Mitsubishi EDR36 Forklift Service Manual

$50.00

- Type Of Manual: Service Manual

- Number of Pages: 296

- Size: 4.7MB

- Format: PDF

Category: Mitsubishi Service Manual PDF

-

Model List:

- EDR36 Forklift

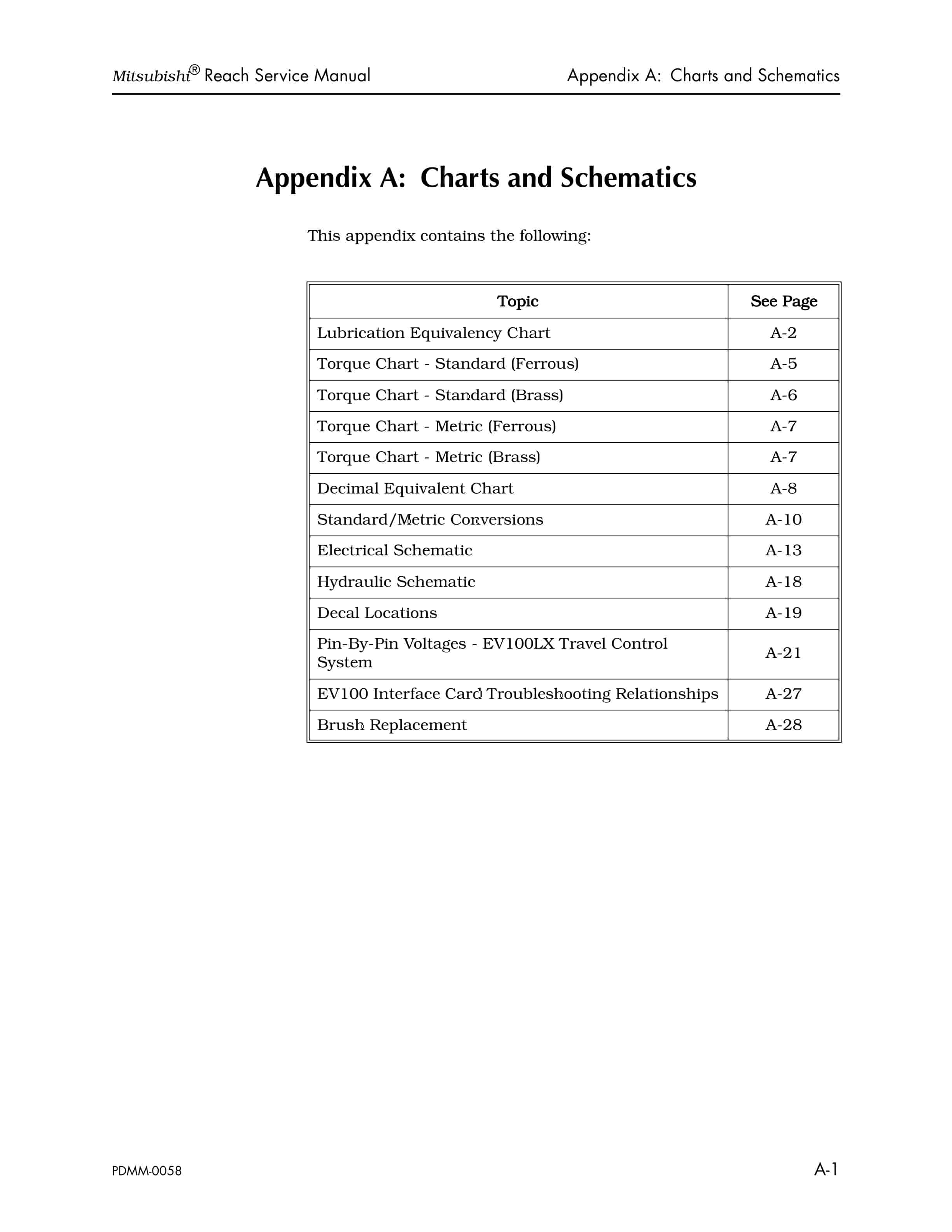

- 1. CHARTS AND SCHEMATICS

- 1.1. APPENDIX A CHARTS AND SCHEMATICS

- 1.1.1. Lubrication Equivalency Chart

- 1.1.2. Torque Chart – Standard (Ferrous)

- 1.1.3. Torque Chart – Standard (Brass)

- 1.1.4. Torque Chart – Metric (Ferrous)

- 1.1.5. Torque Chart – Metric (Brass)

- 1.1.6. Decimal Equivalent Chart

- 1.1.7. Standard/Metric Conversions

- 1.1.8. Electrical Schematic

- 1.1.9. Hydraulic Schematic

- 1.1.10. Decal Locations

- 1.1.11. Pin-By-Pin Voltages – EV100LX Travel Control System

- 1.1.12. EV100 Interface Card Troubleshooting Relationships

- 1.1.13. Brush Replacement

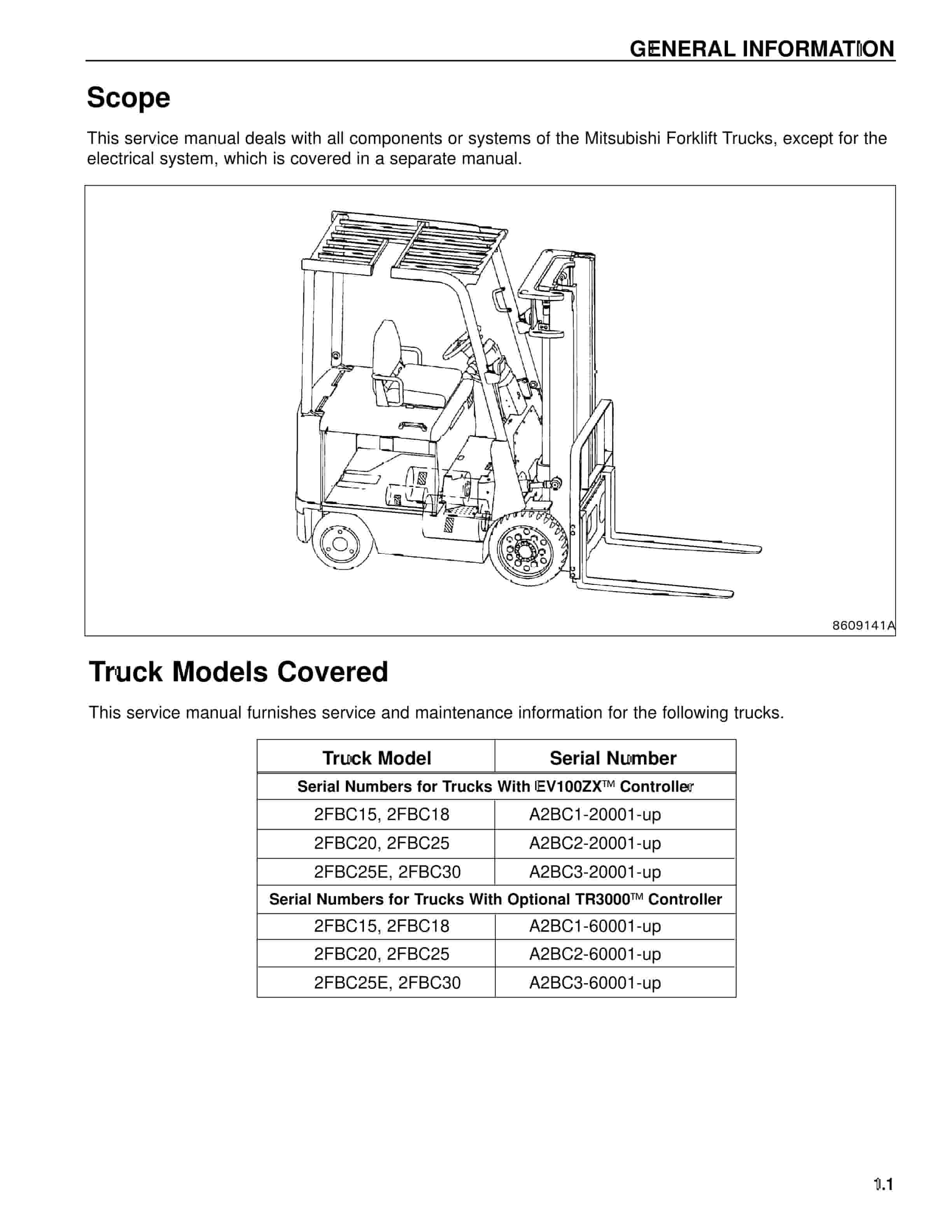

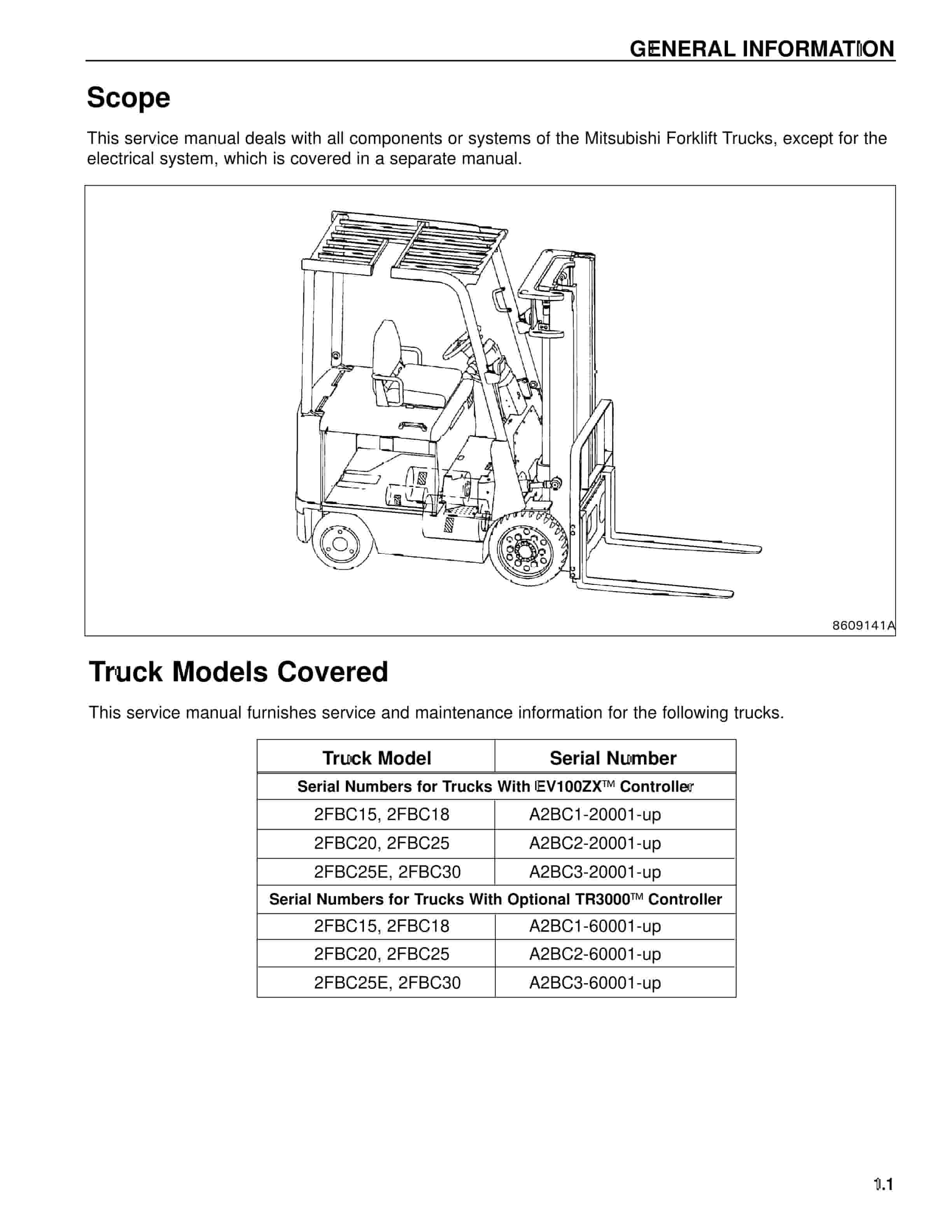

- 2. GENERAL INFORMATION

- 2.1. GENERAL INFORMATION

- 2.1.1. Warning Pages

- 2.1.2. Overview of this Manual

- 2.1.3. List of Figures

- 2.1.4. List of Tables

- 3. INSTALLATION

- 3.1. INSTALLATION

- 3.1.1. Overview

- 3.1.1.1. Warranty Coverage

- 3.1.1.2. In this Chapter

- 3.1.2. Inspecting the Truck

- 3.1.2.1. How the Truck is Shipped

- 3.1.2.2. Reasons for Doing a Visual Inspection

- 3.1.2.3. What to Look For

- 3.1.2.4. Repairing Shipping Damage

- 3.1.2.5. Repairing Defects

- 3.1.3. Uprighting a Cradled Truck

- 3.1.3.1. Warnings and Cautions

- 3.1.3.2. Items Needed

- 3.1.3.3. Option 1 Uprighting with Two Chain Hoists

- 3.1.3.4. Option 2 Uprighting with One Chain Hoist and a Lift Truck

- 3.1.4. Assembling the Truck

- 3.1.4.1. Removing the Gaskets

- 3.1.4.2. Greasing the Mast Uprights

- 3.1.4.3. Installing the Battery

- 3.1.5. Doing a Functional Inspection

- 3.1.5.1. Who Does the Inspection

- 3.1.5.2. What Needs to be Done

- 3.1.5.3. Starting the Mitsubishi Warranty

- 3.1.5.4. Reporting Repairs

- 3.1.5.5. Using the Checklist

- 3.1.6. Preparing the Truck for Cold Storage

- 3.1.6.1. Classes of Cold Storage

- 3.1.6.2. Types of Oil

- 3.1.6.3. Changing the Hydraulic System Oil

- 3.1.7. Preparing the Truck for Storage

- 3.1.7.1. Storage Warranty

- 3.1.7.2. General Storage Tips

- 3.1.7.3. Hydraulic System

- 3.1.7.4. Hydraulic Cylinders

- 3.1.7.5. Lift Chains

- 3.1.7.6. Mast Uprights

- 3.1.7.7. Electronics

- 3.1.7.8. Battery

- 4. MAINTENANCE

- 4.1. MAINTENANCE

- 4.1.1. General Maintenance Instructions

- 4.1.1.1. In this Chapter

- 4.1.2. Maintenance Practices

- 4.1.2.1. Jacking the Truck

- 4.1.2.2. Welding Procedures

- 4.1.2.2.1. Electrostatic Discharge Damage

- 4.1.2.2.2. Proper Handling of Static Sensitive Devices

- 4.1.2.2.3. Discharging the Truck

- 4.1.2.2.4. Removing the Circuit Card

- 4.1.2.2.5. Removing an Integrated Circuit (IC)

- 4.1.2.2.6. Installing a New Integrated Circuit

- 4.1.2.2.7. Removing a Pin

- 4.1.2.2.8. Troubleshooting with the Cable Connector Breakout Board

- 4.1.2.3. Shunt Locations

- 4.1.3. Planned Maintenance

- 4.1.3.1. Service Manual

- 4.1.3.2. Planned Maintenance Schedule

- 4.1.3.3. Time Requirements

- 4.1.3.4. Planned Maintenance Checks

- 4.1.3.4.1. Inspection Schedule

- 4.1.3.5. Grease Fitting Locations

- 4.1.4. Battery Maintenance

- 4.1.4.1. How Batteries Get Damaged

- 4.1.4.2. Removing a Battery

- 4.1.4.3. Installing a Battery

- 4.1.4.4. Cleaning the Battery

- 4.1.4.5. Testing the Battery Electrical Leakage To Frame

- 4.1.4.6. Battery Discharge Indicator (BDI)

- 4.1.4.6.1. Internal Resistance Compensation

- 4.1.4.6.2. Adjusting the Internal Compensation

- 4.1.4.7. Changing the Battery

- 4.1.4.7.1. Precautions

- 4.1.4.7.2. Using the Hydrometer

- 4.1.4.7.3. Checking the Specific Gravity

- 4.1.4.8. Voltage Check

- 4.1.4.9. Adding Water to the Battery

- 4.1.4.10. Keeping a Battery History Record

- 4.1.5. Maintaining the Motor

- 4.1.5.1. Motor Cleaning

- 4.1.5.2. Brush Care

- 4.1.5.2.1. Cleaning the Brushes

- 4.1.5.2.2. Measuring the Brush Spring Tension

- 4.1.5.2.3. Replacing a Brush

- 4.1.5.3. Preventing the Motor from Overheating

- 4.1.5.3.1. Checking the Torque on the Motor Stud Terminals

- 4.1.5.4. Open Circuits

- 4.1.5.4.1. Testing for Open Circuits

- 4.1.5.5. Short Circuits

- 4.1.5.5.1. Testing for Short Circuits

- 4.1.5.6. Armature Shorts

- 4.1.5.6.1. Checking for Armature Shorts

- 4.1.5.7. Grounded Motors

- 4.1.5.7.1. Testing for a Grounded Motor

- 4.1.5.8. Truck Grounds – General

- 4.1.5.8.1. Testing for Grounds on the Truck Frame

- 4.1.6. Hydraulic System Maintenance

- 4.1.6.1. Selecting the Oil

- 4.1.6.2. Changing the Reservoir Fluid

- 4.1.6.3. Checking the Reservoir Fluid Level

- 4.1.6.4. Changing the Reservoir Filter

- 4.1.6.5. Bleeding the Hydraulic System

- 4.1.7. Mechanical Maintenance

- 4.1.7.1. Power Section

- 4.1.7.1.1. Drive Unit Service

- 4.1.7.1.2. Removing the Drive Unit

- 4.1.7.1.3. Installing the Drive Unit

- 4.1.7.1.4. Preparing to Replace the Drive Axle Seal (36-Volt)

- 4.1.7.1.5. Replacing the Drive Axle Seal (36-Volt)

- 4.1.7.1.6. Preparing to Replace the Drive Axle Seal (24-Volt)

- 4.1.7.1.7. Disassembling the Drive Unit (24-Volt)

- 4.1.7.1.8. Assembling the Drive Unit (24-Volt)

- 4.1.7.2. Braking System

- 4.1.7.2.1. Braking Process

- 4.1.7.2.2. Adjusting Nut-Retained Style Brakes

- 4.1.7.2.3. Inspecting the Brake Pad

- 4.1.7.2.4. Bleeding the Brake

- 4.1.7.2.5. Adjusting the Deadman Pedal

- 4.1.7.2.6. Replacing the Brake Master Cylinder

- 4.1.7.2.7. Replacing the Brake Pads

- 4.1.7.2.8. Brake Installation

- 4.1.7.2.9. Reassembling the Brake

- 4.1.7.2.10. Replacing the Brake O-Ring Seal

- 4.1.7.3. Steering System

- 4.1.7.3.1. Steering Adjustment with Steerable Caster

- 4.1.7.3.2. Initial Adjustments

- 4.1.7.3.3. Adjusting the Casters

- 4.1.7.3.4. Service Notes for Steering Components

- 4.1.7.4. Lift/Lower System

- 4.1.7.4.1. Lift Chains

- 4.1.7.4.2. Removing and Inspecting the Chain

- 4.1.7.4.3. Lubricating the Lift Chain

- 4.1.7.4.4. Adjusting the Over the Mast Hose and Cable

- 4.1.7.4.5. Replacing the Over the Mast Hose

- 4.1.7.4.6. Replacing the Flow Control

- 4.1.7.4.7. Adjusting the Equalization Chain

- 4.1.7.4.8. Equalization Chain Removal and Installation

- 4.1.7.4.9. Replacing the Equalization Chain Sheave

- 4.1.7.4.10. Applying Loctite to the Reach Carriage Chain Anchors

- 4.1.7.4.11. Adjusting the Mechanical Stop

- 4.1.7.4.12. Reach Carriage Lubrication Points

- 4.1.7.4.13. Removing the Fork Carriage Tilt Pins

- 4.1.7.4.14. Attaching the Mast to the Tractor

- 4.1.7.4.15. Adjusting the High Pressure Relief Valve

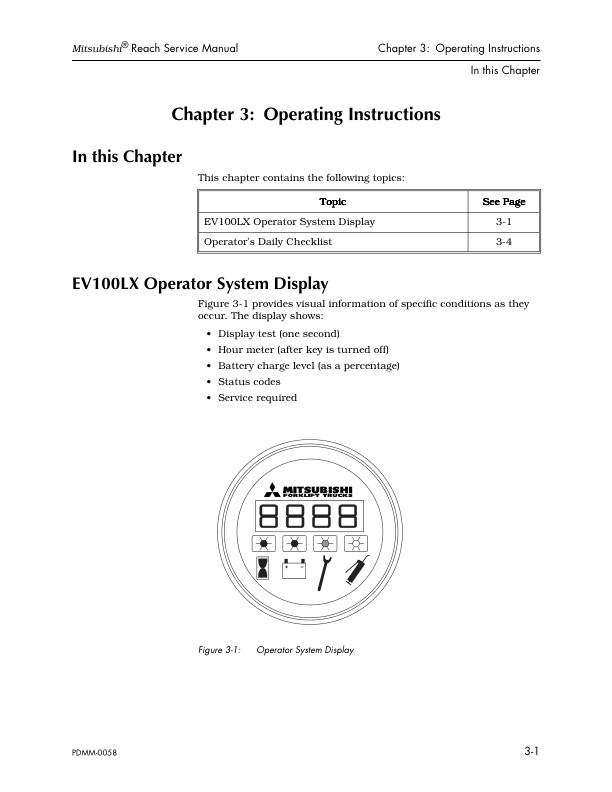

- 5. OPERATING INSTRUCTIONS

- 5.1. OPERATING INSTRUCTIONS

- 5.1.1. In this Chapter

- 5.1.2. EV100LX Operator System Display

- 5.1.2.1. Display Test

- 5.1.2.2. Hour Meter

- 5.1.2.3. Battery Charge Level

- 5.1.2.4. Status Codes

- 5.1.2.4.1. Informational Messages

- 5.1.2.4.2. Performance Limiting Codes

- 5.1.2.4.3. Fault Codes

- 5.1.3. Operators Daily Checklist

- 5.1.3.1. Visual Checks

- 5.1.3.2. Operational Checks

- 5.1.3.2.1. Start-up Procedure

- 5.1.3.2.2. Forward/Reverse Travel

- 5.1.3.2.3. Braking

- 5.1.3.2.4. Plugging

- 5.1.3.2.5. Parking

- 5.1.3.2.6. Entering an Aisle

- 5.1.3.2.7. Operating the Truck on a Ramp

- 5.1.3.2.8. Travel Speed and Lift Limits

- 6. THEORY OF OPERATION

- 6.1. THEORY OF OPERATION

- 6.1.1. In this Chapter

- 6.1.2. EV100LX Control Panel

- 6.1.3. System Components

- 6.1.3.1. Silicon Controlled Rectifiers (SCR)

- 6.1.3.1.1. 1 Rectifier (REC1) Chopper SCR

- 6.1.3.1.2. 2 Rectifier (REC2) Commutating SCR

- 6.1.3.1.3. 5 Rectifier (REC5) Charging SCR

- 6.1.3.2. Diode Rectifiers

- 6.1.3.2.1. 3 Rectifier (REC3) Free Wheeling

- 6.1.3.2.2. 4 Rectifier (REC4) Plugging

- 6.1.3.2.3. Reactor (Coil T3/T4)

- 6.1.3.2.4. Capacitor 1-C

- 6.1.3.2.5. Filters REC22, REC23, REC24, REC25

- 6.1.3.3. Thermal Protector (TP)

- 6.1.3.4. Sensor (Sensor 1)

- 6.1.4. Control Features

- 6.1.4.1. Creep Speed

- 6.1.4.2. Controlled Acceleration

- 6.1.4.3. Current Limit

- 6.1.4.4. Plugging

- 6.1.4.5. Current Dropout

- 6.1.4.6. Speed Limit 1 (SL1) and Speed Limit 3 (SL3)

- 6.1.4.7. Static Return to OFF

- 6.1.4.8. Accelerator Volts Hold-Off

- 6.1.4.9. Coil Driver Modules

- 6.1.4.10. Thermal Cutback

- 6.1.4.11. Pulse Monitor Trip (PMT)

- 6.1.4.12. Internal Resistance Compensation

- 6.1.4.13. Steer Pump Time Delay

- 6.1.4.14. Stored Fault Code

- 6.1.4.15. Battery Discharge Indicator

- 6.1.4.16. Hour Meter

- 6.1.4.17. On-board Diagnostics

- 6.1.5. Basic SCR Controller Circuit Operation

- 6.1.5.1. Energizing the Control Circuit

- 6.1.5.2. Gate Pulse to REC2

- 6.1.5.3. Gate Pulse to REC1

- 6.1.5.4. Firing REC2

- 6.1.5.5. OFF Time

- 6.1.5.6. Oscillation Frequency

- 6.1.5.7. Oscillator Features

- 6.1.6. Wiring Conventions

- 6.1.7. Operation of the Travel System

- 6.1.7.1. Sequence 1 Truck at Rest

- 6.1.7.2. Sequence 2 Connect the Battery

- 6.1.7.3. Sequence 3 Closing the Key Switch and the Deadman Pedal

- 6.1.7.4. Sequence 4 PMT Test

- 6.1.7.5. Sequence 5 Directional Contactor Closure

- 6.1.7.6. Sequence 6 REC1 Turn ON

- 6.1.7.7. Sequence 7 REC5 Turn ON

- 6.1.7.8. Sequence 8 Reverse Charging the 1C Capacitor

- 6.1.7.9. Sequence 9 REC2 Turn ON and REC1 Turn OFF

- 6.1.7.10. Sequence 10 Free-Wheeling Current

- 6.1.7.11. Sequence 11 1A or Bypass Contactor Operation

- 6.1.7.12. Sequence 12 Controlled Plugging

- 6.1.8. Lift/Lower System

- 6.1.8.1. System Overview

- 6.1.8.2. Unique System Features

- 6.1.8.3. Components

- 6.1.8.4. Functionality

- 6.1.9. Braking

- 7. TROUBLESHOOTING

- 7.1. TROUBLESHOOTING

- 7.1.1. In this Chapter

- 7.1.2. Troubleshooting Procedure

- 7.1.2.1. Verifying Problems

- 7.1.2.2. Locating the Problem Area

- 7.1.2.3. Establishing a Logical Testing Sequence

- 7.1.2.4. Identifying the Cause of the Problem

- 7.1.2.5. Correcting the Problem

- 7.1.3. Electrical

- 7.1.3.1. Checking the Wiring

- 7.1.3.1.1. Troubleshooting Procedure

- 7.1.3.1.2. Shorts to the Truck Frame – Causes

- 7.1.3.1.3. Shorts to the Truck Frame – Checking

- 7.1.3.1.4. Voltage To Frame – Causes

- 7.1.3.1.5. Voltage To Frame – Checking

- 7.1.3.1.6. Voltage To Frame – Eliminating

- 7.1.3.2. Board and Component Swapping Precautions

- 7.1.3.2.1. Troubleshooting Order for Component Failure

- 7.1.3.2.2. Handling Printed Circuit Cards

- 7.1.3.2.3. Cleaning and Inspecting the Contactors

- 7.1.3.2.4. Contactors Specifications

- 7.1.3.2.5. Testing Other Electrical Components

- 7.1.3.2.6. EV100LX Component Tests

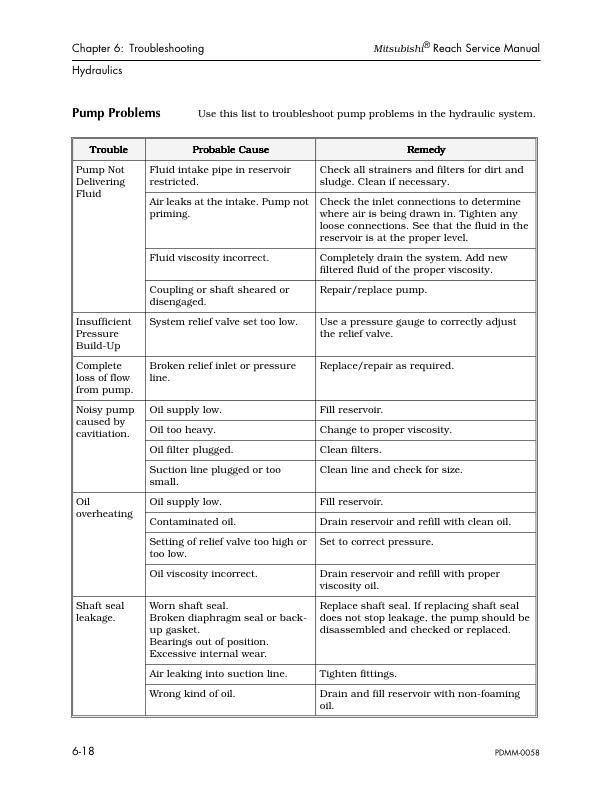

- 7.1.4. Hydraulics

- 7.1.4.1. Checking for Hydraulic Leaks

- 7.1.4.2. Maintenance Tips

- 7.1.4.2.1. Avoiding Hydraulic Problems

- 7.1.4.2.2. Lift/Lower Hydraulic System Troubleshooting

- 7.1.4.2.3. Steps for Locating Problems in the Lift/Lower System

- 7.1.4.2.4. Pump Problems

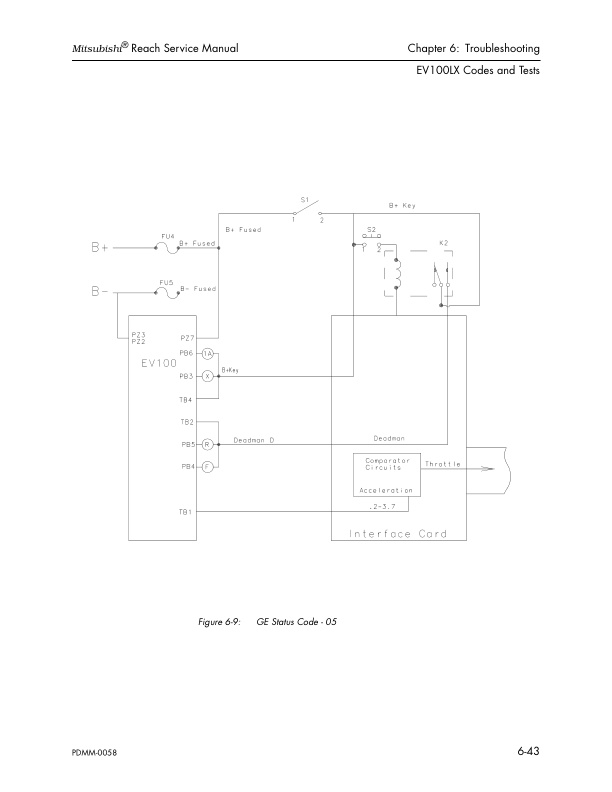

- 7.1.5. EV100LX Codes and Tests

- 7.1.5.1. Troubleshooting the EV100LX Solid-State Control System

- 7.1.5.1.1. Identifying a Malfunction

- 7.1.5.1.2. Replacing the Logic Card

- 7.1.5.1.3. Wire Numbers

- 7.1.5.1.4. Jacking the Truck

- 7.1.5.1.5. Accessing the Terminals

- 7.1.5.1.6. Visual Check

- 7.1.5.2. Using the LX Handset

- 7.1.5.2.1. Operating the Handset

- 7.1.5.2.2. Function Set-Up Procedures

- 7.1.5.2.3. Handset Programmable Functions

- 7.1.5.2.4. System Voltage Drop vs. Function Setting

- 7.1.5.3. GE Status Codes

- 7.1.5.3.1. Status Code – Blank display

- 7.1.5.3.2. Status Code – 01

- 7.1.5.3.3. Status Code – 02

- 7.1.5.3.4. Status Code – 03

- 7.1.5.3.5. Status Code – 04

- 7.1.5.3.6. Status Code – 05

- 7.1.5.3.7. Status Code – 06

- 7.1.5.3.8. Status Code – 07

- 7.1.5.3.9. Status Code – 08

- 7.1.5.3.10. Status Code – 09

- 7.1.5.3.11. Status Code – 15

- 7.1.5.3.12. Status Code – 16

- 7.1.5.3.13. Status Code – 17

- 7.1.5.3.14. Status Code – 23

- 7.1.5.3.15. Status Code – 24

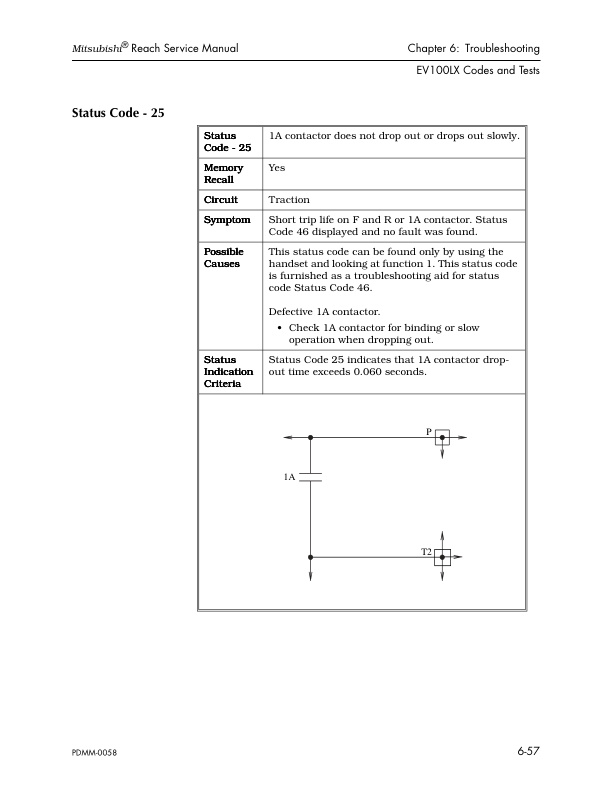

- 7.1.5.3.16. Status Code – 25

- 7.1.5.3.17. Status Code – 41

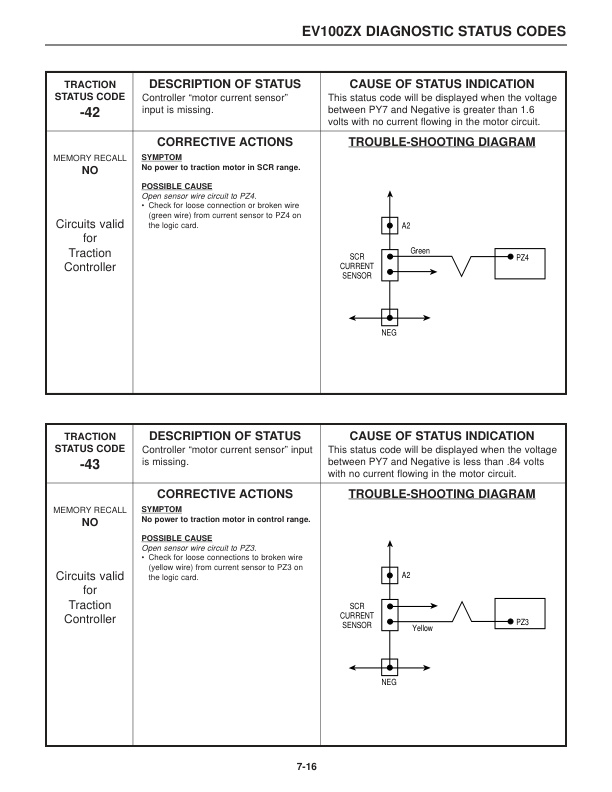

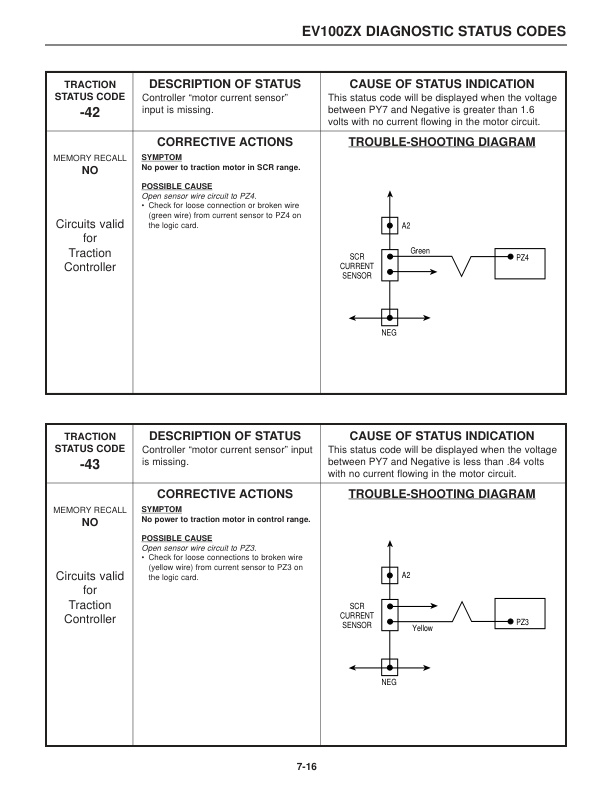

- 7.1.5.3.18. Status Code – 42

- 7.1.5.3.19. Status Code – 43

- 7.1.5.3.20. Status Code – 44

- 7.1.5.3.21. Status Code – 45

- 7.1.5.3.22. Status Code – 46

- 7.1.5.3.23. Status Code – 47

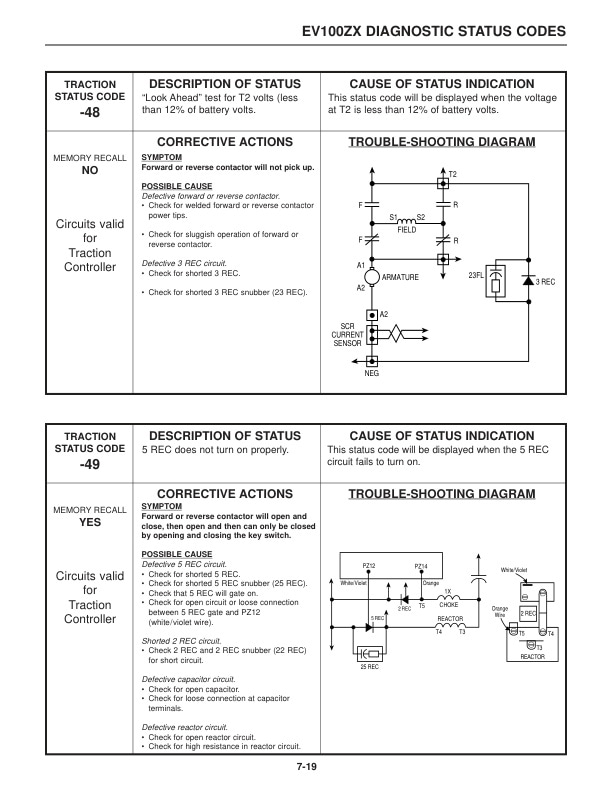

- 7.1.5.3.24. Status Code – 48

- 7.1.5.3.25. Status Code – 49

- 7.1.5.3.26. Status Code – 50

- 7.1.5.3.27. Status Code – 51

- 7.1.5.3.28. Status Code – 52

- 7.1.5.3.29. Status Code – 53

- 7.1.5.3.30. Status Code – 54

- 7.1.5.3.31. Status Code – 57

- 7.1.6. Troubleshooting the Interface Card System

- 7.1.6.1. Running Learn

- 7.1.6.2. Setting up the Truck

- 7.1.6.3. Interface Card Switch Settings

- 7.1.6.4. Interface Card Assembly

- 7.1.6.5. Interface Card Codes

- 7.1.7. Troubleshooting the Interface Card

- 7.1.7.1. Display on Interface Card is Dark

- 7.1.7.2. No Auxiliary Functions Aux. Motor Runs Other Functions OK

- 7.1.7.3. Auxiliary Motor Does not Run Other functions OK

- 7.1.7.4. One Auxiliary Function Is Inoperative

- 7.1.7.5. Auxiliary Functions Operate In Only One Direction Steering OK

- 7.1.7.5.1. No Lift

- 7.1.7.5.2. No Lower

- 7.1.7.6. No Travel, Other Functions OK

- 7.1.7.7. No Speed Limit

- 7.1.7.8. No Lift Inhibit

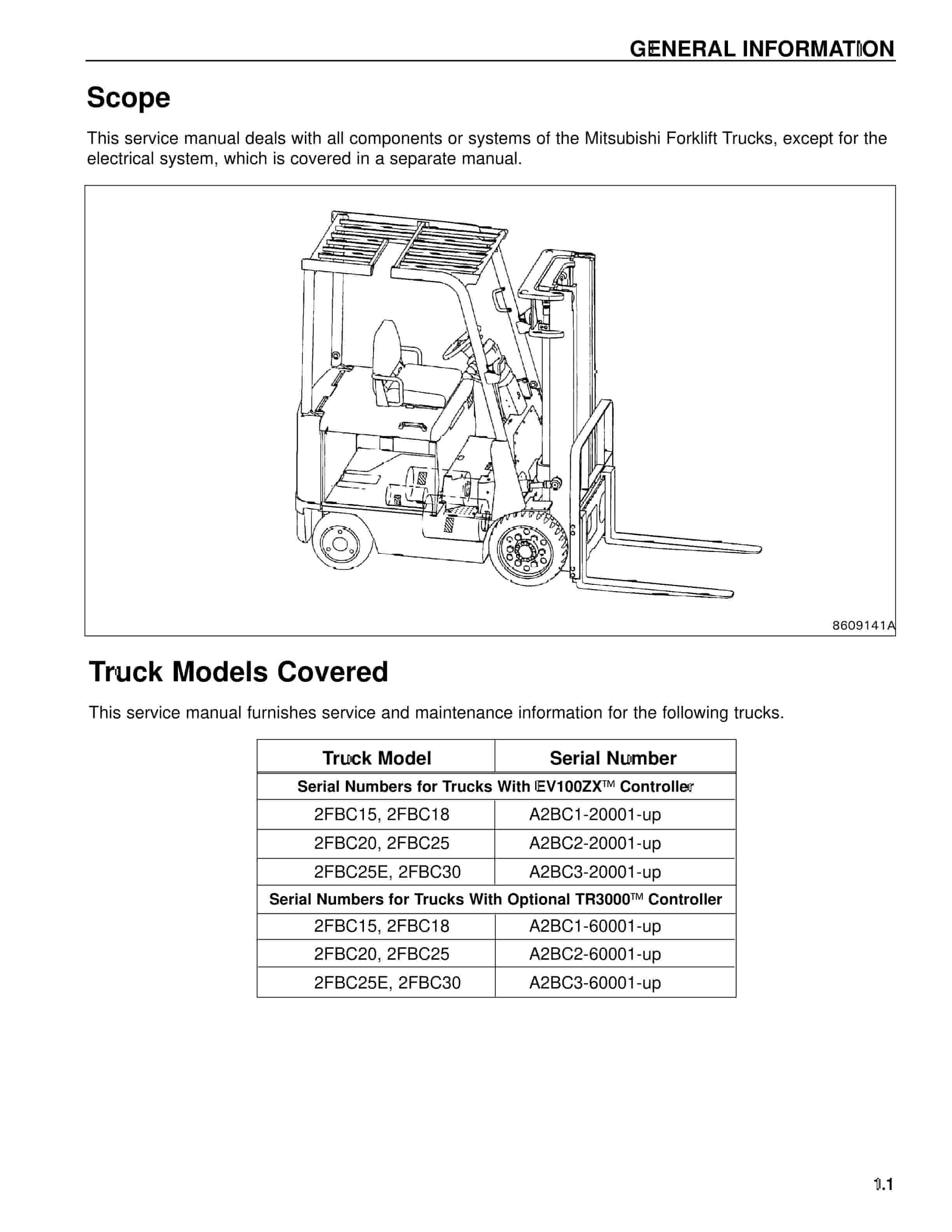

- 8. TRUCK DESCRIPTION

- 8.1. TRUCK DESCRIPTION

- 8.1.1. Overview

- 8.1.1.1. In this Chapter

- 8.1.2. Truck Overview

Rate this product

You may also like

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Fuel System Supplement Service Manual 99729-75110

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64, 6G72 Liquefied Petroleum Gas Supplement Service Manual 99729-75100

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

$50.00

Mitsubishi Service Manual PDF

Mitsubishi 4G63, 4G64 Gasoline Engine Service Manual 99729-74120

$50.00

Mitsubishi Service Manual PDF

Mitsubishi GM 4.3L (G6) Fuel System Supplement Service Manual 99789-74111

$50.00