Caterpillar NSR12N2 to NPS30N2 Operation and Maintenance Manual OM23GBST1AC7

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OM23GBST1AC7

- Number of Pages: 180

- Size: 23.1MB

- Format: PDF

-

Model List:

- NSR12N2, NSR12N2I, NSR16N2, NSR16N2I, NSR16N2S, NSR20N2, NSR20N2I, NSR20N2S, NSR12N2TF, NPR20N2, NPR30N2, NSS16N2, NSS16N2I, NSS16N2S, NSS20N2, NSS20N2I, NSS20N2S, NSS12N2TF, NPS20N2, NPS30N2

- 1. INTRODUCTION

- 1.1. Operation and Maintenance Manual

- 2. TRUCK MODIFICATION

- 2.1. Truck modification

- 3. ENVIRONMENTAL CONSIDERATIONS

- 3.1. We respect the environment

- 4. THE SUPERVISOR

- 4.1. Foremans responsibility

- 5. TRUCK OPERATOR

- 5.1. Authorization to operate a truck

- 5.2. Operator requirements

- 5.3. Inspection of the truck

- 6. MACHINE PLATES

- 6.1. Machine plate/Actual capacity plates

- 6.2. Location of machine plates

- 7. DESCRIPTION OF THE TRUCK

- 7.1. Stand-in stacker

- 7.2. Stand-in low lifter

- 7.3. Sit-on stacker

- 7.4. Sit-on low lifter

- 7.5. Operator environment

- 7.5.1. Dashboard and controls overview, stand-in truck

- 7.5.2. Dashboard and controls overview, sit-on truck

- 7.5.3. Hydraulic functions

- 7.5.4. Standard stand-in travel controls

- 7.5.5. Sit-on travel controls

- 7.5.6. Ergo Forks Trailing Control (EFTC) (option)

- 7.5.7. Travel speed limitations

- 7.5.8. Operator presence detection

- 7.5.9. Foot protection (option)

- 7.5.10. Armrest adjustment

- 7.5.11. Steering arm

- 7.5.12. Progressive steering

- 7.5.13. Operator seat

- 7.5.14. Foldable seat (option)

- 7.6. Options

- 7.6.1. Additional equipment stacker, overview

- 7.6.2. Additional equipment low lifter, overview

- 7.6.3. Additional equipment

- 7.6.4. Opportunity charging (option)

- 7.6.5. Telescopic forks (option)

- 7.6.6. Wide straddle legs (option)

- 7.6.7. Side stabilizers (option)

- 7.6.8. Mast initial lift (option)

- 7.6.9. Floor spot (option)

- 7.6.10. Load backrest (option)

- 7.6.11. Interior lights (option)

- 7.6.12. Work light (option)

- 7.6.13. USB-power supply socket (option)

- 7.6.14. power supply socket (option)

- 7.6.15. V DC / 12 V DC converter (option)

- 7.6.16. Radio (Option)

- 7.6.17. Closed Pallet Entry and Exit (option)

- 7.6.18. steering (option)

- 7.6.19. Reversed steering (option)

- 7.6.20. Increased drive speed 12 km/h (option)

- 7.6.21. Lift stop (option)

- 7.6.22. Level Assistance System, LAS (option)

- 7.6.23. Laser position guide (option)

- 7.6.24. Laser position guide battery charging

- 7.6.25. Travel alarm (option)

- 7.7. Storage compartments

- 8. BATTERY

- 8.1. Battery specification

- 8.2. Battery, general information

- 8.3. Charging the lead-acid battery

- 8.4. Maintaining and changing the battery (Lead Acid)

- 8.5. Battery servicing

- 8.6. Lithium-ion battery

- 8.6.1. General information

- 8.6.2. Description of the operating and display unit of the charger

- 8.6.3. Charging

- 8.6.4. Battery maintenance and inspection

- 8.6.5. Remove and install the battery (Lithium-ion)

- 9. DISPLAY

- 9.1. Standard display

- 9.1.1. Standard display general

- 9.1.2. Standard display

- 9.1.3. Warnings

- 9.2. Multi function display (option)

- 9.2.1. Multi function display

- 9.2.2. Overview of multi function display

- 9.2.3. Start the truck by logging on using the multi function display

- 9.2.4. Key switch logon for multi function display

- 9.2.5. Operational screen

- 9.2.6. Battery discharge indicator (BDI)

- 9.2.7. Centre indicator

- 9.2.8. Weight screen (option)

- 9.2.9. Steering angle indicator

- 9.2.10. steering selection screen (option)

- 9.2.11. Symbols in the display

- 9.2.12. Audible alert

- 9.2.13. Menu screen multi function display

- 9.2.14. Multi function display warnings

- 10. DRIVING INSTRUCTIONS

- 10.1. Starting the truck

- 10.2. Driving instructions

- 10.3. Switching off the truck

- 10.4. Drive mode

- 11. GENERAL LOADING AND UNLOADING INFORMATION

- 11.1. Responsibility for the load

- 11.2. Responsibility for others

- 11.3. Maximum load

- 11.4. Picking up a load

- 11.5. High visibility fork tips and Crossway pallet handling indication

- 11.6. Double stacking

- 12. STACKING AND PICKING UP

- 12.1. Stacking

- 13. MAINTENANCE OF THE TRUCK

- 13.1. Daily inspection (before each shift)

- 13.2. Daily inspection (after each shift)

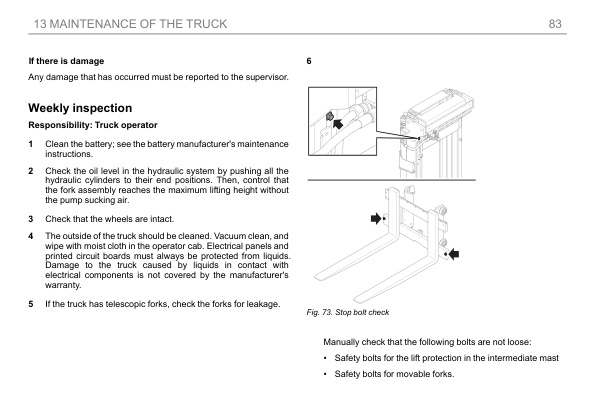

- 13.3. Weekly inspection

- 13.4. Preventive maintenance

- 14. SERVICE AND MAINTENANCE

- 14.1. Service technician

- 14.2. Safety instructions for maintenance

- 14.2.1. Working at height

- 14.2.2. Precautionary measures during repairs

- 14.3. Maintenance intervals

- 14.3.1. Recommended replacements

- 14.3.2. Servicing, type and frequency

- 14.3.3. Lubrication chart

- 14.3.4. Symbol key, lubrication chart

- 14.4. Maintenance instructions

- 14.4.1. Genuine replacement parts

- 14.4.2. Basic Troubleshooting

- 14.4.3. Dismantle and assemble the panels

- 14.4.4. Remove and install wheels

- 15. SAFETY REGULATIONS

- 15.1. The authority and obligations of the truck operator

- 15.2. Getting in and out

- 15.3. Driving the truck

- 15.3.1. Driving in public areas

- 15.3.2. Distance between vehicles

- 15.3.3. Pinch risk

- 15.3.4. Passengers

- 15.3.5. Clearance height

- 15.3.6. The truck in an industrial lift

- 15.3.7. Floor load

- 15.3.8. Signalling

- 15.3.9. Reduced vision

- 15.3.10. Transports

- 15.3.11. Speed reduction at height

- 15.3.12. Driving space

- 15.3.13. Load backrest

- 15.3.14. Risk zones

- 15.3.15. Overturning

- 15.3.16. Trucks on another vehicles loading platform or on a ramp

- 15.3.17. Direction of travel when driving on slopes

- 15.3.18. Awareness

- 15.4. Work in hazardous environments

- 15.5. Transportation security

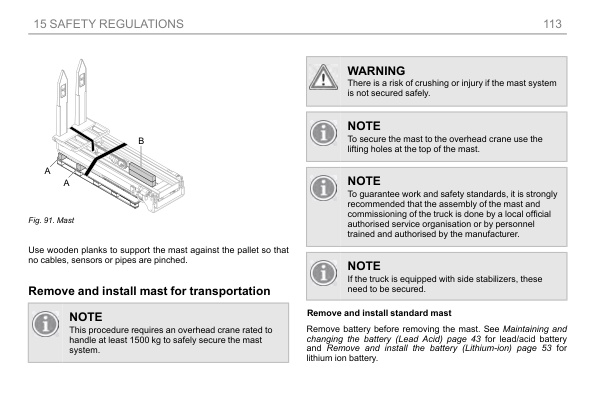

- 15.6. Transportation security with mast removed

- 15.7. Remove and install mast for transportation

- 15.8. Functionality and safety check after mast reassembly

- 15.9. Lifting the forks

- 15.10. Moving the forks

- 15.11. Emergency lowering the forks/straddles

- 15.12. Normal operating conditions

- 15.13. Exceptional operating conditions

- 15.14. Parking

- 15.15. When lifting the truck

- 15.15.1. General

- 15.15.2. When lifting the truck

- 15.15.3. Towing/moving inoperable truck

- 15.16. Subsequent mounting of radio equipment

- 15.17. Moving an inoperable truck

- 15.18. Hanging load

- 15.19. Fixed load centre

- 15.20. In the event of accidents

- 15.21. Noise levels

- 15.22. Vibrations

- 15.23. Climatic conditions

- 15.24. Cold store (option)

- 15.25. Overhead guard

- 15.26. Protective shoes

- 15.27. Work Light

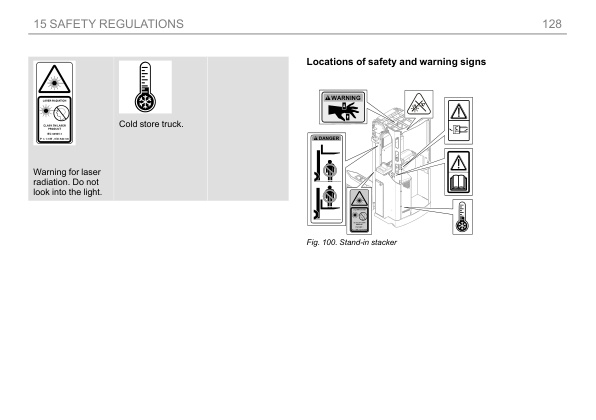

- 15.28. Safety and warning signs

- 15.28.1. Explanation of symbols

- 15.28.2. Locations of safety and warning signs

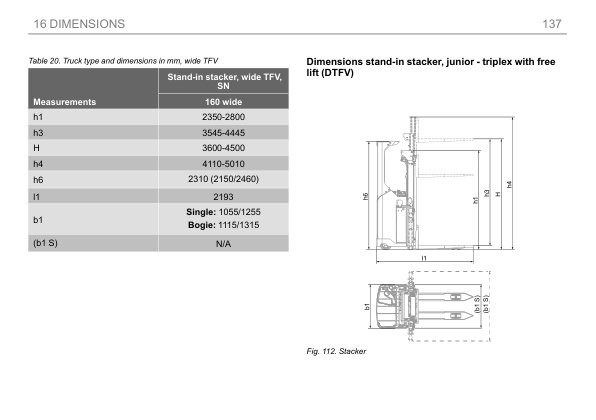

- 16. DIMENSIONS

- 16.1. Dimensions, stand-in version

- 16.1.1. Dimensions stand-in stacker, junior – duplex (TV)

- 16.1.2. Dimensions stand-in stacker, junior – duplex with free lift (TFV)

- 16.1.3. Dimensions stand-in stacker, senior – duplex with free lift (TFV)

- 16.1.4. Dimensions stand-in stacker, junior – triplex with free lift (DTFV)

- 16.1.5. Dimensions stand-in stacker, senior – triplex with free lift (DTFV)

- 16.1.6. Dimensions stand-in low lifter, junior and senior

- 16.2. Dimensions, sit-on version

- 16.2.1. Dimensions sit-on stacker, junior – Duplex with free lift (TFV)

- 16.2.2. Dimensions sit-on stacker, senior – duplex with free lift (TFV)

- 16.2.3. Dimensions sit-on stacker, junior – Triplex with free lift (DTFV)

- 16.2.4. Dimensions sit-on stacker, senior – triplex with free lift (DTFV)

- 16.2.5. Dimensions sit-on low lifter, senior

- 17. WEIGHT

- 17.1. Weight, stand-in stacker version

- 17.1.1. Weight stand-in stacker – Duplex (TV)

- 17.1.2. Weight stand-in stacker – Duplex with free lift (TFV)

- 17.1.3. Weight stand-in stacker – Triplex with free lift (DTFV)

- 17.2. Weight, sit-on stacker version

- 17.2.1. Weight sit-on stacker – Duplex with free lift (TFV)

- 17.2.2. Weight sit-on stacker – Triplex with free lift (DTFV)

- 17.3. Weight, low lifter

- 18. ORDERING HANDBOOKS AND MANUALS

- 18.1. Replacement Parts Manual

Caterpillar Operation Manual PDF

Caterpillar 4.236 Gasoline Engine Disassembly and Assembly SENB8097

Caterpillar Operation Manual PDF

Caterpillar 3208, 3208T Vehicular Engines Disassembly and Assembly SENB8324

Caterpillar Operation Manual PDF

Caterpillar DP100N, DP120N, DP135N, DP150N, DP160N Operation and Maintenance Manual 99790-32101

Caterpillar Operation Manual PDF

Caterpillar DP100NM1 to DP150NM1S Operation and Maintenance Manual OCFEG-JBT15-190

Caterpillar Operation Manual PDF

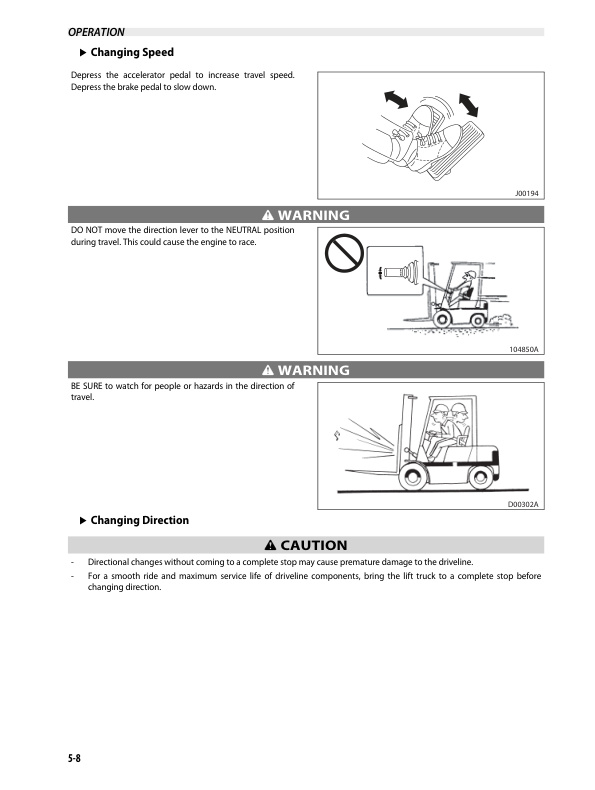

Caterpillar DP100NM1, DP120NM1, DP135NM1, DP150NM1 Operation and Maintenance Manual 99790-87100

Caterpillar Operation Manual PDF

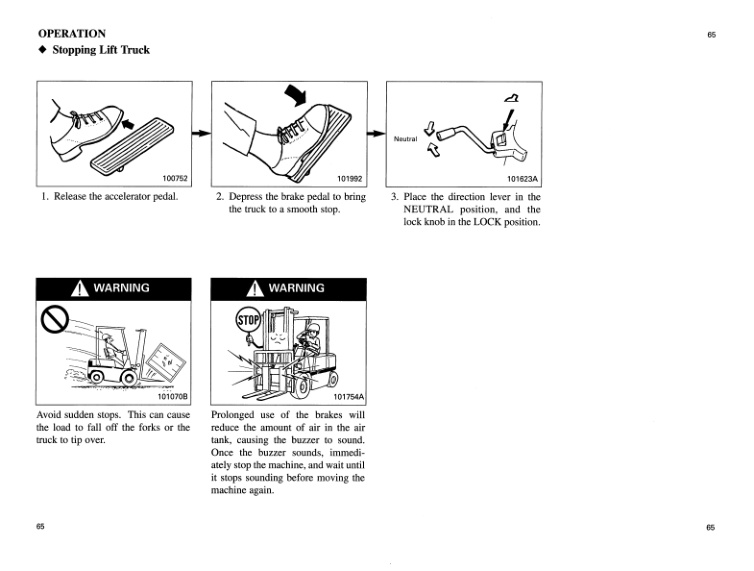

Caterpillar DP100, DP115, DP135, DP150 Operation and Maintenance Manual 99790-33120

Caterpillar Operation Manual PDF

Caterpillar DP100NL-160SNL Lift Trucks Operation and Maintenance Manual OCFEG-J091K-211

Caterpillar Operation Manual PDF

Caterpillar DP100, DP115, DP135, DP150 Operation and Maintenance Manual 99790-83130

Caterpillar Operation Manual PDF

Caterpillar 2C7000 – 2C8000-SWB Lift Trucks Operation and Maintenance Manual OCFAA-AC1F2-200

Caterpillar Operation Manual PDF

Caterpillar DP60NM, DP60NMS, DP70NM, DP70NMS Operation and Maintenance Manual 99700-27110