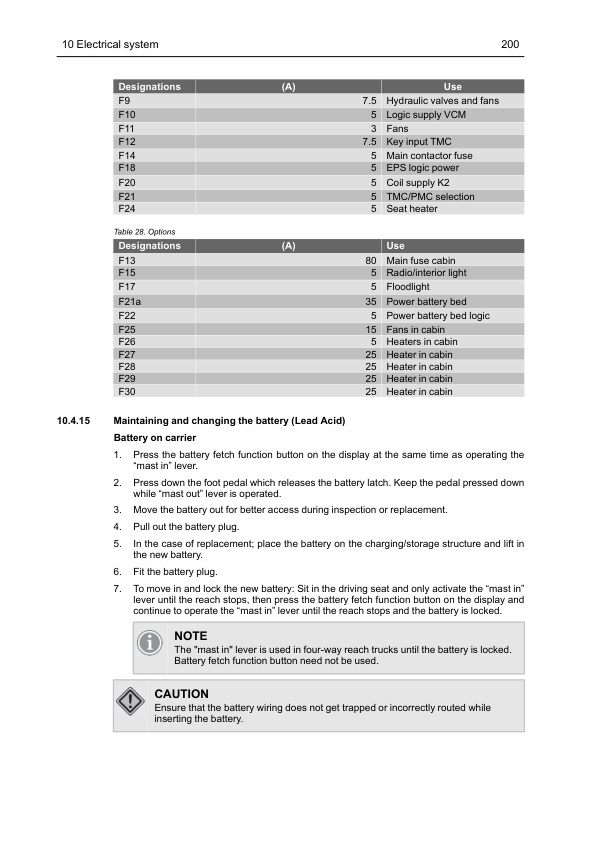

- 10. ELECTRICAL SYSTEM

- 10.1. Introduction

- 10.1.1. Overview of components

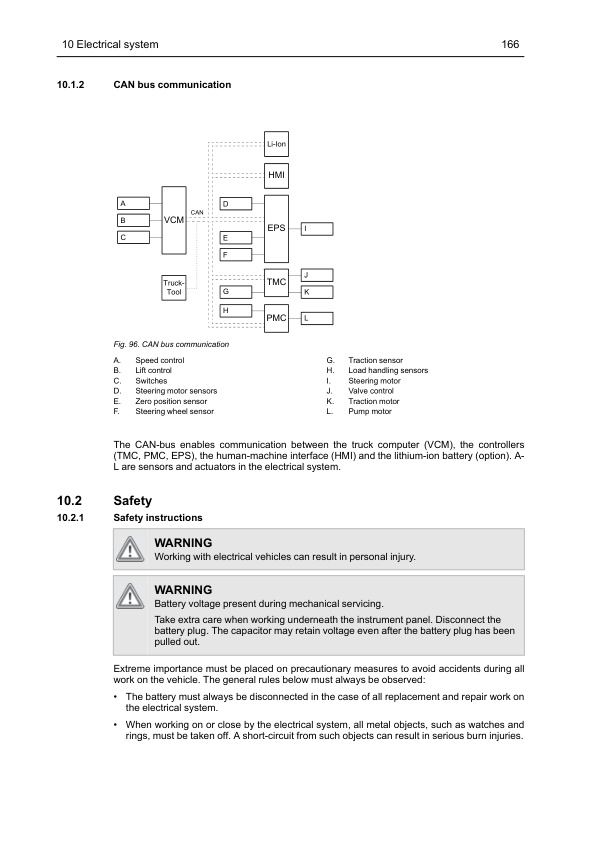

- 10.1.2. CAN bus communication

- 10.2. Safety

- 10.2.1. Safety instructions

- 10.2.2. Electronic controllers

- 10.2.3. Traction system

- 10.2.4. Hydraulic system

- 10.2.5. Sensors

- 10.2.6. Maximum drive speed and drive stop

- 10.3. Design and function

- 10.3.1. Battery

- 10.3.2. Battery capacity measurement (lead-acid)

- 10.3.3. Battery parameters

- 10.3.4. Display

- 10.3.5. VCM (Vehicle Control Module) (truck computer)

- 10.3.6. TMC (Traction Motor Controller)

- 10.3.7. PMC (Pump Motor Controller)

- 10.3.8. EPS (Electrical Power Steering) controller

- 10.3.9. Connector specifications

- 10.4. Repair and maintenance instructions

- 10.4.1. Wiring diagram

- 10.4.2. Preventive maintenance

- 10.4.3. Remove and install the multi function display (HMI-20)

- 10.4.4. Remove and install the horn

- 10.4.5. Remove and install the emergency stop

- 10.4.6. Remove and install the direction selector button (option)

- 10.4.7. Remove and install the DC/DC converter (option)

- 10.4.8. Ergologic unit

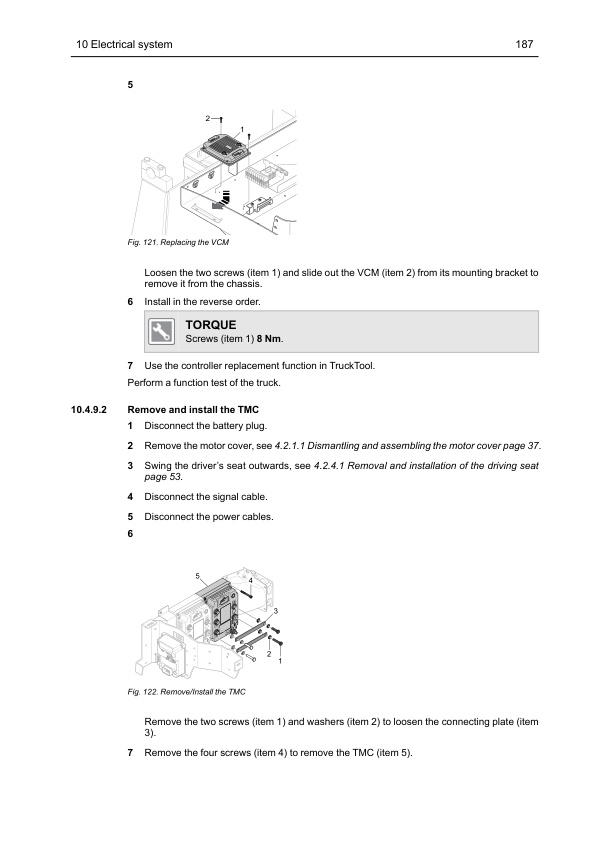

- 10.4.9. Remove and install the electrical components

- 10.4.10. Traction and pump regulation

- 10.4.11. Insulation resistance

- 10.4.12. Temperature measurement and management

- 10.4.13. System for detecting the reach carriage position

- 10.4.14. Electrical monitoring of battery locking

- 10.4.15. Maintaining and changing the battery (Lead Acid)

- 10.4.16. TruckTool

- 10.5. Diagnostics and troubleshooting

- 10.5.1. General instructions for all types of faults in combination with a loss of voltage

- 10.5.2. Troubleshooting – operational disturbances

- 10.5.3. Troubleshooting table – battery

- 11. SPEED CONTROL AND BRAKE SYSTEMS

- 11.1. Design and function

- 11.1.1. Electric brake

- 11.1.2. Speed and brake sensor

- 11.2. Repair and maintenance instructions

- 11.2.1. Electric brakes

- 11.2.2. Brake Pedal Assembly

- 11.2.3. Left-foot switch

- 11.2.4. Speed Controller

- 11.3. Diagnostics and troubleshooting

- 12. MISCELLANEOUS

- 12.1. Options

- 12.1.1. General

- 12.1.2. Service indication

- 12.1.3. Trucks equipped with restart

- 12.1.4. Side shift and tilt centring

- 12.1.5. Speed reduction

- 12.1.6. Automatic logging off

- 12.1.7. Buzzer when the battery voltage is low

- 12.1.8. Hand-controlled direction selector

- 12.1.9. Cold storage cab

- 12.1.10. Battery on motor-powered rollers

- 12.1.11. Levers

- 12.1.12. Electrically heated drivers seat (option)

- 12.2. Level selector and height indication

- 12.2.1. Pulse height preset

- 12.2.2. Level Assistance System, LAS

- 12.2.3. Height indication on the display

- 12.2.4. Checking the fork offset

- 12.3. Stability Support System, S3-1

- 12.3.1. Identification

- 12.3.2. Functionality, S3-1

- 12.3.3. Drive Speed

- 12.3.4. Hydraulic functions

- 12.3.5. Technical description

- 12.4. Weight system

- 12.4.1. Introduction

- 12.4.2. Enable options

- 12.4.3. Accompanying hardware

- 12.4.4. Premises and requirements

- 12.4.5. Calibration of the weight system

- 12.4.6. Weight indication

- 12.5. Fork Safe Zone System, four-way reach truck

- 12.6. Delivery mode

- 12.6.1. Driving in delivery mode and platform mode

Caterpillar Service Manual PDF

Caterpillar 2EC15 to 2EC30 MicroCommand II Control Service Manual SENB8604-02

Caterpillar Service Manual PDF

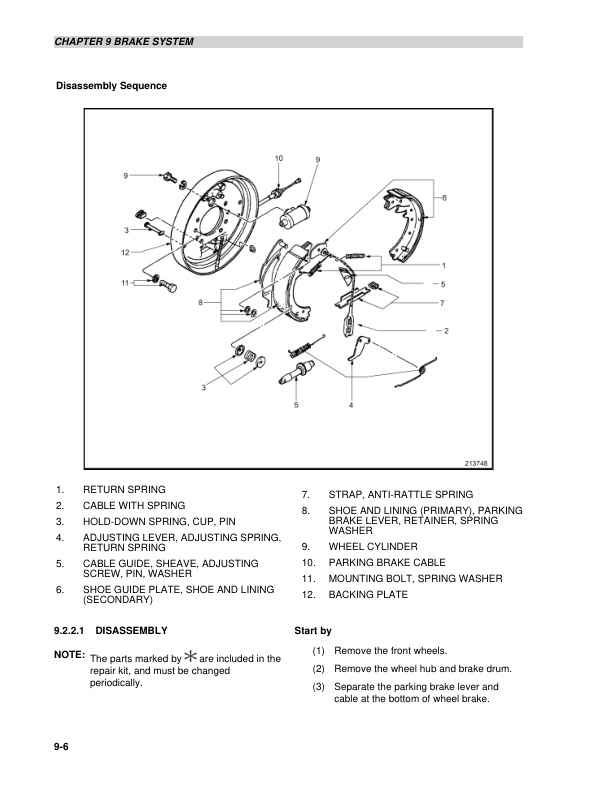

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-64103

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-85100

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Service Manual SCEEA-AT15E-200

Caterpillar Service Manual PDF

Caterpillar 1.4 Liter (4G33) to 3.0 Liter (6G72) LP Gas Supplement Service Manual SENB8531

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Disassembly and Assembly Service Manual 99799-67102

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-67103