Caterpillar DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Operation and Maintenance Manual 99790-42010

$30.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 99790-42010

- Number of Pages: 222

- Size: 24.3MB

- Format: PDF

-

Model List:

- DP100N1, DP120N1, DP135N1, DP150N1, DP160N1

- 1. FOREWORD

- 1.1. How to Use This Manual

- 1.2. LOCKOUT/TAGOUT

- 2. SAFETY RULES FOR LIFT TRUCK OPERATORS

- 2.1. General

- 2.2. Warning Decals, Location

- 2.3. Description of Danger, Warning, and Caution Decals

- 2.3.1. Fasten Seat Belt Decal

- 2.3.2. Survive in a Tipover Decal

- 2.3.3. Operation Warning Decal

- 2.3.4. Overhead Guard Decal

- 2.3.5. No Access With Engine Running Decal

- 2.3.6. Parking Brake Decal

- 2.3.7. No Riders Warning Decal

- 2.3.8. Pinch Points Decal

- 2.3.9. No One on the Fender

- 2.3.10. No One Under / On Forks and No One Between Mast and Chassis Decal

- 2.3.11. Brake Warning Buzzer Decal

- 2.3.12. Capacity Plate

- 2.3.13. Backup Alarm Decal

- 2.3.14. Operator Restraint System Decal

- 2.3.15. No Contamination Permissible Decal

- 2.3.16. Precautions for Handling ECU Decal

- 2.4. Safety Rules

- 2.5. Operating Precautions

- 2.6. Working Precautions

- 3. KNOW YOUR LIFT TRUCK

- 3.1. Serial Number and Capacity Plate

- 3.2. Electrical Components

- 3.3. Model View

- 3.3.1. FC Model (Type A)

- 3.3.2. FC Model (Type B)

- 3.3.3. LC Model

- 3.4. Driving Switches and Controls

- 3.4.1. Key Switch

- 3.4.2. Direction Lever (Powershift Model)

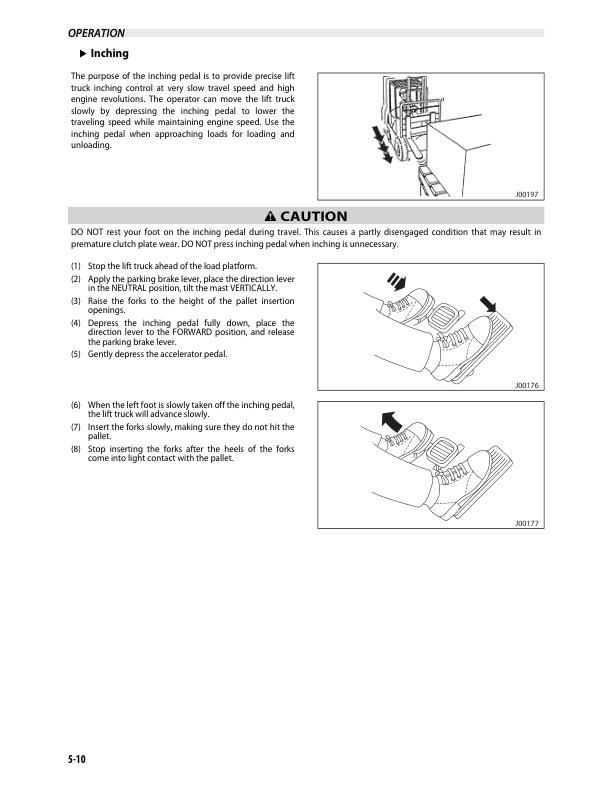

- 3.4.3. Inching Pedal

- 3.4.4. Turn Signal / Light Switch

- 3.4.5. Steering Column Tilt Lever

- 3.5. Meter Panel

- 3.5.1. Warning Icons Glow Check

- 3.5.2. LCD Screen

- 3.5.3. Warning Icons and Indicators

- 3.5.4. Basic Screen Display

- 3.5.5. Basic Operation

- 3.5.6. When Diagnostic Code Is Shown on Display

- 3.5.7. When Several Warnings Occur Simultaneously

- 3.5.8. Warning Symbols

- 3.5.9. Warning Icons

- 3.5.10. Optional Features

- 3.6. Side Panel

- 3.6.1. Speed Mode Selector Switch

- 3.6.2. Brake Warning Icon

- 3.7. Presence Detection System

- 3.7.1. Mast Interlock System

- 3.7.2. Mast Interlock System Functions

- 3.7.3. Driving Interlock System

- 3.7.4. Driving Interlock System With Operator Restraint Function (For Powershift Models With Australia Specification Only)

- 3.7.5. Driving Interlock System Functions (For Powershift Models Only)

- 3.7.6. Driving Interlock System Functions (For Powershift Models With Australia Specification Only)

- 3.7.7. Neutral System

- 3.7.8. Neutral System Functions

- 3.7.9. Seat Belt Warning Icon

- 3.7.10. Seat Belt Warning Functions

- 3.7.11. Parking Brake Warning Alarm and Warning Icon

- 3.7.12. Parking Brake Warning Functions

- 3.8. Operating Switches and Controls

- 3.8.1. FC Control Box (Type-A)

- 3.8.2. FC Control Box (Type-B)

- 3.8.3. Lift Switch

- 3.8.4. Tilt Switch

- 3.8.5. Lowering Speed Selector Switch (Optional)

- 3.8.6. Direction Switch (Optional)

- 3.8.7. Attachment Switch A/B (Optional)

- 3.8.8. Selector Switch Between Fourth and Fifth Attachment (Optional)

- 3.8.9. Other Controls (Standard)

- 3.8.10. Emergency Mast Stop Button

- 3.8.11. Forward and Backward Adjustment Stopper Knob (FC Control Box Type-A)

- 3.8.12. Up and Down Adjustment Stopper Knob (FC Control Box Type-A)

- 3.8.13. Forward and Backward Adjustment (FC Control Box Type-B)

- 3.8.14. Up and Down Adjustment (FC Control Box Type-B)

- 3.8.15. LC Control Box

- 3.8.16. Lift Lever

- 3.8.17. Tilt Lever

- 3.8.18. Attachment Lever A/B (Option)

- 3.9. Operator Seat

- 3.9.1. Seat Adjustment

- 3.9.2. Forward and Back Adjustment

- 3.9.3. Reclining Angle Adjustment

- 3.9.4. Adjustment of Suspension

- 3.9.5. Pocket for the Operation Maintenance Manual

- 3.9.6. Operator Presence Switch and Buzzer

- 3.10. Seat Belt

- 3.11. Fork Locking Pins

- 3.12. Drawbar Pin

- 3.13. Assist Grips and Foot Step

- 3.14. Engine Hood

- 3.14.1. Hood Latch

- 3.15. Hydraulic Tank Oil Filler Hole

- 3.16. Fuel Filler

- 3.17. Air Tank

- 4. HOW TO AVOID A TIPOVER / HOW TO SURVIVE ONE

- 4.1. Know What Lift Truck Stability Is

- 4.2. Center of Gravity (CG)

- 4.3. Stability and Center of Gravity (Top View)

- 4.4. Lift Truck Stability Base

- 4.5. Capacity (Weight and Load Center)

- 4.6. Capacity Plate

- 4.7. Dos and Donts to Avoid Tipover

- 4.8. How to Survive in a Tipover

- 5. REFUELING

- 5.1. Diesel Engine Equipped

- 6. OPERATION

- 6.1. New Lift Truck Break-in

- 6.2. Before Starting Engine

- 6.3. Starting Engine

- 6.4. Engine Wont Start

- 6.5. After Starting Engine

- 6.6. Before Moving Lift Truck

- 6.7. Lift Truck Operation

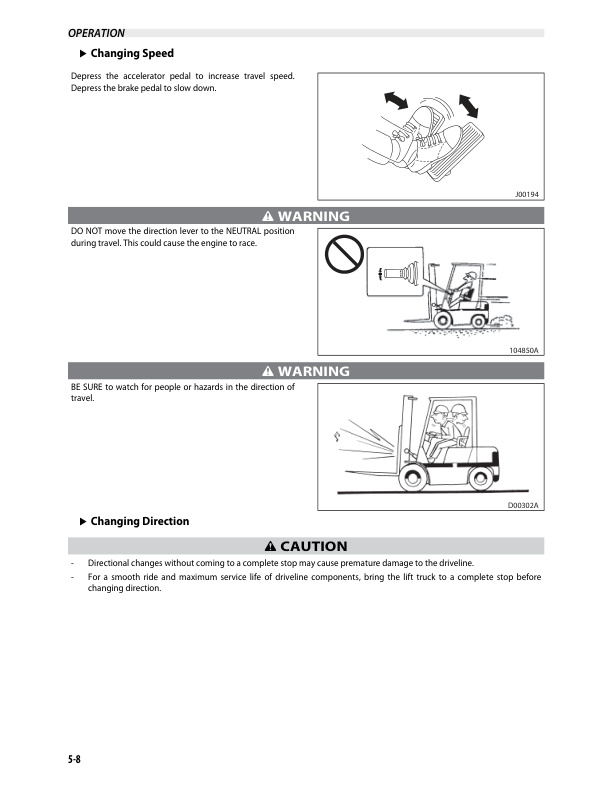

- 6.7.1. Changing Speed

- 6.7.2. Changing Direction

- 6.7.3. Operating Techniques

- 6.7.4. Steering (Turning)

- 6.7.5. Inching

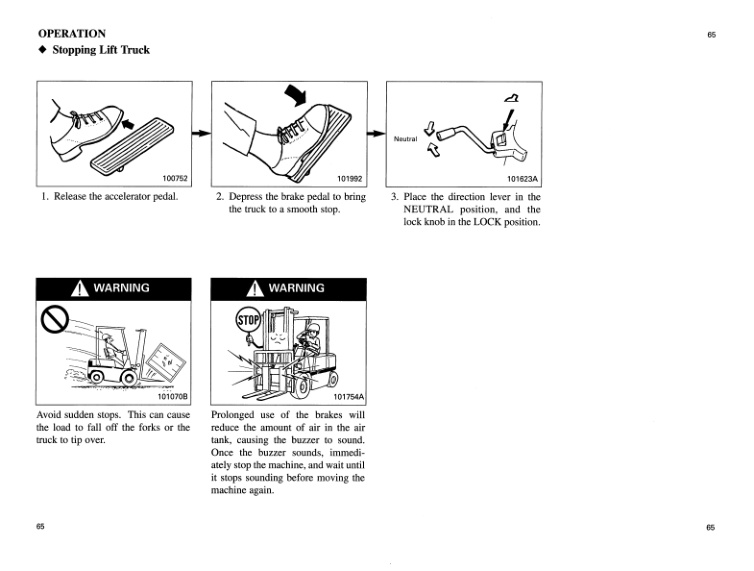

- 6.8. Stopping Lift Truck

- 6.9. Parking Lift Truck (After Stopping)

- 7. OPERATING TECHNIQUES

- 7.1. Stacking Methods

- 7.1.1. Stacking Different Size Loads

- 7.1.2. Stacking Small Identical Loads

- 7.1.3. Stacking Large Identical Loads

- 7.2. Handling Loads Safely

- 7.2.1. Adjusting Fork Spread

- 7.3. Before Operating the Lift Truck

- 7.4. Blinking of the Mast Interlock Indicator Icon

- 7.5. Lifting the Load

- 7.6. Traveling With the Load

- 7.7. Unloading

- 7.8. Working on Grades

- 7.8.1. Normal Travel Position

- 7.8.2. Traveling on a Grade

- 7.8.3. Stopping on a Grade

- 7.9. Starting on a Grade (Engine Stalls on a Grade)

- 8. STORING THE LIFT TRUCK

- 8.1. End of Each Shift Storage

- 8.2. Long Term Storage

- 8.2.1. Storage Within Three Months

- 8.2.2. Storage Exceeding Three Months

- 9. TRANSPORTATION HINTS

- 9.1. Lift Truck Loading and Shipping

- 9.2. Lift Truck Lifting and Tie Down Information

- 10. SPECIAL SITUATIONS

- 10.1. Care in Cold Weather

- 10.1.1. Fuel Oils and Lubrication Oils

- 10.1.2. Battery

- 10.1.3. Engine Coolant

- 10.2. Care in Hot Weather

- 10.2.1. Fuel Oils and Lubrication Oils

- 10.2.2. Battery

- 10.2.3. Engine Coolant

- 10.3. Severe Dust or Lint Conditions

- 10.3.1. Air Cleaner Element

- 10.3.2. Engine Oil and Engine Oil Filter

- 10.3.3. Hydraulic Oil

- 10.3.4. Hydraulic Tank Return Filter

- 11. TROUBLESHOOTING

- 11.1. Stalled Engine

- 11.2. If a Tire Blows Out

- 11.2.1. If a Tire Blows out During Travel or Operation

- 11.3. Replacing Tires

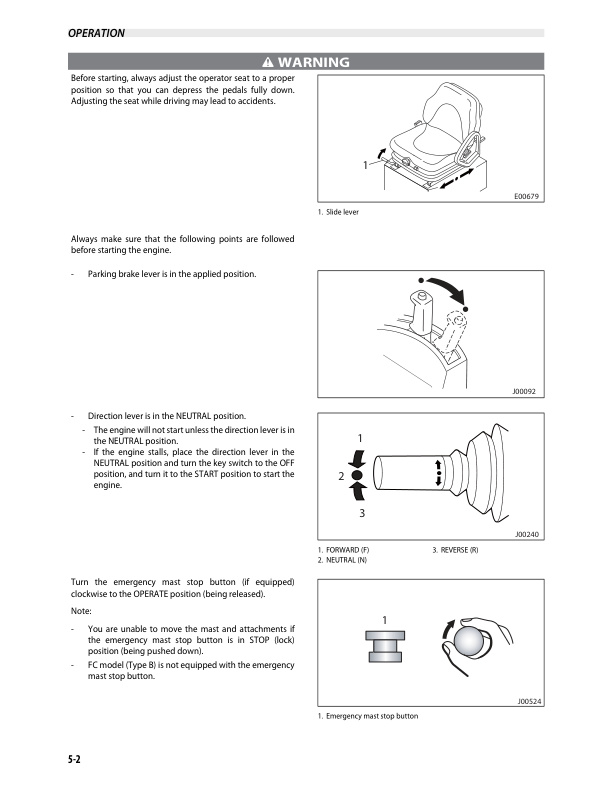

- 11.4. Before Replacing Tires

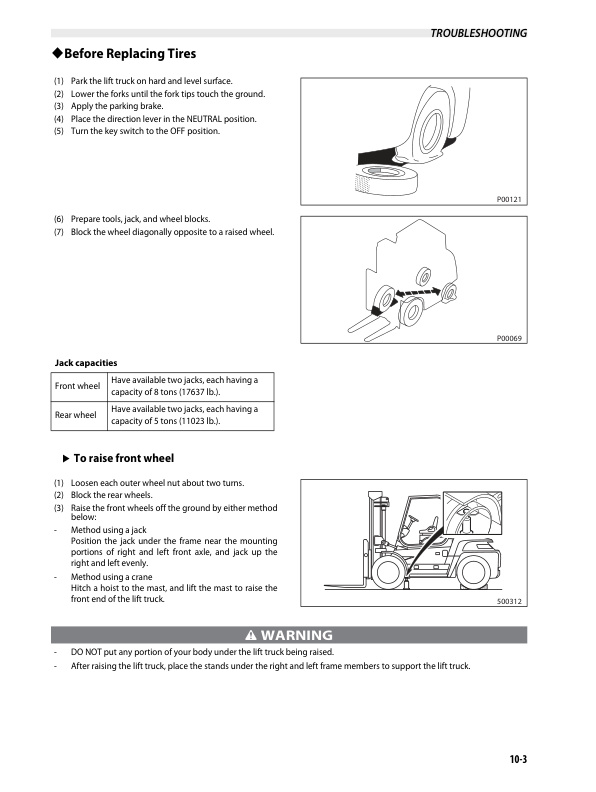

- 11.4.1. To raise front wheel

- 11.4.2. To Remove Front Wheel

- 11.4.3. To Install Front Wheel

- 11.4.4. To Remove Rear Wheel

- 11.4.5. To Install Rear Wheel

- 11.4.6. To Add Air to Tires

- 11.5. Starting With Jumper Cables

- 11.6. If Lights Wont Glow

- 11.6.1. How to Check Fuses and Lights

- 11.7. If the Engine Coolant Temperature Gauge Shows RED Zone

- 11.8. If Torque Converter Oil Temperature Warning Icon Glows (Powershift Model)

- 11.9. If the Lift Truck Wont Change Direction

- 11.10. If the Lift Truck Wont Change Directions (For Powershift Models With Australia Specification Only)

- 11.11. If the Mast Stops Moving

- 11.12. If the Mast and Attachments Malfunction

- 11.13. Diagnostic Codes and Explanations

- 12. MAINTENANCE

- 12.1. General

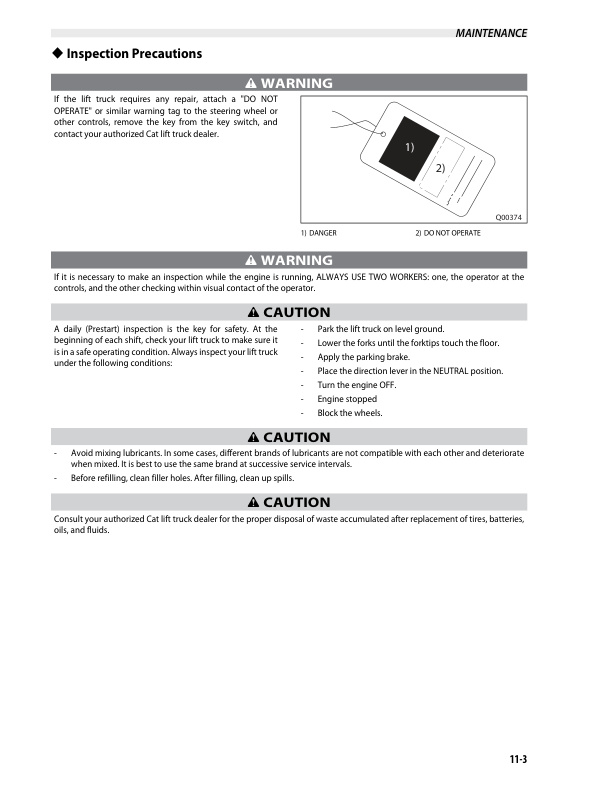

- 12.2. Inspection Precautions

- 12.3. Maintenance Schedule

- 12.3.1. Every 10 Service Hours or Daily (Prestart), Whichever Comes First

- 12.3.2. Every 50 Service Hours or Weekly, Whichever Comes First

- 12.3.3. One Month (30 days) or 200 Service Hours After Delivery of a New Lift Truck, Whichever Comes First

- 12.3.4. Every 500 Service Hours or 3 Months, Whichever Comes First

- 12.3.5. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 12.3.6. Every 2000 Service Hours or 1 year, Whichever Comes First

- 12.3.7. Every 1 to 2 years

- 12.3.8. Every 2 years

- 12.3.9. to 4 years

- 12.3.10. Every 1500 Service Hours

- 12.3.11. Every 3000 Service Hours

- 12.4. Every 10 Service Hours or Daily (Prestart), Whichever Comes First

- 12.4.1. Faulty Operation Found the Day Before

- 12.4.2. Oil, Fuel, or Coolant Leaks

- 12.4.3. Brake Pedal

- 12.4.4. Parking Brake Lever

- 12.4.5. Service Brake

- 12.4.6. Air Tank

- 12.4.7. Engine Coolant

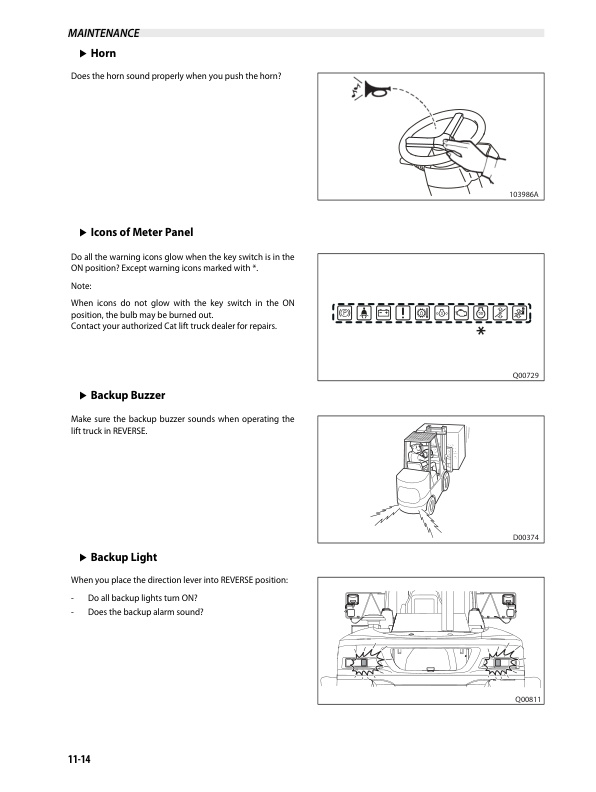

- 12.4.8. Icons of Meter Panel

- 12.4.9. Backup Buzzer

- 12.4.10. Backup Light

- 12.4.11. Stop Light

- 12.4.12. Battery

- 12.4.13. Mast Interlock System

- 12.4.14. Driving Interlock System

- 12.4.15. Parking Brake Warning Alarm and Warning Icon

- 12.4.16. Seat Belt Warning Icon and Alarm

- 12.4.17. Engine (Exhaust, Noise, and Vibration)

- 12.4.18. Engine Oil

- 12.4.19. Overhead Guard

- 12.4.20. Assist Grips

- 12.4.21. Seat Belt

- 12.4.22. Seat Adjustment

- 12.4.23. Hydraulic Oil

- 12.4.24. Tilt Cylinder Socket Nuts

- 12.4.25. Lift Chains

- 12.4.26. Mast and Forks

- 12.4.27. Wheel Nuts

- 12.4.28. Tires and Rims

- 12.4.29. Steering Wheel

- 12.4.30. Accelerator Pedal

- 12.4.31. Inching Pedal

- 12.4.32. Transmission Oil

- 12.5. Every 50 Service Hours or Weekly, Whichever Comes First

- 12.5.1. Alternator Belt

- 12.5.2. Air Cleaner

- 12.6. One Month (30 Days) or 200 Service Hours After Delivery of a New Lift Truck, Whichever Comes First

- 12.6.1. Cooling Oil (in Wet Disk Brake)

- 12.6.2. Cooling Fan

- 12.6.3. Battery Electrolyte Specific Gravity

- 12.6.4. Engine Oil and Oil Filter

- 12.6.5. Bolts and Nuts

- 12.6.6. Primary Fuel Filter

- 12.6.7. Secondary Fuel Filter

- 12.6.8. Hydraulic Tank Return Oil Filter and Strainer

- 12.7. Every 500 Service Hours or 3 Months, Whichever Comes First

- 12.7.1. Primary Fuel Filter

- 12.7.2. Secondary Fuel Filter

- 12.8. Lubrication Chart

- 12.8.1. Fan Belt Pulleys

- 12.8.2. Mast Support

- 12.8.3. Fork Guide Bar

- 12.8.4. Mast Strips Surfaces

- 12.8.5. Mast and Lift Bracket Side Rollers

- 12.8.6. Lift Chains

- 12.8.7. Tilt Socket Pins

- 12.8.8. Tilt Cylinder Pins

- 12.8.9. Tie Rod Pins

- 12.8.10. Rear Axle Supports

- 12.8.11. Universal Joints

- 12.9. Every 1000 Service Hours or 6 Months, Whichever Comes First

- 12.9.1. Air Dryer Desiccant

- 12.9.2. Air Cleaner

- 12.10. Every 2000 Service Hours or 1 Year, Whichever Comes First

- 12.10.1. Brake Fluid

- 12.10.2. Air Dryer Desiccant

- 12.11. Parts to be Replaced Periodically

- 13. SERVICE DATA

- 13.1. Fuel Information

- 13.1.1. Fuel Specifications

- 13.2. Coolant Information

- 13.2.1. Coolant Water

- 13.2.2. Antifreeze Solution

- 13.3. Recommended Fuels and Oils

- 13.4. Specifications (Standard Models)

- 13.5. Refill Capacities

- 13.6. Capacities and Lift Truck Weight (Standard Models)

- 14. TO THE CAT LIFT TRUCK OWNER

- 14.1. The Importance of Genuine Parts

- 14.2. Proper Disposal of Your Lift Truck

- 14.3. Instructions for Ordering Parts

- 14.4. Service Registration

Caterpillar Operation Manual PDF

Caterpillar DP100NL-160SNL Lift Trucks Operation and Maintenance Manual OCFEG-J091K-211

Caterpillar Operation Manual PDF

Caterpillar 3208, 3208T Vehicular Engines Disassembly and Assembly SENB8324

Caterpillar Operation Manual PDF

Caterpillar DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Operation and Maintenance Manual 99790-63100

Caterpillar Operation Manual PDF

Caterpillar DP60NM, DP60NMS, DP70NM, DP70NMS Operation and Maintenance Manual 99700-27110

Caterpillar Operation Manual PDF

Caterpillar Operation Manual PDF

Caterpillar DP100, DP115, DP135, DP150 Operation and Maintenance Manual 99790-83130

Caterpillar Operation Manual PDF

Caterpillar Operation Manual PDF

Caterpillar DP60NM, DP60NMS, DP70NM, DP70NMS Operation and Maintenance Manual 99700-27120

Caterpillar Operation Manual PDF

Caterpillar 4.236 Gasoline Engine Specifications Systems Operation Testing and Adjusting SENB8081-03

Caterpillar Operation Manual PDF

Caterpillar DP100, DP115, DP135, DP150 Operation and Maintenance Manual 99790-33120