Caterpillar GK21E, GK25E Engine Electronic Control System Gasoline – LPG – Dual Fuel Service Manual SCEEG-MT13H-231

$50.00

- Type Of Manual: Service Manual

- Manual ID: SCEEG-MT13H-231

- Number of Pages: 180

- Size: 9.6MB

- Format: PDF

-

Model List:

- GK21E, GK25E

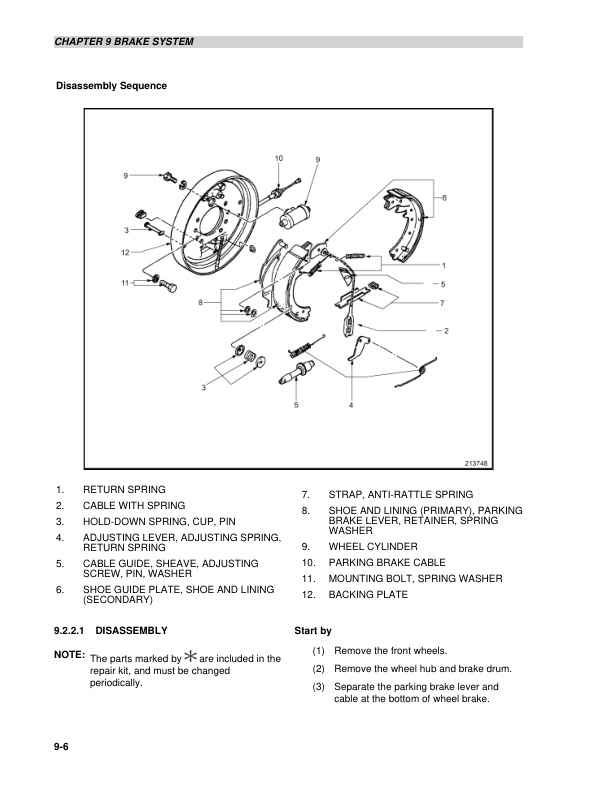

- 1. _COVER

- 2. _FOREWORD

- 2.1. HOW TO USE THIS MANUAL

- 2.1.1. Overview

- 2.1.2. Definition of Terms

- 2.1.3. Abbreviations and Standards

- 2.1.4. Definition of Units

- 2.1.5. Description

- 2.2. PRECAUTIONS FOR SAFETY AND QUALITY

- 2.2.1. Safe Operation

- 2.2.2. Correct Operation

- 2.2.3. Precautions for Radio Equipment Installation

- 2.2.4. Prohibition of Tamper

- 2.3. PRECAUTIONS

- 2.3.1. Precautions for Draining Engine Coolant

- 2.3.2. Precautions for Disconnecting Fuel Piping

- 2.3.3. Precautions for Removing and Disassembling

- 2.3.4. Precautions for Inspection, Correction, and Replacement

- 2.3.5. Precautions for Assembly and Installation

- 2.3.6. Precaution for Angle Wrench to Tightening Cylinder Head Bolts

- 2.3.7. Precautions for Using Power Tools

- 2.3.8. Precautions for Liquid Gasket Application

- 2.4. SPECIAL SERVICE TOOL

- 2.5. ENGINE OUT SIDE DRAWING

- 2.6. MAIN SPECIFICATION DATA

- 2.6.1. Main Specifications

- 2.6.2. Ignition System

- 2.6.3. Engine Fuel System and Engine Speed Control System

- 2.7. STAMPED LOCATION OF ENGINE NO.

- 2.8. ENGINE MAINTENANCE

- 2.8.1. Specifications

- 2.8.2. Maintenance Schedule

- 2.8.3. Oils and Capacity

- 2.8.4. Engine Inspection and Servicing

- 2.9. TIGHTENING TORQUE

- 2.9.1. Standard Bolt Tightening Torque

- 2.9.2. Tightening Torque for Engine Parts

- 2.10. TROUBLESHOOTING

- 2.11. ADJUSTMENT VALUE

- 2.12. ENGINE REMOVAL AND INSTALLATION

- 2.12.1. Removal of the Engine

- 2.12.2. Installation of the Engine

- 2.12.3. Inspection of the Engine

- 2.13. ENGINE SERVICE

- 2.13.1. Engine Disassembly

- 2.13.2. Inspection and Adjustment

- 2.13.3. Engine Assembly

- 2.14. ENGINE LUBRICATION SYSTEM

- 2.14.1. Lubrication system diagram

- 2.14.2. Specifications

- 2.14.3. Hydraulic Pressure

- 2.14.4. Tightening Torque

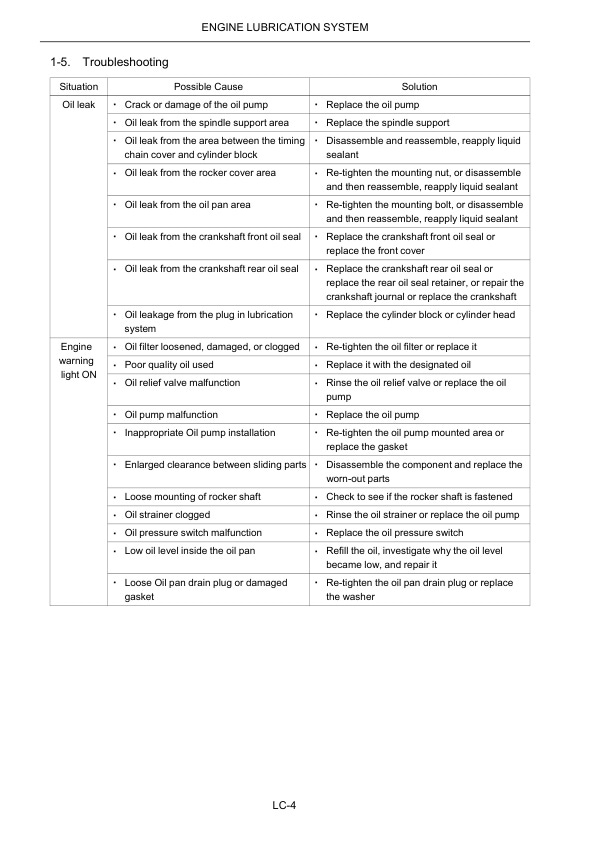

- 2.14.5. Troubleshooting

- 2.15. ENGINE COOLING SYSTEM

- 2.15.1. Cooling System Diagram

- 2.15.2. Specifications

- 2.15.3. Adjustment Value

- 2.15.4. Tightening torque

- 2.15.5. Troubleshooting

- 2.15.6. Cooling System Schematic

- 2.15.7. Water pump

- 2.15.8. Thermostat

- 2.15.9. Filling LLC into the Cooling System

- 2.16. TROUBLESHOOTING

- 2.17. ELECTRONIC CONTROLLED SYSTEM

- 2.17.1. System diagram for gasoline use

- 2.17.2. System diagram for LPG use

- 2.17.3. System diagram for gasoline and LPG combined use

- 2.18. REMOVAL AND INSTALLATION OF THE THROTTLE CHAMBER

- 2.18.1. Removal of the Throttle Chamber

- 2.18.2. Installing the Throttle Chamber

- 2.19. REMOVAL AND INSTALLATION OF GASOLINE FUEL INJECTOR

- 2.19.1. Auxiliary Work Preparation

- 2.19.2. Removal and Installation of the Fuel Hose

- 2.19.3. Removal and Installation of the Fuel Tube and Fuel Injector

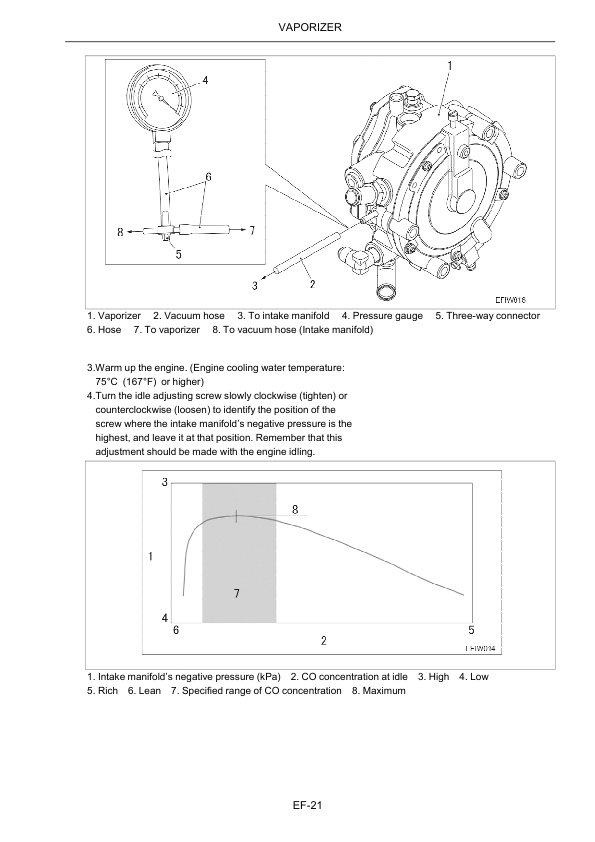

- 2.20. VAPORIZER

- 2.20.1. Description

- 2.20.2. Primary (Decompression) Chamber

- 2.20.3. Secondary Valve Room

- 2.20.4. Removal and Installation

- 2.20.5. Disassembly, Assembly, And Inspection

- 2.21. BLOWBY GAS RECIRCULATION DEVICE

- 2.21.1. System Diangram

- 2.21.2. Inspection of the Components

- 2.22. PRECAUTIONS FOR WORK

- 2.22.1. Engine Trouble Diagnosis

- 2.22.2. General Caution for Maintenance Work

- 2.23. ELECTRONIC CONTROLLED SYSTEM

- 2.23.1. Overview

- 2.23.2. Electronic Controlled System

- 2.23.3. Sensor and Actuator Control Items

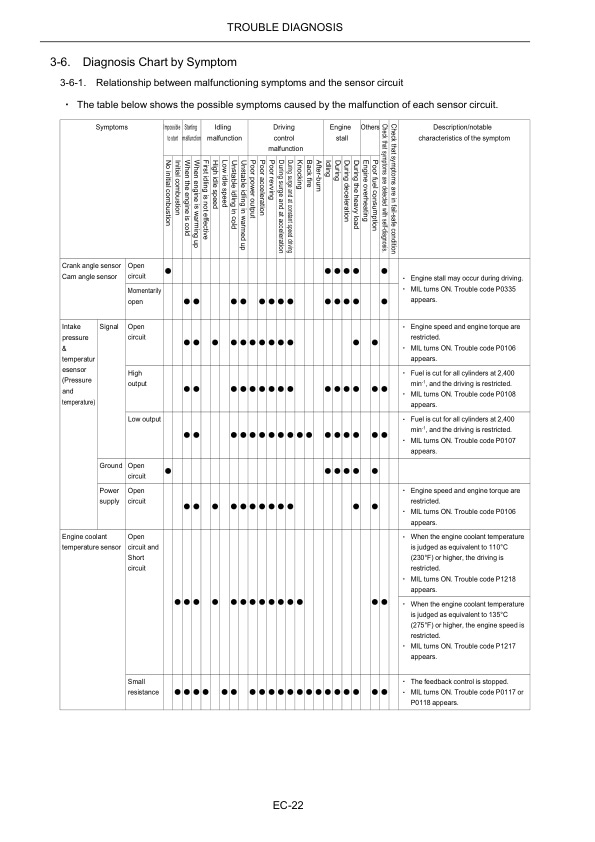

- 2.24. TROUBLE DIAGNOSIS

- 2.24.1. ECU Component Parts Location

- 2.24.2. Circuit Diagram

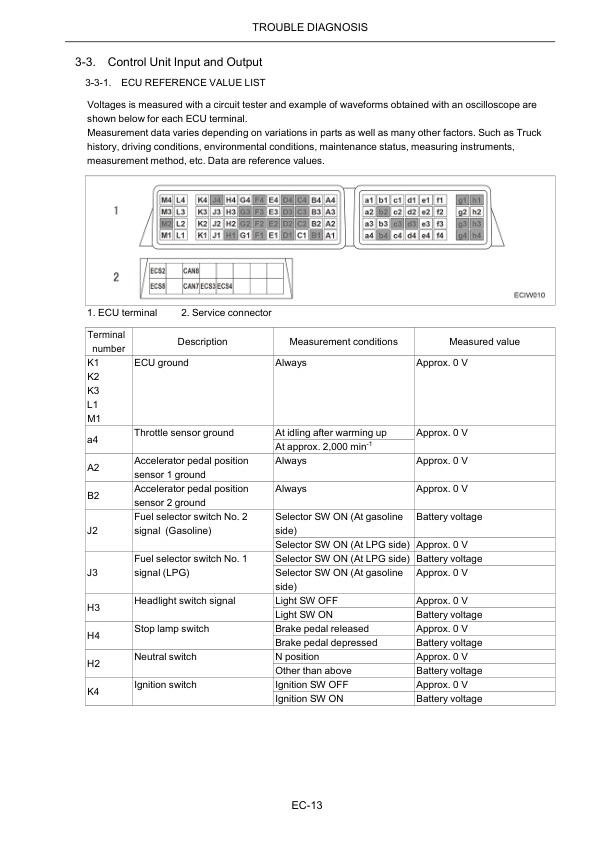

- 2.24.3. Control Unit Input and Output

- 2.24.4. Engine wiring reference value list

- 2.24.5. How to Proceed with Trouble Diagnosis

- 2.24.6. Diagnosis Chart by Symptom

- 2.24.7. Fail-safe function

- 2.24.8. DTC List

- 2.24.9. Service Tool

- 2.24.10. Active Test Support

- 2.25. BASIC INSPECTION

- 2.25.1. Inspection of Idle Speed

- 2.25.2. Inspection of the Ignition Timing

- 2.25.3. Throttle Learning Clear

- 2.25.4. Fuel Pressure Removal

- 2.26. COMPONENT PART INSPECTION

- 2.26.1. Symbol for Harness Connector

- 2.26.2. Crank angle Sensor

- 2.26.3. Cam angle sensor

- 2.26.4. Intake Pressure Temperature Sensor

- 2.26.5. Engine Coolant Temperature Sensor

- 2.26.6. Throttle Position Sensors 1 and 2

- 2.26.7. Accelerator Pedal Position Sensors 1 and 2

- 2.26.8. Stop Lamp Switch

- 2.26.9. Spark plug

- 2.26.10. Ignition coil

- 2.26.11. Gasoline injector

- 2.26.12. Fuel Pump

- 2.26.13. Throttle Control Motor

- 2.26.14. LPG shutoff valve

- 2.27. ENGINE CONTROL SYSTEM COMPONENTS

- 2.27.1. Removal and Installation

- 2.28. TROUBLESHOOTING

- 2.29. STARTER MOTOR (Dry Type)

- 2.29.1. Specifications

- 2.29.2. Components Diagram

- 2.29.3. Tightening Torque

- 2.30. ALTERNATOR

- 2.30.1. Inspection Before Removing the Alternator

- 2.30.2. Removal of the Alternator

- 3. _RR END

Caterpillar Service Manual PDF

Caterpillar 5M15D to 5M35D Mast Supplement Service Manual 99739-351T0

Caterpillar Service Manual PDF

Caterpillar 2EC15-30 Chassis and Mast Service Manual 99759-80100

Caterpillar Service Manual PDF

Caterpillar 1204F Diesel Engine Systems Operation Testing and Adjusting Service Manual 99799-67103

Caterpillar Service Manual PDF

Caterpillar 2P3000 to 2PD7000, GP15NM-35NM Chassis and Mast Service Manual 99719-8M110

Caterpillar Service Manual PDF

Caterpillar 5V15D to 5V35D Mast Supplement Service Manual 99739-351S0

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Troubleshooting Service Manual 99799-64104

Caterpillar Service Manual PDF

Caterpillar 4G15, 4G63, 4G64, 6G72 Engine Service Manual 99719-34130

Caterpillar Service Manual PDF

Caterpillar Service Manual PDF

Caterpillar 1204E Diesel Engine Service Manual SCEEA-AT15E-200

Caterpillar Service Manual PDF